Abstract

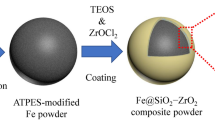

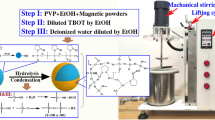

In this work, the intergranular insulated Fe/SiO2 soft magnetic composite cores with tunable insulating layer thickness were prepared by a modified Stöber method combined with the spark plasma sintering technology. Most of the conductive Fe particles could be coated uniformly by insulated SiO2 using the modified Stöber method, and the high compact and intergranular insulated cores could be obtained quickly by the spark plasma sintering process. The intergranular insulated Fe/SiO2 composite cores exhibited much higher electrical resistivity, lower core loss, better frequency stability of permeability and large higher quality factor than that of raw Fe core without insulated SiO2. The thickness of SiO2 insulating layer, electrical and magnetic properties of intergranular insulated Fe/SiO2 composite cores could be readily controlled by adjusting the tetraethyl orthosilicate concentration. The thickness of SiO2 insulating layer and resistivity of Fe/SiO2 composite cores first increased and then dropped with increasing the tetraethyl orthosilicate concentration, while the permeability and core loss changed in the opposite direction. Fe/SiO2 composite core showed the optimal performance when the tetraethyl orthosilicate concentration was 0.135 mol l−1, which exhibited better frequency stability at high frequencies, much higher electrical resistivity, higher quality factor and lower core loss.

Similar content being viewed by others

References

Suetsuna T, Suenaga S, Harada K (2016) Bulk nanogranular composite of magnetic metal and insulating oxide matrix. Scr Mater 113:89–92

Shokrollahi H, Janghorban K (2007) Soft magnetic composite materials (SMCs). J Mater Process Technol 189:1–12

Jankowski B, Kapelski D, Ślusarek B et al (2015) Determination of power loss in Fe-based soft magnetic composites. Arch Metall Mater 60(2):1411–1415

Liu C, Zhu J, Wang Y et al (2016) Design considerations of PM transverse flux machines with soft magnetic composite cores. IEEE Trans Appl Supercond 26(4):1–5

Wang SX, Sun NX, Yamaguchi M et al (2000) Sandwich films: properties of a new soft magnetic material. Nature 407:150–151

Lei G, Liu C, Guo Y et al (2016) Robust multidisciplinary design optimization of PM machines with soft magnetic composite cores for batch production. IEEE Trans Magn 52(3):1–4

Gutfleisch O, Willard MA, Brück E et al (2011) Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv Mater 23:821–842

Oikonomou C, Hryha E, Nyborg L (2016) An XPS investigation on the thermal stability of the insulating surface layer of soft magnetic composite powder. Surf Interface Anal 48(7):445–450

Bayramlı E, Gölgelioğlu Ö, Ertan HB (2005) Powder metal development for electrical motor applications. J Mater Process Technol 161(1):83–88

Kollár P, Vojtek V, Birčáková Z et al (2014) Steinmetz law in iron–phenolformaldehyde resin soft magnetic composites. J Magn Magn Mater 353:65–70

Dias MM, Mozetic HJ, Barboza JS et al (2013) Influence of resin type and content on electrical and magnetic properties of soft magnetic composites (SMCs). Powder Technol 237:213–220

Wu S, Sun A, Zhai F et al (2012) Annealing effects on magnetic properties of silicone-coated iron-based soft magnetic composites. J Magn Magn Mater 324(5):818–822

Peng Y, Nie J, Zhang W et al (2015) Preparation of soft magnetic composites for Fe particles coated with (NiZn)Fe2O4 via microwave treatment. J Magn Magn Mater 395:245–250

Hemmati I, Hosseini HRM, Miraghaei S (2007) Effect of processing parameters on electrical, mechanical and magnetic properties of iron–resin soft magnetic composite. Powder Metall 50(1):86–90

Uozumi G, Watanabe M, Nakayama R et al (2007) Properties of soft magnetic composite with evaporated MgO insulation coating for low iron loss. Mater Sci Forum 534:1361–1364

