Abstract

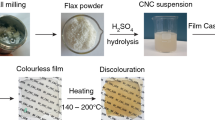

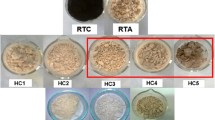

Cellulose extracted from recycled pulverized cotton in nanocrystalline cellulose (CNC) and nanofibrillated cellulose (NFC) forms is investigated as a reinforcing agent in low-density polyethylene (LDPE) nanocomposites. The effect of extraction processing on the pulverized cotton is shown to influence the degree of crystallinity, morphology, and thermal stability of cellulose nanomaterials. Melt compounding of CNC with LDPE resulted in polymer nanocomposites with no discoloration at 170 °C. Significant differences observed in transparency, mechanical, and thermal properties of LDPE nanocomposite films, are demonstrated to be a result of the microstructure and the content of cellulose nanomaterials. Thermal analysis using thermogravimetric analyzer and differential scanning calorimeter showed higher thermal stability and degree of crystallinity of NFC/LDPE comparing to CNC/LDPE nanocomposite films. Tensile analysis exhibited a higher elastic modulus and tensile strength for the NFC material. 10 wt% of NFC reinforcing agent showed 32% improved strength and higher transparency over the one with CNC.

Similar content being viewed by others

References

Stammen JA, Williams S, Ku DN, Guldberg RE (2001) Mechanical properties of a novel PVA hydrogel in shear and unconfined compression. Biomaterials 22:799–806

Engelberg I, Kohn J (1991) Physico-mechanical properties of degradable polymers used in medical applications: a comparative study. Biomaterials 12:292–304

Hallab NJ, Bundy KJ, O’Connor K, Moses RL, Jacobs JJ (2001) Evaluation of metallic and polymeric biomaterial surface energy and surface roughness characteristics for directed cell adhesion. Tissue Eng 7:55–71

Shahbeig Roodposhti P, Farahbakhsh N, Sarkar A, Murty KL (2015) A microstructural approach to the equal channel angular processing of commercially pure titanium—a review. Trans Nonferr Met Soc China 25:1353–1366

Shahbeigi Roodposhti P, Sarkar A, Murty KL, Scattergood R (2015) Microstructural development of high temperature deformed AZ31 magnesium alloys. Mater Sci Eng A 626:195–202

Wang B, Sain M (2007) Isolation of nanofibers from soybean source and their reinforcing capability on synthetic polymers. Compos Sci Technol 67:2521–2527

Junior de Menezes A, Siqueira G, Curvelo AAS, Dufresne A (2009) Extrusion and characterization of functionalized cellulose whiskers reinforced polyethylene nanocomposites. Polymer 50:4552–4563

Xu X, Liu F, Jiang L, Zhu JY, Haagenson D, Wiesenborn DP (2013) Cellulose nanocrystals vs. cellulose nanofibrils: a comparative study on their microstructures and effects as polymer reinforcing agents. ACS Appl Mater Interfaces 5:2999–3009

Tingaut P, Zimmermann T, Sèbe G (2012) Cellulose nanocrystals and microfibrillated cellulose as building blocks for the design of hierarchical functional materials. J Mater Chem 22:20105–20111

Dong X, Revol J, Gray D (1998) Effect of microcrystallite preparation conditions on the formation of colloid crystals of cellulose. Cellulose 5:19–32

Ben Azouz K, Ramires EC, Van Den Fonteyne W, El Kissi N, Dufresne A (2012) Simple method for the melt extrusion of a cellulose nanocrystal reinforced hydrophobic polymer. ACS Macro Lett 1:236–240

Bahar E, Ucar N, Onen A, Wang Y, Oksuz M, Ayaz O, Ucar M, Demir A (2012) Thermal and mechanical properties of polypropylene nanocomposite materials reinforced with cellulose nano whiskers. J Appl Polym Sci 125:2882–2889

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18:1097–1111

Roman M, Winter WT (2004) Effect of sulfate groups from sulfuric acid hydrolysis on the thermal degradation behavior of bacterial cellulose. Biomacromolecules 5:1671–1677

Oksman K, Etang JA, Mathew AP, Jonoobi M (2011) Cellulose nanowhiskers separated from a bio-residue from wood bioethanol production. Biomass Bioenergy 35:146–152

Bras J, Viet D, Bruzzese C, Dufresne A (2011) Correlation between stiffness of sheets prepared from cellulose whiskers and nanoparticles dimensions. Carbohydr Polym 84:211–215

Farahbakhsh N, ShahbeigiRoodposhti P, Ayoub AS, Venditti RA, Jur JS (2014) Melt extrusion of polyethylene nanocomposites reinforced with nanofibrillated cellulose from cotton and wood sources. J Appl Polym Sci 132:41857

Farahbakhsh N, Venditti RA, Jur JS (2014) Mechanical and thermal investigation of thermoplastic nanocomposite films fabricated using micro- and nano-sized fillers from recycled cotton T-shirts. Cellulose 21:2743–2755

Segal L, Creely J, Martin A, Conrad C (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Zhang J, Rizvi GM, Park CB (2011) Effects of wood fiber content on the rheological properties, crystallization behavior, and cell morphology of extruded wood fiber/HDPE composites foams. Bioresources 6:4979–4989

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux JL, Heux L, Dubreuil F, Rochas C (2008) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 9:57–65

Ebeling T, Paillet M, Borsali R, Diat O, Dufresne A, Cavaillé JY, Chanzy H (1999) Shear-induced orientation phenomena in suspensions of cellulose microcrystals, revealed by small angle X-ray scattering. Langmuir 15:6123–6126

