Abstract

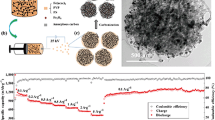

Polystyrene-derived carbon with hierarchical macro–meso–microporous structure was prepared via a simple template-free method. As anode materials for lithium-ion batteries, the as-prepared hierarchical porous carbon (HPC) exhibited good electrochemical performance, attaining a stable capacity of 410 mAh g−1 for over 100 cycles. It was also highlighted that, HPC showed an excellent high-rate performance in contrast to other amorphous carbon materials. These good lithium storage performances could be attributed to the developed nanostructures of HPC: (1) The continuous macro-/meso-pores were believed to facilitate rapid ion transport by serving as ion-buffering reservoirs/ion-transport pathways, especially at high current densities; (2) The small-sized nanopores including small mesopores and micropores in carbon nanoparticles provided many active sites for Li+ storage reaction; and (3) The as-constructed continuous carbon nanonetwork also represented an excellent conductive skeleton throughout the material. We hope that this class of HPC provides new opportunities for anode materials of LIBs.

Similar content being viewed by others

References

Palanisamy K, Kim Y, Kim H, Man Kim J, Yoon WS (2015) Self-assembled porous MoO2/graphene microspheres towards high performance anodes for lithium ion batteries. J Power Sources 275:351–361

Huo YT, Rao ZH, Liu XJ, Zhao JT (2015) Investigation of power battery thermal management by using mini-channel cold plate. Energy Convers Manage 89:387–395

Zhu J, Lu L, Kai Y (2013) Nanoscale mapping of lithium-ion diffusion in a cathode within an all-solid-state lithium-ion battery by advanced scanning probe microscopy techniques. ACS Nano 7:1666–1675

Du DJ, Yue WB, Ren Y, Yang XJ (2014) Fabrication of graphene-encapsulated CoO/CoFe2O4 composites derived from layered double hydroxides and their application as anode materials for lithium-ion batteries. J Mater Sci 49:8031–8039. doi:10.1007/s10853-014-8510-y

Tian H, Tan XJ, Xin FX, Wang CS, Han WQ (2015) Micro-sized nano-porous Si/C anodes for lithium ion batteries. Nano Energy 11:490–499

Yi J, Li XP, Hu SJ, Li WS, Zhou L, Xu MQ (2011) Preparation of hierarchical porous carbon and its rate performance as anode of lithium ion battery. J Power Sources 196:6670–6675

Dhrubajyoti B, Hyean YP, Min SK, Hyuck SC, Inamdar SN, Yu JS (2014) Nitrogen-doped carbon nanoparticles by flame synthesis as anode material for rechargeable lithium-ion batteries. Langmuir 30:318–324

Fan CL, Chen H (2011) Preparation, structure, and electrochemical performance of anodes from artificial graphite scrap for lithium ion batteries. J Mater Sci 46:2140–2147. doi:10.1007/s10853-010-5050-y

Cheng Q, Ryota Y, Kentaro N, Noriyuki T, Shigeyuki M (2015) KOH etched graphite for fast chargeable lithium-ion batteries. J Power Sources 284:258–263

Jing MJ, Hou HS, Yang YC, Zhang Y, Yang YM, Chen QY, Ji XB (2015) Electrochemically alternating voltage induced Mn3O4/Graphite powder composite with enhanced electrochemical performances for lithium-ion batteries. Electrochim Acta 155:157–163

Zhu YH, Xiang XX, Liu EH, Wu YH, Xie H, Wu ZL, Tian YG (2012) An activated microporous carbon prepared from phenol-melamine-formaldehyde resin for lithium ion battery anode. Mater Res Bull 47:2045–2050

Li CC, Yin XM, Chen LB, Li QH, Wang TH (2009) Porous carbon nanofibers derived from conducting polymer: synthesis and application in lithium-ion batteries with high-rate capability. J Phys Chem C 113:13438–13442

Ji LW, Zhang XW (2009) Fabrication of porous carbon nanofibers and their application as anode materials for rechargeable lithium-ion batteries. Nanotechnology 20:155705–155711

Wang Y, Su FB, Wood CD, Lee JY, Zhao XS (2008) Preparation and characterization of carbon nanospheres as anode materials in lithium-ion secondary batteries. Ind Eng Chem Res 47:2294–2300

Han FD, Bai YJ, Liu R, Yao B, Qi YX, Lun N, Zhang JX (2011) Template-free synthesis of interconnected hollow carbon nanospheres for high-performance anode material in lithium-ion batteries. Adv Energy Mater 1:798–801

Li GD, Xu LQ, Hao Q, Wang M, Qian YT (2012) Synthesis, characterization and application of carbon nanocages as anode materials for high-performance lithium-ion batteries. RSC Adv 2:284–291

