Abstract

Ultrasound-assisted extraction and enzyme-assisted extraction are two methods that can be employed to recover valuable compounds from seaweeds at milder operating conditions than conventional chemical extraction methods. The aim of the study was to determine whether pH, enzyme addition and extraction temperature significantly impacted extraction of alginate from Ecklonia maxima in the presence of ultrasonication and to model extraction kinetics. Firstly, a 23 factorial experimental design was employed at constant sonication rate, with pH (8 and 10), temperature (50 and 60 °C), and enzyme-to-substrate ratio (E:S 0 and 1 %) as the independent variables. Secondly, extraction kinetics of alginate were investigated at different extraction conditions, through fitting of the Peleg and Power models. Highest extraction for alginate was achieved at pH 10, 60 °C, E:S = 0 % within the first 60 min of extraction. The addition of enzyme improved solubilised dry matter content, but it had a less clear impact on the alginate yield. Both the Peleg (R2 = 0.893 – 0.997) and Power function (R2 = 0.861 – 0.987) models provided good fit to the experimental data and can used to describe extraction kinetics of alginate during combined ultrasound-enzymatic assisted extraction.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

New processing routes are being developed for the recovery of a range of compounds from marine macroalgae (seaweeds). Seaweeds are increasingly viewed as a biomass feedstock that can potentially play a significant role in addressing the future needs of a large global population in a sustainable manner. Compared to terrestrial sources of biomass, seaweeds have some sustainability advantages, including minimal use of arable land or freshwater resources for cultivation. Further, due to the large diversity of seaweeds these species harbour a wide range of valuable compounds that can be extracted, with the added advantage that seaweeds contain no lignin, which can result in easier processing compared to terrestrial biomass (Song et al. 2015; Bordoloi and Goosen 2020).

Conventional extraction of polysaccharides from seaweeds is essentially a solid-liquid extraction and employs the use of either mineral acids or bases and relatively high temperatures. Harsh conditions of high temperature and extreme pH can degrade the quality of extracted compounds and affect their functionality (Li et al. 2006). Milder and more environmentally friendly solid-liquid extraction techniques such as ultrasound-assisted extraction (UAE), enzyme-assisted extraction (EAE), microwave-assisted extraction (MAE), sub-critical water extraction (SWE), and super-critical fluid extraction (SFE), are promising methods currently being developed, with some of these methods resulting in higher yields and shorter extraction time than conventional methods (Bordoloi and Goosen 2020; Gomez et al. 2020). However, these methods also have limitations, including high equipment and/or operational costs, high energy usage or sometimes long extraction times.

Coupling of novel extraction methods could overcome some of their limitations, which could lead to overall improved processing and process efficiency. In previous work the coupling of UAE and EAE has been shown to enhance extraction yield of fucoidan from the brown seaweed Nizamuddinia zanardinii (Alboofetileh et al. 2019) and of phenolics from brown seaweed Saccharina muticum (Casas et al. 2019).

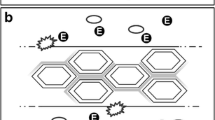

Ultrasound application facilitates extraction by acoustic cavitation, which results in disruption of cell walls and rupturing of cells to release their content for solubilisation (Tiwari 2015; Le Guillard et al. 2016; Cikoš et al. 2018). As a result UAE is an effective method to use in combination with other extraction techniques. The method has been successfully employed in biofuel and oil manufacture, as it requires shorter extraction times and uses lower volumes of solvent than conventional solvent extraction, has a higher yield, and in some instances requires less processing energy (Ying et al. 2011; Le Guillard et al. 2015; Chemat et al. 2017; Flórez-Fernández et al. 2017). However, presently its largescale application is still limited by lack of economic feasibly, mostly due to high capital expenditure and energy costs (Kadam et al. 2015; Tiwari 2015).

The use of enzymes in EAE facilitates the disruption of structural barriers like cell walls, hence improving the releasing of entrapped biomolecules such as alginates, sulfated polysaccharide fractions, phlorotannins and fucoxanthins (Kadam et al. 2013; Charoensiddhi et al. 2017). Various commercial enzymes including carbohydrases and proteases have been employed in the extraction of bioactive compounds from seaweed (Charoensiddhi et al. 2017). EAE has shown promise with the production of enhanced biofunctional hydrolysates from macroalgae (Wijesinghe and Jeon 2012; Rodrigues et al. 2015). However, EAE is hampered by prolonged extraction time and the lack of industrial enzymes that are specific to the polysaccharides found in seaweeds (Bordoloi and Goosen 2020).

The extraction of hydrocolloids like alginates using ultrasound alone or in combination with enzymes remain poorly described (Charoensiddhi et al. 2017; Gomez et al. 2020). Recent work has described the extraction of other compounds like R-phycoerythrin (Le Guillard et al. 2023), fucoxanthin (Flora et al. 2023), polyphenols and phlorotannins (Ummat et al. 2020), protein (Pan-utai et al. 2023), fucoidan (Mapholi and Goosen 2023) and various polysaccharides (Park and Lee 2021). Alginate is a major product in the food industry and is valued for its gelling and thickening properties, and is found in the cell wall of brown seaweeds, along with cellulose, hemicellulose, fucoidan and proteins (Deniaud-Bouët et al. 2014; Rhein-Knudsen et al. 2015; Charoensiddhi et al. 2017). Alginate macro-molecules are water soluble and form viscous solutions when dissolved, although their solubility is a strong function of pH, with solubility being higher at elevated pH (McHugh 2003), leading to commercial operations employing high-pH alginate extraction methods (Hernández-Carmona et al. 2013). Industrially, alginate extraction commonly employs solvent based pretreatment to remove contaminating compounds like lipids, pigments and polyphenols, followed by a mild acidic pre-extraction, then a hot alkaline extraction step and downstream processing. The base addition during the alkaline extraction is typically quite high, in the range of 2-3% or reaching pH-values around 10 (Hernández-Carmona et al. 1999; Bojorges et al. 2023) and elevated temperatures around 80°C are often employed during industrial extraction (Hernández-Carmona et al. 2013). Alternative alginate extraction methods that decrease some of the chemical use in conventional extraction processes, or is performed at lower temperatures, may therefore lead to lower environmental impact and may result in alginate with improved properties.

