Abstract

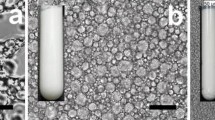

A series of polymerized high internal phase emulsion (polyHIPE) monoliths with internal phase contents varying from 82.5 to 94.0 % were synthesized. The limited spaces of the polyHIPE were used as reactors to polymerize methyl methacrylate (MMA) by reverse atom transfer radical polymerization (RATRP). The main purpose of this research was to investigate the effect of limited spaces of polyHIPE on RATRP polymerization. The monoliths before and after MMA polymerization and PMMA obtained in the polyHIPE were characterized by scanning electron microscopy, gel permeation chromatography, Fourier transform infrared spectroscopy, thermogravimetry analysis, hydrogen nuclear magnetic resonance, and differential scanning calorimetry. The results suggested that the monomer MMA had polymerized in the polyHIPE. Compared with PMMA by RATRP without confined space, the molecular weight, initial thermal decomposition temperature, glass transition temperature (T g), and the isotacticity of the PMMA obtained from polyHIPE were increased significantly and the molecular weight distribution broadened. The increase in the internal phase contents increased the numbers of the cavities and windows, whereas the molecular weight, molecular weight distribution, and T g of the PMMA obtained from different polyHIPEs did not change much.

Similar content being viewed by others

References

Sun JT, Piao JG, Wang LH, Javed M, Hong CY, Pan CY (2013) One-pot synthesis of redox-responsive polymers-coated mesoporous silica nanoparticles and their controlled drug release. Macromol Rapid Commun 34:1387. doi:10.1002/marc.201300477

He H, Zhong M, Konkolewicz D et al (2013) Three-dimensionally ordered macroporous polymeric materials by colloidal crystal templating for reversible CO2 capture. Adv Funct Mater 23:4720. doi:10.1002/adfm.201300401

Das SK, Bhunia MK, Sinha AK, Bhaumik A (2011) Synthesis, characterization, and biofuel application of mesoporous zirconium oxophosphates. ACS Catal 1:493. doi:10.1021/cs200005z

Tao SY, Li GT (2007) Porphyrin-doped mesoporous silica films for rapid TNT detection Colloid. Polym Sci 285:721. doi:10.1007/s00396-007-1643-7

Han X, Zhu YH, Yang XL, Luan SR (2010) In situ polymerization of pyrrole in mesoporous silica and application to electrode modification. Int J Polym Anal Charact 15:155. doi:10.1080/10236661003669458

Fontanals N, Cormack PAG, Sherrington DC (2008) Hypercrosslinked polymer microspheres with weak anion-exchange character: preparation of the microspheres and their applications in pH-tuneable, selective extractions of analytes from complex environmental samples. J Chromatogr A 1215:21. doi:10.1016/j.chroma.2008.10.124

Silverstein MS (2014) Emulsion-templated porous polymers: a retrospective perspective. Polymer 55:304. doi:10.1016/j.polymer.2013.08.068

Audouin F, Larragy R, Fox M, O’Connor B, Heise A (2012) Protein immobilization onto poly(acrylic acid) functional macroporous PolyHIPE obtained by surface-initiated ARGET ATRP. Biomacromolecules 13:3787. doi:10.1021/bm301251r

Dong XC, Wang L, Wang JJ, Zhou JF, Sun TX (2006) Evidence of nanoconfinement effects of MCM-41 on propylene polymerization catalyzed by MCM-41 supported metallocene catalyst in the presence and absence of beta-cyclodextrin. J Phys Chem B 110:9100. doi:10.1021/Jp060238v

Wei ZB, Rui B, Zhang FA (2013) MMA solution polymerization in the channels of modified mesoporous molecular sieves SBA-15. Acta Polym Sin. doi:10.3724/sp.j.1105.2013.12288

Sun FM, Xu WF, Chen MS, Zhang FA (2014) Polymerization of MMA in polyHIPEs by RATRP. J Polym Res 21:610. doi:10.1007/s10965-014-0610-5

Audouin F, Heise A (2013) Surface-initiated RAFT polymerization of NIPAM from monolithic macroporous polyHIPE. Eur Polym J 49:1073. doi:10.1016/j.eurpolymj.2013.01.013

Moine L, Deleuze H, Maillard B (2003) Preparation of high loading PolyHIPE monoliths as scavengers for organic chemistry. Tetrahedron Lett 44:7813. doi:10.1016/j.tetlet.2003.08.051

Moine L, Deleuze H, Degueil M, Maillard B (2004) Copper-mediated radical polymerization on a microcellular monolith surface. J Polym Sci Part A 42:1216. doi:10.1002/pola.11090

Cummins D, Duxbury CJ, Quaedflieg PJLM, Magusin PCMM, Koning CE, Heise A (2009) Click chemistry as a means to functionalize macroporous PolyHIPE. Soft Matter 5:804. doi:10.1039/B810823D

Cummins D, Wyman P, Duxbury CJ, Thies J, Koning CE, Heise A (2007) Synthesis of functional photopolymerized macroporous PolyHIPEs by atom transfer radical polymerization surface grafting. Chem Mater 19:5285. doi:10.1021/cm071511o

Xu WF, Bai R, Zhang FA (2014) Effects of internal-phase contents on porous polymers prepared by a high-internal-phase emulsion method. J Polym Res 21:524. doi:10.1007/s10965-014-0524-2

Nising P, Zeilmann T, Meyer T (2003) On the degradation and stabilization of poly(methyl methacrylate) in a continuous process. Chem Eng Technol 26:599. doi:10.1002/ceat.200390092

Zhu S, Yan D, Zhang G (2001) Reverse atom transfer radical polymerization of methyl methacrylate with a new catalytic system, FeCl3/isophthalic acid. J Polym Sci Part A 39:765. doi:10.1002/1099-0518(20010315)39:6,765

Acknowledgements

We gratefully acknowledge the financial support from the National Natural Science Foundation of China (51263004), the Innovation Team of Guangxi University’s Talent Highland, and the Guangxi Funds for Specially Appointed Experts.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, M., Sun, F., Xu, W. et al. Polymerization of MMA by RATRP in the confined space of polyHIPEs with varied internal phase contents. J Mater Sci 51, 5113–5121 (2016). https://doi.org/10.1007/s10853-016-9814-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9814-x