Abstract

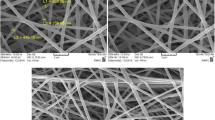

There is a significant interest in using synthetic polymers, such as polycaprolactone (PCL), in engineering skin to avoid the need for donor sites with autografts, immunological rejection issues with allograft and reproducibility issues with using natural polymers. PCL is promising as it is a US Food and Drug Administration—approved biodegradable polymer with good mechanical properties. However, its hydrophobic nature is not optimal for cellular interaction and biodegradation in skin tissue engineering. In this study, titanium oxide–PCL composite films were prepared using an in situ, one-step synthesis method. Titanium dioxide (TiO2) was introduced to improve the wetting properties of the hydrophobic polymer and so enhance the cell–material interactions and material biodegradation to be more suitable for skin regeneration. Results showed that the simple synthesis method produced nano- and submicron TiO2 particles well dispersed within the PCL matrix. Spin-coated composite films showed increasing hydrophilicity with increasing concentration of TiO2. Degradation of the composite films and pure PCL films were compared using gel permeation chromatography of the films after 14-day-immersion experiments. Molecular weights of PCL after immersion were found to steadily decrease by up to ~65 % with increasing concentration of TiO2. Rates of water penetration into the composite films were found to increase with the concentration of TiO2 and correlate with the molecular weight decreases observed. In vitro experiments with fibroblasts demonstrated enhanced cell adhesion and proliferation on the composite films. This synthesis method therefore provides a simple means of tuning the wetting properties of hydrophobic polymers to enhance their cellular interactions, as well as tuning their biodegradation properties to suit applications such as skin tissue engineering.

Similar content being viewed by others

References

Khor HL, Ng KW, Schantz J-T, Phan T-T, Lim TC, Teoh S-H, Hutmacher D (2002) Poly (ε-caprolactone) films as a potential substrate for tissue engineering an epidermal equivalent. Mater Sci Eng, C 20(1):71–75

Toworfe GK, Composto RJ, Adams CS, Shapiro IM, Ducheyne P (2004) Fibronectin adsorption on surface-activated poly (dimethylsiloxane) and its effect on cellular function. J Biomed Mater Res A 71(3):449–461

Bergkvist M, Carlsson J, Oscarsson S (2002) Surface-dependent conformations of human plasma fibronectin adsorbed to silica, mica, and hydrophobic surfaces, studied with use of atomic force microscopy. J Biomed Mater Res A 64(2):349–356

Arima Y, Iwata H (2007) Effect of wettability and surface functional groups on protein adsorption and cell adhesion using well-defined mixed self-assembled monolayers. Biomaterials 28(20):3074–3082

Lam CXF, Savalani MM, Teoh SH, Hutmacher DW (2008) Dynamics of in vitro polymer degradation of polycaprolactone-based scaffolds: accelerated versus simulated physiological conditions. Biomed Mater 3(3):034108

Lam CXF, Teoh SH, Hutmacher DW (2007) Comparison of the degradation of polycaprolactone and polycaprolactone–(β-tricalcium phosphate) scaffolds in alkaline medium. Polym Int 56(6):718–728

Coombes A, Rizzi S, Williamson M, Barralet J, Downes S, Wallace W (2004) Precipitation casting of polycaprolactone for applications in tissue engineering and drug delivery. Biomaterials 25(2):315–325

Löfgren A, Albertsson AC, Dubois P, Jérôme R (1995) Recent advances in ring-opening polymerization of lactones and related compounds. J Macromol Sci Part C Polym Rev 35(3):379–418

Kweon HY, Yoo MK, Park IK, Kim TH, Lee HC, Lee HS, Oh JS, Akaike T, Cho CS (2003) A novel degradable polycaprolactone networks for tissue engineering. Biomaterials 24(5):801–808

Dash TK, Konkimalla VB (2012) Poly-ε-caprolactone based formulations for drug delivery and tissue engineering: a review. J Control Release 158(1):15–33

Lam CX, Hutmacher DW, Schantz JT, Woodruff MA, Teoh SH (2009) Evaluation of polycaprolactone scaffold degradation for 6 months in vitro and in vivo. J Biomed Mater Res A 90(3):906–919

Yeo A, Wong W, Khoo H, Teoh S (2010) Surface modification of PCL–TCP scaffolds improve interfacial mechanical interlock and enhance early bone formation: an in vitro and in vivo characterization. J Biomed Mater Res A 92(1):311–321

Croll TI, O’Connor AJ, Stevens GW, Cooper-White JJ (2004) Controllable surface modification of poly (lactic-co-glycolic acid) (PLGA) by hydrolysis or aminolysis I: physical, chemical, and theoretical aspects. Biomacromolecules 5(2):463–473

Casaletto M, Ingo G, Kaciulis S, Mattogno G, Pandolfi L, Scavia G (2001) Surface studies of in vitro biocompatibility of titanium oxide coatings. Appl Surf Sci 172(1):167–177

