Abstract

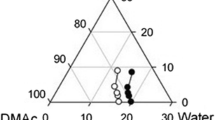

Poly(vinyl chloride) (PVC)-based asymmetric membrane was prepared by nonsolvent-induced phase separation method using N,N-dimethylacetamide (DMAc) and N-methyl-2-pyrrolidone (NMP) as solvents. Poly(ethylene glycol) (PEG) of three different molecular weights (PEG-400, PEG-4000, PEG-20000) was used as the pore former and hydrophilic additive. Solvent effect on the phase inversion mechanism and morphology was interpreted using the Hansen solubility parameter. Effect of molecular weight of PEG additive on the morphology and performance of the membrane was systematically investigated. It was observed that the pure water flux has been increased initially (up to 236.8 ± 3.3 Lm−2 h−1) and then decreased (134.3 ± 0.7 Lm−2 h−1) with the increase in the molecular weight of PEG in the PVC/PEG/DMAc system. However, pure water flux value of PVC/PEG/NMP system progressed (61.1 ± 1.2 to 184.1 ± 3.8 Lm−2 h−1) with the rise in molecular weight of PEG. As the molecular weight of PEG increased, phase separation was enhanced, and membrane with higher porosity was formed. It was found that the shape and size of finger-like structures in the sub-layer increase with the increase in the molecular weight of PEG. Residual PEG content in the membrane also showed a positive gradation with the molecular weight of PEG, which extends the hydrophilicity of the membrane. Between the two solvents used, NMP showed better interaction with PVC than DMAc. The membranes exhibited sufficient thermal stability, mechanical strength and antifouling property suitable for ultrafiltration operation.

Similar content being viewed by others

References

Karim Z, Claudpierre S, Grahn M et al (2016) Nanocellulose based functional membranes for water cleaning: tailoring of mechanical properties, porosity and metal ion capture. J Membr Sci 514:418–428

Ma W, Rajabzadeh S, Shaikh AR et al (2016) Effect of type of poly(ethylene glycol) (PEG) based amphiphilic copolymer on antifouling properties of copolymer/poly(vinylidene fluoride) (PVDF) blend membranes. J Membr Sci 514:429–439

Lin J, Ye W, Baltaru M-CC et al (2016) Tight ultrafiltration membranes for enhanced separation of dyes and Na2SO4 during textile wastewater treatment. J Membr Sci 514:217–228

Lin J, Tang CY, Huang C et al (2016) A comprehensive physico-chemical characterization of superhydrophilic loose nanofiltration membranes. J Membr Sci 501:1–14

Lin J, Ye W, Zeng H et al (2015) Fractionation of direct dyes and salts in aqueous solution using loose nanofiltration membranes. J Membr Sci 477:183–193

Lin J, Tang CY, Ye W et al (2015) Unraveling flux behavior of superhydrophilic loose nanofiltration membranes during textile wastewater treatment. J Membr Sci 493:690–702

Lin J, Ye W, Huang J et al (2015) Toward resource recovery from textile wastewater: dye extraction, water and base/acid regeneration using a hybrid NF-BMED process. ACS Sustain Chem Eng 3:1993–2001

Wang P, Ma J, Wang Z et al (2012) Enhanced separation performance of PVDF/PVP-g-MMT nanocomposite ultrafiltration membrane based on the NVP-grafted polymerization modification of montmorillonite (MMT). Langmuir 28:4776–4786

Tian Z, Wang S, Wang Y et al (2016) Enhanced gas separation performance of mixed matrix membranes from graphitic carbon nitride nanosheets and polymers of intrinsic microporosity. J Membr Sci 514:15–24

Hosseini SS, Li Y, Chung TS, Liu Y (2007) Enhanced gas separation performance of nanocomposite membranes using MgO nanoparticles. J Membr Sci 302:207–217

Wienk IM, Boom RM, Beerlage MAM et al (1996) Recent advances in the formation of phase inversion membranes made from amorphous or semi-crystalline polymers. J Membr Sci 113:361–371

Young TH, Chen LW (1995) Pore formation mechanism of membranes from phase inversion process. Desalination 103:233–247

Guillen GR, Pan Y, Li M, Hoek EMV (2011) Preparation and characterization of membranes formed by nonsolvent induced phase separation: a review. Ind Eng Chem Res 50:3798–3817

