Abstract

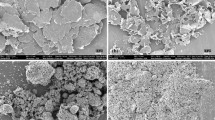

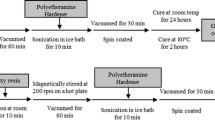

Graphene nanoplatelets (GNPs) are recently developed nanoparticles that are formed by stacks of short disk-like layers of graphite. They cost considerably less than their carbon nanotubes (CNTs) counterparts, and can be potentially used to generate multi-functional material systems. However, there are significant number of structural differences between GNPs and CNTs. It is therefore timely to review and optimize the current processing techniques used for generating GNP-nanocomposites. In this research, a scalable shear mixing approach (i.e., a three-roll mill) is utilized for achieving uniform dispersion of different fractions of GNPs in an epoxy resin. Then, the stiffness, electrical and thermal conductivity, and linear coefficient of thermal expansion of the resulting nanocomposites were evaluated. The as-processed nanocomposites exhibited significant improvement in their thermal properties, but a moderate increase in stiffness. The electrical percolation threshold of the nanocomposite occurred at higher concentration of GNP than that predicted by the available micromechanical models. This is attributed to the change in size of GNPs, which occurs as a result of manufacturing process, as observed by scanning electron microscopy.

Similar content being viewed by others

References

Fim FdC, Guterres JM, Basso NRS, Galland GB (2010) Polyethylene/graphite nanocomposites obtained by in situ polymerization. J Polym Sci A 48(3):692–698. doi:10.1002/pola.23822

Ruoff SR, Lorents DC (1995) Mechanical and thermal properties of carbon nanotubes. Carbon 33(7):925–930

Lanticse LJ, Tanabe Y, Matsui K, Kaburagi Y, Suda K, Hoteida M, Endo M, Yasuda E (2006) Shear-induced preferential alignment of carbon nanotubes resulted in anisotropic electrical conductivity of polymer composites. Carbon 44(14):3078–3086. doi:10.1016/j.carbon.2006.05.008

Yeh M-K, Tai N-H, Liu J-H (2006) Mechanical behavior of phenolic-based composites reinforced with multi-walled carbon nanotubes. Carbon 44(1):1–9. doi:10.1016/j.carbon.2005.07.005

Scott CD, Arepalli S, Nikolaev P, Smalley RE (2001) Growth mechanisms for single-wall carbon nanotubes in a laser-ablation process. Appl Phys A 72(5):573–580. doi:10.1007/s003390100761

See CH, Harris AT (2007) A review of carbon nanotube synthesis via fluidized-bed chemical vapor deposition. Ind Eng Chem Res 46(4):997–1012. doi:10.1021/ie060955b

Cho D, Lee S, Yang G, Fukushima H, Drzal LT (2005) Dynamic mechanical and thermal properties of phenylethynyl-terminated polyimide composites reinforced with expanded graphite nanoplatelets. Macromol Mater Eng 290(3):179–187. doi:10.1002/mame.200400281

Viculis LM, Mack JJ, Mayer OM, Hahn HT, Kaner RB (2005) Intercalation and exfoliation routes to graphite nanoplatelets. J Mater Chem 15(9):974–978. doi:10.1039/B413029D

Chatterjee S, Nuesch FA, Chu BT (2011) Comparing carbon nanotubes and graphene nanoplatelets as reinforcements in polyamide 12 composites. Nanotechnology 22(27):275714. doi:10.1088/0957-4484/22/27/275714

Li W, Dichiara A, Bai J (2013) Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos Sci Technol 74:221–227. doi:10.1016/j.compscitech.2012.11.015

Bortz DR, Heras EG, Martin-Gullon I (2012) Impressive fatigue life and fracture toughness improvements in graphene oxide/epoxy composites. Macromolecules 45(1):238–245. doi:10.1021/ma201563k

Chatterjee S, Nafezarefi F, Tai NH, Schlagenhauf L, Nüesch FA, Chu BTT (2012) Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon 50(15):5380–5386. doi:10.1016/j.carbon.2007.021

King JA, Klimek DR, Miskioglu I, Odegard GM (2013) Mechanical properties of graphene nanoplatelet/epoxy composites. J Appl Polym Sci 128(6):4217–4223. doi:10.1002/app.38645

Ramakrishna S, Lim TC, Inai R, Fujihara K (2006) Modified Halpin–Tsai equation for clay-reinforced polymer nanofiber. Mech Adv Mater Struct 13(1):77–81. doi:10.1080/15376490500343824

