Abstract

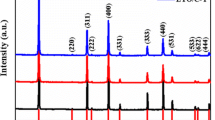

Organic carbon-coated LiNi0.5Mn0.3Co0.2O2 materials are prepared by mixing 2 or 5% starch or bagasse evenly with the synthesized LiNi0.5Mn0.3Co0.2O2 material and calcining for 10 h at 750 °C. The microstructures and electrochemical performance are investigated by X-ray diffraction, scanning electron microscopy, carbon/sulfur analysis, transmission electron microscopy and electrochemical testing. The results indicate that the organic carbon coated on the surface of LiNi0.5Mn0.3Co0.2O2 material does not change the surface morphology and crystal structure, but greatly improves the conductivity, rate and cycle performance of the LiNi0.5Mn0.3Co0.2O2 cathode in a Li-ion battery. The initial discharge capacity of the synthesized LiNi0.5Mn0.3Co0.2O2 material is 147.8 mAh g−1, which increases to 152.4 and 153.3 mAh g−1 for 2% starch and bagasse, respectively. After 100 cycles, the capacity retention rates are 70.7% (uncoated), 83.3% (coated with 2% starch), 90.1% (coated with 2% bagasse), 83.1% (coated with 5% starch) and 91.1% (coated with 5% bagasse). The influence of the percentage of coated carbon and its dispersion uniformity on the performance of the battery is analyzed. A small coating capacity and uniform carbon film can achieve better performance. Rational organic carbon coating technology is an effective way to improve the electrochemical performance of LiNi1−x−y Mn x Co y O2-based material.

Similar content being viewed by others

References

Armand M, Tarascon JM (2008) Building better batteries. Nature 451:652–657

Goodenough JB, Kim Y (2010) Challenges for rechargeable Li batteries. Chem Mater 22:587–603

Hayashi T, Miyazaki T, Matsuda Y, Kuwata N, Saruwatari M (2016) Effect of lithium-ion diffusibility on interfacial resistance of LiCoO2 thin film electrode modified with lithium tungsten oxides. J Power Sources 305:46–53

Yan ZQ, Yao WL, Hu L, Liu DD, Wang CD, Lee CS (2015) Progress in the preparation and application of three-dimensional graphene-based porous nanocomposites. Nanoscale 7:5563–5577

Lee MJ, Lee S, Oh P, Kim Y, Cho J (2014) High performance LiMn2O4 cathode materials grown with epitaxial layered nanostructure for Li-ion batteries. Nano Lett 14:993–999

Jiang SH, Yue WB, Gao ZQ, Ren Y, Ma H, Zhao XH, Liu YL, Yang XJ (2013) Graphene-encapsulated mesoporous SnO2 composites as high performance anodes for lithium-ion batteries. J Mater Sci 48:3870–3876. https://doi.org/10.1007/s10853-013-7189-9

Qiu S, Zhang X, Li Y, Sun T, Wang C (2016) Facile synthesis and electrochemical performances of secondary carbon-coated LiFePO4–C composite for Li-ion capacitors based on neutral aqueous electrolytes. J Mater Sci 27:7255–7264. https://doi.org/10.1007/s10854-016-4692-1

Zhang X, Mauger A, Qi L, Groult H, Perrigaud L (2010) Synthesis and characterization of LiNi1/3Mn1/3Co1/3O2 by wet-chemical method. Electrochim Acta 55:6440–6449

Li D, Sasaki Y, Kageyama M, Kobayakawa K, Sato Y (2005) Structure, morphology and electrochemical properties of LiNi0.5Mn0.5−x Co x O2 prepared by solid state reaction. J Power Sources 148:85–89

Mun J, Park JH, Choi W, Benayad A, Park JH, Lee JM, Doo SG, Oh SM (2014) New dry carbon nanotube coating of over-lithiated layered oxide cathode for lithium ion batteries. J Mater Chem A 2:19670–19677

Belharouak I, Sun YK, Liu J (2003) LiCo1/3Ni1/3Mn1/3O2 as a suitable cathode for high power application. J Power Sources 132:247–252

Kim Y, Kim HS, Martin SW (2006) Synthesis and electrochemical characteristics of Al2O3-coated LiNi1/3Co1/3Mn1/3O2 cathode materials for lithium ion batteries. Electrochim Acta 52:1316–1322

