Abstract

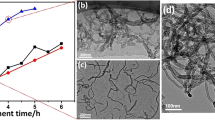

A novel process of electrolytic copper alloy modification by carbon nanotubes (CNT) was investigated. Modification was carried out in traditional casting process where a specially fabricated modifier was introduced into molten metal before pouring. Mechanical properties and thermal conductivity of the obtained alloy were examined. Tensile tests evaluated that incorporation of 0.01 wt% of CNT improved ultimate tensile strength and yield strength of the alloy by 20% and 10%, respectively. Hardness of 0.01 wt% modified CNT alloy was also enhanced by 28%. Thermal conductivity tests were performed as well and evaluated the temperature-sensitive improvement by 40–50% in thermal conductivity of the modified copper alloy. Simultaneous improvement in mechanical properties and thermal conductivity of the alloy were attributed to the presence of the CNT inside the bulk of the alloy.

Similar content being viewed by others

References

Chen Y, Cheng M, Song H, Zhang S, Liu J, Zhu Y (2014) Effects of lanthanum addition on microstructure and mechanical properties of as-cast pure copper. J Rare Earths 32(11):1056–1063

Sarma VS, Sivaprasad K, Sturm D, Heilmaier M (2008) Microstructure and mechanical properties of ultrafine grained Cu–Zn and Cu–Al alloys produced by cryorolling and annealing. Mater Sci Eng A 489:253–258

Maki K, Ito Y, Matsunaga H, Mori H (2013) Solid-solution copper alloys with high strength and high electrical conductivity. Scripta Mater 68:777–780

Okayasu M, Muranaga T, Endo A (2017) Analysis of microstructural effects on mechanical properties of copper alloys. J Sci Adv Mater Dev 2:128–139

Das D, Samanta A, Chattopadhyay PP (2006) Mechanical properties of bulk ultrafine-grained copper, synthesis and reactivity in inorganic, metal-organic and nano-metal. Chemistry 36:221–225

Yao G, Cao C, Pan S, Lin TC, Sokoluk M, Li X (2019) High-performance copper reinforced with dispersed nanoparticles. J Mater Sci 54(5):4423–4432. https://doi.org/10.1016/j.promfg.2019.06.138

Rajkovic V, Bozic D, Devecerski A, Jovanovic MT (2012) Characteristic of copper matrix simultaneously reinforced with nano- and micro-sized Al2O3 particles. Mater Charact 67:129–137

Chu K, Jia C, Jiang L, Li W (2013) Improvement of interface and mechanical properties in carbon nanotube reinforced Cu–Cr matrix composites. Mater Des 45:407–411

Liu J, Xiong DB, Su Y, Guo Q, Li Z, Zhang D (2019) Effect of thermal cycling on the mechanical properties of carbon nanotubes reinforced copper matrix nanolaminated composites. Mater Sci Eng A 739:132–139

Kim KT, Eckert J, Menzel SB, Gemming T, Hong SH (2008) Grain refinement assisted strengthening of carbon nanotube reinforced copper matrix nanocomposites. Appl Phys Lett 92:121901

Özerinç S, Tai K, Vo NQ, Bellon P, Averbackb RS, King WP (2012) Grain boundary doping strengthens nanocrystalline copper alloys. Scripta Mater 67:720–723

Borodianskiy K, Zinigrad M, Gedanken A (2011) Aluminum A356 reinforcement by carbide nanoparticles. J Nano Res 13:41–46

Borodianskiy K, Selivorstov V, Dotsenko Y, Zinigrad M (2015) Effect of additions of ceramic nanoparticles and gas-dynamic treatment on Al casting alloys. Metals 5:2277–2288

Borodianskiy K, Zinigrad M (2016) Modification performance of WC nanoparticles in aluminum and an Al–Si casting alloy. Metall Mater Trans B 47(2):1302–1308

Mazloum A, Kováčik J, Emmer Š, Sevostianov I (2016) Copper–graphite composites: thermal expansion, thermal and electrical conductivities, and cross-property connections. J Mater Sci 51(17):7977–7990. https://doi.org/10.1007/s10853-016-0067-5

Firkowska I, Boden A, Boerner B, Reich S (2015) The origin of high thermal conductivity and ultralow thermal expansion in copper–graphite composites. Nano Lett 15:4745–4751

Li J, Wang X, Qiao Y, Zhang Y, He Z, Zhang H (2015) High thermal conductivity through interfacial layer optimization in diamond particles dispersed Zr-alloyed Cu matrix composites. Scripta Mater 109:72–75

Wejrzanowski T, Grybczuk M, Chmielewski M, Pietrzak K, Kurzydlowski KJ, Strojny-Nedza A (2016) Thermal conductivity of metal-graphene composites. Mater Des 99:163–173

Gao X, Yue H, Guo E, Zhang S, Yao L, Lin X, Wang B, Guan E (2018) Tribological properties of copper matrix composites reinforced with homogeneously dispersed graphene nanosheets. J Mater Sci Technol 34(10):1925–1931

Wang H, Zhang ZH, Hu ZY, Song Q, Yin SP, Kang Z, Li SL (2018) Improvement of interfacial interaction and mechanical properties in copper matrix composites reinforced with copper coated carbon nanotubes. Mater Sci Eng A 715:163–173

Kwon H, Park GH, Silvain JF, Kawasaki A (2010) Investigation of carbon nanotube reinforced aluminum matrix composite materials. Compos Sci Technol 70:546–550

Tritt TM (2004) Thermal conductivity: theory, properties and application. Kluwer Academic, New York

Barber S, Kwon YK, Tomanek D (2000) Unusually high thermal conductivity of carbon nanotubes. Phys Rev Lett 84(20):4613–4616

Samani MK, Khosravian N, Chen GCK, Shakerzadeh M, Baillargeat D, Tay BK (2012) Thermal conductivity of individual multiwalled carbon nanotubes. Int J Therm Sci 62:40–43

Acknowledgements

This work was supported by Kamin program of the Israeli Ministry of Economy (Grant No. 59112). Author would like to thank Ms. Natalia Litvak and Dr. Olga Krichevski from the Engineering and Technology Unit at the Ariel University for their help with electron microscopy investigations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Borodianskiy, K. Effect of carbon nanotubes’ addition on mechanical properties and thermal conductivity of copper. J Mater Sci 54, 13767–13774 (2019). https://doi.org/10.1007/s10853-019-03858-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03858-1