Abstract

The objective of this work was to assess the antimicrobial effect of crude extracts and non-polar and mid-polar subfractions of the brown macroalga Ericaria selaginoides, using a mid-polarity extraction medium. The activity was evaluated through challenge testing against Listeria monocytogenes in Catalan “mató” (fresh cheese) selected as a food matrix. Three concentrations were tested, representing 2 ×, 4 × and 10 × Minimum Bactericidal Concentration values obtained for crude extract in previous in vitro assays. Ericaria selaginoides extracts inhibited L. monocytogenes growth in a dose-dependent manner. Intermediate concentrations of the three extracts were able to notably reduce the growth rate of the pathogen. Highest concentration of crude extract and non-polar subfraction were able to completely inhibit the growth of L. monocytogenes during the 10 days of storage at 8 °C. Moreover, a slight listericidal effect was observed in presence of the non-polar subfraction, reducing the L. monocytogenes level by ca. 3 log after 10 days of refrigerated storage. These results prove the potential of E. selaginoides extracts as a source of valuable antimicrobial compounds that can be used as natural food ingredients to develop safer fresh dairy food.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microbial food safety is crucial in the supply chains of food manufacturers in order to assure consumer protection from potential health risks as well as to reduce food losses, which can have a great impact in global economy (Hussain and Dawson 2013; Petruzzi et al. 2017) Listeria monocytogenes, the causative agent of listeriosis, is reported as the fifth most prevalent zoonotic foodborne disease in Europe and, although the number of cases is relatively low, it shows the highest hospitalisation and case fatality rates (> 90% and 14–30% respectively, depending on the year and the region) (Desai et al. 2019; EFSA-ECDC 2021). It can be especially deleterious in neonates, pregnant women, and immunocompromised or elderly people since it can cross intestinal, blood–brain and feto-placental barriers causing spontaneous abortion or severe infections such as septicaemia or meningitis (Lecuit 2005).

Listeria monocytogenes represents a noticeable threat in food industry as it can contaminate products during post-processing operations due to its ability to form biofilms in inert surfaces of food processing environment. It is usually found in a wide range of products, including raw vegetables, raw milk, raw meat, soft cheese, fish, and poultry, although the main source of human exposure are minimally processed and/or ready-to-eat products (RTE) as this pathogen has high tolerance to stressful pH conditions, freezing, drying, and heating, and can grow under refrigeration (Thakur et al. 2018). In this regard, a quantitative modelling suggests that more than 90% of invasive listeriosis is caused by consumption of RTE containing > 2000 colony forming units per gram (cfu g−1) and that one-third of cases are related to growth at the consumer phase (EFSA Biohaz Panel (EFSA Panel on Biological Hazards) et al. 2018).

Europe is a major player in global cheese industry and has the highest level of per capita of cheese consumption (Statista Research Department 2021). Among dairy products, soft cheeses are one of the most common causes of listeriosis, being detected at 0.5% in EU during 2020 and recognized by EFSA as a RTE product of risk for L. monocytogenes growth (EFSA-ECDC 2021). In this case, problems are mainly related to post-pasteurization contamination of milk, since they constitute a very suitable food matrices for the pathogen growth because of its physicochemical characteristics (pH 5.8–6.8, aw 0.94–0.99, 0.1–1.2% NaCl) (Vrdoljak et al. 2016).

Food safety regulations concerning L. monocytogenes in RTE products differ between countries. In Europe (EC 2005), microbiological criteria of a maximum of 100 cfu g−1 during the shelf-life of the product is stablished, whereas in other countries such as USA, a zero-tolerance policy is enforced (FSIS 2003a, b). Control measures based on risk approach could be implemented, either minimizing the occurrence of the pathogen in raw materials, reducing the levels by applying lethality or post-lethality treatment (PLT) and/or preventing its increase through the use of antimicrobial agents (AMA) or other processes.

Traditionally, synthetic additives have been used as preservatives in order to control microbial pathogens and extend the shelf-life of food. However, consumer demands for more “natural” products free of synthetic additives is rising and this tendency is gaining force in food industry, which is experiencing a shift towards the development of more sustainable, safer, and healthier food supplies (Bondi et al. 2017). Thus, this current scenario has encouraged the search for new and natural preservatives to be applied in bio-based preservation strategies.

Macroalgae have been traditionally consumed in Asian countries for centuries due to their high nutritional attributes while in Western countries their interest lies mainly in hydrocolloids, e.g., thickening, and gelling agents such as alginate, carrageenan, and agar; and their use as additives to animal feed and fertilizers (Kilinç et al. 2013). However, recently seaweed biomass production has increased exponentially (Araújo et al. 2021) due to their great potential uses as well as their value in bioactive compounds with application in multiple areas such as pharmaceutical, cosmetic and food industries (Leandro et al. 2020). More than 15,000 primary and secondary compounds have been isolated from brown macroalgae (Phaeophyceae), specially from the families Sargassaceae and Dictyotaceae, which constitute the main producers with more than 1100 secondary metabolites described in literature, mainly from the genera Cystoseira, Fucus and Sargassum (Blunt et al. 2011; Bouzidi et al. 2019). Interest has been focused on chemical structures typical from this group such as phlorotannins (phenolic compounds), fucoidans (sulphated polysaccharides) or fucoxanthin (carotenoid) due to their multiple described bioactivities: antioxidant, antibacterial, antifungal, anticancer, anti-inflammatory, antiallergic, among others (Andrade et al. 2013; Michalak and Chojnacka 2015; Martínez et al. 2021).