Idris A, Yet LK (2006) The effect of different molecular weight PEG additives on cellulose acetate asymmetric dialysis membrane performance. J Membr Sci 280:920–927

Chou W, Yu D, Yang M, Jou C (2007) Effect of molecular weight and concentration of PEG additives on morphology and permeation performance of cellulose acetate hollow fibers. Sep Purif Technol 57:209–219

Chakrabarty B, Ghoshal AK, Purkait MK (2008) Effect of molecular weight of PEG on membrane morphology and transport properties. J Membr Sci 309:209–221

Jung B, Joon KY, Kim B et al (2004) Effect of molecular weight of polymeric additives on formation, permeation properties and hypochlorite treatment of asymmetric polyacrylonitrile membranes. J Membr Sci 243:45–57

Yeow ML, Liu YT, Li K (2004) Morphological study of poly (vinylidene fluoride) asymmetric membranes: effects of the solvent, additive, and dope temperature. J Appl Polym Sci 92:1782–1789

Idris A, Mat N, Noordin MYY et al (2007) Synthesis, characterization and performance of asymmetric polyethersulfone (PES) ultrafiltration membranes with polyethylene glycol of different molecular weights as additives. Desalination 207:324–339

Panda SR, De S (2014) Effects of polymer molecular weight, concentration, and role of polyethylene glycol as additive on polyacrylonitrile homopolymer membranes. Polym Eng Sci 54:2375–2391

Wongchitphimon S, Wang R, Jiraratananon R et al (2011) Effect of polyethylene glycol (PEG) as an additive on the fabrication of polyvinylidene fluoride-co-hexafluropropylene (PVDF-HFP) asymmetric microporous hollow fiber membranes. J Membr Sci 369:329–338

Peng N, Widjojo N, Sukitpaneenit P et al (2012) Progress in polymer science evolution of polymeric hollow fibers as sustainable technologies: past, present, and future. Prog Polym Sci 37:1401–1424

Van De Witte P, Van Den Berg JWA, Feijen J (1996) Phase separation processes in polymer solutions in relation to membrane formation. J Membr Sci 117:1–31

Liu H, Xiao C, Huang Q, Hu X (2013) Structure design and performance study on homogeneous-reinforced polyvinyl chloride hollow fiber membranes. Desalination 331:35–45

Zhang X, Chen Y, Konsowa AHH et al (2009) Evaluation of an innovative polyvinyl chloride (PVC) ultrafiltration membrane for wastewater treatment. Sep Purif Technol 70:71–78

Yang C, Ming J, Wu C (2009) Poly (vinyl alcohol)/poly (vinyl chloride) composite polymer membranes for secondary zinc electrodes. J Power Sources 191:669–677

Mei S, Xiao C, Hu X, Shu W (2011) Hydrolysis modification of PVC/PAN/SiO 2 composite hollow fi ber membrane. Desalination 280:378–383

Zhao Y, Lu J, Liu X et al (2016) Performance enhancement of polyvinyl chloride ultrafiltration membrane modified with graphene oxide. J Colloid Interface Sci 480:1–8

Fan X, Su Y, Zhao X et al (2014) Fabrication of polyvinyl chloride ultrafiltration membranes with stable antifouling property by exploring the pore formation and surface modification capabilities of polyvinyl formal. J Membr Sci 464:100–109

Babu PR, Gaikar VG (1999) Preparation, structure, and transport properties of ultrafiltration membranes of poly (vinyl chloride) and poly (vinyl pyrrolidone) blends. J Appl Polym Sci 77:2606–2620

Peng Y, Sui Y (2006) Compatibility research on PVC/PVB blended membranes. Desalination 196:13–21

Zhang H, Hu X, Chen Y et al (2015) Dynamic rheological property and membrane formation of mechanochemically modified polyvinylchloride. J Mater Sci 50:4371–4378. doi:10.1007/s10853-015-8991-3

Okuno H, Renzo K, Uragami T (1993) Influence of casting solution additive, degree of polymerization, and polymer concentration on poly(vinyl chloride) membrane properties and performance. J Membr Sci 83:199–209

Rabiee H, Farahani MHDA, Vatanpour V (2014) Preparation and characterization of emulsion poly(vinyl chloride) (EPVC)/TiO2 nanocomposite ultrafiltration membrane. J Membr Sci 472:185–193

Hirose S, Shimizu A, Nose T (1979) Preparation and structures of the poly(vinyl chloride) porous membranes. J Appl Polym Sci 23:3193–3204