Zhao J, Zhang CC, Wang DB, Zhang P (2015) Free-binder lithium ion battery based on a hybrid multiwalled carbon nanotube-graphitic platelet architecture. Ionics 21:1247–1252

Yun YS, Jin HJ (2014) Electrochemical performance of heteroatom-enriched amorphous carbon with hierarchical porous structure as anode for lithium-ion batteries. Mater Lett 108:311–315

Wang FF, Song RR, Song HH, Chen XH, Zhou JS, Ma ZK, Li MC, Lei Q (2015) Simple synthesis of novel hierarchical porous carbon microspheres and their application to rechargeable lithium-ion batteries. Carbon 81:314–321

Song RR, Song HH, Zhou JS, Chen XH, Wu B, Yang HY (2012) Hierarchical porous carbon nanosheets and their favorable high-rate performance in lithium ion batteries. J Mater Chem 22:12369–12374

Zhang F, Wang KX, Li GD, Chen JS (2009) Hierarchical porous carbon derived from rice straw for lithium ion batteries with high-rate performance. Electrochem Commun 11:130–133

Yang XQ, Zhang GQ, Zhong ML, Wu DC, Fu RW (2014) Ammonia-assisted semicarbonization: a simple method to introduce micropores without damaging a 3D mesoporous carbon nanonetwork structure. Langmuir 30:9183–9189

Zou C, Wu DC, Li MZ, Zeng QC, Xu F, Huang ZY, Fu RW (2010) Template-free fabrication of hierarchical porous carbon by constructing carbonyl crosslinking bridges between polystyrene chains. J Mater Chem 20:731–735

Yang XQ, Wu DC, Chen XM, Fu RW (2010) Nitrogen-enriched nanocarbons with a 3-D continuous mesopore structure from polyacrylonitrile for supercapacitor application. J Phys Chem C 114:8581–8586

Yang XQ, Huang H, Zhang GQ, Li XX, Wu DC, Fu RW (2015) Carbon aerogel with 3-D continuous skeleton and mesopore structure for lithium-ion batteries application. Mater Chem Phys 149–150:657–662

Hu CG, XiaoY ZhaoY, ChenN Zhang ZP, Cao MH, Qu LT (2013) Highly nitrogen-doped carbon capsules: scalable preparation and high-performance applications in fuel cells and lithium ion batteries. Nanoscale 5:2726–2733

Wang KX, Li ZL, Wang YG, Liu HM, Chen JS, Justin H, Zhou HS (2010) Carbon nanocages with nanographene shell for high-rate lithium ion batteries. J Mater Chem 20:9748–9753

Zhou JS, Song HH, Fu BC, WuB Chen XH (2010) Synthesis and high-rate capability of quadrangular carbon nanotubes with one open end as anode materials for lithium-ion batteries. J Mater Chem 20:2794–2800

Chen TQ, Pan LK, Loh TAJ, Chua DHC, Yao YF, Chen Q, Li DS, Qin W, Sun Z (2014) Porous nitrogen-doped carbon microspheres as anode materials for lithium ion batteries. Dalton Trans 43:14931–14935

Tang YK, Liu L, Wang XC, Zhou HJ, Jia DZ (2014) High-yield bamboo-like porous carbon nanotubes with high-rate capability as anodes for lithium-ion batteries. RSC Adv 4:44852–44857

Lotfabad EM, Ding J, Cui K, Kohandehghan A, Kalisvaart WP, Hazelton M, Mitlin D (2014) High-density sodium and lithium ion battery anodes from banana peel. ACS Nano 8:7115–7129

Lotfabad EM, Kalisvaart P, Kohandehghan A, Karpuzov D, Mitlin D (2014) Origin of non-SEI related Coulombic efficiency loss in carbons tested against Na and Li. J Mater Chem A 2:19685–19695

Mukherjee R, Thomas AV, Datta D, Singh E, Li JW, Eksik O, Shenoy VB, Koratkar N (2014) Defect-induced plating of lithium metal within porous graphene networks. Nat Commun 5:3710. doi:10.1038/ncomms4710

Acknowledgements

This research was financially supported by The Start-up funding for “One-Hundred Young Talents” of Guangdong University of technology (220413521), National Science Foundation for Post-doctoral Scientists of China (2013M542153), Scientific and technological innovation project for small and medium technology enterprises of Shunde District (2014CX001), and Scientific and technological project of Administration of Quality and Technology Supervision of Guangdong Province (2015PJ03).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, X., Li, C., Zhang, G. et al. Polystyrene-derived carbon with hierarchical macro–meso–microporous structure for high-rate lithium-ion batteries application. J Mater Sci 50, 6649–6655 (2015). https://doi.org/10.1007/s10853-015-9214-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9214-7