Macroalgae could constitute a great alternative as a source of potential compounds as natural biopreservatives in food industry due to their antimicrobial potential widely reported in literature (Cabral et al. 2021). Besides, their characteristic technological properties allow their incorporation in food matrices, improving their nutritional composition, their quality, their health-related benefits, as well as its shelf-life (Roohinejad et al. 2017).

The aim of this work was to evaluate the antimicrobial potential of extracts from the brown alga Ericaria selaginoides against the foodborne pathogen L. monocytogenes artificially inoculated in a Catalan fresh cheese (“mató”) chosen as food matrix. From the best of our knowledge, it is the first time that derived extracts from E. selaginoides have been assessed in a food matrix to improve the safety through the inhibition of the growth of relevant pathogens.

Material and methods

Macroalgae collection

The marine macroalga Ericaria selaginoides (Linnaeus) Molinari-Novoa and Guiry 2020 (Ochrophyta, Phaeophyceae, Fucales, Sargassaceae) (formerly Carpodesmia tamariscifolia (Hudson) Orellana & Sansón and Cystoseira tamariscifolia (Hudson) Papenfuss) was collected on rocky substrata in the lower intertidal and upper subtidal zones (< 1 m depth) in March 2020 in Comillas (Cantabria region, Spain) within the geographical coordinates 43° 23΄N / 4° 17΄W.

Apical and median parts of the thallus from adult specimens were selected and carefully washed with sterile seawater to remove sediments and epibionts. Then samples were wrapped in sterile cloths moistened with seawater and kept under darkness, humid atmosphere (> 84%) and cool conditions (< 15 °C) into expanded polystyrene boxes (EPS) to preserve algae until transport to our laboratory at IRTA (Monells, Spain). Samples were kept at -80 ºC until their processing. In the laboratory, algal biomass was ground and stored at -80 °C under vacuum and darkness conditions until extract preparation.

Seaweed extraction procedure

Crude extracts

Crude algae extract was prepared according to Rubiño et al. (2022a) using a mid-polarity extraction medium composed of a mixture of hexane–isopropanol-water in proportion 10:80:10 (v:v:v). Briefly, pooled supernatants (3000 xg, 10 min, 4 ºC) of three consecutive extractions performed at room temperature for 60 min were evaporated to dryness under vacuum at room temperature (Thermo Scientific Savant SpeedVac SPD120 Vacuum; Thermo Fisher Scientific, USA). The dried extract (5.48% fresh algae) was collected and then kept at -20 °C until further use (Section Preparation of extracts). Because of safety concern regarding to the use of some organic solvents to produce macroalgae extracts with possible further applications for food, in this study the current legislation was taken into consideration (2009/32/EC) (EC 2009) and food-grade solvents were selected.

Two-phase extraction procedure

Crude extract was also subjected to further purification by liquid–liquid separation. The crude extract was transferred into a separating funnel and hexane (VWR Chemicals, USA) was added in proportion 1:1 (v:v). The mixture was thoroughly shaken for 3 min and kept aside for layer separation. After clear phase separation, the top (non-polar) and bottom (mid-polar) phases were collected. The non-polar subfraction was evaporated to dryness at room temperature under vacuum and the mid-polar subfraction was lyophilized. The weight of dried subfractions was collected and then kept at -20 °C until further use (section Preparation of extracts).

Experimental design of the challenge test

Strains and culture conditions

The selected target bacterium, Listeria monocytogenes CTC1011 (serotype 1/2c) was a strain isolated from food that belongs to the IRTA-Food Safety and Functionality Program’s culture collection.

The recommendations given in the technical guidance document for conducting shelf-life studies on L. monocytogenes in RTE products (EURL Lm 2021) were followed to obtain early stationary phase and cold adapted culture. Stocks of L. monocytogenes were kept at -80 ºC in 20% glycerol as cryoprotectant. The bacterial culture was performed using BHI medium (Brain Heart Infusion broth, Oxoid Thermo Fisher Scientific, USA) in two consecutive steps; first an inoculum was incubated 18 h at 37 ºC and then 72 h at 8 ºC, until ca. 109 cfu mL−1. The physiological state of the cold adapted cells simulates the chilled real conditions usually found in food industry for RTE products.

Preparation of extracts

Prior to testing the antimicrobial activity of crude extract and the two subfractions (non-polar and mid-polar) in the fresh-cheese model, the crude extract and the non-polar subfraction were resuspended under sterile conditions in a mixture of water-glycerol-Tween 80 in proportion 80:10:10 (v:v:v), whereas the mid-polar subfraction was dissolved in sterile water.

