Abstract

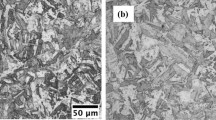

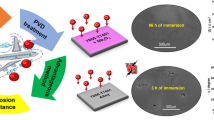

Microbially influenced corrosion is one of the main issues of concern in industries due to its significant economic impact. In this work, we focused on Lacticaseibacillus paracasei, a typical microorganism identified in the corrosion products of aircraft fuel systems. The corrosion behavior of the 7B04 aluminum alloy was investigated using electrochemical measurements. The surface morphology was examined using stereomicroscopy and scanning electron microscopy. It was observed that when the Al alloy was immersed in the bacterial system, the impedance value decreased and the corrosion current density increased compared to the sterile system. Furthermore, with increasing immersion time, the pH value was found to be smaller than that in the sterile system, indicating that the acidic metabolic products of the bacteria exacerbated the corrosion. These findings were further supported by surface analyses, and the corrosion mechanism was discussed.

Graphical abstract

Similar content being viewed by others

Data availability

All data and materials are available

References

Sabel CF, Victor DG (2015) Governing global problems under uncertainty: making bottom-up climate policy work. Clim Change 144:15–27. https://doi.org/10.1007/s10584-015-1507-y

Xu D, Li Y, Song F et al (2013) Laboratory investigation of microbiologically influenced corrosion of C1018 carbon steel by nitrate reducing bacterium Bacillus licheniformis. Corros Sci 77:385–390. https://doi.org/10.1016/j.corsci.2013.07.044

Wang J, Lv M, Du M et al (2022) Effects of cathodic polarization on X65 steel inhibition behavior and mechanism of mixed microorganisms induced corrosion in seawater. Corros Sci. https://doi.org/10.1016/j.corsci.2022.110670

Alasvand Zarasvand K, Rai VR (2014) Microorganisms: induction and inhibition of corrosion in metals. Int Biodeterior Biodegrad 87:66–74. https://doi.org/10.1016/j.ibiod.2013.10.023

Kong L, Liu C, Cao M et al (2018) Mechanism study of the role of biofilm played in sewage corrosion of mortar. Constr Build Mater 164:44–56. https://doi.org/10.1016/j.conbuildmat.2017.12.190

Guan F, Duan J, Zhai X et al (2020) Interaction between sulfate-reducing bacteria and aluminum alloys—corrosion mechanisms of 5052 and Al-Zn-In-Cd aluminum alloys. J Mater Sci Technol 36:55–64. https://doi.org/10.1016/j.jmst.2019.07.009

Wang J, Xiong F, Liu H et al (2019) Study of the corrosion behavior of Aspergillus niger on 7075–T6 aluminum alloy in a high salinity environment. Bioelectrochemistry 129:10–17. https://doi.org/10.1016/j.jmst.2019.07.009

Qian H, Zhang D, Cui T et al (2021) Accelerating effect of catalase on microbiologically influenced corrosion of 304 stainless steel by the halophilic archaeon Natronorubrum tibetense. Corros. Sci 178:109057. https://doi.org/10.1016/j.corsci.2020.109057

Marciales A, Peralta Y, Haile T et al (2019) Mechanistic microbiologically influenced corrosion modeling—a review. Corros Sci 146:99–111. https://doi.org/10.1016/j.corsci.2018.10.004

Lv M, Du M, Li Z (2022) Investigation of mixed species biofilm on corrosion of X65 steel in seawater environment. Bioelectrochemistry 143:107951. https://doi.org/10.1016/j.bioelechem.2021.107951

Li Y, Xu D, Chen C et al (2018) Anaerobic microbiologically influenced corrosion mechanisms interpreted using bioenergetics and bioelectrochemistry: a review. J Mater Sci Technol 34:1713–1718. https://doi.org/10.1016/j.jmst.2018.02.023

Jia R, Unsal T, Xu D et al (2019) Microbiologically influenced corrosion and current mitigation strategies: a state of the art review. Int Biodeterior Biodegrad 137:42–58. https://doi.org/10.1016/j.ibiod.2018.11.007

Li S, Li L, Qu Q et al (2019) Extracellular electron transfer of Bacillus cereus biofilm and its effect on the corrosion behaviour of 316L stainless steel. Colloids Surf B 173:139–147. https://doi.org/10.1016/j.colsurfb.2018.09.059

Li S, Qu Q, Li L et al (2019) Bacillus cereus s-EPS as a dual bio-functional corrosion and scale inhibitor in artificial seawater. Water Res 166:115094. https://doi.org/10.1016/j.watres.2019.115094