Given the known advantages of UAE, the current study aimed to determine important process parameters during enzymatic extraction of alginate in the presence of ultrasonication. The extraction enzyme was chosen to have high activity within the alkaline pH range (below and up to the high pH ranges of commercial extraction procedures), to take advantage of the enhanced solubility of alginate at these pH levels and potentially increasing the overall alginate extraction. The specific objectives of the study were to i) determine the impact of extraction temperature, pH and enzyme-to-substrate ratio on the extraction of alginate at constant sonication conditions, using a factorial experimental design, and ii) to investigate the extraction kinetics of alginate at different extraction conditions, through fitting of the Peleg and Power models using regression techniques.

Materials and methods

Materials and sample preparation

Figure 1 illustrates the sample preparation and extraction procedure. Brown seaweed (Ecklonia maxima) was harvested from a concession area along the West Coast of Cape Town, South Africa, during the summer month of February 2019. The seaweed material was washed with water to remove residual sand, salts, and epiphytes, then homogenised with water in a ratio 1:1 (by mass) using a Comitrol colloid mill as described previously (Mapholi and Goosen 2023), yielding a fine slurry with all biomass particles passing 0.5 mm, although the majority of particles were significantly below this particle size. The homogenised samples were frozen at -18 °C until required. Defrosting of samples was carried out at 4 °C. Samples were moisture analysed (in triplicates) at 180 °C using a halogen lamp moisture analyser (KERN DBS) and thereafter corrected to 4.0 % (w/v) solids loading with deionised water. The enzyme Carezyme 1000 L (Novozyme) (procured from Sigma Aldrich) is a cellulase with optimal operating conditions reported at pH 8 and 60 °C according to supplier specifications.

Experimental design

A 23 full factorial experimental design (Table 1) was applied and replicated once (i.e., two full replicates of the entire design was performed) to obtain an optimal set of processing parameters for maximising seaweed solubilised dry matter content and alginate yield, in the presence of ultrasound. The experimental factors chosen for investigation were temperature (50 and 60 °C), pH (8 and 10) and enzyme-to-substrate ratio (E:S) (0 and 1 %). The specific enzyme chosen was a cellulose-degrading enzyme cocktail with an optimum working pH within the alkaline region: Carezyme 1000 L. Temperature is known to affect both enzymatic hydrolysis rate and mass transfer operations (Chen et al. 2012), whereas pH affects alginate solubility and enzyme activity (Tiwari and Troy 2015; Zhang et al. 2015; Bojorges et al. 2023). Cellulase dosage was found to be important for solubilisation of biomass from E. maxima previously (Van Breda 2019) and a cellulase-hemicellulase cocktail significantly impacted total carbohydrate extraction from the same species (Mapholi and Goosen 2023). Enzyme dosage levels for this study were limited to a maximum of 1%, as higher dosage rates will become limiting to industrial operations due to enzyme costs. The temperature range was chosen to reach up to the reported optimum temperature of the enzyme as higher temperatures will start deactivating the enzyme, and the pH range was chosen to include the reported optimum pH for the enzyme (pH 8), and reach up to pH 10, which is the value where conventional alginate extraction occurs (Bojorges et al. 2023). All experimental runs were performed at constant stirring speed (275 rpm), pump rate (1 L h-1) and sonication rate (59-66 W) of the ultrasound batch bioreactor system (Fig. 2). Hydrolysate solution samples were drawn and analyzed at 0, 30, 60, 120, 180, and 240 min of extraction.

Extraction system

Ultrasound-assisted enzymatic extraction was carried out using a batch bioreactor system equipped with a flow-through ultrasound setup (Fig. 2), as described in Mapholi and Goosen (2023). The ultrasound equipment consisted of an ultrasound generator at 24 kHz UP200St (200 W with maximum amplitude of 190 μm) with a horn tip probe of surface area equivalent to 0.38 cm2, manufactured by Heilscher, Germany. The probe was operated within a flow cell through which the reactor content was continuously circulated. A stirred extraction reactor consisted of a 1 L jacketed and stirred reactor unit (Glasschem, South Africa), equipped with temperature and pH probes. Both the flow cell and jacketed reactor units are heated from a temperature-controlled water bath. To perform hydrolysis, the system was loaded with 800 mL of seaweed feed mixture at 4.0 % solids loading, equilibrated to the required temperature and adjusted to the required pH using 3 M NaOH solution, and then circulated within the system by a peristaltic pump. For runs without enzyme, the run started when ultrasonication was initiated; for runs with enzymes, ultrasonication was initiated immediately upon addition of the enzymes. The feed mixture was circulated at a constant rate (1 L h-1), sonicated at a uniform ultrasound intensity (59-66 W cm-2) during the 240 min extraction regime, under constant impeller rate (275 rpm). Hydrolysate solution samples of about 12 mL were drawn out at 0, 30, 60, 120, 180, and 240 min and weighed. The solution was centrifuged at 10000 rpm for 10 min and the supernatant extract heated at 95 °C for 5 min in a heating block to deactivate the enzymatic reaction, followed by immediate cooling in an ice bath. Aliquots of 2 mL supernatant extract in Eppendorf tubes were stored at -18 °C until further analysis.