Liu D, Wu C, Yan M (2015) Investigation on sol–gel Al2O3 and hybrid phosphate-alumina insulation coatings for FeSiAl soft magnetic composites. J Mater Sci 50(20):6559–6566. doi:10.1007/s10853-015-9189-4

Zhong X, Liu Y, Li J et al (2012) Structure and magnetic properties of FeSiAl-based soft magnetic composite with AlN and Al2O3 insulating layer prepared by selective nitridation and oxidation. J Magn Magn Mater 324:2631–2636

Kang Y, Huang Y, Yang R et al (2016) Synthesis and properties of core–shell structured Fe(CO)5/SiO2 composites. J Magn Magn Mater 399:149–154

Kim YB, Jee KK, Choi GB (2008) Fe-based nanocrystalline alloy powder cores with excellent high frequency magnetic properties. J Appl Phys 103(7):07E704-1–07E704-3

Kim TH, Jee KK, Kim YB et al (2010) High-frequency magnetic properties of soft magnetic cores based on nanocrystalline alloy powder prepared by thermal oxidation. J Magn Magn Mater 322(16):2423–2427

Zhao G, Wu C, Yan M (2016) Enhanced magnetic properties of Fe soft magnetic composites by surface oxidation. J Magn Magn Mater 399:51–57

Wu S, Sun A, Lu Z et al (2015) Magnetic properties of iron-based soft magnetic composites with SiO2 coating obtained by reverse microemulsion method. J Magn Magn Mater 381:451–456

Stöber W, Fink A, Bohn E (1968) Controlled growth of monodisperse silica spheres in the micron size range. J Colloid Interface Sci 26:62–69

Zhu J, Wei S, Haldolaarachchige N et al (2011) Electromagnetic field shielding polyurethane nanocomposites reinforced with core–shell Fe–Silica nanoparticles. J Phys Chem C 115:15304–15310

Xu H, Wang R, Wei D et al (2015) Crystallization kinetics and magnetic properties of FeSiCr amorphous alloy powder cores. J Magn Magn Mater 385:326–330

Soohoo RF (1979) Magnetic thin film inductors for integrated circuit applications. IEEE Trans Magn 15:1803–1805

Ni X, Zheng Z, Hu X et al (2010) Silica-coated iron nanocubes: preparation, characterization and application in microwave absorption. J Colloid Interface Sci 341(1):18–22

Tie SL, Lee HC, Bae YS et al (2007) Monodisperse Fe3O4/Fe@SiO2 core/shell nanoparticles with enhanced magnetic property. Colloids Surf A 293(1):278–285

Pal R, Kundu D (2009) Sol–gel synthesis of porous and dense silica microspheres. J Non-Cryst Solids 355(1):76–78

Li X, Makino A, Kato H et al (2011) Fe76Si9.6B8.4P6 glassy powder soft-magnetic cores with low core loss prepared by spark-plasma sintering. Mater Sci Eng B-Solid 176:1247–1250

Lin GQ, Li ZW, Chen L et al (2006) Influence of demagnetizing field on the permeability of soft magnetic composites. J Magn Magn Mater 305:291–295

Wu S, Sun A, Zhai F et al (2012) Annealing effects on magnetic properties of silicone-coated iron-based soft magnetic composites. J Magn Magn Mater 324:818–822

Wang R, Liu J, Wang Z et al (2012) Crystallization kinetics and magnetic properties of Fe63.5Co10Si13.5B9Cu1Nb3 nanocrystalline powder cores. J Non-Cryst Solids 358:200–203

Acknowledgement

This work was co-sponsored by National Natural Science Foundation of China (51674181, 51274155) and the Key Projects of Hubei Provincial Department of Education (D20151103). The authors also appreciate Professor Jun Wu for effective helps in measuring the electric and magnetic properties.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Fan, X., Wu, Z. et al. Regulation and control of insulated layers for intergranular insulated Fe/SiO2 soft magnetic composites. J Mater Sci 52, 7091–7099 (2017). https://doi.org/10.1007/s10853-017-0941-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0941-9