Capelossi VR, Poelman M, Recloux I et al (2014) Corrosion protection of clad 2024 aluminum alloy anodized in tartaric-sulfuric acid bath and protected with hybrid sol–gel coating. Electrochim. Acta 124:69–79. https://doi.org/10.1016/j.electacta.2013.09.004

Kalita SJ (2011) Microstructure and corrosion properties of diode laser melted friction stir weld of aluminum alloy 2024 T351. Appl Surf Sci 257(9):3985–3997. https://doi.org/10.1016/j.apsusc.2010.11.163

Dalmoro V, Dos Santos JHZ, Armelin E et al (2013) A synergistic combination of tetraethylorthosilicate and multiphosphonic acid offers excellent corrosion protection to AA1100 aluminum alloy. Appl Surf Sci 273:758–768. https://doi.org/10.1016/j.apsusc.2013.02.131

Brown LM, Mccomb JP, Vangsness MD et al (2010) Community dynamics and phylogenetics of bacteria fouling Jet A and JP-8 aviation fuel. Int Biodeterior Biodegrad 64:253–261. https://doi.org/10.1016/j.ibiod.2010.01.008

Passman FJ (2013) Microbial contamination and its control in fuels and fuel systems since 1980—a review. Int Biodeterior Biodegrad 81:88–104. https://doi.org/10.1016/j.ibiod.2012.08.002

He J, Tan Y, Liu H et al (2022) Extracellular polymeric substances secreted by marine fungus Aspergillus terreus: full characterization and detailed effects on aluminum alloy corrosion. Corros Sci 09:110703. https://doi.org/10.1016/j.corsci.2022.110703

Vejar DN (2016) Enhanced corrosion of 7075 alloy by the presence of Bacillus megaterium. Int J Electrochem Sci 11:9723–9733. https://doi.org/10.20964/2016.11.33

Zhang Y, He J, Zheng L et al (2022) Corrosion of aluminum alloy 7075 induced by marine Aspergillus terreus with continued organic carbon starvation. NPJ Mater Degrad 6:7. https://doi.org/10.1038/s41529-022-00236-2

Abdoli L, Huang J, Li H (2016) Electrochemical corrosion behaviors of aluminum-based marine coatings in the presence of Escherichia coli bacterial biofilm. Mater Chem Phys 173:62–69. https://doi.org/10.1016/j.matchemphys.2016.01.038

De Andrade JS, Vieira MRS, Oliveira SH et al (2020) Study of microbiologically induced corrosion of 5052 aluminum alloy by sulfate-reducing bacteria in seawater. Mater Chem Phys 241:122296. https://doi.org/10.1016/j.matchemphys.2019.122296

Jirón-Lazos U, Corvo F, De La Rosa SC et al (2018) Localized corrosion of aluminum alloy 6061 in the presence of Aspergillus niger. Int Biodeterior. Biodegrad 133:17–25. https://doi.org/10.1016/j.ibiod.2018.05.007

Wang S, Zhao X, Rong H et al (2022) Role of Lysinibacillus sphaericus on aviation kerosene degradation and corrosion of 7B04 aluminum alloy. J Mater Res Technol 18:2641–2653. https://doi.org/10.1016/j.jmrt.2022.03.148

Zhang T, Wang J, Zhang G et al (2020) The corrosion promoting mechanism of Aspergillus niger on 5083 aluminum alloy and inhibition performance of miconazole nitrate. Corros Sci 176:108930. https://doi.org/10.1016/j.corsci.2020.108930

Dai X, Wang H, Ju L-K et al (2016) Corrosion of aluminum alloy 2024 caused by Aspergillus niger. Int Biodeterior Biodegrad 115:1–10. https://doi.org/10.1016/j.ibiod.2016.07.009

Liu T, Cheng YF (2017) The influence of cathodic protection potential on the biofilm formation and corrosion behaviour of an X70 steel pipeline in sulfate reducing bacteria media. J Alloys Compd 729:180–188. https://doi.org/10.1016/j.jallcom.2017.09.181

Guan F, Zhai X, Duan J et al (2017) Influence of sulfate-reducing bacteria on the corrosion behavior of 5052 aluminum alloy. Surf Coat Technol 316:171–179. https://doi.org/10.1016/j.surfcoat.2017.02.057

Liu H, Fu C, Gu T et al (2015) Corrosion behavior of carbon steel in the presence of sulfate reducing bacteria and iron oxidizing bacteria cultured in oilfield produced water. Corros Sci 100:484–495. https://doi.org/10.1016/j.corsci.2015.08.023