The antimicrobial activity of extracts was previously assessed in vitro by means of agar-disk diffusion and microdilution plate assays (Rubiño et al. 2022b). The obtained Minimum Bactericidal Concentration (MBC) (6.54 mg mL−1) for the crude extract against L. monocytogenes was used as reference concentration to calculate the concentration of extract applied in the food matrix. In particular, three different concentrations were tested corresponding to 2 × , 4 × and 10 × the MBC for the crude extract. The selected concentrations MBC values for subfractions showed a mean MBC of 0.44 mg mL-1 and 4.29 mg mL-1 for the nonpolar and mid-polar, respectively” FOR " The MBC values for subfractions showed a mean of 0.44 mg mL-1 and 4.29 mg mL-1 for the non-polar and mid-polar, respectively. The amount to be tested was calculated according to the proportion they represent in the crude extract: 70% and 30% for non-polar and mid-polar subfractions, respectively. Thus, final extract concentrations used were: 14, 28 and 70 mg g−1 for crude extracts; 5, 10 and 20 mg g−1 for the non-polar subfraction and 10, 25 and 50 mg g−1 for the mid-polar subfraction.

Fresh cheese model: Preparation, inoculum, and storage conditions

A pasteurised cow’s milk fresh cheese typical from Catalonia called “mató” commercially available at local retailers, was selected as a food matrix. The labelled cheese composition was 10% fat (including 6.9% saturated fat), 8.3% protein, 3.1% carbohydrates (being 1.3% free sugars), 0.1% NaCl, 250 mg (100 g)−1 calcium (31% Nutrient Reference Values (NRV)), 165 mg (100 g)−1 phosphorous (23% NRV). Fresh cheese at the early stage of its shelf-life was used for the assays. Two independent trials using two batches of fresh cheese and newly dissolved crude extract and subfractions were performed on different days. Fresh cheese samples were prepared under aseptic environment into a biosafety cabinet (Scanlaf Mars Pro, Labogene, Denmark) in miniaturised format in 12-wells plates (Fig. 1).

Three gram of fresh cheese was weighed in each individual well and each concentration of prepared extract was added (0.45 v/w) in two wells (duplicate) into the food matrix. Afterwards, each well was inoculated (1% v/w) with 104 cfu g−1 of the L. monocytogenes culture and gently mixed with a sterile stick until complete homogenization. Two wells without any extract but inoculated with L. monocytogenes were used as control. One well without extracts nor L. monocytogenes inoculum was also included in the assay to verify the hygienic conditions of handling and storage (i.e., non-inoculated control).

The microtiter plates were covered and sealed in polyamide/polyethylene (PA/PE) bags (oxygen permeability of 50 cm3 m−2 per 24 h and low water vapor permeability of 2.8 g m−2 per 24 h) (Sistemvac, Estudi Graf S.A., Girona, Spain). Sealed 12-well microtiter plates were stored for 10 days at 8 °C. Temperature was constantly recorded by real-time wireless LABGUARD system (BioMerieux, Marcy l’Etoile, France).

Sampling scheme and analytical determinations

Variations in pH (Crison Instruments, Spain) and water activity (aw) by an Aqualab system (Ferrer Lab, Spain) were tested in representative sample of fresh-cheese model. The initial microbiological status of miniaturized cheeses was controlled by Enterobacteriaceae counts using the TEMPO system (Biomerieux, Marcy-l'Étoile, Francia) and total aerobic counts were also measured initially and at subsequent sampling times.

Microbial analyses were performed after 2 h of fresh cheese sample preparation being stored at 8 °C (t0) and almost every day in controls (t1, t2, t3, t4, t5, t6, t8, t10), whereas samples with seaweed extracts were assayed every 2 days (t2, t4, t6, t8, t10) during storage under refrigeration at 8 ºC.

Two gram of sample was weighed, diluted 1:10 in 0.1% Bacto Peptone physiological saline solution (Difco Laboratories, USA) with 0.85% NaCl and mixed thoroughly. Then, appropriate tenfold serial dilutions were performed in saline solution and spread onto CHROMagar Listeria plates (CHROMagar, France). Plate counting was performed after incubation at 37 °C after 48 h, with the detection limit set at 4 cfu g−1.

Growth curve fitting and statistical analysis

To estimate the growth kinetic parameters of L. monocytogenes, the primary growth model of Baranyi and Roberts (1994) was fitted to the log count data of each experiment using DMFit Add-in for MS-Excel (downloaded from ComBase portal, www.combase.cc). The goodness of fit was assessed by means of root-mean-square deviation (RMSE) and adjusted determined coefficient (R2adj).

The growth rate values allowed quantitative characterisation of the effect of the seaweed extract on the safe shelf-life of refrigerated cheese. From the food safety point of view, the growth rate values determine the time needed to reach the critical pathogen concentration of 100 cfu g−1, as the maximum level allowed by the microbiological criteria established by the Regulation (CE) 2073/2005 (EC 2005). A hypothetical initial contamination of 1 cfu g−1 was assumed as a conservative but reasonably foreseeable scenario (Ross 2010; Jofré et al. 2019). The “time to 2-log increase” was used as an indicator of the safe shelf-life (SSL, Hereu et al. 2014) of the product and was compared in relative terms (RSSL, expressed in fold-increase) with control cheese without extract to quantify the impact of the seaweed extract. The growth potential of L. monocytogenes was calculated by subtracting the initial log count to the maximum population density.

The effect of the concentration on the growth rate (µ) was statistically analysed by one-way analysis of variance (ANOVA), following post-hoc multiple pairwise comparison Tukey–Kramer test. The dose-dependent effect was analysed by comparison of linear regression slopes.

