Abstract

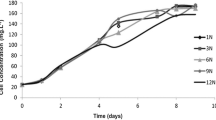

Fucoxanthin is one of the most important carotenoids and is found in diatoms such as Phaeodactylum tricornutum. The aim of this study was to evaluate the use of both the constant volumetric power consumption rate as scale-up strategy and the constant light energy per unit volume for transition from 1000-mL bottle to 2-L and 7-L flat plate photobioreactors for fucoxanthin production in P. tricornutum, considering whether an increase in the fucoxanthin yield could be achieved. The cell concentration and fucoxanthin content were enhanced with increasing the cultivation volume. It was found that the fucoxanthin yield increased 2.3 times in 2-L photobioreactor and 2.6 times in 7-L photobioreactor in comparison to the value of 1.05 mg g−1 dry weight in the cultivation bottle. Consequently, fucoxanthin production was successfully step-wise scaled-up from 1000-mL bottle to 7-L photobioreactor using both constant volumetric power consumption rate and the constant light energy per unit volume under laboratory conditions.

Similar content being viewed by others

References

Ascanio G, Castro B, Galindo E (2004) Measurement of power consumption in stirred vessels—a review. Chem Eng Res Design 82:1282–1290

Bailey JE, Ollis DF (1986) Biochemical Engineering Fundamentals. McGraw-Hill Chemical Engineering Series, New York, pp 984

Benavides AMS, Torzillo G, Kopecký J, Masojídek J (2013) Productivity and biochemical composition of Phaeodactylum tricornutum (Bacillariophyceae) cultures grown outdoors in tubular photobioreactors and open ponds. Biomass Bioenergy 54:115–122

Borowitzka MA, Volcani BE (1978) The polymorphic diatom Phaeodactylum tricornutum: ultrastructure of its morphotypes. J Phycol 14:10–21

Chini Zittelli G, Rodolfi L, Bassi N, Biondi N, Tredici M (2013) Photobioreactors for microalgae biofuel production. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 115–131

Choochote W, Suklampoo L, Ochaikul D (2014) Evaluation of antioxidant capacities of green microalgae. J Appl Phycol 26:43–48

Deng X-Y, Chen B, Li D, Hu X-L, Cheng J, Gao K, Wang C-H (2017) Growth and physiological responses of a marine diatom (Phaeodactylum tricornutum) against two imidazolium-based ionic liquids ([C4mim] BF4 and [C8mim] BF4). Aquat Toxicol 189:115–122

Deniz I, Imamoglu E, Sukan FV (2015) Evaluation of scale-up parameters of bioethanol production from Escherichia coli KO11/[Escherichia coli KO11 suşundan biyoetanol üretimi için ölçek büyütme parametrelerinin değerlendirilmesi]. Turk J Biochem 40:74–80

Erdoğan A, Çağır A, Dalay MC, Eroğlu AE (2015) Composition of carotenoids in Scenedesmus protuberans: application of chromatographic and spectroscopic methods. Food Analyt Meth 8:1970–1978

Gilbert-López B, Barranco A, Herrero M, Cifuentes A, Ibáñez E (2017) Development of new green processes for the recovery of bioactives from Phaeodactylum tricornutum. Food Res Int 99:1056–1065

Gómez-Loredo A, Benavides J, Rito-Palomares M (2016) Growth kinetics and fucoxanthin production of Phaeodactylum tricornutum and Isochrysis galbana cultures at different light and agitation conditions. J Appl Phycol 28:849–860

Guillard RR, Ryther JH (1962) Studies of marine planktonic diatoms: I. Cyclotella nana Hustedt, and Detonula confervacea (Cleve) Gran. Can J Microbiol 8:229–239

Imamoglu E, Sukan FV (2013) Scale-up and kinetic modeling for bioethanol production. Bioresour Technol 144:311–320

Kim SM, Jung Y-J, Kwon O-N, Cha KH, Um B-H, Chung D, Pan C-H (2012) A potential commercial source of fucoxanthin extracted from the microalga Phaeodactylum tricornutum. Appl Biochem Biotechnol 166:1843–1855

Lepetit B, Goss R, Jakob T, Wilhelm C (2012) Molecular dynamics of the diatom thylakoid membrane under different light conditions. Photosynth Res 111:245–257

Marques MP, Cabral J, Fernandes P (2010) Bioprocess scale-up: quest for the parameters to be used as criterion to move from microreactors to lab-scale. J Chem Technol Biotechnol 85:1184–1198

