Abstract

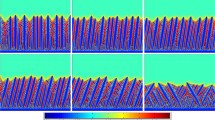

The influence of pressure rate on dendritic growth kinetics in solidification of succinonitrile was studied via in situ observation based on a novel apparatus established in our previous work and using phase-field modeling where a pressure term associated with pressure rate was introduced. The experimental and simulation results revealed that dendrites grew much faster at higher pressure rate, resulting in dendrites characterized by more developed secondary arms and larger secondary dendrite arm spacing (SDAS), while dendrites growing at lower pressure rate was more cellular-like with small secondary arms. Higher pressure rate facilitated the competitive growth of dendrites, which led to fewer but larger dominate primary dendrites and larger primary dendrite arm spacing (PDAS) in the final microstructure. The cellular-to-dendrite transition (CDT) was more advanced at higher pressure rate, and it was demonstrated that it was the higher pressure rate not the high value of pressure that motivated CDT, via elevating effective undercooling and thus growth velocity at CDT moment. Furthermore, the growth kinetics was analyzed quantitatively, and the variation of tip velocity at different pressure rates was consistent with that of the corresponding undercooling induced by pressure and thermal condition. Moreover, the slope of growth and re-melting velocity—the tip acceleration—increased with pressure-rising rate and pressure-declining rate, respectively, even in a complicated periodic pattern, which was qualitatively consistent with the theoretical relationship of tip acceleration and pressure rate.

Similar content being viewed by others

References

Sachdeva D, Tiwari S, Sundarraj S, Luo AA (2010) Microstructure and corrosion characterization of squeeze cast AM50 magnesium alloys. Metall Mater Trans B 41:1375–1383

Masoumi M, Hu H (2011) Influence of applied pressure on microstructure and tensile properties of squeeze cast magnesium Mg–Al–Ca alloy. Mater Sci Eng A 528:3589–3593

Ghomashchi MR, Vikhrov A (2000) Squeeze casting: an overview. J Mater Process Technol 101:1–9

Han Z, Pan H, Li Y, Luo AA, Sachdev AK (2015) Study on pressurized solidification behavior and microstructure characteristics of squeeze casting magnesium alloy AZ91D. Metall Mater Trans B 46:328–336

Xu R (2005) The effect of high pressure on solidification microstructure of Al–Ni–Y alloy. Mater Lett 59:2818–2820

Sobczak JJ, Drenchev L, Asthana R (2012) Effect of pressure on solidification of metallic materials. Int J Cast Metal Res 25:1–14

Jie J, Zou C, Brosh E, Wang H, Wei Z, Li T (2013) Microstructure and mechanical properties of an Al–Mg alloy solidified under high pressures. J Alloy Compd 578:394–404

Pan H, Han Z, Liu B (2016) Study on dendritic growth in pressurized solidification of Mg–Al alloy using phase field simulation. J Mater Sci Technol 32:68–75

Börzsönyi T, Tóth-Katona T, Buka Á, Gránásy L (1999) Dendrites regularized by spatially homogeneous time-periodic forcing. Phys Rev Lett 83:2853–2856

Shang S, Guo Z, Han Z (2016) On the kinetics of dendritic sidebranching: a three dimensional phase field study. J Appl Phys 119:164305

Shang S, Han Z, Sun W, Luo AA (2017) A phase field model coupled with pressure-effect-embedded thermodynamic modeling for describing microstructure and microsegregation in pressurized solidification of a ternary magnesium alloy. Comput Mater Sci 136:264–270

Han Z, Huang X, Luo AA, Sachdev AK, Liu B (2012) A quantitative model for describing crystal nucleation in pressurized solidification during squeeze casting. Scr Mater 66:215–218

Börzsönyi T, Tóth-Katona T, Buka Á, Gránásy L (2000) Regular dendritic patterns induced by nonlocal time-periodic forcing. Phys Rev E 62:7817–7827

Wang F, Ma Q, Meng W, Han Z (2017) Experimental study on the heat transfer behavior and contact pressure at the casting-mold interface in squeeze casting of aluminum alloy. Int J Heat Mass Tran 112:1032–1043

Trivedi R, Somboonsuk K (1985) Pattern formation during the directional solidification of binary systems. Acta Metall 33:1061–1068

Jackson KA, Hunt JD (1965) Transparent compounds that freeze like metals. Acta Metall 13:1212–1215

Cummins HZ, Qian XW (1990) Dendritic sidebranching initiation by a localized heat pulse. Phys Rev Lett 64:3038–3041

Farup I, Drezet JM, Rappaz M (2001) In situ observation of hot tearing formation in succinonitrile–acetone. Acta Mater 49:1261–1269

Koss MB, LaCombe JC, Tennenhouse LA, Glicksman ME, Winsa EA (1999) Dendritic growth tip velocities and radii of curvature in microgravity. Metall Mater Trans A 30:3177–3190

Reinhart G, Buffet A, Nguyen-Thi H, Billia B, Jung H, Mangelinck-Noël N, Bergeon N, Schenk T, Härtwig J, Baruchel J (2008) In-situ and real-time analysis of the formation of strains and microstructure defects during solidification of Al-3.5 wt Pct Ni alloys. Metall Mater Trans A 39:865–874

Limodin N, Salvo L, Boller E, Suéry M, Felberbaum M, Gailliègue S, Madi K (2009) In situ and real-time 3-D microtomography investigation of dendritic solidification in an Al–10 wt% Cu alloy. Acta Mater 57:2300–2310