Results

Effect of seaweed crude extract on L. monocytogenes behaviour in fresh cheese

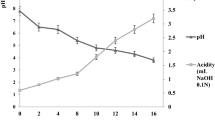

The effect of crude extracts over L. monocytogenes growth was tested using a traditional Catalan fresh cheese called “mató” as a food matrix. The extract addition into the food product had minimal effect on the aw (0.989 ± 0.002) and pH (6.76 ± 0.02) values. Total aerobic microorganisms and Enterobacteriaceae were under the limit of detection (< 10 cfu g−1 and < 100 cfu g−1, respectively) in the commercial product, and no colonies were counted in control samples without pathogen inoculation nor addition of extract during the storage time.

Figure 2 shows the behaviour of L. monocytogenes inoculated in fresh cheese with three increasing concentrations of E. selaginoides crude extract in comparison with the control fresh cheese.

The results of the growth kinetic parameters obtained from primary model fitting are presented in Table 1, together with the satisfactory goodness of fit indexes (i.e., R2adj = 0.78–0.99; SE = 0.05–0.37). The evaluation of the effect of purified subfractions of crude extract was undertaken in order to assess the chemical nature related to the antimicrobial activity against L. monocytogenes. To facilitate comparisons, equivalent amounts of purified subfractions based on the proportional content in crude extract of each subfraction (70% and 30%) were tested: 5, 10 and 20 mg g−1 for the non-polar subfraction and 10, 25 and 50 mg g−1 for the mid-polar subfraction.

Despite using concentrations 2× , 4× and 10× higher than MBC, no immediate listericidal effect was observed in any of the fresh cheeses, as little differences in the initial counts were observed after 2 h of inoculation. In control samples, average counts increased from 3.95 ± 0.14 to 8.06 ± 0.15 cfu g−1 after 10 days, with an average growth rate of 0.80 ± 0.06 days−1. In general, the effects observed on the growth rate of L. monocytogenes when exposed at increasing concentrations of the crude extract showed a statistically significant (ANOVA: F5,23 = 2.64, p < 0.001), with a clear dose-dependent relationship as shown by the statistically slope (p < 0.05) of the linear trend between the square root of the growth rate and the concentration of extracts (Fig. 3).

Dose–response effect of crude E. selaginoides extract and non-polar and mid-polar subfractions on the L. monocytogenes growth rate during the refrigerated storage (8 ºC) of fresh cheese. Dots (triangles, circles and squares) represent the square root of the growth rate of L. monocytogenes obtained from the primary model fitting, while lines are the linear model fit (p < 0.05)

Thus a slight effect on its growth rate was observed in cheeses supplemented at the lowest concentration (14 mg g−1). However, with intermediate concentration (28 mg g−1) growth rate halved, having a considerable impact in the safe shelf-life, which increased almost twice compared to the control cheese. The most remarkable effect was observed at the highest concentration of crude extract, since L. monocytogenes growth was completely inhibited during the 10 days of storage (growth potential < 0.5 log), therefore L. monocytogenes would not be relevant for setting the safe shelf-life of the product (EFSA BIOHAZ Panel (EFSA Panel on Biological Hazards) et al. 2020).

Effect of non-polar and mid-polar subfractions from crude extract on L. monocytogenes behaviour in fresh cheese

Results regarding the antilisterial activity of the non-polar subfraction are shown in Fig. 4, being the kinetic parameters summarised in Table 1. Slight differences in the growth of L. monocytogenes were observed between the control and the lowest concentration (5 mg g−1). However, the effect with the intermediate concentration (10 mg g−1) was more pronounced and almost halved the growth rate compared to the control. Samples with extract at the highest concentration (20 mg g−1) showed the highest antimicrobial effect against L. monocytogenes, with variable results between the two independent batches assayed, showing a listericidal effect in batch 1 (with almost 3 log reduction of the pathogen levels during the storage) and a listeriostatic effect (no growth) in batch 2.

Results of the mid-polar subfraction are shown in Fig. 5, being the kinetic parameters summarised in Table 1. The lowest concentration of the mid-polar subfraction (10 mg g−1) showed minor effect on the growth of Listeria as well as for the crude extract and non-polar subfraction. Moreover, the time to 2 log increase (5.44 ± 0.13 days) and the RSSL doubled since the growth rate decreased to 0.37 ± 0.01 days−1 at the intermediate concentration (25 mg g−1). Additionally, best results were also observed at the highest concentration (50 mg g−1) as the growth rate decreased 4 times comparing with the control. This meant more than fourfold increase of the safe shelf-life with respect to the control without extract.

Discussion

A traditional Catalan fresh cheese called “mató” was selected as a food matrix, since its pH and aw values together with low NaCl content and the absence of other antimicrobial preservatives, determine the inclusion of this product into 1.2 category of RTE products that supports the growth of L. monocytogenes according to the European Regulation (EC) 2073/2005 (EC 2005). The composition and the volume of the solvent mixture used for the addition of crude extract into the food product was carefully selected to have a minimal effect on the aw and pH values of the “mató” cheese matrix under experimental conditions. Moreover, storage temperature at 8 ºC was chosen to assess a worst-case scenario with a slight abuse of the refrigeration temperature corresponding to a reasonably foreseeable condition of the consumer stage (EURL Lm 2021; Jofré et al. 2019).

Total aerobic microorganisms and Enterobacteriaceae counts of the commercial product under the limit of detection ensured the microbiological hygienic quality of the commercial cheese, avoiding possible interferences between L. monocytogenes and endogenous microbiota. Furthermore, no colonies counted in control samples confirmed the hygienic handling conditions.