Analytical procedures

Solubilised dry matter content

The liquefaction of seaweed material was assessed by tracking the dry matter content in the supernatant extract solution. A 500 µL sample of the supernatant extract solution was analysed for moisture content at 180°C using a halogen lamp moisture analyser (KERN DBS) from where the dry matter content in the supernatant was determined.

Modified Dubois assay for alginate

Alginate yield was quantified as the soluble alginate in accordance with the DuBois assay with modifications (Dubois et al. 1956; Lötze and Hoffman 2016). One millilitre of particulate-free supernatant sample was precipitated by adding 1 mL of 1 M HCl before vortexing and centrifuging (13000 × g for 10 min) to separate the pellet from the supernatant. The supernatant was discarded and the pellet washed with 2 mL 0.5 M HCl to remove impurities by vortexing and centrifuging again. The resulting pellet was solubilised in 1 mL of 3 % Na2CO3 by vortexing, then incubated at 50 °C in a water bath for 20 min. The solution was centrifuged in tubes at 4000 \(\times\) g for 1 min and the supernatant kept for analysis. An extract aliquot of 0.5 mL was mixed with 1.40 mL of sulphuric acid-phenol solution (prepared by mixing 80 % aqueous phenol with concentrated sulphuric acid). Readings were performed on 200 µL of the extract mixture at 480 nm of absorbance using a microplate reader (ELx800, Bio Tek Instruments, USA). A calibration curve was prepared using standard sodium alginate concentrations (0.25–2.0 g L−1). The alginate yield was expressed as a percentage of the gram of alginate per gram of dry weight (DW) of extract and results presented as means from triplicate measurements.

Kinetic modelling

Peleg’s model (Peleg 1988) for sorption kinetics was adopted for modelling the extraction kinetics of alginate. The model has been previously used to successfully describe the extraction kinetics of various compounds from biological plant material, with kinetic extraction curves exhibiting similar trends compared to Peleg’s sorption kinetics (Bucić-Kojić et al. 2007; Jang et al. 2011; Galván D’Alessandro et al. 2014). Peleg’s model (Equation 1) was fitted on the concentration-time experimental data of alginate extraction.

where \({C}_{t}\) (g L-1) is the alginate concentration at a given extraction time \(t\) (min), \({C}_{0}\) (g L-1) is the alginate concentration at the initial time (\(t\) = 0 min), \({K}_{1}\) (min L g-1) is the Peleg’s rate constant, and \({K}_{2}\) (L g-1) is the Peleg’s capacity constant. The Peleg’s rate constant \({K}_{1}\) relates to the initial alginate extraction rate (\({R}_{0}\)) at \(t\) = 0 (Equation 2), while \({K}_{2}\) relates to maximum extractable alginate concentration achieved at equilibrium as \(t\) → ∞. Equation 3 gives the relationship between the Peleg’s capacity constant \({K}_{2}\) and the predicted equilibrium alginate concentration \({C}_{e}\).

By implication, the constant \({K}_{1}\) relates to the mass transfer rate, where smaller values for K1 are equivalent to higher initial extraction rates, while K2 relates to the maximum extraction where smaller values of K2 are equivalent to higher equilibrium concentrations of extracted alginate (assuming starting concentrations of the alginate to be equal for all extraction runs).

A second empirical model, the Power function (Equation 4) was also used to model the alginate extraction.

where \(K\) (g L-1min-1) is the power law constant, n (dimensionless) is the diffusion exponent (expected to be < 1 for extractions from plant materials), and \(a\) represents the y-intercept of the model, which was added seeing that there was already a certain amount of alginate present in the liquid phase at initiation of each experimental run. Constant \(K\) accounts for the characteristics of the extraction system, while the diffusion exponent n relates to the transport mechanism (Kitanović et al. 2008).

Statistical analysis

All statistical analyses were completed using Statistica software (version 13.3, Tibco Software Inc., USA). Analysis of variance (ANOVA) was carried out at 95 % confidence interval to assess the linear and interaction effects of pH, temperature, E:S ratio on the extraction of total dry matter and alginate. ANOVA was only performed on data obtained at the endpoint of each experimental run (i.e., at 240 min extraction time). Non-linear regression was used to fit the Peleg’s and Power function to the data on alginate extraction. The quality of the fit between the experimental and predicted data was determined based on R2 values.

Results

Impact of extraction parameters on yield

Solubilised dry matter content

Results on solubilised dry matter content are summarised in Fig. 3. The ANOVA at endpoint extraction showed that only the main effects of temperature and enzyme-substrate ratio significantly influenced the solubilised dry matter content, whereas the pH and all interaction effects showed no significant influence (Table 2). In this study, the endpoint solubilised dry matter content ranged from 2.9 % (pH 8, 50 °C, E:S 0 %) to 3.5 % (pH 10, 60 °C, E:S 1 % and pH 8, 50 °C, E:S 1 %). The difference between the highest and lowest solubilised dry matter content at endpoints was 0.4 % for runs with no enzyme addition, and 0.2 % for runs with enzyme addition. Generally, in experimental runs with no enzyme addition solubilised dry matter content increased over the early stages of the extraction (until 60 min) in a non-linear manner, followed by a stagnation (Fig. 3a). Conversely, in runs with enzyme addition solubilised dry matter content increased rapidly and non-linearly over the first 60 min of extraction, and thereafter continued (albeit fairly slowly) increasing until the 240 min endpoint (Fig. 3b). The addition of enzymes increased solubilised dry matter content by 0.7-1.0 % at endpoint conditions compared to experiments with no enzyme addition.