Nguyen-Thi H, Salvo L, Mathiesen RH, Arnberg L, Billia B, Suery M, Reinhart G (2012) On the interest of synchrotron X-ray imaging for the study of solidification in metallic alloys. C R Phys 13:237–245

Cai B, Wang J, Kao A, Pericleous K, Phillion AB, Atwood RC, Lee PD (2016) 4D synchrotron X-ray tomographic quantification of the transition from cellular to dendrite growth during directional solidification. Acta Mater 117:160–169

Sawada T, Takemura K, Shigematsu K, Yoda S, Kawasaki K (1996) Dynamic pressure control for solution growth and its microgravity application. J Cryst Growth 158:328–335

Sawada T, Takemura K, Shigematsu K, Yoda S, Kawasaki K (1998) Effects of gravity on a free dendrite of NH4Cl grown by dynamic pressure control. J Cryst Growth 191:225–233

LaCombe JC, Koss MB, Tennenhouse LA, Winsa EA, Glicksman ME (1998) The Clapeyron effect in succinonitrile: applications to crystal growth. J Cryst Growth 194:143–148

Kar P, LaCombe JC, Koss MB (2004) Velocity and radius transients during pressure mediated dendritic growth of succinonitrile. Mater Sci Technol Lond 20:1273–1280

Koss MB, LaCombe JC, Chait A, Pines V, Zlatkowski M, Glicksman ME, Kar P (2005) Pressure-mediated effects on thermal dendrites. J Cryst Growth 279:170–185

Sazaki G, Nagatoshi Y, Suzuki Y, Durbin SD, Miyashita S, Nakada T, Komatsu H (1999) Solubility of tetragonal and orthorhombic lysozyme crystals under high pressure. J Cryst Growth 196:204–209

Provatas N, Elder K (2011) Phase-field methods in materials science and engineering. Wiley, Weinheim

Kim SG (2007) A phase-field model with antitrapping current for multicomponent alloys with arbitrary thermodynamic properties. Acta Mater 55:4391–4399

Karma A (2001) Phase-field formulation for quantitative modeling of alloy solidification. Phys Rev Lett 87:115701

Han G, Han Z, Luo AA, Liu B (2015) Three-dimensional phase-field simulation and experimental validation of β-Mg17Al12 phase precipitation in Mg-Al-based alloys. Metall Mater Trans A 46:948–962

Zhu J, Liu Z, Vaithyanathan V, Chen L (2002) Linking phase-field model to CALPHAD: application to precipitate shape evolution in Ni-base alloys. Scr Mater 46:401–406

Liu H, Gao Y, Zhu Y, Wang Y, Nie J (2014) A simulation study of β1 precipitation on dislocations in an Mg–rare earth alloy. Acta Mater 77:133–150

Xing H, Ankit K, Dong X, Chen H, Jin K (2018) Growth direction selection of tilted dendritic arrays in directional solidification over a wide range of pulling velocity: a phase-field study. Int J Heat Mass Transf 117:1107–1114

Xing H, Zhang L, Song K, Chen H, Jin K (2017) Effect of interface anisotropy on growth direction of tilted dendritic arrays in directional solidification of alloys: insights from phase-field simulations. Int J Heat Mass Transf 104:607–614

Yang C, Xu Q, Liu B (2018) Primary dendrite spacing selection during directional solidification of multicomponent nickel-based superalloy: multiphase-field study. J Mater Sci 53:9755–9770. https://doi.org/10.1007/s10853-018-2236-1

Tourret D, Karma A (2015) Growth competition of columnar dendritic grains: a phase-field study. Acta Mater 82:64–83

Tourret D, Song Y, Clarke AJ, Karma A (2017) Grain growth competition during thin-sample directional solidification of dendritic microstructures: a phase-field study. Acta Mater 122:220–235

Shang S, Han Z, Luo AA (2018) Phase-field modelling on effect of pressure on growth kinetics of Mg–Al–Sn alloy. Mater Sci Technol Lond 34:1362–1369

Shang S, Han Z, Luo AA (2018) Study on the response of dendritic growth to periodic increase-decrease pressure in solidification via in situ observation using succinonitrile. J Cryst Growth 498:85–92

Seah KHW, Hemanth J, Sharma SC (1998) Effect of the cooling rate on the dendrite arm spacing and the ultimate tensile strength of cast iron. J Mater Sci 33:23–28. https://doi.org/10.1023/A:1004321007806

Boschetto A, Costanza G, Quadrini F, Tata ME (2007) Cooling rate inference in aluminum alloy squeeze casting. Mater Lett 61:2969–2972

Karma A, Rappel W (1998) Quantitative phase-field modeling of dendritic growth in two and three dimensions. Phys Rev E 57:4323–4349

Echebarria B, Folch R, Karma A, Plapp M (2004) Quantitative phase-field model of alloy solidification. Phys Rev E 70:61604

Ananth R, Gill WN (1997) Dendritic growth in microgravity and forced convection. J Cryst Growth 179:263–276

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant Number U1737208]. The authors would also like to thank the National Laboratory for Information Science and Technology at Tsinghua University for access to supercomputing facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shang, S., Han, Z. In situ observation and phase-field simulation on the influence of pressure rate on dendritic growth kinetics in the solidification of succinonitrile. J Mater Sci 54, 3111–3124 (2019). https://doi.org/10.1007/s10853-018-3074-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-3074-x