A broad mixture of valuable bioactive compounds, including lipophilic pigments (chlorophyll a and fucoxanthin), polyphenols, polysaccharides and other uncharacterised compounds have been extracted and assessed previously from E. selaginoides using a mid-polarity extraction medium including 0.73% fucoxanthin, 7.97% polyphenolic compounds and 3.57% carbohydrates (Rubiño et al. 2022b). Antimicrobial activity has been previously reported for these compounds (Pérez et al. 2016), as well as antilisterial activity of crude extract from E. selaginoides in in vitro assays (Rubiño et al. 2022b).

Antilisterial activity was reported testing chemical standard and purified fucoxanthin (1 mg mL−1) from Himanthalia elongata (Rajauria and Abu-Ghannam 2013). No more references testing antimicrobial activity of fucoxanthin against L. monocytogenes have been found in literature, however, other works have also reported activity of both commercial and purified fucoxanthin against other Gram-positive and Gram-negative target strains by disk diffusion and microdilution methods, with the effect stronger against Gram-positive strains (Karpinski and Adamczak 2019; Liu et al. 2019).

Antimicrobial activity of phenolic compounds from brown macroalgal species Laminaria digitata, Saccharina latissima and H. elongata against spoilage and foodborne pathogenic bacteria, including L. monocytogenes, was reported by Cox et al. (2010), as well as antilisterial activity of ethyl acetate fractions rich in phenolic compounds obtained from Ecklonia cava and Eisenia bicyclis with MIC values of 128–256 µg mL−1 (Cox et al. 2010; Nshimiyumukiza et al. 2014; Kim et al. 2018). Among polyphenolic compounds in brown algae, phlorotannins are reported to be the predominant class and have been described as molecules with antimicrobial potential found in algal extracts since their -OH groups can bind with the -NH groups of bacterial proteins and cause cell lysis (Ford et al. 2020). Although they are only composed of monomers of phloroglucinol (1,3,5‐trihydroxybenzene), there is limited knowledge about the macroalgae-derived phlorotannin profile because of their polymeric nature with diverse molecular weights together with the complexity of their molecular structure (Heffernan et al. 2015). Thus, quantification of extracted phlorotannins is usually recorded for total phenolic content. Currently, only low-molecular-weight phlorotannins (2–8 phloroglucinol units) have been described in the literature. Nevertheless, the occurrence of six phlorotannins has been reported in purified ethyl acetate fraction of E. bicyclis, such as eckol (EK), fucofuroeckol-A (FFA), 7-phloroeckol (7-P), dioxinodehydroeckol (DD), phlorofucofuroeckol (PFF) and dieckol (DE). Noticeable antilisterial activity was reported for FFA and PFF with MIC values that ranged 16–32, 32–128 µg mL−1, respectively, whereas the activity against L. monocytogenes of 7-P, DD and DE was moderate (64–128 µg mL−1) and minor in the case of EK (128–256 µg mL−1) (Kim et al. 2018).

Crude extract used in this study also co-extracted a proportion of polysaccharides (Rubiño et al. 2022b), which was assumed to be probably linked to polyphenols (Ayrapetyan et al. 2021). Brown macroalgae are a rich source of polysaccharides with diverse molecular structures such as alginates, laminarin and fucoidan (sulphated polysaccharide) (Stiger-Pouvreau et al. 2016). The antimicrobial effect against L. monocytogenes of laminarin-rich extracts from Laminaria hyperborea with MIC values of 2.6–7.0 mg mL−1 and in acidic extracts of Ascophyllum nodosum at MIC values of 59.7–66.8 mg mL−1 has been reported by Kadam et al. (2015). Antimicrobial activity of commercial fucoidan (74.2 g mol−1 weight-average molar mass) from Fucus vesiculosus against L. monocytogenes KCTC 13,064 achieving MIC values of 250 µg mL−1 has been also described (Jun et al. 2018). Antimicrobial activity was also reported in sulphated polysaccharides, mainly fucoidan, extracted from brown macroalgae including Sargassum sp., Saccharina japonica, Spatoglossum asperum and F. vesiculosus (Cabral et al. 2021). Poveda-Castillo et al. (2018) also evaluated the effect of commercial purified fucoidan (purity ≥ 95%) from F. vesiculosus against L. monocytogenes in apple beverage. Fucoidan added at concentration levels of 100 and 1000 µg mL−1 reduced bacterial population in 0.40 ± 0.02 and 0.70 ± 0.01 log respectively after 12 days of incubation at 8 ºC.

The identified presence of potential antimicrobial compounds of diverse nature in crude extracts of E. selaginoides studied in this work allows for the consideration that the observed antimicrobial effect could not be attributed to a single compound. The assumption is reinforced by the differences in dose-dependent effect that were also observed for the assayed subfractions. Thus, the concentration effect of the crude extract and the mid-polar subfraction on the growth rate of L. monocytogenes was significantly different to the observed for the non-polar subfraction (Fig. 4). It should be expected that an additive, synergic and/or antagonist action of the individual active compounds are affected by the interaction among the wide structural diversity of compounds occurring in the crude extract, such as polyphenols and polysaccharides. Indeed, the minimization of these interactions in the non-polar subfraction could be responsible of the observed differences in the antimicrobial effect between extracts.