Li J, Kim J-K (2007) Percolation threshold of conducting polymer composites containing 3D randomly distributed graphite nanoplatelets. Compos Sci Technol 67(10):2114–2120. doi:10.1016/j.compscitech.2006.11.010

Chatterjee S, Wang JW, Kuo WS, Tai NH, Salzmann C, Li WL, Hollertz R, Nüesch FA, Chu BTT (2012) Mechanical reinforcement and thermal conductivity in expanded graphene nanoplatelets reinforced epoxy composites. Chem Phys Lett 531:6–10. doi:10.1016/j.cplett.2012.02.006

Thostenson ET, Chou T-W (2006) Processing-structure-multi-functional property relationship in carbon nanotube/epoxy composites. Carbon 44(14):3022–3029. doi:10.1016/j.carbon.2006.05.014

Gojny FH, Wichmann MHG, Köpke U, Fiedler B, Schulte K (2004) Carbon nanotube-reinforced epoxy-composites: enhanced stiffness and fracture toughness at low nanotube content. Compos Sci Technol 64(15):2363–2371. doi:10.1016/j.compscitech.2004.04.002

ASTM D638 (2010) Standard test method for tensile properies of plastics. ASTM International, West conshohocken, PA

ASTM D257 (2007) Standard test method for DC resistance or conductance of insulating material. ASTM International, West Conshohocken, PA

ASTM D4496 (2004) Standard test method for D–C resistance or condutance of moderately conductive materials. ASTM International, West Conshoohoken, PA

Bryan C, Whitman CA, Johnson MB, Niven JF, Murray P, Bourque A, Dąbkowska HA, Gaulin BD, White MA (2012) Thermal conductivity of (Er1−x Y x )2Ti2O7 pyrochlore oxide solid solutions. Phys Rev B 86(5):054303

ASTM D228 (2011) Standard test Method for linear thermal expansion of solid material with a push-rod dilatometer. ASTM international, West conshohocken PA

Wong M, Paramsothy M, Xu XJ, Ren Y, Li S, Liao K (2003) Physical interactions at carbon nanotube-polymer interface. Polymer 44(25):7757–7764. doi:10.1016/j.polymer.2003.10.011

Celzard A, McRae E, Deleuze C, Dufort M, Furdin G, Marêché JF (1996) Critical concentration in percolating systems containing a high-aspect-ratio filler. Phys Rev B 53(10):6209–6214

Lu C, Mai YW (2005) Influence of aspect ratio on barrier properties of polymer-clay nanocomposites. Phys Rev Lett 95(8):088303

Ayatollahi MR, Shadlou S, Shokrieh MM, Chitsazzadeh M (2011) Effect of multi-walled carbon nanotube aspect ratio on mechanical and electrical properties of epoxy-based nanocomposites. Polym Test 30(5):548–556. doi:10.1016/j.polymertesting.2011.04.008

Yang S-Y, Ma C-CM, Teng C–C, Huang Y-W, Liao S-H, Huang Y-L, Tien H-W, Lee T-M, Chiou K-C (2010) Effect of functionalized carbon nanotubes on the thermal conductivity of epoxy composites. Carbon 48(3):592–603. doi:10.1016/j.carbon.2009.08.047

Jiang H, Liu B, Huang Y, Hwang KC (2004) Thermal expansion of single wall carbon nanotubes. J Eng Mater Technol 126(3):265. doi:10.1115/1.1752925

Chow TS (1980) The effect of Particles shape on the mechanical properties of filled polymer. J Mater Sci 15:1873–1888. doi:10.1007/BF00550613

Wang S, Tambraparni M, Qiu J, Tipton J, Dean D (2009) Thermal expansion of graphene composites. Macromolecules 42(14):5251–5255. doi:10.1021/ma900631c

Acknowledgements

This research was funded by the National Science and Engineering Research Council of Canada (NSERC) through the Collaborative Research and Training Experience (CREATE) program. The authors are grateful to the granting agency. The use of Dalhousie Institute for Research in Material (IRM) equipment, through Professor M.A. White (Chemistry Department, Dalhousie University) and Professor S. Corbin (Civil & Resource Engineering Department, Dalhousie University) is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmadi-Moghadam, B., Taheri, F. Effect of processing parameters on the structure and multi-functional performance of epoxy/GNP-nanocomposites. J Mater Sci 49, 6180–6190 (2014). https://doi.org/10.1007/s10853-014-8332-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8332-y