Abstract

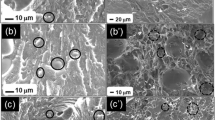

A series of polyamide 66 (PA66) and multi-walled carbon nanotube (MWNT) composites were condensed using amino-functionalized MWNTs (AMWNTs), hexanediamine adipate salts, and adipic acid as raw materials. The covalent grafting of maleic acid diamine onto the surfaces of the MWNTs by a Diels–Alder reaction prevented the AMWNTs from suffering entanglement, and facilitated excellent dispersion of AMWNTs in the PA66 matrix. Analyses revealed not only that the AMWNTs are uniformly dispersed in the PA66 matrix, but also that a strong interfacial interaction exists between the AMWNTs and the matrix. An AMWNT loading of only 0.5 wt% ensured a maximum dispersibility of AMWNTs in the PA66 matrix, which was far better than that of MWNTs. Additionally, the crystallization and melting behavior of PA66/AMWNT (PACNT) composite fibers were characterized. Finally, mechanical testing results demonstrated that the Young’s modulus and tensile strength of the composite fiber with 0.5 wt% AMWNT loading were increased by about 384% and 140%, respectively, compared with those of the pure PA66 fiber. Therefore, the proposed PACNT composite fibers are promising for high-performance applications.

Similar content being viewed by others

References

Kumar A, Sharma K, Dixit AR (2019) A review of the mechanical and thermal properties of graphene and its hybrid polymer nanocomposites for structural applications. J Mater Sci 54:5992–6026. https://doi.org/10.1007/s10853-018-03244-3

Bai YX, Zhang RF, Ye X et al (2018) Carbon nanotube bundles with tensile strength over 80 GPa. Nat Nanotechnol 13:589–595. https://doi.org/10.1038/s41565-018-0141-z

Sharma K, Shukla M (2014) Molecular modeling of the mechanical behavior of carbon fiber-amine functionalized multiwall carbon nanotube/epoxy composites. New Carbon Mater 29(2):132–142

Tasis D, Tagmatarchis N, Bianco A, Prato M (2006) Chemistry of carbon nanotubes. Chem Rev 106:1105–1136

Hong CY, You YZ, Pan CY (2006) A new approach to functionalize multi-walled carbon nanotubes by the use of functional polymers. Polymer 47:4300–4309

Mohammad M, Winey KI (2006) Polymer nanocomposites containing carbon nanotubes. Macromolecules 39:543–545

Gromov A, Dittmer S, Svensson J, Nerushev OA, Perez-García SA, Licea-Jiménez L, Rychwalski R, Campbell EEB (2005) Covalent amino-functionalisation of single-wall carbon nanotubes. J Mater Chem 15:3334–3339

Le CMQ, Cao XT, Lim KT (2017) Ultrasound-promoted direct functionalization of multi-walled carbon nanotubes in water via Diels–Alder “click chemistry”. Ultrason Sonochem 39:321–329

Le CMQ, Cao XT, Jeong YT, Lim KT (2018) Covalent functionalization of multi-walled carbon nanotubes with imidazolium-based poly(ionic liquid)s by Diels–Alder “click” reaction. J Ind Eng Chem 64:337–343. https://doi.org/10.1016/j.jiec.2018.03.034

Zydziak N, Hübner C, Bruns M, Barnerkowollik C (2011) One-step functionalization of single-walled carbon nanotubes (SWCNTs) with cyclopentadienyl-capped macromolecules via Diels–Alder chemistry. Macromolecules 44:3374–3380

Delgado JL, Cruz PDL, Langa F, Urbina A, Casado J, López N (2004) Microwave-assisted sidewall functionalization of single-wall carbon nanotubes by Diels–Alder cycloaddition. Chem Commun 15:1734–1735

Socher R, Krause B, Boldt R, Hermasch SWR, Pötschke P (2011) Melt mixed nano composites of PA12 with MWNTs: influence of MWNT and matrix properties on macrodispersion and electrical properties. Compos Sci Technol 71:306–314

Wu ZG, Zhou CX, Zhu N (2002) The nucleating effect of montmorillonite on crystallization of nylon 1212/montmorillonite nanocomposite. Polym Test 21:479–483

Yu ZZ, Yan C, Yang MS, Mai YW (2004) Mechanical and dynamic mechanical properties of nylon 66/montmorillonite nanocomposites fabricated by melt compounding. Polym Int 53:1093–1098