Currently, few studies evaluating the potential of including whole macroalgae and/or their compounds/extracts against foodborne pathogens and spoilage bacteria are found in literature, aiming to assess the antimicrobial functionality of macroalgae in food matrices. Furthermore, although studies in this sense are still at an early stage, one of the main factors that limits the use of these innovative ingredients as food preservatives is the impact that can cause over the sensory attributes of food, influencing the acceptability by consumers (Cabral et al. 2021). Further purification steps could allow to get compounds with higher purity minimizing the impact in organoleptic features; i.e., Poveda-Castillo et al. (2018) reported that added commercial purified fucoidan with antilisterial activity in apple beverage remained organoleptic properties intact at all concentrations tested.

Legislative context according to L. monocytogenes control policies in RTE products

Considering the present results in the framework of current EU food safety regulations (EC 2005, 2007), the results of our study provide the scientific justification to include cheeses formulated with the highest concentration of crude extract of E. selaginoides and the non-polar subfraction into the category 1.3 of RTE food unable to support the growth of L. monocytogenes according to the Regulation (CE) 2073/2005 (EC 2005), as no more than 0.5 log units of pathogen growth are observed during the refrigerated storage of the product (EURL Lm 2021). Similarly, according to Health Canada policies (Health Canada 2011), also the formulation of cheese with high concentrations of extracts allowed to consider the product in the health risk 2. More specifically cheese containing crude extract and non-polar subfraction would be included in the category 2B as growth was inhibited during the studied shelf-life. In this last category, products receive a lower priority with regards to industry verification and control, as well as regulatory oversight and compliance activities. In other countries such as USA, applying zero tolerance against the occurrence of L. monocytogenes in RTE food (FSIS 2003a, b), use of high concentrations of the three extracts would allow the classification of the operating procedure into the Alternative 2b by the application of an AMA able to reduce or inhibit the growth of L. monocytogenes (less than 2 log increase during the stablished shelf-life).

Conclusions

This study showed that crude extract together with the non-polar subfraction of E. selaginoides at the highest concentration tested could totally inhibit the growth of L. monocytogenes artificially inoculated in fresh cheese (“mató”) during the refrigerated storage. Moreover, a listericidal effect was observed with the non-polar subfraction, which could even reduce L. monocytogenes level by ca. 3 log after 10 days of refrigerated storage in one batch. The observed dose-dependent effect provides useful information to justify proper concentrations in their application as a L. monocytogenes control strategy. Results of the present study extend knowledge for the application of brown macroalgae extracts as biopreservatives to minimize the risk of foodborne pathogens as L. monocytogenes in food products, emphasizing that a tailor-made approach based on specific product formulations, is important for validation and implementation of natural antimicrobials. Further research based on the purification of these extracts is needed to describe the active principle/s, which could allow to minimize the observed variability in the antimicrobial effect and address the drawbacks associated with the impact of the extracts on the sensory characteristics of the food matrix.

Data availability

The datasets generated and analysed during the current study are available from the corresponding author on reasonable request.

References

Andrade PB, Barbosa M, Matos R, Lopes G, Vinholes J, Mouga T, Valentão P (2013) Valuable compounds in macroalgae extracts. Food Chem 138:1819–1828

Araújo R, Vázquez Calderón F, Sánchez López J, Azevedo IC, Bruhn A, Fluch S, Garcia Tasende M, Ghaderiardakani F, Ilmjärv T, Laurans M, Mac Monagail M, Mangini S, Peteiro C, Rebours C, Stefansson T, Ullmann J (2021) Current status of the algae production industry in Europe: An emerging sector of the Blue Bioeconomy. Front Mar Sci 7:1247

Ayrapetyan ON, Obluchinskaya ED, Zhurishkina EV, Skorik YA, Lebedev DV, Kulminskaya AA, Lapina IM (2021) Antibacterial properties of fucoidans from the brown algae Fucus vesiculosus L. of the Barents Sea. Biology 10:67

Baranyi J, Roberts TA (1994) A dynamic approach to predicting bacterial growth in food. Int J Food Microbiol 23:277–294

Blunt JW, Copp BR, Munro MHG, Northcote PT, Prinsep MR (2011) Marine natural products. Nat Prod Rep 28:196–268

Bondi M, Lauková A, de Niederhausen S, Messi P, Papadopoulou C (2017) Natural preservatives to improve food quality and safety. J Food Qual 1090932:3

Bouzidi N, Viano Y, Ortalo-Magne A, Seridi H, Alliche Z, Daghbouche Y, Culioli G, El Hattab M (2019) Sterols from the brown alga Cystoseira foeniculacea: Degradation of fucosterol into saringosterol epimers. Arab J Chem 12:1474–1478

Cabral EM, Oliveira M, Modala JRM, Curtin J, Tiwari BK, García-Vaquero M (2021) Antimicrobials from seaweeds for food applications. Mar Drugs 19:211

Cox S, Abu-Ghannam N, Gupta S (2010) An assessment of the antioxidant and antimicrobial activity of six species of edible Irish seaweeds. Int Food Res J 17:205–220

Desai AN, Anyoha A, Lawrence CM, Lassmann B (2019) Changing epidemiology of Listeria monocytogenes outbreaks, sporadic cases, and recalls globally: A review of ProMED reports from 1996 to 2018. Int J Infect Dis 84:48–53