Advincula MC, Rahemtulla FG, Advincula RC, Ada ET, Lemons JE, Bellis SL (2006) Osteoblast adhesion and matrix mineralization on sol–gel-derived titanium oxide. Biomaterials 27(10):2201–2212

Czarnowska E, Wierzchoń T, Maranda-Niedbała A (1999) Properties of the surface layers on titanium alloy and their biocompatibility in in vitro tests. J Mater Process Technol 92:190–194

Popescu S, Demetrescu I, Sarantopoulos C, Gleizes AN, Iordachescu D (2007) The biocompatibility of titanium in a buffer solution: compared effects of a thin film of TiO2 deposited by MOCVD and of collagen deposited from a gel. J Mater Sci Mater Med 18(10):2075–2083

Karuppuchamy S, Jeong JM (2005) Super-hydrophilic amorphous titanium dioxide thin film deposited by cathodic electrodeposition. Mater Chem Phys 93(2):251–254

Benedix R, Dehn F, Quaas J, Orgass M (2000) Application of titanium dioxide photocatalysis to create self-cleaning building materials. Lacer 5:157–168

Watanabe T, Nakajima A, Wang R, Minabe M, Koizumi S, Fujishima A, Hashimoto K (1999) Photocatalytic activity and photoinduced hydrophilicity of titanium dioxide coated glass. Thin Solid Films 351(1):260–263

Wang R, Hashimoto K, Fujishima A, Chikuni M, Kojima E, Kitamura A, Shimohigoshi M, Watanabe T (1997) Light-induced amphiphilic surfaces. Nature 388(6641):431–432

Nakata K, Nishimoto S, Yuda Y, Ochiai T, Murakami T, Fujishima A (2010) Rewritable superhydrophilic–superhydrophobic patterns on a sintered titanium dioxide substrate. Langmuir 26(14):11628–11630

Feng X, Zhai J, Jiang L (2005) The fabrication and switchable superhydrophobicity of TiO2 nanorod films. Angew Chem Int Ed 44(32):5115–5118

Berridge M, Tan AS (1993) Characterization of the cellular reduction of 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT): subcellular localization, substrate dependence, and involvement of mitochondrial electron transport in MTT reduction. Arch Biochem Biophys 303(2):474

Briggs D (1991) Handbook of X-ray photoelectron spectroscopy CD Wanger, WM Riggs, LE Davis, JF Moulder and GE Muilenberg Perkin-Elmer Corp., Physical electronics division, Eden Prairie, Minnesota, USA, 1979. 190 pp. $195. Surf Interface Anal 3(4): v–v (1981). doi:10.1002/sia.740030412

Skalak R, Chien S (eds) (1987) Handbook of bioengineering. McGraw-Hill, New York

Fu S-Y, Feng X-Q, Lauke B, Mai Y-W (2008) Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos Part B Eng 39(6):933–961

Dekkers M, Heikens D (1983) The effect of interfacial adhesion on the tensile behavior of polystyrene–glass-bead composites. J Appl Polym Sci 28(12):3809–3815

Fu S-Y, Lauke B (1998) Characterization of tensile behaviour of hybrid short glass fibre/calcite particle/ABS composites. Compos Part A Appl Sci Manuf 29(5):575–583

Fu S, Lauke B (1997) Analysis of mechanical properties of injection molded short glass fibre (SGF)/calcite/ABS composites. J Mater Sci Technol 13:389–396

Zhou J, Wang W, Villarroya S, Thurecht KJ, Howdle SM (2008) Epoxy functionalised poly (ε-caprolactone): synthesis and application. Chem Commun 44:5806–5808

Maloney W, Smith R, Castro F, Schurman D (1993) Fibroblast response to metallic debris in vitro. Enzyme induction cell proliferation, and toxicity. J Bone Joint Surg Am 75(6):835

Todaro GJ, Green H, Goldberg BD (1964) Transformation of properties of an established cell line by SV40 and polyoma virus. Proc Natl Acad Sci USA 51(1):66

Acknowledgements

The authors acknowledge the Particulate Fluids Processing Centre, a Special Research Centre of the Australian Research Council, for access to infrastructure. PA Tran gladly acknowledges support from The University of Melbourne via the McKenzie Fellowship and Interdisciplinary Seed Funding from Melbourne Materials Institute and Bio21 Institute.

Author information

Authors and Affiliations

Corresponding author

Additional information

No benefit of any kind will be received either directly or indirectly by the author(s).

Rights and permissions

About this article

Cite this article

Tran, P.A., Biswas, D.P. & O’Connor, A.J. Simple one-step method to produce titanium dioxide–polycaprolactone composite films with increased hydrophilicity, enhanced cellular interaction and improved degradation for skin tissue engineering. J Mater Sci 49, 6373–6382 (2014). https://doi.org/10.1007/s10853-014-8364-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8364-3