Mikami K, Hosokawa M (2013) Biosynthetic pathway and health benefits of fucoxanthin, an algae-specific xanthophyll in brown seaweeds. Int J Mol Sci 14:13763–13781

Mirón AS, Garcıa MCC, Gómez AC, Camacho FG, Grima EM, Chisti Y (2003) Shear stress tolerance and biochemical characterization of Phaeodactylum tricornutum in quasi steady-state continuous culture in outdoor photobioreactors. Biochem Eng J 16:287–297

Ogbonna JC, Yada H, Tanaka H (1995) Light supply coefficient: a new engineering parameter for photobioreactor design. J Ferment Bioeng 80:369–376

Petrushkina M, Gusev E, Sorokin B, Zotko N, Mamaeva A, Filimonova A, Kulikovskiy M, Maltsev Y, Yampolsky I, Guglya E (2017) Fucoxanthin production by heterokont microalgae. Algal Res 24:387–393

Prestegard SK, Erga SR, Steinrücken P, Mjøs SA, Knutsen G, Rohloff J (2015) Specific metabolites in a Phaeodactylum tricornutum strain isolated from western Norwegian fjord water. Mar Drugs 14(1):9

Reyna-Velarde R, Cristiani-Urbina E, Hernández-Melchor DJ, Thalasso F, Cañizares-Villanueva RO (2010) Hydrodynamic and mass transfer characterization of a flat-panel airlift photobioreactor with high light path. Chem Eng Process Process Intensif 49:97–103

Riveros K, Sepulveda C, Bazaes J, Marticorena P, Riquelme C, Acién G (2018) Overall development of a bioprocess for the outdoor production of Nannochloropsis gaditana for aquaculture. Aquac Res 49(1):165–176

Sanchez S, Demain AL (2008) Metabolic regulation and overproduction of primary metabolites. Microb Biotechnol 1:283–319

Seely G, Duncan M, Vidaver W (1972) Preparative and analytical extraction of pigments from brown algae with dimethyl sulfoxide. Mar Biol 12:184–188

Sierra E, Acién F, Fernández J, García J, González C, Molina E (2008) Characterization of a flat plate photobioreactor for the production of microalgae. Chem Eng J 138:136–147

Steinrücken P, Prestegard SK, de Vree JH, Storesund JE, Pree B, Mjøs SA, Erga SR (2018) Comparing EPA production and fatty acid profiles of three Phaeodactylum tricornutum strains under western Norwegian climate conditions. Algal Res 30:11–22

Takache H, Pruvost J, Cornet JF (2012) Kinetic modelling of the photosynthetic growth of Chlamydomonas reinhardtii in a photobioreactor. Biotechnol Prog 28:681–692

Tesson B, Genet MJ, Fernandez V, Degand S, Rouxhet PG, Martin-Jezequel V (2009) Surface chemical composition of diatoms. ChemBioChem 10:2011–2024

Ugwu C, Aoyagi H, Uchiyama H (2008) Photobioreactors for mass cultivation of algae. Bioresour Technol 99:4021–4028

Vasumathi K, Premalatha M, Subramanian P (2012) Parameters influencing the design of photobioreactor for the growth of microalgae. Renew Sustain Energy Rev 16:5443–5450

Xia S, Wang K, Wan L, Li A, Hu Q, Zhang C (2013) Production, characterization, and antioxidant activity of fucoxanthin from the marine diatom Odontella aurita. Mar Drugs 11:2667–2681

Xu K, Lv B, Huo Y-X, Li C (2018) Toward the lowest energy consumption and emission in biofuel production: combination of ideal reactors and robust hosts. Curr Opin Biotechnol 50:19–24

Yadala S, Cremaschi S (2014) Design and optimization of artificial cultivation units for algae production. Energy 78:23–39

Zhao P, Zang Z, Xie X, Huang A, Wang G (2014) The influence of different flocculants on the physiological activity and fucoxanthin production of Phaeodactylum tricornutum. Process Biochem 49:681–687

Acknowledgments

This study was a part of Cost action ES1408 and this study was financially supported by the Scientific and Technological Research Council of Turkey (TUBITAK) with the project number of 115M014.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aslanbay Guler, B., Deniz, I., Demirel, Z. et al. Transition from start-up to scale-up for fucoxanthin production in flat plate photobioreactor. J Appl Phycol 31, 1525–1533 (2019). https://doi.org/10.1007/s10811-018-1696-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-018-1696-7