EFSA-ECDC (2021) The European Union one health 2020 zoonoses report. EFSA J 19:6971

EFSA Biohaz Panel (EFSA Panel on Biological Hazards), Koutsoumanis K, Allende A, Alvarez-Ordóñez A, Bolton D, Bover-Cid S, Chemaly M, Davies R, De Cesare A, Herman L, Nauta M, Peixe L, Ru G, Simmons M, Skandamis P, Suffredini E, Jacxsens L, Skjerdal T, Da Silva Felicio MT, Hempen M, Messens W, Lindqvist R (2020) Guidance on date marking and related food information: part 1 (date marking). EFSA J 18:6306

EFSA Biohaz Panel (EFSA Panel on Biological Hazards), Ricci A, Allende A, Bolton D, Chemaly M, Davies R, Fernández Escámez PS, Girones R, Herman L, Koutsoumanis K, Nørrung B, Robertson L, Ru G, Sanaa M, Simmons M, Skandamis P, Snary E, Speybroeck N, Ter Kuile B, Threlfall J, Wahlström H, Takkinen J, Wagner M, Arcella D, Da Silva Felicio MT, Georgiadis M, Messens W, Lindqvist R (2018) Scientific Opinion on the Listeria monocytogenes contamination of ready-to-eat foods and the risk for human health in the EU. EFSA J 16:5134

EC (European Commission) (2009) European Parliament & Council of the European Union, Directive 2009/32/EC of the European Parliament and of the Council of 23 April 2009 on the approximation of the laws of the Member States on extraction solvents used in the production of foodstuffs and food ingredients. Off J Eur Communities L 141:3–1

EC (European Commission) (2007) Commission Regulation (EC) No. 1447/2007 of 5 December 2007 amending Regulation (EC) No 2073/2005 on microbiological criteria for foodstuffs. Off J Eur Communities L 322:12–29

EC (European Commission) (2005) Commission Regulation (EC) No 2073/2005 of 15 November 2005 on microbiological criteria for foodstuff (Text with EEA relevance). Off J Eur Communities L 338:1–26

Eurl Lm (2021) Technical Guidance document on challenge tests and durability studies for assessing shelf-life of ready-to-eat foods related to Listeria monocytogenes.Anses – Food Safety Laboratory. Version 4 of 1 July 2021.

Ford L, Stratakos AC, Theodoridou K, Dick JTA, Sheldrake GN, Linton M, Corcionivoschi N, Walsh PJ (2020) Polyphenols from brown seaweeds as a potential antimicrobial agent in animal feeds. ACS Omega 5:9093–9103

FSIS (2003a) Control of Listeria monocytogenes in RTE meat and poultry products. Federal Register 68 FR 34208.

FSIS (2003b) Control of Listeria monocytogenes in post-lethality exposed Ready-to-Eat products. Federal Register 9 CFR 430.1.

Heffernan N, Brunton NP, FitzGerald RJ, Smyth TJ (2015) Profiling of the molecular weight and structural isomer abundance of macroalgae-derived phlorotannins. Mar Drugs 13:509–528

Health Canada (2011) Policy on Listeria monocytogenes in Ready-to-Eat Foods (DF-FSNP 421 0071). F.D. Bureau of Microbial Hazards, Health Products and Food Branch

Hereu A, Dalgaard P, Garriga M, Aymerich T, Bover-Cid S (2014) Analysing and modelling the growth behaviour of Listeria monocytogenes on RTE cooked meat products after a high pressure treatment at 400 MPa. Int J Food Microbiol 186:84–94

Hussain MA, Dawson CO (2013) Economic impact of food safety outbreaks on food business. Foods 2:585–589

Jofré A, Latorre-Moratalla ML, Garriga M, Bover-Cid S (2019) Domestic refrigerator temperatures in Spain: Assessment of its impact on the safety and shelf-life of cooked meat products. Food Res Int 126:108578

Jun JY, Jung MJ, Jeong IH, Yamazaki K, Kawai Y, Kim BM (2018) Antimicrobial and antibiofilm activities of sulphated polysaccharides from marine algae against dental plaque bacteria. Mar Drugs 16:301

Kadam SU, Donnell CP, Rai DK, Hossain MB, Burgess CM, Walsh D, Tiwari BK (2015) Laminarin from Irish brown seaweeds Ascophyllum nodosum and Laminaria hyperborea: Ultrasound assisted extraction, characterization and bioactivity. Mar Drugs 13:4270–4280

Karpinski TM, Adamczak A (2019) Fucoxanthin – An antibacterial carotenoid. Antioxidants 8:239

Kilinç B, Cirik S, Turan G, Tekogul H, Koru E (2013) Seaweeds for food and industrial applications. Chem Age India 33:475–482

Kim HJ, Dasagrandhi C, Kim SH, Kim BG, Eom SH, Kim YM (2018) In vitro antibacterial activity of phlorotannins from edible brown algae, Eisenia bicyclis against streptomycin-resistant Listeria monocytogenes. Indian J Microbiol 58:105–108

Leandro A, Pereira L, Goncąlves AMM (2020) Diverse applications of marine macroalgae. Mar Drugs 18:17

Lecuit M (2005) Understanding how Listeria monocytogenes targets and crosses host barriers. Clin Microbiol Infect 11:430–436