Liu H, Gu T, Asif M et al (2017) The corrosion behavior and mechanism of carbon steel induced by extracellular polymeric substances of iron-oxidizing bacteria. Corros Sci 114:102–111. https://doi.org/10.1016/j.corsci.2016.10.025

Xu D, Xia J, Zhou E et al (2017) Accelerated corrosion of 2205 duplex stainless steel caused by marine aerobic Pseudomonas aeruginosa biofilm. Bioelectrochemistry 113:1–8. https://doi.org/10.1016/j.bioelechem.2016.08.001

Jia R, Yang D, Xu D et al (2017) Electron transfer mediators accelerated the microbiologically influence corrosion against carbon steel by nitrate reducing Pseudomonas aeruginosa biofilm. Bioelectrochemistry 118:38–46. https://doi.org/10.1016/j.bioelechem.2017.06.013

Tian X, Liu X, Zhang Y et al (2021) Metabolic engineering coupled with adaptive evolution strategies for the efficient production of high-quality L-lactic acid by Lactobacillus paracasei. Bioresour Technol 323:124549. https://doi.org/10.1016/j.biortech.2020.124549

Trueba M, Trasatti SP (2010) Study of Al alloy corrosion in neutral NaCl by the pitting scan technique. Mater Chem Phys 121:523–533. https://doi.org/10.1016/j.matchemphys.2010.02.022

Sachan R, Singh AK (2020) Comparison of microbial influenced corrosion in presence of iron oxidizing bacteria (strains DASEWM1 and DASEWM2). Constr Build Mater 256:119438. https://doi.org/10.1016/j.conbuildmat.2020.119438

Vejar N, Gutierrez S, Tareelap N et al (2022) Influence of Bacillus safensis and Bacillus pumilus on the electrochemical behavior of 2024–T3 aluminum alloy. Bioelectrochemistry 143:107950. https://doi.org/10.1016/j.bioelechem.2021.107950

Ma S, ZhaoY PuJ, Zhao Z et al (2019) Effect of welding speed on performance of friction stir welded spray forming 7055 aluminum alloy. J Manuf Process 46:304–316. https://doi.org/10.1016/j.jmapro.2019.08.019

He L, Jia P, Zhang L, Cui J (2016) Evolution of secondary phases and properties of 7B04 aluminum alloy during DC homogenization. Trans Nonferrous Met Soc China 26:319–327. https://doi.org/10.1016/S1003-6326(16)64122-5

Kawasaki Y, Fukui S, Fukuyama T (2022) Phenomenological process of rebar corrosion in reinforced concrete evaluated by acoustic emission and electrochemical noise. Constr Build Mater 352:128829. https://doi.org/10.2139/ssrn.4064367

Liu Y, Zhang J, Wei Y et al (2019) Effect of different UV intensity on corrosion behavior of carbon steel exposed to simulated Nansha atmospheric environment. Mater Chem Phys 237:121855. https://doi.org/10.1016/j.matchemphys.2019.121855

Al-Qutub A, Laoui T, Zulhazmi G et al (2022) Evaluation of durability of alumina, silicon carbide and siliconized silicon carbide foams as absorber materials for concentrated solar power applications. Sol Energy 242:45–55. https://doi.org/10.1016/j.solener.2022.07.008

Sowa M, Olesiński A, Szumski B et al (2022) Electrochemical characterization of anti-corrosion coatings formed on 6061 aluminum alloy by plasma electrolytic oxidation in the corrosion inhibitor-enriched aqueous solutions. Electrochim Acta 424:140652. https://doi.org/10.1016/j.electacta.2022.140652

Yang C, Dou W, Pittman CC et al (2020) Microbiologically influenced corrosion behavior of friction stir welded S32654 super austenitic stainless steel in the presence of Acidithiobacillus caldus SM-1 biofilm. Mater Today Commun 25:101491. https://doi.org/10.1016/j.mtcomm.2020.101491

Jia R, Yang D, Abd Rahman HB et al (2017) Laboratory testing of enhanced biocide mitigation of an oilfield biofilm and its microbiologically influenced corrosion of carbon steel in the presence of oilfield chemicals. Int Biodeterior Biodegrad 125:116–124. https://doi.org/10.1016/j.ibiod.2017.09.006

Zhou E, Wang J, Moradi M et al (2020) Methanogenic archaea and sulfate reducing bacteria induce severe corrosion of steel pipelines after hydrostatic testing. J Mater Sci Technol 48:72–83. https://doi.org/10.1016/j.jmst.2020.01.052

