Abstract

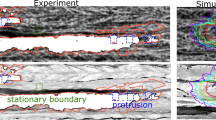

A three-dimensional model relating to the abnormal grain growth in austenite is developed in the presented work, based on the cellular automata technique with the use of a local transition function. The model allows consideration of both anisotropy of energy and mobility of grain boundaries and shows the oscillation motion of the boundaries at the stagnation stage. Calibration of the model in relation to experimental data for austenite has allowed the calculation of the quantitative parameters of the system, such as Gibbs energy, driving and pinning forces, grain boundary velocity and mobility, duration of the incubation period of the abnormal grain growth and the critical grain size. The derived data allows the quantitative description of the kinetics of the secondary recrystallisation process in austenite and can be used for the deeper understanding of the abnormal grain growth phenomenon in metals.

Similar content being viewed by others

References

Riontino G, Antonione C, Battezzati L, Marino F, Tabasso MC (1979) Kinetics of abnormal grain growth in pure iron. J Mater Sci 14:86–90. doi:10.1007/BF01028331

Antonione C, Battezzati L, Lucci A, Riontino G, Tabasso MC (1980) A statistical investigation of normal and abnormal grain growth in iron. J Mater Sci 15:1730–1735. doi:10.1007/BF00550592

Humphreys J, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier, Oxford

Gottstein G, Shvindlerman LS (2002) Triple junction drag and grain growth in 2D polycrystals. Acta Mater 50:703–713

Rollett AD, Srolovitz DJ, Anderson MP (1989) Simulation and theory of abnormal grain growth—anosotropic grain boundary energies and mobiliities. Acta Metall Mater 37(4):1227–1240

Grest GS, Anderson MP, Srolovitz DJ, Rollett AD (1990) Abnormal grain growth in three dimensions. Scripta Metall Mater 24:661–665

Ivasishin OM, Shevchenko SV, Semiatin SL (2004) Modeling of abnormal grain growth in textured materials. Scripta Mater 50(9):1241–1245. doi:10.1016/j.scriptamat.2004.01.036

Ko K-J, Rollett AD, Hwang N-M (2010) Abnormal grain growth of Goss grains in Fe–3 % Si steel driven by sub-boundary-enhanced solid-state wetting: Analysis by Monte Carlo simulation. Acta Mater 58(13):4414–4423. doi:10.1016/j.actamat.2010.04.038

Rudnizki J, Zeislmair B, Prahl U, Bleck W (2010) Prediction of abnormal grain growth during high temperature treatment. Comp Mater Sci 49(2):209–216. doi:10.1016/j.commatsci.2010.04.015

Srolovitz DJ, Grest GS, Anderson MP (1985) Computer simulation of grain growth-V. Abnormal grain growth. Acta Metall Mater 33(12):2233–2247

Maazi N, Rouag N, Etter AL, Penelle R, Baudin T (2006) Influence of neighbourhood on abnormal Goss grain growth in Fe–3% Si steels: Formation of island grains in the large growing grain. Scripta Mater 55(7):641–644. doi:10.1016/j.scriptamat.2006.06.007

Rios PR (1997) Abnormal grain growth development from uniform grain size distributions. Acta Mater 45:1785–1789

Rhines F, Craig K, DeHoff R (1974) Mechanism of steady-state grain growth in aluminum. Metall Trans 5(2):413–425

Wejrzanowski T, Batorski K, Kurzydłowski KJ (2006) Grain growth modelling: 3D and 2D correlation. Mater Charact 56(4–5):336–339. doi:10.1016/j.matchar.2005.09.010

Wolfram S (2002) A new kind of science. Wolfram Media. Inc, Champaign

Raabe D (2002) Cellular automata in materials science with particular reference to recrystallization simulation. Annu Rev Mater Res 32(1):53–76. doi:10.1146/annurev.matsci.32.090601.152855

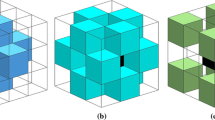

Vertyagina Ye, Mahfouf M, Xu X (2013) 3d-modelling of ferrite and austenite grain coarsening using of real-valued cellular automata based on transition function. J Mater Sci 48(16):5517–5527. doi:10.1007/s10853-013-7346-1

Moon J, Lee J, Lee C (2007) Prediction for the austenite grain size in the presence of growing particles in the weld HAZ of Ti-microalloyed steel. Mat Sci Eng A-Struct 459(1–2):40–46. doi:10.1016/j.msea.2006.12.073

Rabkin E (1999) Theory of triple junctions mobility in crystals with impurities. Interface Sci 7:297–305

Bokstein BS, Kopetskii CV, Shvindlerman LS (1986) Thermodynamics and kinetics of grain boundaries in metals. Metallurgiya, Moscow

Hu H, Rath BB (1970) On the time exponent in isothermal grain growth. Metall Trans 1:3181–3184

Gleiter H (1969) Theory of grain boundary migration rate. Acta Metall Mater 17:853–862

Zener C (1948) (quoted by CS Smith). Grains, phases and interphases: An interpretation of microstructure. Trans AIME 175:15–51

Burke JE, Turnbull D (1952) Recrystallization and grain growth. Prog Met Phys 3:220–292

Gottstein G (2005) Physical Foundations of Materials Science. Springer-Verlag, Berlin

Johnson WA, Mehl RF (1939) Reaction kinetics in processes of nucleation and growth. Trans AIMME 135:416–458

Avrami M (1939) Kinetics of Phase Change I General Theory. J Chem Phys 7(12):1103–1112. doi:10.1063/1.1750380

Kolmogorov A (1937) A statistical theory for the recrystallization of metals. Akad nauk SSSR, Izv, Ser Matem 1:355–359

Chongmo L, Hillert M (1981) A metallographic study of diffusion-induced grain boundary migration in the Fe-Zn system. Acta Metall Mater 29:1949–1960

Gottstein G, Shvindlerman LS (1992) On the true dependence of grain boundary migration rate on driving force. Scripta Metall Mater 27:1521–1526

Zhang YB, Godfrey A, Liu Q, Liu W, Juul Jensen D (2009) Analysis of the growth of individual grains during recrystallization in pure nickel. Acta Mater 57(9):2631–2639. doi:10.1016/j.actamat.2009.01.039

Acknowledgements

The authors wish to acknowledge the UK-Engineering and Physical Sciences Research Council (UK-EPSRC) for their financial support under Grant No. EP/F023464/1. The authors also acknowledge the many fruitful discussions they had with Drs A. Howe (Tata Steel) and Xu Xu (Sheffield Hallam University).

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was performed whilst the author Ye. Vertyagina worked at the University of Sheffield.

Rights and permissions

About this article

Cite this article

Vertyagina, Y., Mahfouf, M. A 3D cellular automata model of the abnormal grain growth in austenite. J Mater Sci 50, 745–754 (2015). https://doi.org/10.1007/s10853-014-8634-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8634-0