Abstract

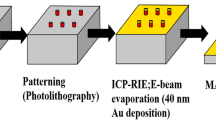

Well-separated silicon nanowires with good periodicity and lower porosity density are fabricated using thermal oxidization and HF acid etching after forming silicon nanowire (Si NW) arrays with high diameter-to-pitch ratio by metal-assisted chemical etching based on nanosphere lithography. The factors responsible for the special morphology features of Si NW during the oxidation process are understood by thermal oxidation process simulation. A high-temperature oxidation process is proposed to facilitate the alleviation of necking and the acceleration of oxidation of NWs. Furthermore, to reduce the tapering trend, an oxygen diffuse barrier layer is proposed to be pre-deposited on the top of Si NWs before the high-temperature thermal oxidation treatment. By using these methods, a periodic array of Si NWs with a large pitch and small diameter is created. This approach can substantially reduce porosities and surface defects on the outer surface of Si NWs.

Similar content being viewed by others

References

Wagner RS, Ellis WC (1964) Vapor–liquid–solid mechanism of single crystal growth. Appl Phys Lett 4:89–90

Fu YQ, Colli A, Fasoli A, Luo JK, Flewitt AJ, Ferrari AC, Milne WI (2009) Deep reactive ion etching as a tool for nanostructure fabrication. J Vac Sci Technol B 27:1520–1526

Hobbs RG, Petkov N, Holmes JD (2012) Semiconductor nanowire fabrication by bottom-up and top-down paradigms. Chem Mater 24:1975–1991

Huang Z, Geyer N, Werner P, de Boor J, Gösele U (2011) Metal-assisted chemical etching of silicon: a review. Adv Mater 23:285–308

Dong Won C, Tae Kyoung K, Duyoung C, Elizabeth C, Young Jin K, Jae Cheol P, Sungho J, Renkun C (2016) Vertical Si nanowire arrays fabricated by magnetically guided metal-assisted chemical etching. Nanotechnology 27:455302

Kong L, Dasgupta B, Ren Y, Mohseni PK, Hong M, Li X, Chim WK, Chiam SY (2016) Evidences for redox reaction driven charge transfer and mass transport in metal-assisted chemical etching of silicon. Sci Rep 6:36582

Liu K, Qu S, Zhang X, Wang Z (2013) Anisotropic characteristics and morphological control of silicon nanowires fabricated by metal-assisted chemical etching. J Mater Sci 48:1755–1762. doi:10.1007/s10853-012-6936-7

Yeom J, Ratchford D, Field CR, Brintlinger TH, Pehrsson PE (2014) Decoupling diameter and pitch in silicon nanowire arrays made by metal-assisted chemical etching. Adv Funct Mater 24:106–116

Huang Z, Fang H, Zhu J (2007) Fabrication of silicon nanowire arrays with controlled diameter, length, and density. Adv Mater 19:744–748

Peng K, Zhang M, Lu A, Wong N-B, Zhang R, Lee S-T (2007) Ordered silicon nanowire arrays via nanosphere lithography and metal-induced etching. Appl Phys Lett 90:163123

Cheung CL, Nikolić RJ, Reinhardt CE, Wang TF (2006) Fabrication of nanopillars by nanosphere lithography. Nanotechnology 17:1339

Chan CK, Peng H, Liu G, McIlwrath K, Zhang XF, Huggins RA, Cui Y (2008) High-performance lithium battery anodes using silicon nanowires. Nat Nanotechnol 3:31–35

Seo K, Wober M, Steinvurzel P, Schonbrun E, Dan Y, Ellenbogen T, Crozier KB (2011) Multicolored vertical silicon nanowires. Nano Lett 11:1851–1856

Wang Y, Schmidt V, Senz S, Gosele U (2006) Epitaxial growth of silicon nanowires using an aluminium catalyst. Nat Nanotechnol 1:186–189

Morton KJ, Nieberg G, Bai S, Chou SY (2008) Wafer-scale patterning of sub-40 nm diameter and high aspect ratio (>50:1) silicon pillar arrays by nanoimprint and etching. Nanotechnology 19:345301