Sadeghi M, Chenar MP, Rahimian M et al (2008) Gas permeation properties of polyvinylchloride/polyethyleneglycol blend membranes. J Appl Polym Sci 110:1093–1098

Roy KJ, Anjali TV, Sujith A (2016) Poly(vinyl chloride) asymmetric membrane modified with poly(ethylene glycol): effect of additive concentration on the morphology and performance. Polym Plast Technol Eng. doi:10.1080/03602559.2016.1253731

Mei Shuo, Changfa Xiao XH, Mei S, Xiao C, Hu X (2011) Preparation of porous PVC membrane via a phase inversion method from PVC/DMAc/Water/Additives. J Appl Polym Sci 120:557–562

Davood Abadi Farahani MH, Rabiee H, Vatanpour V, Borghei SM (2016) Fouling reduction of emulsion polyvinylchloride ultrafiltration membranes blended by PEG: the effect of additive concentration and coagulation bath temperature. Desalin Water Treat 57:11931–11944

Liu B, Chen C, Zhang W et al (2012) Low-cost antifouling PVC ultrafiltration membrane fabrication with Pluronic F 127: effect of additives on properties and performance. Desalination 307:26–33

Xu J, Xu Z-LL (2002) Poly (vinyl chloride)(PVC) hollow fiber ultrafiltration membranes prepared from PVC/additives/solvent. J Membr Sci 208:203–212

Machado PS, Habert A, Borges C (1999) Membrane formation mechanism based on precipitation kinetics and membrane morphology: flat and hollow fiber polysulfone membranes. J Membr Sci 155:171–183

Li JF, Xu ZL, Yang H et al (2009) Effect of TiO2 nanoparticles on the surface morphology and performance of microporous PES membrane. Appl Surf Sci 255:4725–4732

Feng C, Wang R, Shi B et al (2006) Factors affecting pore structure and performance of poly (vinylidene fluoride-co-hexafluoro propylene) asymmetric porous membrane. J Membr Sci 277:55–64

Zhang G, Lu S, Zhang L et al (2013) Novel polysulfone hybrid ultrafiltration membrane prepared with TiO2-g-HEMA and its antifouling characteristics. J Membr Sci 436:163–173

Zhao X, Su Y, Li Y et al (2014) Engineering amphiphilic membrane surfaces based on PEO and PDMS segments for improved antifouling performances. J Membr Sci 450:111–123

Lv C, Su Y, Wang Y et al (2007) Enhanced permeation performance of cellulose acetate ultrafiltration membrane by incorporation of Pluronic F127. J Membr Sci 294:68–74

Hansen CM (2007) Hansen solubility parameters: a users hand book, 2nd edn. CRC Press, Taylor & Francis Group, Florida

Guan R, Dai H, Li C et al (2006) Effect of casting solvent on the morphology and performance of sulfonated polyethersulfone membranes. J Membr Sci 277:148–156

García-fernández L, García-payo MC, Khayet M (2014) Effects of mixed solvents on the structural morphology and membrane distillation performance of PVDF-HFP hollow fi ber membranes. J Membr Sci 468:324–338

Brandrup J, Immergut EH (1989) Polymer handbook, 3rd edn. Wiley, New York

Zhao Yuanyuan, Jiaqi Lu, Liu Xuyang, Wang Yudan, Lin Jiuyang, Na Peng JL, Zhao F (2016) Performance enhancement of polyvinyl chloride ultrafiltration membrane modified with graphene oxide. J Colloid Interface Sci 480:1–8

Lin J, Zhang R, Ye W et al (2013) Nano-WS2 embedded PES membrane with improved fouling and permselectivity. J Colloid Interface Sci 396:120–128

Lin J, Ye W, Zhong K et al (2014) Enhancement of polyethersulfone (PES) membrane doped by monodisperse Stöber silica for water treatment. Chem Eng Process 107:194–205

Yuan Z, Dan-li X (2008) Porous PVDF/TPU blends asymmetric hollow fiber membranes prepared with the use of hydrophilic additive PVP (K30). Desalination 223:438–447

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roy, K.J., Anjali, T.V. & Sujith, A. Asymmetric membranes based on poly(vinyl chloride): effect of molecular weight of additive and solvent power on the morphology and performance. J Mater Sci 52, 5708–5725 (2017). https://doi.org/10.1007/s10853-017-0807-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0807-1