Liu Z, Xiaowen S, Xun S, Shuhui W, Ying X (2019) Fucoxanthin isolated from Undaria pinnatifida can interact with Escherichia coli and lactobacilli in the intestine and inhibit the growth of pathogenic bacteria. J Ocean Univ China 18:926–932

Martínez MA, Ares I, Martínez M, Lopez-Torres B, Maximiliano JE, Rodríguez JL, Martínez-Larrañaga MR, Anadón A, Peteiro C, Rubiño S, Hortós M (2021) Brown marine algae Gongolaria baccata extract protects Caco-2 cells from oxidative stress induced by tert-butyl hydroperoxide. Food Chem Toxicol 156:112460

Michalak I, Chojnacka K (2015) Algae as production systems of bioactive compounds. Eng Life Sci 15:160–176

Molinari-Novoa EA, Guiry MD (2020) Reinstatement of the genera Gongolaria Boehmer and Ericaria Stackhouse (Sargassaceae, Phaeophyceae). Notulae Algarum 172:1–10

Nshimiyumukiza O, Kang SK, Kim HJ, Lee EH, Han HN, Kim Y, Kim D, Kim JH, Eom SH, Kim YM (2014) Synergistic antibacterial activity of Ecklonia cava (Phaeophyceae: Laminariales) against Listeria monocytogenes (Bacillales: Listeriaceae). Fish Aquat Sci 18:1–6

Pérez MJ, Falqué E, Domínguez H (2016) Antimicrobial action of compounds from marine seaweed. Mar Drugs 14:52

Petruzzi L, Corbo MR, Sinigaglia M, Bevilacqua A (2017) Microbial spoilage of foods: Fundamentals. In: Bevilacqua A, Corbo MR, Sinigaglia M (eds) Microbiological quality of food: Foodborne spoilers. Woodhead Publishing, Cambridge, pp 1–21

Poveda-Castillo GDC, Rodrigo D, Martínez A, Pina-Pérez MC (2018) Bioactivity of fucoidan as antimicrobial agent in a new functional beverage. Beverages 4:64

Rajauria G and Abu-Ghannam N (2013) Isolation and partial characterization of bioactive fucoxanthin from Himanthalia elongata brown seaweed: A TLC-based approach. Int J Anal Chem 2013:02573

Roohinejad S, Koubaa M, Barba J, Saljoughian S, Amid M, Greiner R (2017) Application of seaweeds to develop new food products with enhanced shelf-life, quality and health related beneficial properties. Food Res Int 99:1066–1083

Ross T (2010) Defining "short shelf life" foods with respect to risk from Listeria monocytogenes. Food Safety Centre, University of Tasmania, ROCU 2688. 31 pp.

Rubiño S, Peteiro C, Aymerich T, Hortós M (2022a) Brown macroalgae (Phaeophyceae): A valuable reservoir of antimicrobial compounds on Northern coast of Spain. Mar Drugs 20:775

Rubiño S, Peteiro C, Aymerich T, Hortós M (2022b) Major lipophilic pigments in Atlantic seaweeds as valuable food ingredients: analysis and assessment of quantification methods. Food Res Int 159:111609

Statista Research Department (2021) Global per capita consumption of cheese 2020 by country. https://www.statista.com/statistics/527195/consumption-of-cheese-per-capita-worldwide-country/; accessed 25 April 2022

Stiger-Pouvreau V, Bourgougnon N, Deslandes E (2016) Carbohydrates from seaweeds. In: Fleurence J, Levine I (eds) Seaweed in health and disease prevention. Academic Press, Cambridge, pp 223–274

Thakur M, Asrani RK, Patial V (2018) Listeria monocytogenes: A food-borne pathogen. In: Grumezescu A, Holban AM (eds) Foodborne diseases. Academic Press, Cambridge, pp 157–192

Vrdoljak J, Dobranić V, Filipović I, Zdolec N (2016) Microbiological quality of soft, semi-hard and hard cheeses during the shelf-life. Macedonian Vet Rev 39:59–64

Acknowledgements

The authors thank the financing of the Spanish Ministry of Economy and Competitiveness (INIA Project: RTA2015-00010-C03-01), the CERCA Programme (Generalitat de Catalunya) and the Consolidated Research Group (2017 SGR 1650). Susana Rubiño acknowledges the FPI Ph.D. grant from the Spanish Ministry of Economy and Competitiveness (BES-2017-0027).

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This work was supported by the Spanish Ministry of Economy and Competitiveness (INIA Project: RTA2015-00010-C03-01), and by the Generalitat de Catalunya (CERCA Programme).

Author information

Authors and Affiliations

Contributions

Susana Rubiño: methodology, formal analysis, writing-original draft, investigation, and editing; Teresa Aymerich: conceptualization, methodology, formal analysis, investigation, writing-original draft, and review; César Peteiro: resources, investigation, and review; Sara Bover-Cid: methodology, formal analysis, review, and editing; Maria Hortós: funding acquisition, methodology, investigation, and review.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rubiño, S., Aymerich, T., Peteiro, C. et al. Antimicrobial potential of Ericaria selaginoides extracts against Listeria monocytogenes in “mató”, a Catalan fresh cheese. J Appl Phycol 35, 949–959 (2023). https://doi.org/10.1007/s10811-023-02923-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-023-02923-2