Qiu XY, Zhuang QC, Zhang QQ, Cao R, Qiang YH (2012) Investigation of layered LiNi1/3Co1/3Mn1/3O2 cathode of lithium ion battery by electrochemical impedance spectroscopy. J Electroanal Chem 687:35–44

Jouanneau J, Macneil D, Lu Z (2003) Morphology and safety of Li[Ni x Co1−2x Mn x ]O2 (0 < x < 1/2). J Electrochem Soc 150:A1299–A1304

Zhong SW, Lai MZ, Yao WL, Li ZC (2016) Synthesis and electrochemical properties of LiNi0.8Co x Mn0.2−x O2 positive-electrode material for lithium-ion batteries. Electrochim Acta 212:343–351

Chen Y, Wang GX, Konstantinov K (2003) Synthesis and characterization of LiCo x Mn y Ni1−x−y O2 as a cathode material for secondary lithium batteries. J Power Sources 119–121:184–188

Verma P, Maire P, Novák P (2010) A review of the features and analyses of the solid electrolyte interphase in Li-ion batteries. Electrochim Acta 55:6332–6341

Li JL, Yao RM, Cao CB (2014) LiNi1, 3Co1, 3Mn1, 3O2 nanoplates with 010 active lanes exposing prepared in polyol medium as a high-performance cathode for Li-ion battery. ACS Appl Mater Interfaces 6:5075–5082

Liang CH, Liu LB, Jia Z, Dai C, Xiong Y (2015) Synergy of Nyquist and bode electrochemical impedance spectroscopy studies to particle size effect on the electrochemical properties of LiNi0.5Co0.2Mn0.3O2. Electrochim Acta 186:413–419

Cho YH, Jang D, Yoon J (2013) Thermal stability of charged LiNi0.5Co0.2Mn0.3O2 cathode for Li-ion batteries investigated by synchrotron based in situ X-ray diffraction. J Alloys Compd 562:219–223

Wu KC, Wang F, Gao LL, Li MR, Xiao LL (2012) Effect of precursor and synthesis temperature on the structural and electrochemical properties of LiNi0.5Co0.2Mn0.3O2. Electrochim Acta 75:393–398

Xia L, Qiu KH, Gao YY, He X, Zhou FD (2015) High potential performance of Cerium-doped LiNi0.5Co0.2Mn0.3O2 cathode material for Li-ion battery. J Mater Sci 50:2914–2920. https://doi.org/10.1007/s10853-015-8856-9

Wang J, Zhang YJ, Dong P, Xia SB (2014) Progess in surface coating of temporary cathode materials Li[Ni Co, Mn]O2 for lithium batteries. Chin J Power Sources 38:560–563

Ding Y, Chen LH, Pan P, Du J, Wang F (2017) Nitrogen-doped carbon coated MnO nanopeapods as superior anode materials for lithium ion batteries. Appl Surf Sci 422:1113–1119

Hua WB, Zhang JB, Zheng Z, Liu WY, Guo XD, Zhong BH, Wang YJ, Wang XL (2014) Na-doped Ni-rich LiNi0.5Co0.2Mn0.3O2 cathode material with both high rate capability and high tap density for lithium ion batteries. Dalton Trans 43:14824–14832

Karan NK, Balasubramanian M, Abraham DP, Furczon MM, Pradhan DK, Saavedra-Arias JJ, Thomas R, Katiyar RS (2009) Structural characteristics and electrochemical performance of layered Li[Mn0.5−x Cr2x Ni0.5−x ]O2 cathode materials. J Power Sources 187:586–590

Yang ZX, Song ZL, Chu G, Kang XX, Ren TQ, Yang WS, Qiao QD (2012) Surface modification of LiCo1/3Ni1/3Mn1/3O2 with CoAl–MMO for lithium-ion batteries. J Mater Sci 47:4205–4209. https://doi.org/10.1007/s10853-012-6275-8

Ni JF, Zhou HH, Chen JT (2008) Improved electrochemical performance of layered LiNi0.4Co0.2Mn0.4O2 via Li2ZrO3 coating. Electrochim Acta 53:3075–3083

Li N, Wang YP, Rao RC, Dong XZ, Zhu S (2017) The preparation and graphene surface coating NaTi2(PO4)3 as cathode material for lithium ion batteries. Appl Surf Sci 399:624–629