Su S, Lin L, Li Z, Feng J, Zhang Z (2013) The fabrication of large-scale sub-10-nm core-shell silicon nanowire arrays. Nanoscale Res Lett 8:1–7

Nakamura J, Higuchi K, Maenaka K (2013) Vertical Si nanowire with ultra-high-aspect-ratio by combined top-down processing technique. Microsyst Technol 19:433–438

Shi X, Kurstjens R, Vos I, Everaert J-L, Schaekers M (2011) Review of silicon nanowire oxidation. ECS Trans 34:535–540

Kurstjens R, Vos I, Dross F, Poortmans J, Mertens R (2012) Thermal oxidation of a densely packed array of vertical Si nanowires. J Electrochem Soc 159:H300–H306

Synopsys T (2010) Sentaurus Process User Guide, Version D-2010.03

Coffin H, Bonafos C, Schamm S, Cherkashin N, Assayag GB, Claverie A, Respaud M, Dimitrakis P, Normand P (2006) Oxidation of Si nanocrystals fabricated by ultralow-energy ion implantation in thin SiO2 layers. J Appl Phys 99:044302

Kao DB, McVittie JP, Nix WD, Saraswat KC (1988) Two-dimensional thermal oxidation of silicon. II. Modeling stress effects in wet oxides. IEEE Trans Electron Devices 35:25–37

Egorkin AV, Kalinin SV (2014) Two-dimensional modeling the process of thermal oxidation of non-planar silicon structures in CMOS-circuits’ isolation. In: 15th International conference of young specialists on micro/nanotechnologies and electron devices (EDM), pp 61–66

Deal BE, Grove AS (1965) General relationship for the thermal oxidation of silicon. J Appl Phys 36:3770–3778

Gordon MJ, Baron T, Dhalluin F, Gentile P, Ferret P (2009) Size effects in mechanical deformation and fracture of cantilevered silicon nanowires. Nano Lett 9:525–529

Tang D-M, Ren C-L, Wang M-S, Wei X, Kawamoto N, Liu C, Bando Y, Mitome M, Fukata N, Golberg D (2012) Mechanical properties of Si nanowires as revealed by in situ transmission electron microscopy and molecular dynamics simulations. Nano Lett 12:1898–1904

Büttner CC, Zacharias M (2006) Retarded oxidation of Si nanowires. Appl Phys Lett 89:263106

Cui H, Wang CX, Yang GW (2008) Origin of self-limiting oxidation of Si nanowires. Nano Lett 8:2731–2737

Krzeminski CD, Han X-L, Larrieu G (2012) Understanding of the retarded oxidation effects in silicon nanostructures. Appl Phys Lett 100:263111

EerNisse EP (1977) Viscous flow of thermal SiO2. Appl Phys Lett 30:290–293

Stan G, Krylyuk S, Davydov AV, Cook RF (2010) Compressive stress effect on the radial elastic modulus of oxidized Si nanowires. Nano Lett 10:2031–2037

Weber ER (1983) Transition metals in silicon. Appl Phys A 30:1–22

Istratov AA, Flink C, Hieslmair H, McHugo SA, Weber ER (2000) Diffusion, solubility and gettering of copper in silicon. Mater Sci Eng B 72:99–104

Luping L, Yin F, Cheng X, Yang Z, Nanzhi Z, Peng J, Kirk JZ (2016) Fabricating vertically aligned sub-20 nm Si nanowire arrays by chemical etching and thermal oxidation. Nanotechnology 27:165303

Titova LV, Hoang TB, Jackson HE, Smith LM, Yarrison-Rice JM, Kim Y, Joyce HJ, Tan HH, Jagadish C (2006) Temperature dependence of photoluminescence from single core-shell GaAs–AlGaAs nanowires. Appl Phys Lett 89:173126

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51472247, 51671182).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, B., Li, X., Shi, T. et al. Synthesis and morphology control of diluted Si nanowire arrays by metal-assisted chemical etching and thermal oxidation based on nanosphere lithography. J Mater Sci 52, 6449–6458 (2017). https://doi.org/10.1007/s10853-017-0880-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0880-5