Alginate yield

Figure 4 shows the alginate extraction yield across all tested conditions of pH, temperature and enzyme-substrate ratio. The ANOVA results at the extraction endpoint revealed that main effects of pH, temperature and enzyme-substrate ratio (E:S), as well as all the two-way interactions had a significant influence (P ≤ 0.05) on the alginate extraction yield (Table 3); Fig. 5 depicts the impact of main effects. In general, for all experimental runs, the alginate extraction yield increased non-linearly fairly rapidly (compared to the later extraction times) for the first 60 min of extraction. Post 60 min, a slower and more linear increase was observed to the end of the extraction. Measured alginate concentrations ranged between 11.6 – 18.1 g L-1 at the end of the extraction process; when considering that 4% or 40 g L-1 of dry matter was charged at the start of the experiment, these yields equate to 29.0 – 45.3% of initial dry weight (DW) being extracted as alginate. Experimental runs 4 (pH 10, 60 °C, E:S 0 %) and 8 (pH 10, 60 °C, E:S 1 %) distinctively produced the highest alginate yields of 45.3% and 40.3 % of initial DW at endpoint conditions, respectively.

Yield-time profiles of alginate extraction from Ecklonia maxima using the combined ultrasound-enzymatic extraction technique: in the absence (a) and presence (b) of an alkaline cellulase enzyme. Each data point on the graph represents the mean value of two extraction replicates, and each analysis was done in triplicate. DW is the dry weight of the supernatant extract solution

Kinetic modelling and model comparisons

Tables 4 and 5 summarise the results of curve fitting and show the values of constants obtained through regression analysis for both Peleg’s model and the Power function, respectively. It is evident from the R2-values that Peleg’s model provides a slightly better fit to the data than the Power function. For this reason, Fig. 6 shows the data-points for each run, and the regression curves for the Peleg model. Irrespective of which regression model fits best, both the Peleg’s and Power function models in general, provided a good fit to the experimental data. Both can therefore be employed to describe the extraction kinetics of alginates from E. maxima during ultrasound-assisted enzyme hydrolysis. This is evidenced by the high values of the coefficients of determination (R2) in the ranges of 0.893 – 0.997 and 0.861 – 0.987 obtained from the Peleg’s model and Power function, respectively.

Concentration-time profiles of alginate extraction from Ecklonia maxima using the combined ultrasound-enzymatic extraction technique: in the absence (a) and presence (b) of an alkaline cellulase enzyme. The regression curves were fitted based on Peleg’s model. All data points for both extraction replicates are shown, and each data point is the mean value of three analytical replicates.

Peleg’s model for alginates extraction kinetics

Generally, similar \({K}_{1}\) values were observed between experiments with no enzyme addition and with enzyme addition. The highest (9.86 min L g-1) and lowest (4.12 min L g-1) values of \({K}_{1}\) were observed at 60 °C and pH 8 with no enzyme addition, and at 60 °C and pH 10 with enzyme addition, respectively. Constant K2 was highest (0.18 L g-1) at 50 °C and pH 8 with enzyme addition, and lowest (0.07 L g-1) at 60 °C and pH 10 (both with and with no enzyme addition). In Table 4, the initial extraction rates (1/K1) and predicted equilibrium concentration of alginate (Ce) are also shown. The final alginate concentration measured at the end of the extraction was expressed as a percentage of the predicted equilibrium concentration. The highest initial extraction rate was 0.24 g (L min)-1 at extraction conditions of 60 °C, pH 10 and no enzyme, and the lowest initial extraction rate obtained was 0.10 g (L min)-1 at extraction conditions of 60 °C, pH 8 and no enzyme addition. The highest predicted value for Ce was 21.1 g L-1 at 60 °C and pH 10 with no enzyme addition (and was almost equal to the 21.0 g L-1 obtained at 60 °C and pH 10 with enzyme addition), whereas the lowest value predicted was 12.8 L-1 for both 50 °C and 60 °C at pH 8, with enzyme addition.

Power law for alginates extraction kinetics

Table 5 shows the results of the constant \(K\), the diffusion exponent n, and the y-intercept \(a\) of the power law model. The values for the exponent n were well below 1 and ranged from 0.29 (60° C, pH 10, no enzyme addition) to 0.52 (60 ° C, pH 8, no enzyme addition). For the Power law constant K, values were between 0.48 g (L min)-1 at 60 °C, pH 8 and no enzyme addition, to 1.53 g (L min)-1 at 60 °C, pH 10 and no enzyme addition.

Discussion

The current work set out to determine optimum conditions for extraction of alginate using enzymatic extraction in the presence of ultrasonication, and to model extraction kinetics using the Peleg and Power kinetic models. The results in Section "Impact of extraction parameters on yield" demonstrated that increasing temperature and enzyme addition improved solubilised dry matter content, whereas increasing temperature and pH increased alginate yields, while the effect of enzyme addition on alginate extraction remained unclear (as supported by extraction kinetics in Section "Kinetic modelling and model comparisons").

The utility of employing the particular enzyme cocktail specifically for alginate recovery under constant sonication conditions is unclear. Although there were clear benefits to dry matter extraction upon enzyme addition (with higher dry matter contents in extracts when the enzyme cocktail was present), the results for alginate yield are less obvious. Cellulase addition has been shown to significantly increase dry matter recovery into the extraction supernatant from green seaweed before (Hardouin et al. 2016), although under conditions where no ultrasound was applied. Carbohydrase enzymes are expected to disrupt the cell walls of seaweed and thereby facilitate the release of biomolecules in the cell wall and intracellularly, consequently resulting in increasing solubilised yield (Kadam et al. 2013; Charoensiddhi et al. 2016, 2017). The increase in the recovery of dry matter is therefore to be expected. However, when considering the effect of enzyme addition on alginate recovery the results are less clear due to all the second order interaction effects being statistically significant. At pH values of 8, the addition of the cellulase-degrading enzyme resulted in decreased alginate extraction at 50 °C and 60 °C, whereas at a pH level of 10, enzyme addition resulted in slightly increased alginate extraction at 50 °C, but decreased extraction at 60 °C.

