Abstract

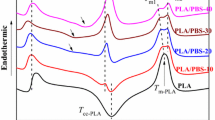

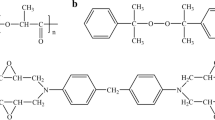

This work is focused on the structural, thermal and mechanical studies of direct polycondensation of poly (lactic acid) (PLA) modified with three different chain extenders (1,3-phenylene-bis-2-oxazoline, PBO; pyromellitic dianhydride, PMDA; and 1,1′-carbonyl bis caprolactam, CBC). Three concentrations of PBO, PMDA and CBC chain extenders (0.2, 0.5 and 1 wt%) were added during three stages (S): monomer dehydration (80 °C, S1), oligomer polycondensation (130 °C, S2) and melt polycondensation (160 °C, S3). FTIR, Raman and 1H-NMR spectroscopies revealed the presence of signals produced by interactions between OH and C=O end groups of PLA and reactive functional groups of chain extenders. It was found that the interaction with the PMDA chain extender decreased the PLA crystallinity. Furthermore, data from thermal analysis revealed that the interaction between PLA and chain extenders increased the chain mobility, which represented a decrease in its Tg. Enhanced mechanical properties, hardness, elastic modulus and indentation creep were observed with the addition of chain extenders, improving the performance with the addition of 1 wt% of PBO at S3, 1 wt% of PMDA at either S2 or S3 and 0.25 wt% of CBC at either S2 or S3. Additionally to the synthesis, the degradation was mainly influenced by the interaction more than by any specific stage of chain extender addition. Finally, the thermal and structural characterizations revealed that the PLA-PBO, PLA-PMDA and PLA-CBC systems were more resistant than PLA to UV light and humidity during the accelerated weathering test.

Similar content being viewed by others

References

Samanta KK, Basak S, Chattopadhyay SK (2016) Potentials of fibrous and nonfibrous materials in biodegradable packaging. In: Muthu SS (ed) Environmental footprints of packaging. Springer Singapore, Singapore, pp 75–113

Khankrua R, Pivsa-Art S, Hiroyuki H, Suttiruengwong S (2014) Effect of chain extenders on thermal and mechanical properties of poly(lactic acid) at high processing temperatures: potential application in PLA/polyamide 6 blend. Polym Degrad Stab 108(Supplement C):232–240

Elsawy MA, Kim K-H, Park J-W, Deep A (2017) Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew Sustain Energy Rev 79(Supplement C):1346–1352

Lambert S, Wagner M (2017) Environmental performance of bio-based and biodegradable plastics: the road ahead. Chem Soc Rev 46(22):6855–6871

Luckachan GE, Pillai CKS (2011) Biodegradable polymers—a review on recent trends and emerging perspectives. J Polym Environ 19(3):637–676

Nair NR, Sekhar VC, Nampoothiri KM, Pandey A (2017) Biodegradation of biopolymers, current developments in biotechnology and bioengineering. Elsevier, New York, pp 739–755

Gupta B, Revagade N, Hilborn J (2007) Poly(lactic acid) fiber: an overview. Prog Polym Sci 32(4):455–482

Gu S, Yang M, Yu T, Ren T, Ren J (2008) Synthesis and characterization of biodegradable lactic acid-based polymers by chain extension. Polym Int 57(8):982–986

Rasal RM, Janorkar AV, Hirt DE (2010) Poly(lactic acid) modifications. Prog Polym Sci 35(3):338–356

Tuominen J, Kylmä J, Seppälä J (2002) Chain extending of lactic acid oligomers. 2. Increase of molecular weight with 1,6-hexamethylene diisocyanate and 2,2′-bis(2-oxazoline). Polymer 43(1):3–10

Kolahchi AR, Kontopoulou M (2015) Chain extended poly(3-hydroxybutyrate) with improved rheological properties and thermal stability, through reactive modification in the melt state. Polym Degrad Stab 121(Supplement C):222–229

Wang Y, Fu C, Luo Y, Ruan C, Zhang Y, Fu Y (2010) Melt synthesis and characterization of poly(l-lactic acid) chain linked by multifunctional epoxy compound. J Wuhan Univ Technol Mater Sci Ed 25(5):774–779

Gupta AP, Dev A, Kumar V (2012) Studies of novel chain linked biodegradable polymers. J Polym Environ 20(2):514–518

Xu H, Teng C, Mao Z, Yu M (2012) Study on the preparation and properties of lactic acid based copolymer. J Polym Res 19(9):9960. https://doi.org/10.1007/s10965-012-9960-z

Li X, Bhushan B (2002) A review of nanoindentation continuous stiffness measurement technique and its applications. Mater Charact 48(1):11–36

Schuh CA (2006) Nanoindentation studies of materials. Mater Today 9(5):32–40

Oliver WC, Pharr GM (2011) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19(1):3–20

Najafi N, Heuzey MC, Carreau PJ (2012) Polylactide (PLA)-clay nanocomposites prepared by melt compounding in the presence of a chain extender. Compos Sci Technol 72(5):608–615