He R, Zhang LH, Yan MF, Gao YH, Liu ZF (2017) Effects of Cr2O3-modified LiNi1/3Co1/3Mn1/3O2 cathode materials on the electrochemical performance of lithium-ion batteries. J Mater Sci 52:4599–4607. https://doi.org/10.1007/s10853-016-0704-z

Yang K, Fan LZ, Guo J (2012) Significant improvement of electrochemical properties of AlF3-coated LiNi0.5Co0.2Mn0.3O2 cathode materials. Electrochim Acta 63:363–368

Wu TH, Tu FY, Liu SQ, Zhuang SX, Jin GH, Pan CY (2014) MnO nanorods on graphene as an anode material for high capacity lithium ion batteries. J Mater Sci 49:1861–1867. https://doi.org/10.1007/s10853-013-7874-8

Huang YH, Chou HL, Wang FM, Hwang BJ (2013) Synergy between experiment and simulation in describing the electro-chemical performance of Mg-doped LiNi x Co y Mn z O2 cathode material of lithium ion battery. Int J Electrochem Sci 8:8005–8018

Woo SW, Myung ST, Bang H, Kim DW, Sun YK (2009) Improvement of electrochemical and thermal properties of Li[Ni0.8Co0.1Mn0.1]O2 positive electrode materials by multiple metal (Al, Mg) substitution. Electrochim Acta 54:3851–3856

Zhong SK, Wang Y, Liu JQ, Wan K (2011) Synthesis and electrochemical properties of Ce-doped LiNi1/3Mn1/3O2 cathode material for Li-ion batteries. J Rare Earths 29:891–895

Wang D, Li XH, Wang ZX, Guo HJ, Xu Y, Fan YL, Ru JJ (2015) Role of zirconium dopant on the structure and high voltage electrochemical performances of LiNi0.5Co0.2Mn0.3O2 cathode materials for lithium ion batteries. Electrochim Acta 188:48–56

Liu J, Reeja-Jayan B, Manthiram A (2010) Conductive surface modification with aluminum of high capacity layered Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathodes. J Phys Chem C 114:9528–9533

Bai T, Zhou HC, Zhou XY, Liao QC, Chen SM, Yang J (2017) N-doped carbon-encapsulated MnO@graphene nanosheet as high-performance anode material for lithium-ion batteries. J Mater Sci 52:11608–11619. https://doi.org/10.1007/s10853-017-1247-7

Zhang S, Deng C, Fu BL (2010) Synthetic optimization of spherical LiCo1/3Ni1/3Mn1/3O2 prepared by a carbonate co-precipitation method. Powder Technol 198:373–380

Deng C, Liu L, Zhou W (2008) Effect of synthesis condition on the structure and electrochemical properties LiCo1/3Ni1/3Mn1/3O2 prepared by hydroxide co-precipitation method. Electrochim Acta 53:2441–2447

Han YM, Zhang ZF, Zhang LB, Peng JH, Fu MB, Du J (2013) Influence of carbon coating prepared by microwave pyrolysis on properties of LiNi1/3Mn1/3Co1/3O2. Trans Nonferrous Met Soc China 23:2971–2976

Xiong XH, Ding D, Wang ZX, Huang B, Guo HJ, Li XH (2014) Surface modification of LiNi0.8Co0.1Mn0.1O2 with conducting polypyrrole. J Solid State Electrochem 18:2619–2624

Churikov AV, Romanova VO (2013) Determination of diffusion coefficient of lithium in substituted LiMn1.95Cr0.05O4 spinel using impedance technique. Russ J Electrochem 49:272–277

Zou BK, Ding CX, Chen CH (2014) Research progress in ternary cathode materials Li(Ni Co, Mn)O2 for lithium ion batteries. Sci Sin Chim 44:1104–1115

Acknowledgements

The authors would like to express their sincere thanks to the National Natural Science Foundation of China (Nos. 21762019 and 51372104), the Science and Technology Project of Jiangxi Province (Nos. 20161BAB213082 and 20171BAB206017), the Science Research Project of Jiangxi Provincial Department of Education (No. GJJ150672), and the College Students Innovation and Entrepreneurship Project (No. 201610407006).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhu, C., Chen, J., Liu, S. et al. Improved electrochemical performance of bagasse and starch-modified LiNi0.5Mn0.3Co0.2O2 materials for lithium-ion batteries. J Mater Sci 53, 5242–5254 (2018). https://doi.org/10.1007/s10853-017-1926-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1926-4