Abstract

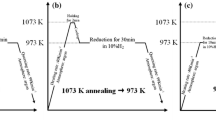

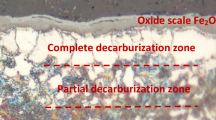

In this study, a novel double-stage reduction method of “low temperature and high temperature” was proposed to improve the reaction efficiency of the hydrogen reduction technology of the oxide scale formed on hot-rolled steel. The reduction behavior of the oxide scale in 20 vol% H2–Ar at various reduction methods was investigated in detail. The weight change of specimen under various reduction methods was measured by thermogravimetric analysis, and then the reduction degree and the reaction rate were calculated based on the measured value. Scanning electron microscopy was used to observe the surface and the cross-sectional morphologies of the oxide scale after the reduction reaction, and the mass percent of oxygen and iron in the cross-sectional reduction layer was measured by energy-dispersive spectroscopy. X-ray diffraction was applied to characterize the phase transformation of the oxide scale in the heating process, and the phase composition of the oxide scale and reduction layer. The experimental results indicated that the reduction degree and the reaction rate of the oxide scale during the double-stage reduction method increased significantly compared with the traditional single-stage reduction method in the range of 500–800 °C. The mechanism of the double-stage reduction method was discussed from two aspects of the phase transformation of the oxide scale and the restrictive link of the gas (H2)–solid (Fe oxides) reduction reaction.

Similar content being viewed by others

References

Gutierrez-Platas JL, Artigas A, Monsalve A, García-Gómez NA, García-Rincón O, De la Garza-Garza M, Pérez-González FA, Colás R, Garza-Montes-de-Oca NF (2018) High-temperature oxidation and pickling behaviour of HSLA steels. Oxid Met 89:33–48

Ding JW, Tang B, Li MY, Feng XF, Fu FL, Bin LY, Huang SS, Su W, Li DN, Zheng LC (2017) Difference in the characteristics of the rust layers on carbon steel and their corrosion behavior in an acidic medium: limiting factors for cleaner pickling. J Clean Prod 142:2166–2176

Wu G, Guan C, Tan N, Zhang J (2018) Effect of hot rolled substrate of hydrogen reduction on interfacial reaction layer of hot-dip galvanizing. J Mater Process Technol 259:134–140

Lin SN, Huang CC, Wu MT, McDermid JR, Hsieh KC (2017) Studies of interface reactions between zinc and reduced red scale on a Mn/Si dual phase steel. J Alloy Compd 729:257–265

Li ZF, He YQ, Cao GM, Tang JJ, Zhang XJ, Liu ZY (2017) Effects of Al contents on microstructure and properties of hot-dip Zn–Al alloy coatings on hydrogen reduced hot-rolled steel without acid pickling. J Iron Steel Res Int 24:1032–1040

Jing YA, Zang X, Shang Q, Qin Y, Li Y, Song B (2015) The evolution of surface morphologies and microstructures during cold rolling after hydrogen reduction. J Mater Process Technol 219:303–313

Primavera A, Cattarino S, Pavlicevic M (2007) Influence of process parameters on scale reduction with H2. Ironmak Steelmak 34:290–294

Guan C, Li J, Tan N, Zhang SG (2016) Continuous reduction of the oxide scale of hot-rolled steel strip in hydrogen. Ironmak Steelmak 43:739–743

Jing YA, Yuan YM, Yan XL, Zhang L, Sha MH (2017) Decarburization mechanism during hydrogen reduction descaling of hot-rolled strip steel. Int J Hydrog Energy 42:10611–10621

Tanei H, Kondo Y (2012) Effect of initial scale structure on transformation behavior of wüstite. ISIJ Int 52:105–109

Chen RY (2017) Mechanism of iron oxide scale reduction in 5% H2–N2 gas at 650–900 °C. Oxid Met 88:687–717

Saeki I, Ikeda T, Ohno K, Sato T, Kurosawa S (2011) Reduction of oxide scales formed on low carbon steel sheet in synthesized combustion gas. Tetsu-to-Hagane 97:12–18

Moukassi M, Steinmetz P, Dupre B, Gleitzer C (1983) A study of the mechanism of reduction with hydrogen of pure wustite single crystals. Metall Trans B 14:125–132

He YQ, Jia T, Li ZF, Cao GM, Liu ZY, Li J (2016) Isothermal reduction of oxide scale on hot-rolled, low-carbon steel in 10 pct H2-Ar. Metall Mater Trans A 47:4845–4852

Guan C, Li J, Tan N, He YQ, Zhang SG (2014) Reduction of oxide scale on hot-rolled steel by hydrogen at low temperature. Int J Hydrog Energy 39:15116–15124

Badin V, Diamanti E, Forêt P, Darque-Ceretti E (2016) Early steps of pore formation during stainless steel oxides reduction with hydrogen at 1373 K (1100 °C). Metall Mater Trans B 47:1445–1452

Liu XJ, Cao GM, He YQ, Yang M, Liu ZY (2014) Reduction of oxide scale with hydrogen. J Iron Steel Res Int 21:24–29

Li ZF, Cao GM, Lin F, Sun XZ, He YQ, Liu ZY (2017) Effect of cold rolling before hydrogen reduction on reduction behavior and morphologies of oxide scale on hot-rolled low-carbon steel. ISIJ Int 57:2034–2041

Shi J, Wang DR, He YD, Qi HB, Gao W (2008) Reduction of oxide scale on hot-rolled strip steels by carbon monoxide. Mater Lett 62:3500–3502

Ding D, Peng H, Peng W, Yu Y, Wu G, Zhang J (2017) Isothermal hydrogen reduction of oxide scale on hot-rolled steel strip in 30 pct H2–N2 atmosphere. Int J Hydrog Energy 42:29921–29928

Li W, Fu GQ, Chu MS, Zhu MY (2017) Effect of reducing conditions on swelling behavior and mechanism of Hongge vanadium titanomagnetite-oxidized pellet with hydrogen-rich gases. Int J Hydrog Energy 42:24667–24674

Lin SN, Huang CC, Wu MT, Wang WL, Hsieh KC (2017) Crucial mechanism to the eutectoid transformation of wüstite scale on low carbon steel. Steel Res Int 88:1700045

Yu XL, Jiang ZY, Zhao JW, Wei DB, Zhou J, Zhou CL, Huang QX (2016) The role of oxide-scale microtexture on tribological behaviour in the nanoparticle lubrication of hot rolling. Tribol Int 93:190–201

Basabe VV, Szpunar JA (2004) Growth rate and phase composition of oxide scales during hot rolling of low carbon steel. ISIJ Int 44:1554–1559

Hayes PC (2010) Stability criteria for product microstructures formed on gaseous reduction of solid metal oxides. Metall Mater Trans B 41:19–34

Matthew SP, Cho TR, Hayes PC (1990) Mechanisms of porous iron growth on wustite and magnetite during gaseous reduction. Metall Trans B 21:733–741

Acknowledgements

The work was supported by the National Nature Science Foundation of China (Grant No. U1660117); the China Postdoctoral Science Foundation (Grant No. 2019M651132); and the Fundamental Research Funds for the Central Universities (Grant No. N180703010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, ZF., Gao, Y., Cao, GM. et al. High-efficiency reduction behavior for the oxide scale formed on hot-rolled steel in a mixed atmosphere of hydrogen and argon. J Mater Sci 55, 1826–1839 (2020). https://doi.org/10.1007/s10853-019-04027-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04027-0