Jeon HS, Rameshwaram JK, Kim G, Weinkauf DH (2003) Characterization of polyisoprene–clay nanocomposites prepared by solution blending. Polymer 44:5749–5758

Xu Z, Gao C (2010) In situ polymerization approach to graphene-reinforced nylon-6 composites. Macromolecules 43:6716–6723

Zeng HL, Gao C, Wang YP, Watts PCP, Kong H, Cui XW, Yan DY (2006) In situ polymerization approach to multiwalled carbon nanotubes-reinforced nylon 1010 composites: mechanical properties and crystallization behavior. Polymer 47:113–122

Wang X, Kalali EN, Wang DY (2015) An in situ polymerization approach for functionalized MoS2/nylon-6 nanocomposites with enhanced mechanical properties and thermal stability. J Mater Chem A 3:24112–24120

Cao JS, Cheng ZQ, Kang LJ, Zhang YY, Zhao XD, Zhao SZ, Gao B (2017) Novel anti-fouling polyethersulfone/polyamide 66 membrane preparation for air filtration by electrospinning. Mater Lett 192:12–16

Baji A, Mai YW, Wong SC, Abtahi M, Du XS (2010) Mechanical behavior of self-assembled carbon nanotube reinforced nylon 66 fibers. Compos Sci Technol 70:1401–1409

Mirvakil SM, Hunter IW (2017) Multidirectional artificial muscles from nylon. Adv Mater 29:160–166. https://doi.org/10.1002/adma.201604734

Sengupta R, Ganguly A, Sabharwal S, Chaki TK, Bhowmick AK (2007) MWCNT reinforced polyamide-66 films: preparation, characterization and properties. J Mater Sci 42:923–934. https://doi.org/10.1007/s10853-006-0011-1

Zhang XX, Meng QJ, Wang XC, Bai SH (2010) Poly(adipic acid-hexamethylene diamine)-functionalized multi-walled carbon nanotube nanocomposites. J Mater Sci 46:923–930. https://doi.org/10.1007/s10853-010-4836-2

Mahmood N, Islam M, As Hameed, Saeed S, Khan AN (2013) Polyamide-6-based composites reinforced with pristine or functionalized multi-walled carbon nanotubes produced using melt extrusion technique. J Compos Mater 48:1197–1207

Jose MV, Steinert BW, Thomas V, Dean DR, Abdalla MA, Price G, Janowski GM (2007) Morphology and mechanical properties of nylon 6/MWNT nanofibers. Polymer 48:1096–1104

Haggenmueller R, Du FM, Fischer JE, Winey KI (2006) Interfacial in situ polymerization of single wall carbon nanotube/nylon 66 nanocomposites. Polymer 47:2381–2388

Pelech I, Kwiatkowska M, Jedrzejewska A, Pelech R, Kowalczyk I (2017) Thermal and mechanical properties of polyamide 12/modified carbon nanotubes composites prepared via the in situ ring-opening polymerization. Polimery-W 62:101–108

Zhu J, Kim J, Peng HQ, Margrave JL, Khabashesku VN, Barrera EV (2003) Improving the dispersion and integration of single-walled carbon nanotubes in epoxy composites through functionalization. Nano Lett 3:1107–1113

Li YY, Liu K, Xiao R (2017) Preparation and characterization of flame-retarded polyamide 66 with melamine cyanurate by in situ polymerization. Macromol Res 25:779–785

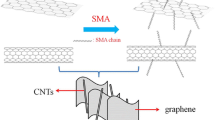

Liu HH, Peng WW, Hou LC, Wang XC, Zhang XX (2013) The production of a melt-spun functionalized graphene/poly(ε-caprolactam) nanocomposite fiber. Compos Sci Technol 81:61–68

Datsyuk V, Kalyva M, Papagelis K, Parthenios J, Tasis D, Siokou A, Kallitsis I, Galiotis C (2008) Chemical oxidation of multiwalled carbon nanotubes. Carbon 46:833–840

Xiao LH, Xu LL, Yang YY, Zhang S, Huang Y, Bielawski CW, Geng JX (2017) Core–shell structured polyamide 66 nanofibers with enhanced flame retardancy. ACS Omega 2:2665–2671

Cao RR, Sai Chen, Liu HB, Liu HH, Zhang XX (2017) Fabrication and characterization of thermo-responsive GO nanosheets with controllable grafting of poly(hexadecyl acrylate) chains. J Mater Sci 53:4103–4117. https://doi.org/10.1007/s10853-017-1864-1