The reason for the different impacts of enzyme addition on dry matter and alginate extraction is likely due to the different mechanisms involved in extraction of the different compounds. Total dry matter in solution measures the sum of all soluble compounds, and measurement of dry matter extraction is therefore not a specific measurement of chemically-similar compounds being extracted. Seeing that the cellulose molecules in seaweeds are found in the cell walls (Charoensiddhi et al. 2017), enzymatic hydrolysis of the cellulose will likely result in the release of soluble cell wall components and cell contents (Rostami et al. 2017), hence the increase in total dry matter in solution. Furthermore, there is a possibility that the application of ultrasound can act synergistically with added enzymes and thereby further enhance dry matter extraction due to improved mass transfer (Le Guillard et al. 2015, 2016), although this potential synergy was not specifically evaluated in the current work. The extraction of alginate, on the other hand, is known to be highly dependent on the solution pH (Fawzy et al. 2017; Bojorges et al. 2023) and it is likely that the increased solubility at elevated pH had a larger impact on alginate recovery than enzymatic degradation of the cell walls.

The extraction temperature is an important process consideration during extraction of both the total dry matter and of the alginate. Increasing the extraction temperature resulted in increased dry matter extraction and increased alginate extraction at constant pH values, both with and without enzyme addition. This is in line with expectations from literature, as temperature increase is known to improve solubility and thus extraction efficiency of organic compounds from seaweed (Zhang and Row 2014; Mahyati and Azis 2019), as is predicted by mass transfer theory. Industrially, alginate is extracted at temperatures around 80°C, although there is a trade-off between increased extraction and decreased alginate quality due to hydrolysis of alginate at elevated temperatures with subsequent lower gel strength (Hernández-Carmona et al. 2013; Bojorges et al. 2023).

The alginate yields obtained in this study are similar to or higher than certain previous studies. The alginate yields of 29.0 – 45.3 % of initial dry weight are higher compared to those obtained during conventional extractions (3 % alkali, 86 °C and 93 % ethanol), that showed alginate yields of 13.6 %, extracted from Sargassum muticum (Mazumder et al. 2016). Using microwave-assisted extraction, authors obtained alginate yields of 18.2 % - 23.1 % from Ascophyllum nodosum (Yuan and Macquarrie 2015). Compared to other ultrasound-assisted extractions, the current study showed lower yields than the 54 % obtained from Sargassum binderi and Turbinaria ornata (Youssouf et al. 2017), although in that particular study extractions were optimised with respect to ultrasonic power input and the ratio of algae to water, which may have resulted in the significantly higher yields.

From the kinetic studies it was apparent that both the Peleg model and the Power function provided good fits to the extraction data with R2-values between 0.893 – 0.997 for the Peleg model and 0.861 – 0.987 for the Power function. It is emphasized that both these models are empirical in nature and not based on fundamental transport phenomena , although certain of the parameters have direct bearing on relevant extraction phenomena. The parameters from the Peleg model allow estimation of initial extraction rate and the expected equilibrium extraction concentration of the extractant, whereas the Power law model does not provide an estimate of equilibrium concentration (Peleg 1988; Kitanović et al. 2008). The kinetic studies revealed typical characteristics of extractions from plant materials, where a high initial rate of extraction is experienced, followed by a more gradual increase until equilibrium has been reached. The fast initial extraction is associated with a washing phase where easily accessible solute is recovered into the extraction solvent, whereas the more gradual increase is associated with slower diffusion of the solute from internal sites of the plant material, into the solvent (Kitanović et al. 2008; Chan et al. 2014). Furthermore, all values obtained for the diffusion exponents in the Power law model were < 1 as is expected for extraction from plant materials.

When considering the preferred Peleg model, there were no apparent advantages of enzyme addition to alginate extraction kinetics. Predicted equilibrium concentrations for alginate were highest for the conditions that had the highest temperature at the highest pH and were almost identical whether enzymes were employed or not. When considering initial extraction rates, there were again no apparent advantages of utilising enzymes. It is likely that in both cases the seeming lack of impact of enzyme addition could be related to the different timescales over which the different extraction mechanisms act. In this work, ultrasound was applied in a concentrated form when the reactor content was circulated through a flow cell where the entire ultrasound power was applied to a small volume of circulating liquid. At the circulation rate applied, the reactor contents would be circulated through the flow cell 6.25 times during the 240 min extraction, thereby ensuring repeated exposure to intense ultrasound cell disruption, which was likely to result in high extraction rates. Enzymatic treatment, on the other hand, is a slower process and in this particular case it is likely that the impacts of ultrasonication and extraction conditions (pH and temperature) on alginate extraction kinetics, dominated the slower effects of enzymatic hydrolysis.

The kinetic models are useful tools to determine two aspects of the system studied: 1) they provide estimates of the upper bounds of alginate extraction through the Ce values of the Peleg model, and 2) they provide information on the initial rate of extraction through the value of K1 in the Peleg model. These models, however, have their limitations and it would be unwise to use them to extrapolate system behaviour beyond the conditions investigated, particularly for this system where alginate behaviour and enzyme activity change as a function of pH (the alginate will start to precipitate as pH becomes acidic and enzyme activity is a strong function of pH) and where enzyme activity and solvent properties will change along with temperature. In future, in order to form a general description of the system from kinetic equations, the range over which kinetic experiments are completed can be expanded, much like what was done by Márquez and Vázquez (1999) for the case of enzymatic protein hydrolysis; however, even in that case it was necessary to incorporate specialist knowledge on the system (e.g., pH-dependent substrate solubility) to develop an appropriate description. The set of factorial experiments in this case should also not be employed for extrapolation due to the limitations of 2k factorial screening designs (Montgomery 2019), although they do indicate the conditions at which additional experiments should be performed: increased temperature and higher pH values were favourable for alginate extraction, and experimental efforts should be focused on these areas. However, more extreme extraction conditions can impact alginate properties negatively (Bojorges et al. 2023) and the likely trade-offs between increased yield vs. impacts on product quality will need to be assessed.

