Abstract

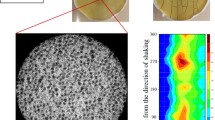

We show that the drying rate of plaster pastes is significantly lower than that expected for a pure liquid evaporating from a simple homogeneous porous medium. This effect is enhanced by the air flow velocity and the initial solid/water ratio. Further tests under various conditions and with the help of additional techniques (MRI, ESEM, Micro-tomography) for measuring the drying rate and local characteristics (water content, porosity) prove that this effect is due to the crystallization of gypsum ions below the sample free surface, which creates a dry region and decreases the drying rate by increasing the length of the path that the vapour has to follow before reaching the free surface.

Similar content being viewed by others

References

Neville HA (1926) Adsorption and reaction I. J Phys Chem 30:1037–1042

Ridge MJ, Beretka J (1969) Calcium sulphate hemihydrate and its hydration. Rev Pure Appl Chem 19:17–44

Hansen WC (1963) Setting and hardening of gypsum plaster. Mater Res Stand 3:359–363

Vignes JL, Essaddam H (1997) Une vie de plâtre. Bulletin de l’union des physiciens 790:145–164

Jaffel H, Korb JP (2006) Probing microstructure evolution during the hardening of gypsum by proton NMR relaxometry. J Phys Chem B 110:7385–7391

Frederiksen R, Marchand E (eds) (2010) Plaster casts: making, collecting and displaying from classical antiquity to the present. De Gruyter, Berlin

Petkovic J, Huinink HP, Pel L, Kopinga K, van Hees RPJ (2007) Salt transport in plaster/substrate layers. Mater Struct 40:475–490

Coussot P (2000) Scaling approach of the convective drying of a porous medium. Eur Phys J B 15:557–566

Van Brakel J (1980) Mass transfer in convective drying, “advances in drying”, vol 1. Hemisphere, Washington

Van der Heijden GHA, Pel L, Huinink HP, Kopinga K (2011) Moisture transport and dehydration in heated gypsum, an NMR study. Chem Eng Sci 66:4241–4250

Vosten B, Hersfeld B (1976) The drying of crust-forming materials as exemplified by the drying of gypsum wallboard. Zement-Kalk-Gips 5:213–222 (in German)

Schultz P, Schlünder EU (1990) Influence of additives on crust formation during drying. Chem Eng Process 28:133–142

Gupta S, Huinink HP, Prat M, Pel L, Kopinga K (2014) Paradoxical drying of a fired-clay brick due to salt crystallization. Chem Eng Sci 109:204–211

Espinosa-Marzal RM, Scherer GW (2013) Impact of in-pore salt crystallization on transport properties. Environ Earth Sci 69:2657–2669

Song KM, Mitchell J, Gladden LF (2009) Magnetic resonance studies of hydration kinetics and microstructural evolution in plaster pastes. J Mater Sci 44:5004–5012. doi:10.1007/s10853-009-3765-4

Song KM, Mitchell J, Jaffel H, Gladden LF (2010) Simultaneous monitoring of hydration kinetics, microstructural evolution, and surface interactions in hydrating gypsum plaster in the presence of additives. J Mater Sci 45:5282–5290. doi:10.1007/s10853-010-4572-7

Jaffel H (2006) Multi-scale characterization of evolving porous media, Ph.D. thesis, Ecole Polytechnique, Palaiseau (in French)

Chou YL (1975) Statistical analysis, 2nd edn. Holt, Rinehart & Winston of Canada Ltd, Toronto

Faure P, Rodts S (2008) Proton NMR relaxation as a probe for setting cement pastes. Magn Reson Imaging 26:1183–1196

Carr H, Purcell E (1954) Effects of diffusion on free precession in nuclear magnetic resonance experiments. Phys Rev 94:630–638

McDonald PJ, Korb JP, Mitchell J, Monteilhet L (2005) Surface relaxation and chemical exchange in hydrating cement pastes: a two-dimensional NMR relaxation study. Phys Rev E 72:011409

Zimmerman JR, Brittin WE (1957) Nuclear magnetic resonance studies in multiple phase systems: lifetime of a water molecule in an adsorbing phase on silica gel. J Phys Chem 61:1328–1333

Browstein KR, Tarr CE (1979) Importance of classical diffusion in NMR studies of water in biological cells. Phys Rev A 19:2446–2453

Keita E, Faure P, Rodts S, Coussot P (2014) MRI evidence for a receding-front effect in drying porous media. Phys Rev 87:062303

Coussot P, Gauthier C, Nadji D, Borgotti JC, Vié P, Bertrand F (1999) Capillary motions during the drying of a granular pastes. C R Acad Sci Paris 327:1101–1106

Acknowledgements

We thank David Hautemayou for his technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seck, M.D., Van Landeghem, M., Faure, P. et al. The mechanisms of plaster drying. J Mater Sci 50, 2491–2501 (2015). https://doi.org/10.1007/s10853-014-8807-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8807-x