Neves JC, De Castro VG, Assis ALS, Veiga AG, Rocco MLM, Silva GG (2018) In-situ determination of amine/epoxy and carboxylic/epoxy exothermic heat of reaction on surface of modified carbon nanotubes and structural verification of covalent bond formation. Appl Surf Sci 436:495–504

Hansen CM (2007) Hansen solubility parameters: a user’s handbook, 2nd edn. Springer, New York

Zhou LF, Liu HH, Zhang XX (2015) Poly(styrene–maleic anhydride) functionalized graphene oxide. J Appl Polym Sci 132:11–17. https://doi.org/10.1002/app.41987

Zhang X, Li YB, Lv GY, Zuo Y, Mu YH (2006) Thermal and crystallization studies of nano-hydroxyapatite reinforced polyamide 66 biocomposites. Polym Degrad Stabil 91:1202–1207

Liu XH, Wu QJ, Berglund LA (2002) Polymorphism in polyamide 66/clay nanocomposites. Polymer 43:4967–4972

Bell JP, Slade PE, Dumbleton JH (1968) Multiple melting in nylon 66. J Polym Sci Part B Pol Phys 6:1773–1781

Valentini L, Biagiotti J, López MMA, Santucci S, Kenny JM (2004) Effects of carbon nanotubes on the crystallization behavior of polypropylene. Polym Eng Sci 44:303–311

Kaynak C, Sankal S (2014) Effects of oxidative functionalized and aminosilanized carbon nanotubes on the crystallization behaviour of polyamide-6 nanocomposites. Polym Bull 71:855–873

Howard W, Starkweather JR, Tarkweather A, Jones EI (1981) Crystalline transitions in powders of nylon 66 crystallized from solution. J Polym Sci Pol Chem 19:467–477

Qiu L, Yang YZ, Xu LH, Liu XG (2013) Influence of surface modification of carbon nanotube on microstructures and properties of polyamide 66/multiwalled carbon nanotube composites. Polym Compos 34:656–664

Vasanthan N, Murthy NS, Bray RG (1998) Investigation of brill transition in nylon 6 and nylon 66 by infrared spectroscopy. Macromolecules 31:8433–8435

Meng H, Sui GX, Fang PF, Yang R (2008) Effects of acid- and diamine-modified MWNTs on the mechanical properties and crystallization behavior of polyamide 6. Polymer 49:610–620

Scaffaro R, Maio A (2017) A green method to prepare nanosilica modified graphene oxide to inhibit nanoparticles re-aggregation during melt processing. Chem Eng J 308:1034–1047

You JW, Choi HH, Cho J, Son JG, Park M, Lee SS, Park JH (2018) Highly thermally conductive and mechanically robust polyamide/graphite nanoplatelet composites via mechanochemical bonding techniques with plasma treatment. Compos Sci Technol 160:245–254

Zheng JC, Han DL, Ye X, Wu XH, Wu YP, Wang YQ, Zhang LQ (2018) Chemical and physical interaction between silane coupling agent with long arms and silica and its effect on silica/natural rubber composites. Polymer 135:200–210

Kim OJ, Lee KY, Jung I, Park M (2017) Dispersion of graphene-based nanocarbon fillers in polyamide 66 by dry processing and its effect on mechanical properties. Compos Part B Eng 114:445–456

Liu HH, Hou LC, Peng WW, Zhang Q, Zhang XX (2012) Fabrication and characterization of polyamide 6-functionalized graphene nanocomposite fiber. J Mater Sci 47:8052–8060. https://doi.org/10.1007/s10853-012-6695-5

Chen T, Liu HH, Wang XC, Zhang H, Zhang XX (2018) Properties and fabrication of PA66/surface-modified multi-walled nanotubes composite fibers by ball milling and melt-spinning. Polymers 10:547–559. https://doi.org/10.3390/polym10050547

Acknowledgements

This work was supported by the National Key Research and Development Program of China (Grant No. 2016YFB0303000) and the New Materials Research Key Program of Tianjin (Grant No. 16ZXCLGX00090).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, J., Gao, X., Zhang, X. et al. Polyamide 66 and amino-functionalized multi-walled carbon nanotube composites and their melt-spun fibers. J Mater Sci 54, 11056–11068 (2019). https://doi.org/10.1007/s10853-019-03619-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03619-0