Huang H, Tian J, Zhang G et al (2016) The corrosion of X52 steel at an elbow of loop system based on array electrode technology. Mater Chem Phys 181:312–320. https://doi.org/10.1016/j.matchemphys.2016.06.064

Zeng L, Zhang GA, Guo XP et al (2015) Inhibition effect of thioureidoimidazoline inhibitor for the flow accelerated corrosion of an elbow. Corros Sci 90:202–215. https://doi.org/10.1016/j.corsci.2014.10.011

San NO, Nazır H, Dönmez G (2014) Microbially influenced corrosion and inhibition of nickel–zinc and nickel–copper coatings by Pseudomonas aeruginosa. Corros Sci 79:177–183. https://doi.org/10.1016/j.corsci.2013.11.004

Paul PK, Yadav M (2020) Investigation on corrosion inhibition and adsorption mechanism of triazine-thiourea derivatives at mild steel/HCl solution interface: electrochemical, XPS, DFT and Monte Carlo simulation approach. J Electroanal Chem 877:114599. https://doi.org/10.1016/j.jelechem.2020.114599

Zhang W, Zhang T, Zhu Z et al (2022) Corrosion electrochemistry properties of thermally sprayed Zn–Cu–Ti coating in simulated ocean atmosphere. J Mater Res Technol 21:3235–3247. https://doi.org/10.1016/j.jmrt.2022.10.108

Lei X, Wang H, Mao F et al (2018) Electrochemical behaviour of martensitic stainless steel after immersion in a H2 S-saturated solution. Corros Sci 131:164–173. https://doi.org/10.1016/j.corsci.2017.10.015

Ju H, Liu S, Zhang W et al (2021) Investigation of pitting corrosion and hydrogen evolution of aluminum and AA2024 alloy by simultaneous electrochemical measurements and imaging. Electrochem Commun 132:107135. https://doi.org/10.1016/j.elecom.2021.107135

Zhang W, Wu Y-C, Li H-J (2021) Apostichopus japonicus polysaccharide as efficient sustainable inhibitor for mild steel against hydrochloric acid corrosion. J Mol Liq 321:114923. https://doi.org/10.1016/j.elecom.2021.107135

Moradi M, Yang Y, Xu D et al (2021) Interspecies interactions of Vibrio azureus and Jeotgalibacillus alkaliphilus on corrosion of duplex stainless steel. Int Biodeterior Biodegrad 160:105212. https://doi.org/10.1016/j.ibiod.2021.105212

Tian X, Liu X, Zhang Y et al (2018) Exploring cellular fatty acid composition and intracellular metabolites of osmotic-tolerant mutant Lactobacillus paracasei NCBIO-M2 for highly efficient lactic acid production with high initial glucose concentration. J Biotechnol 286:27–35. https://doi.org/10.1016/j.jbiotec.2018.09.005

Yang C, Shuo F, Chun A et al (2015) Production of optically pure l-lactic acid from lignocellulosic hydrolysate by using a newly isolated and d-lactate dehydrogenase gene-deficient Lactobacillus paracasei strain. Bioresour Technol 198:651–657. https://doi.org/10.1016/j.biortech.2015.09.071

Wang Y, Cao W, Luo J et al (2019) One step open fermentation for lactic acid production from inedible starchy biomass by thermophilic Bacillus coagulans IPE22. Bioresour Technol 272:398–406. https://doi.org/10.1016/j.biortech.2018.10.043

Acknowledgements

The work was supported by Shandong Provincial Natural Science Foundation, China (ZR2020QD081, ZR2021QD060), the Green innovation science and technology plan of colleges and universities in Shandong Province (No. 2020KJA014), National Natural Science Foundation of China (52101392) and Graduate Innovation Foundation of Yantai University, GIFYTU (No. KGIFYTU2314).

Author information

Authors and Affiliations

Contributions

ZZ carried out the experiments, performed the data analyses and wrote the manuscript. XG contributed to specifically performing the experiments and writing the original draft. BS contributed to data collection. WF contributed to data curation. JY contributed to the organization of experimental data. XZ contributed to investigation, conducting a research investigation process, and project administration. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

We confirm that this work is original and has not been published elsewhere, nor is currently under consideration for publication elsewhere. All the authors listed have agreed to publish the manuscript that is enclosed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, Z., Ge, X., Fan, W. et al. Research on accelerating the corrosion of 7B04 aluminium alloy in the Lacticaseibacillus paracasei environment. J Appl Electrochem 54, 381–392 (2024). https://doi.org/10.1007/s10800-023-01959-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-023-01959-z