Sneddon IN (1965) The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int J Eng Sci 3(1):47–57

Fischer-Cripps AC (2004) A simple phenomenological approach to nanoindentation creep. Mater Sci Eng A 385(1):74–82

Garlotta D (2001) A literature review of poly(lactic acid). J Polym Environ 9(2):63–84

Cai Y, Lv J, Feng J (2013) Spectral characterization of four kinds of biodegradable plastics: poly (lactic acid), poly (butylenes adipate-co-terephthalate), poly (hydroxybutyrate-co-hydroxyvalerate) and poly (butylenes succinate) with FTIR and Raman spectroscopy. J Polym Environ 21(1):108–114

Nikolic L, Ristic I, Adnadjevic B, Nikolic V, Jovanovic J, Stankovic M (2010) Novel microwave-assisted synthesis of poly(d, l-lactide): the influence of monomer/initiator molar ratio on the product properties. Sensors 10(5):5063–5073

Martel-Estrada SA, Olivas-Armendáriz I, Martínez-Pérez CA, Chacón-Nava JG (2012) Bioactividad in vitro de materiales compuestos de quitosana/poli(dl-láctido). Revista mexicana de ingeniería química 11:505–512

Larkin P (2011) Chapter 1—Introduction: infrared and Raman spectroscopy, infrared and Raman spectroscopy. Elsevier, Oxford, pp 1–5

Kister G, Cassanas G, Vert M (1998) Effects of morphology, conformation and configuration on the IR and Raman spectra of various poly(lactic acids). Polymer 39(2):267–273

Furukawa T, Sato H, Murakami R, Zhang J, Noda I, Ochiai S, Ozaki Y (2006) Raman microspectroscopy study of structure, dispersibility, and crystallinity of poly(hydroxybutyrate)/poly(l-lactic acid) blends. Polymer 47(9):3132–3140

Dimonie D, Zaharia C, Petrea C, Fierascu I, Petrache M, Fierascu R, Socoteanu R, Pop S (2012) Overview on mechanical recycling by chain extension of POSTC-PET bottles, INTECH Open Access Publisher

Tuominen J, Seppälä JV (2000) Synthesis and characterization of lactic acid based poly(ester − amide). Macromolecules 33(10):3530–3535

Awaja F, Daver F, Kosior E, Cser F (2004) The effect of chain extension on the thermal behaviour and crystallinity of reactive extruded recycled PET. J Therm Anal Calorim 78(3):865–884

Liu H, Wang X, Zhou H, Liu W, Liu B (2015) The preparation and characterization of branching poly(ethylene terephthalate) and its foaming behavior. Cell Polym 34(2):63–94

Maier S, Loontjens T, Scholtens B, Mülhaupt R (2003) Carbonylbiscaprolactam: a versatile reagent for organic synthesis and isocyanate-free urethane chemistry. Angew Chem Int Ed 42(41):5094–5097

Buccella M, Dorigato A, Pasqualini E, Caldara M, Fambri L (2014) Chain extension behavior and thermo-mechanical properties of polyamide 6 chemically modified with 1,1′-carbonyl-bis-caprolactam. Polym Eng Sci 54(1):158–165

Barrau S, Vanmansart C, Moreau M, Addad A, Stoclet G, Lefebvre JM, Seguela R (2011) Crystallization behavior of carbon nanotube − polylactide nanocomposites. Macromolecules 44(16):6496–6502

Brizzolara D, Cantow H-J, Diederichs K, Keller E, Domb AJ (1996) Mechanism of the stereocomplex formation between enantiomeric poly(lactides). Macromolecules 29(1):191–197

De Santis P, Kovacs AJ (1968) Molecular conformation of poly(S-lactic acid). Biopolymers 6(3):299–306

Maharana T, Mohanty B, Negi YS (2009) Melt–solid polycondensation of lactic acid and its biodegradability. Prog Polym Sci 34(1):99–124

Mathew AP, Oksman K, Sain M (2006) The effect of morphology and chemical characteristics of cellulose reinforcements on the crystallinity of polylactic acid. J Appl Polym Sci 101(1):300–310

Hung C-Y, Wang C-C, Chen C-Y (2013) Enhanced the thermal stability and crystallinity of polylactic acid (PLA) by incorporated reactive PS-b-PMMA-b-PGMA and PS-b-PGMA block copolymers as chain extenders. Polymer 54(7):1860–1866

Fambri L, Migliaresi C (2010) Crystallization and thermal properties, poly(lactic acid). Wiley, London, pp 113–124

Auras R, Harte B, Selke S (2004) An overview of polylactides as packaging materials. Macromol Biosci 4(9):835–864

Righetti MC (2017) Crystallization of polymers investigated by temperature-modulated DSC. Materials 10(4):442. https://doi.org/10.3390/ma10040442

Lim LT, Auras R, Rubino M (2008) Processing technologies for poly(lactic acid). Prog Polym Sci 33(8):820–852