The results from the investigation indicate that ultrasound-assisted processing of brown seaweed could have merits for alginate extraction, particularly at alkaline pH values that favour alginate solubilisation. It is unlikely, however, that ultrasound-assisted extraction is selective toward any individual compounds, as the mechanism revolves around general cell disruption based on cavitation; increased extraction of alginate is therefore also likely to result in increased co-extraction of compounds co-located in the cell wall, like fucoidan, proteins and polyphenols. The work has shown that relatively high yields of alginate can be extracted; despite ultrasound-assisted alginate extraction being technically possible, it remains to be seen whether it can be economically viable and successfully compete against existing alginate extraction technologies. Ultrasound technology can be difficult to scale up and it typically has high capital cost (Zhu et al. 2024). Where the technology does have a potential advantage is in the re-processing of recalcitrant brown seaweed by-products, such as those typically generated in the biostimulant extraction industry when soluble compounds are removed from the raw material, or the residues remaining after a seaweed biorefinery extraction process that are often sent to energy recovery, as animal feed supplements or other low-value applications (Álvarez-Viñas et al. 2019; Zhang and Thomsen 2021; Zhang et al. 2021). The additional cell-wall disruption afforded by ultrasonic cavitation could facilitate the recovery of additional valuable compounds from these by-products, but the question about economic viability remains.

Conclusion

The study focused on optimising the process conditions of temperature, pH and enzyme-to-substrate ratio to maximise extraction of alginate from brown seaweed using ultrasound assisted enzymatic hydrolysis. Furthermore, the extraction kinetics were investigated using the Peleg and Power models. Though the addition of enzymes improved dry matter extraction, its effect on the alginate extraction remained unclear, likely due to the different mechanisms involved in extraction of the different compounds. It was clear that increasing the extraction temperature resulted in higher solubilised dry matter content and alginate yield at the end point extraction across all pH levels, with and without enzyme addition. The extraction kinetics of alginate from E. maxima during enzymatic hydrolysis at constant sonication were adequately modelled and described using both the Peleg model (R2 = 0.893 – 0.997) and the Power function (R2 = 0.861 – 0.987). The Peleg model predicted that the highest equilibrium concentrations were achievable at highest temperature and pH and were almost undistinguishable at conditions with and without enzyme addition. Therefore, there were no apparent advantages of enzyme addition in extraction kinetics probably because the effects pH, temperature and ultrasonication dominated the effects of enzyme addition.

Data availability

Data are available from the corresponding author upon reasonable request.

References

Alboofetileh M, Rezaei M, Tabarsa M, You S (2019) Bioactivities of Nizamuddinia zanardinii sulfated polysaccharides extracted by enzyme, ultrasound and enzyme-ultrasound methods. J Food Sci Technol 56:1212–1220

Álvarez-Viñas M, Flórez-Fernández N, Torres MD, Domínguez H (2019) Successful approaches for a red seaweed biorefinery. Mar Drugs 17:620

Bojorges H, López-Rubio A, Martínez-Abad A, Fabra MJ (2023) Overview of alginate extraction processes: Impact on alginate molecular structure and techno-functional properties. Trends Food Sci Technol 140:104142

Bordoloi A, Goosen NJ (2020) Green and integrated processing approaches for the recovery of high-value compounds from brown seaweeds. Adv Bot Res 95:369–413

Bucić-Kojić A, Planinić M, Tomas S, Bilić M, Velić D (2007) Study of solid–liquid extraction kinetics of total polyphenols from grape seeds. J Food Eng 81:236–242

Casas MP, Conde E, Domínguez H, Moure A (2019) Ecofriendly extraction of bioactive fractions from Sargassum muticum. Process Biochem 79:166–173

Chan C-H, Yussof R, Ngoh G-C (2014) Modeling and kinetics study of conventional and assisted batch solvent extraction. Chem Eng Res Design 92:1169–1186

Charoensiddhi S, Conlon MA, Franco CMM, Zhang W (2017) The development of seaweed-derived bioactive compounds for use as prebiotics and nutraceuticals using enzyme technologies. Trends Food Sci Technol 70:20–33

Charoensiddhi S, Lorbeer AJ, Lahnstein J, Bulone V, Franco CMM, Zhang W (2016) Enzyme-assisted extraction of carbohydrates from the brown alga Ecklonia radiata: Effect of enzyme type, pH and buffer on sugar yield and molecular weight profiles. Process Biochem 51:1503–1510

Chemat F, Rombaut N, Sicaire A-G, Meullemiestre A, Fabiano-Tixier A-S, Abert-Vian M (2017) Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason Sonochem 34:540–560

Chen R, Li S, Liu C, Yang S, Li X (2012) Ultrasound complex enzymes assisted extraction and biochemical activities of polysaccharides from Epimedium leaves. Process Biochem 47:2040–2050

Cikoš A-M, Jokić S, Šubarić D, Jerković I (2018) Overview on the application of modern methods for the extraction of bioactive compounds from marine macroalgae. Mar Drugs 16:348

Deniaud-Bouët E, Kervarec N, Michel G, Tonon T, Kloareg B, Hervé C (2014) Chemical and enzymatic fractionation of cell walls from Fucales: insights into the structure of the extracellular matrix of brown algae. Ann Bot 114:1203–1216