Lu Y, Weng L, Cao X (2005) Biocomposites of plasticized starch reinforced with cellulose crystallites from cottonseed linter. Macromol Biosci 5:1101–1107

Favier V, Canova GR, Cavaille JY, Chanzy H, Dufresne A, Gauthier C (1995) Nanocomposite materials from latex and cellulose whiskers. Polym Adv Technol 6:351–355

Siqueira G, Abdillahi H, Bras J, Dufresne A (2010) High reinforcing capability cellulose nanocrystals extracted from Syngonanthus nitens (Capim Dourado). Cellulose 17:289–298

Siaueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10:425–432

Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47:291–294

Shahbeigi Roodposhti P, Sarkar A, Murty KL, Scattergood RO (2015) Dislocation density evolution during creep of AZ31Mg alloy: a study by X-ray diffraction line profile analysis. Metallogr Microstruct Anal 4:337–343

Moran JI, Alvarez VA, Cyras VP, Vazquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159

Hamad WY, Hu TQ (2010) Structure-process-yield interrelations in nanocrystalline cellulose extraction. Can J Chem Eng 88:392–402

Qin Z-Y, Tong G, Chin YCF, Zhou J-C (2011) Preparation of ultrasonic-assisted high carboxylate content cellulose nanocrystals by TEMPO oxidation. Bioresources 6:1136–1146

Yue Y, Zhou C, French AD, Xia G, Han G, Wang Q, Wu Q (2012) Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 19:1173–1187

Kargarzadeh H, Ahmad I, Abdullah I, Dufresne A, Zainudin SY, Sheltami RM (2012) Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose 19:855–866

Wang N, Ding E, Cheng R (2007) Thermal degradation behaviors of spherical cellulose nanocrystals with sulfate groups. Polymer 48:3486–3493

George J, Ramana KV, Bawa AS, Siddaramaiah (2011) Bacterial cellulose nanocrystals exhibiting high thermal stability and their polymer nanocomposites. Int J Biol Macromol 48:50–57

Ma H, Zhou B, Li HS, Li YQ, Ou SY (2011) Green composite films composed of nanocrystalline cellulose and a cellulose matrix regenerated from functionalized ionic liquid solution. Carbohydr Polym 84:383–389

Pandey JK, Lee CS, Ahn S-H (2010) Preparation and properties of bio-nanoreinforced composites from biodegradable polymer matrix and cellulose whiskers. J Appl Polym Sci 115:2493–2501

Alloin F, D’Aprea A, Dufresne A, El Kissi N, Bossard F (2011) Poly(oxyethylene) and ramie whiskers based nanocomposites: influence of processing: extrusion and casting/evaporation. Cellulose 18:957–973

Trovatti E, Oliveira L, Freire CSR, Silvestre AJD, Pascoal Neto C, Cruz Pinto JJC, Gandini A (2010) Novel bacterial cellulose-acrylic resin nanocomposites. Compos Sci Technol 70:1148–1153

Ben Mabrouk A, Kaddami H, Boufi S, Erchiqui F, Dufresne A (2012) Cellulosic nanoparticles from alfa fibers (Stipa tenacissima): extraction procedures and reinforcement potential in polymer nanocomposites. Cellulose 19:843–853

Petersson L, Oksman K (2006) Biopolymer based nanocomposites: comparing layered silicates and microcrystalline cellulose as nanoreinforcement. Compos Sci Technol 66:2187–2196

Samir A, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whisker, their properties and their application in nanocomposites field. Biomacromolecules 6:612–626

Ouali N, Cavaille JY, Perez J (1991) Elastic, viscoelastic and plastic behavior of multiphase polymer blends. Plast Rubber Compos Process Appl 16:55–60

Halpin JC, Kardos JL (1972) Moduli of crystalline polymers employing composite theory. J Appl Phys 43:2235–2241

Takayanagi M, Minami S, Uemura S (1964) Application of equivalent model method to dynamic rheo-optical properties of crystalline polymer. J Polym Sci Part C 5:113–122

Dufresne A (2006) Comparing the mechanical properties of high performances polymer nanocomposites from biological sources. J Nanosci Nanotechnol 6:322–330

Sturcova A, Davies G, Eichhorn S (2005) Elastic modulus and stress-transfer properties of tunicate. Biomacromolecules 6:1055–1061

Tashiro K, Kobayashi M (1991) Theoretical evaluation of 3-dimensional elastic constants of native and regenerated celluloses—role of hydrogen-bonds. Polymer 32:1516–1530

Rusli R, Eichhorn SJ (2008) Determination of the stiffness of cellulose nanowhiskers and the fiber-matrix interface in a nanocomposite using Raman spectroscopy. Appl Phys Lett 93:033111

Siqueira G, Bras J, Dufresne A (2010) New process of chemical grafting of cellulose nanoparticles with a long chain isocyanate. Langmuir 26:402–411

Acknowledgements

The authors gratefully acknowledge financial support from Cotton Inc. (12-358). The cooperation of MeadWestvaco Company to process NFC-pCot is also greatly appreciated. We also thank Prof. Behnam Pourdeyhimi and the N.C. State Nonwovens Institute for providing LDPE polymer and NCRC characterization facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farahbakhsh, N., Shahbeigi-Roodposhti, P., Sadeghifar, H. et al. Effect of isolation method on reinforcing capability of recycled cotton nanomaterials in thermoplastic polymers. J Mater Sci 52, 4997–5013 (2017). https://doi.org/10.1007/s10853-016-0738-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0738-2