Guo Y, Shao J, Hou H (2017) The toughening behavior of PLLA and its asymmetric PLLA/PDLA blends with lower optical purity. J Appl Polym Sci 134(17):44730. https://doi.org/10.1002/app.44730

Zhou C, Li H, Zhang W, Li J, Huang S, Meng Y, Christiansen Jd, Yu D, Wu Z, Jiang S (2016) Direct investigations on strain-induced cold crystallization behavior and structure evolutions in amorphous poly(lactic acid) with SAXS and WAXS measurements. Polymer 90(Supplement C):111–121

Chiu S-H, Wu C-L, Lee H-T, Gu J-H, Suen M-C (2016) Synthesis and characterisation of novel flame retardant polyurethanes containing designed phosphorus units. J Polym Res 23(10):205. https://doi.org/10.1007/s10965-016-1098-y

Shen L, Phang IY, Chen L, Liu T, Zeng K (2004) Nanoindentation and morphological studies on nylon 66 nanocomposites. I. Effect of clay loading. Polymer 45(10):3341–3349

Mattioli S, Peltzer M, Fortunati E, Armentano I, Jiménez A, Kenny JM (2013) Structure, gas-barrier properties and overall migration of poly(lactic acid) films coated with hydrogenated amorphous carbon layers. Carbon 63(Supplement C):274–282

Fischer-Cripps AC (2011) Nanoindentation. Springer, New York

Meng X, Shi G, Chen W, Wu C, Xin Z, Han T, Shi Y (2015) Structure effect of phosphite on the chain extension in PLA. Polym Degrad Stab 120(Supplement C):283–289

Solarski S, Ferreira M, Devaux E (2008) Ageing of polylactide and polylactide nanocomposite filaments. Polym Degrad Stab 93(3):707–713

Lv S, Liu X, Gu J, Jiang Y, Tan H, Zhang Y (2017) Effect of glycerol introduced into PLA based composites on the UV weathering behavior. Constr Build Mater 144(Supplement C):525–531

Gulmine JV, Janissek PR, Heise HM, Akcelrud L (2003) Degradation profile of polyethylene after artificial accelerated weathering. Polym Degrad Stab 79(3):385–397

Chiu H-T, Huang S-Y, Chen Y-F, Kuo M-T, Chiang T-Y, Chang C-Y, Wang Y-H (2013) Heat treatment effects on the mechanical properties and morphologies of poly (lactic acid)/poly (butylene adipate-co-terephthalate) blends. Int J Polym Sci 2013:951696. https://doi.org/10.1155/2013/951696

Edlund U, Albertsson AC (2003) Polyesters based on diacid monomers. Adv Drug Deliv Rev 55(4):585–609

Witt U, Müller R-J, Deckwer W-D (1995) New biodegradable polyester-copolymers from commodity chemicals with favorable use properties. J Environ Polym Degrad 3(4):215–223

Park KI, Xanthos M (2009) A study on the degradation of polylactic acid in the presence of phosphonium ionic liquids. Polym Degrad Stab 94(5):834–844

Tsuji H, Tezuka Y, Yamada K (2005) Alkaline and enzymatic degradation of l-lactide copolymers. II. Crystallized films of poly(l-lactide-co-d-lactide) and poly(l-lactide) with similar crystallinities. J Polym Sci Part B Polym Phys 43(9):1064–1075

Tsuji H, Mizuno A, Ikada Y (2000) Properties and morphology of poly(l-lactide). III. Effects of initial crystallinity on long-term in vitro hydrolysis of high molecular weight poly(l-lactide) film in phosphate-buffered solution. J Appl Polym Sci 77(7):1452–1464

de Jong SJ, Arias ER, Rijkers DTS, van Nostrum CF, Kettenes-van den Bosch JJ, Hennink WE (2001) New insights into the hydrolytic degradation of poly(lactic acid): participation of the alcohol terminus. Polymer 42(7):2795–2802

Acknowledgements

C. A. Ramírez-Herrera is grateful to CONACYT for her graduate fellowship. The authors acknowledge COFAA and SNI-CONACYT. CNMN-IPN and ESIQIE-IPN are recognized for the technical and experimental support provided in the realization of this research. Thanks to M. E. Adela E. Rodríguez-Salazar for her technical support during the revision of the manuscript.

Funding

This study was funded by Instituto Politécnico Nacional through the SIP2013-0773, SIP2018-0496 and SIP2018-1171 Projects. The authors are also grateful for the financial support provided by the CONACYT Research Fellowship-IPN-CICATA Altamira agreement, 2014-1905 and CONACyT CB2015-252181 Projects.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ramírez-Herrera, C.A., Flores-Vela, A.I., Torres-Huerta, A.M. et al. PLA degradation pathway obtained from direct polycondensation of 2-hydroxypropanoic acid using different chain extenders. J Mater Sci 53, 10846–10871 (2018). https://doi.org/10.1007/s10853-018-2380-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2380-7