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Fawzy MA, Gomaa M, Hifney AF, Abdel-Gawad KM (2017) Optimization of alginate alkaline extraction technology from Sargassum latifolium and its potential antioxidant and emulsifying properties. Carbohydr Polym 157:1903–1912

Flora LAC, Shanmugam K, Sahadevan R (2023) Ultrasonic method on the extraction of fucoxanthin from marine macro algae Padina australis. Austin Chem Eng 10:1100

Flórez-Fernández N, López-García M, González-Muñoz MJ, Vilariño JML, Domínguez H (2017) Ultrasound-assisted extraction of fucoidan from Sargassum muticum. J Appl Phycol 29:1553–1561

Galván D’Alessandro L, Dimitrov K, Vauchel P, Nikov I (2014) Kinetics of ultrasound assisted extraction of anthocyanins from Aronia melanocarpa (black chokeberry) wastes. Chem Eng Res Design 92:1818–1826

Gomez LP, Alvarez C, Zhao M, Tiwari U, Curtin J, Garcia-Vaquero M, Tiwari BK (2020) Innovative processing strategies and technologies to obtain hydrocolloids from macroalgae for food applications. Carbohydr Polym 248:116784

Hardouin K, Bedoux G, Burlot A-S, Donnay-Moreno C, Bergé J-P, Nyvall-Collén P, Bourgougnon N (2016) Enzyme-assisted extraction (EAE) for the production of antiviral and antioxidant extracts from the green seaweed Ulva armoricana (Ulvales, Ulvophyceae). Algal Res 16:233–239

Hernández-Carmona G, Freile-Pelegrín Y, Hernández-Garibay E (2013) Conventional and alternative technologies for the extraction of algal polysaccharides. In: Domínguez H (ed) Functional Ingredients from Algae for Foods and Nutraceuticals. Woodhead Publishing, Duxford, pp 475–516

Hernández-Carmona G, McHugh DJ, López-Gutiérrez F (1999) Pilot plant scale extraction of alginates from Macrocystis pyrifera. 2. Studies on extraction conditions andmethods of separating the alkaline-insoluble residue. J Appl Phycol 11:493–502

Jang S, Kitamura Y, Yoshida S, Yamasaki H (2011) Hot water extraction of brown seaweed, Nagamo (Sargassum horneri) processing residue. Food Sci Technol Research 17:487–492

Kadam SU, Tiwari BK, O’Donnell CP (2013) Application of novel extraction technologies for bioactives from marine algae. J Agric Food Chem 61:4667–4675

Kadam SU, Tiwari BK, Smyth TJ, O’Donnell CP (2015) Optimization of ultrasound assisted extraction of bioactive components from brown seaweed Ascophyllum nodosum using response surface methodology. Ultrason Sonochem 23:308–316

Kitanović S, Milenović D, Veljković VB (2008) Empirical kinetic models for the resinoid extraction from aerial parts of St. John’s wort (Hypericum perforatum L.). Biochem Eng J 41:1–11

Le Guillard C, Bergé J-P, Donnay-Moreno C, Bruzac S, Ragon J-Y, Baron R, Fleurence J, Dumay J (2016) Soft liquefaction of the red seaweed Grateloupia turuturu Yamada by ultrasound-assisted enzymatic hydrolysis process. J Appl Phycol 28:2575–2585

Le Guillard C, Bergé J-P, Donnay-Moreno C, Cornet J, Ragon J-Y, Fleurence J, Dumay J (2023) Optimization of R-phycoerythrin extraction by ultrasound-assisted enzymatic hydrolysis: A comprehensive study on the wet seaweed Grateloupia turuturu. Mar Drugs 21:213

Le Guillard C, Dumay J, Donnay-Moreno C, Bruzac S, Ragon J-Y, Fleurence J, Bergé JP (2015) Ultrasound-assisted extraction of R-phycoerythrin from Grateloupia turuturu with and without enzyme addition. Algal Res 12:522–528

Li BB, Smith B, Hossain MM (2006) Extraction of phenolics from citrus peels: II. Enzyme-assisted extraction method. Separat Purif Technol 48:189–196

Lötze E, Hoffman EW (2016) Nutrient composition and content of various biological active compounds of three South African-based commercial seaweed biostimulants. J Appl Phycol 28:1379–1386

Mahyati M, Azis A (2019) Optimization of temperature and time in carrageenan extraction of seaweed (Kappaphycus alvarezii) using ultrasonic wave extraction methods. IOP Conf Ser Earth Environ Sci 370:012076

Mapholi Z, Goosen NJ (2023) Optimization of fucoidan recovery by ultrasound-assisted enzymatic extraction from South African kelp, Ecklonia maxima. Ultrason Sonochem 101:106710

Márquez MC, Vázquez MA (1999) Modeling of enzymatic protein hydrolysis. Process Biochem 35:111–117

Mazumder A, Holdt SL, De Francisci D, Alvarado-Morales M, Mishra HN, Angelidaki I (2016) Extraction of alginate from Sargassum muticum: process optimization and study of its functional activities. J Appl Phycol 28:3625–3634

McHugh DJ (2003) A guide to the seaweed industry. FAO Fisheries Technical Paper 441. Food and Agricultural Organisation of the United Nations, Rome

Montgomery DC (2019) Design and analysis of experiments. 10th Edition edn. Wiley, NY

Pan-utai W, Pantoa T, Roytrakul S, Praiboon J, Kosawatpat P, Tamtin M, Thongdang B (2023) Ultrasonic-assisted extraction and antioxidant potential of valuable protein from Ulva rigida macroalgae. Life 13:86

Park JJ, Lee WY (2021) Anti-glycation effect of Ecklonia cava polysaccharides extracted by combined ultrasound and enzyme-assisted extraction. Int J Biol Macromol 180:684–691

Peleg M (1988) An empirical model for the description of moisture sorption curves. J Food Sci 53:1216–1217

Rhein-Knudsen N, Ale MT, Meyer AS (2015) Seaweed hydrocolloid production: An update on enzyme assisted extraction and modification technologies. Mar Drugs 13:3340–3359

Rodrigues D, Sousa S, Silva A, Amorim M, Pereira L, Rocha-Santos TAP, Gomes AMP, Duarte AC, Freitas AC (2015) Impact of enzyme- and ultrasound-assisted extraction methods on biological properties of red, brown, and green seaweeds from the Central West Coast of Portugal. J Agric Food Chem 63:3177–3188

Rostami Z, Tabarsa M, You S, Rezaei M (2017) Relationship between molecular weights and biological properties of alginates extracted under different methods from Colpomenia peregrina. Process Biochem 58:289–297

Song M, Pham HD, Seon J, Woo H-C (2015) Marine brown algae: A conundrum answer for sustainable biofuels production. Renew Sustain Energy Rev 50:782–792

Tiwari BK (2015) Ultrasound: A clean, green extraction technology. Trends Anal Chem 71:100–109

Tiwari BK, Troy DJ (2015) Chapter 1: Seaweed sustainability - food and non-food applications. In: Tiwari BK, Troy DJ (eds) Seaweed sustainability - food and non-food applications. Elsevier, Amsterdam, pp 1–6

Ummat V, Tiwari BK, Jaiswal AK, Condon K, Garcia-Vaquero M, O’Doherty J, O’Donnell C, Rajauria G (2020) Optimisation of ultrasound frequency, extraction time and solvent for the recovery of polyphenols, phlorotannins and associated antioxidant activity from brown seaweeds. Mar Drugs 18:250

Van Breda DJ (2019) Enzymatic extraction of laminarin from brown seaweed Ecklonia maxima. MEng Thesis, Stellenbosch University, Stellenbosch

Wijesinghe WAJP, Jeon Y-J (2012) Enzyme-assistant extraction (EAE) of bioactive components: A useful approach for recovery of industrially important metabolites from seaweeds: A review. Fitoterapia 83:6–12

Ying Z, Han X, Li J (2011) Ultrasound-assisted extraction of polysaccharides from mulberry leaves. Food Chem 127:1273–1279

Youssouf L, Lallemand L, Giraud P, Soulé F, Bhaw-Luximon A, Meilhac O, D’Hellencourt CL, Jhurry D, Couprie J (2017) Ultrasound-assisted extraction and structural characterization by NMR of alginates and carrageenans from seaweeds. Carbohydr Polym 166:55–63

Yuan Y, Macquarrie DJ (2015) Microwave assisted step-by-step process for the production of fucoidan, alginate sodium, sugars and biochar from Ascophyllum nodosum through a biorefinery concept. Bioresour Technol 198:819–827

Zhang H, Row KH (2014) Extraction and separation of polysaccharides from Laminaria japonica by size-exclusion chromatography. J Chromatogr Sci 53:498–502

Zhang L, Guo S, Wang M, He L (2015) PEG-based ultrasound-assisted enzymatic extraction of polysaccharides from Ginkgo biloba leaves. Int J Biol Macromol 80:644–650

Zhang X, Border A, Goosen NJ, Thomsen M (2021) Environmental life cycle assessment of cascade valorisation strategies of South African macroalga Ecklonia maxima using green extraction technologies. Algal Res 58:102348

Zhang X, Thomsen M (2021) Techno-economic and environmental assessment of novel biorefinery designs for sequential extraction of high-value biomolecules from brown macroalgae Laminaria digitata, Fucus vesiculosus, and Saccharina latissima. Algal Res 60:103499

Zhu X, Das RS, Bhavya ML, Garcia-Vaquero M, Tiwari BK (2024) Acoustic cavitation for agri-food applications: Mechanism of action, design of new systems, challenges and strategies for scale-up. Ultrason Sonochem 105:106850

Acknowledgement

The joint financial assistance of Cape Marine Industries and the South African Department of Trade and Industry towards this research, under the Technology and Human Resources for Industry Programme (grant number THRIP/70/20/04/2017) is hereby gratefully acknowledged. The authors would also like to acknowledge the technical support from the Department of Process Engineering at Stellenbosch University. Opinions expressed and conclusion derived at, are those of the authors and are not necessarily to be attributed to either of the funders.

Funding

Open access funding provided by Stellenbosch University. The project received funding from Cape Marine Distributors and the South African Department of Trade and Industry, under the Technology and Human Resources for Industry Programme (grant number THRIP/70/20/04/2017).

Department of Trade and Industry- South Africa,THRIP/70/20/04/2017

Author information

Authors and Affiliations

Contributions

Conceptualization: Neill Jurgens Goosen; Methodology: Dylan van Sittert, Zwonaka Mapholi; Formal analysis and investigation: Dylan van Sittert, Zwonaka Mapholi; Writing - original draft preparation: Robert Lufu, Dylan van Sittert, Neill Jurgens Goosen; Writing - review and editing: Robert Lufu, Dylan van Sittert, Neill Jurgens Goosen; Funding acquisition: Neill Jurgens Goosen; Resources: Neill Jurgens Goosen; Supervision: Neill Jurgens Goosen.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

van Sittert, D., Lufu, R., Mapholi, Z. et al. Ultrasound-assisted extraction of alginate from Ecklonia maxima with and without the addition of alkaline cellulase – factorial and kinetic analysis. J Appl Phycol (2024). https://doi.org/10.1007/s10811-024-03276-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10811-024-03276-0