Abstract

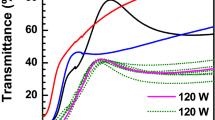

The deposition parameters used during the sputtering process are instrumental in determining the properties of the deposited films and can be optimised to produce thin film coatings that are suitable for specific engineering applications. Deposition parameters such as radio frequency (RF) power, oxygen flow rate, and substrate temperature can be varied during deposition to alter or tune the film structure, stoichiometry, and invariably the functional properties of the prepared thin films. In this paper, chromium oxide thin films prepared by reactive magnetron sputtering under various RF powers were characterised for their work function property and stability in Ringer’s solution. The structural, oxide phase and growth modes of the films were probed with X-ray diffraction (XRD), Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), and scanning electron microscope (SEM). The electrochemical stability and corrosion behaviour of the films were evaluated using an open circuit potential (OCP) measurements, cyclic polarisation, and Mott–Schottky analysis, while the work function (WF) was determined with a Kelvin probe. The XRD and Raman investigations showed that the films are predominantly amorphous with Cr2O3 being the main oxide phase. A mixture of columnar and layer-by-layer growth modes was observed in the deposited films with 500 W, 10 sccm sample showing rougher morphology due to the higher sputtering power. The OCP and cyclic polarisation results showed that the film prepared at a deposition power of 300 W and at an oxygen flow rate of 10 sccm possesses higher film passivation and breakdown potentials, hence, better corrosion resistance when compared to films prepared at higher deposition powers. The finding is further supported by the Mott–Schottky and work function investigations where the same film also showed lower defect density and higher work function values compared to the films deposited at higher powers. A correlation was found between the corrosion, work function and defect density which suggests that both parameters can possibly be used to predict and rank corrosion in thin films. We expect our findings to be significant for future corrosion and wear applications for metals/alloys requiring protection against environmental degradation.

Graphical abstract

Similar content being viewed by others

References

Wint N, Warren DJ, Devooys ACA, Mcmurray HN (2020) The use of chromium and chromium (III) oxide PVD coatings to resist the corrosion driven coating delamination of organically coated packaging steel. Electrochem Soc 167:141506

Oje AM, Ogwu AA, Rahman SU, Oje AI, Tsendzughul N (2019) Effect of temperature variation on the corrosion behaviour and semiconducting properties of the passive film formed on chromium oxide coatings exposed to saline solution. Corros Sci. https://doi.org/10.1016/j.corsci.2019.04.004

Barshilia HC, Rajam KS (2008) Growth and characterization of chromium oxide coatings prepared by pulsed-direct current reactive unbalanced magnetron sputtering. Appl Surf Sci 255:2925–2931

Liu H, Tao J, Xu J, Chen Z, Gao Q (2009) Corrosion and tribological behaviors of chromium oxide coatings prepared by the glow-discharge plasma technique. Surf Coat Technol 204:28–36

Oje AM, Ogwu AA (2017) Chromium oxide coatings with the potential for eliminating the risk of chromium ion release in orthopaedic implants. R Soc Open Sci 4:170218

Ji AL, Wang W, Song GH, Wang QM, Sun C, Wen LS (2004) Microstructures and mechanical properties of chromium oxide films by arc ion plating. Mater Lett 58:1993–1998

Pang X, Gao K, Luo F, Yang H, Qiao L, Wang Y, Volinsky AA (2008) Annealing effects on microstructure and mechanical properties of chromium oxide coatings. Thin Solid Films 516:4685–4689

Mohammadtaheri M, Yang Q, Li Y, Corona-Gomez J (2018) The effect of deposition parameters on the structure and mechanical properties of chromium oxide coatings deposited by reactive magnetron sputtering. Coatings 8:111

Al-Kuhaili MF, Durrani SMA (2007) Optical properties of chromium oxide thin films deposited by electron-beam evaporation. Opt Mater (Amst) 29:709–713

Ivanova T, Surtchev M, Gesheva K (2001) Characterization of CVD chromium oxide thin films. Phys Status Solidi 184:507–513

Hones P, Diserens M, Lévy F (1999) Characterization of sputter-deposited chromium oxide thin films. Surf Coat Technol. https://doi.org/10.1016/S0257-8972(99)00384-9

Wang D, Lin J, Ho W (1998) Study on chromium oxide synthesized by unbalanced magnetron sputtering. Thin Solid Films 332:295–299

Sousa PM, Silvestre AJ, Popovici N, Conde O (2005) Morphological and structural characterization of CrO2/Cr2O3 films grown by Laser-CVD. Appl Surf Sci 247:423–428

Misho RH, Murad WA, Fattahallah GH (1989) Preparation and optical properties of thin films of chromium oxide prepared by the method of chemical spray pyrolysis. Thin Film Solids 169:235–239

Luo F, Pang X, Gao K, Yang H, Wang Y (2007) Role of deposition parameters on microstructure and mechanical properties of chromium oxide coatings. Surf Coat Technol 202:58–62

Oje AM, Ogwu AA, Oje AI, Tsendzughul N, Ur Rahman S (2019) Influence of RF power on the stoichiometry, optical, and electrical properties of chromium oxide coatings prepared by reactive magnetron sputtering. Mater Res Express 6:066408

Yang M, Wang P, Li Y, Tang S, Lin X, Zhang H, Zhu Z, Chen F (2022) Graphene aerogel-based NiAl-LDH/g-C3N4 with ultratight sheet-sheet heterojunction for excellent visible-light photocatalytic activity of CO2 reduction. Appl Catal B 306:121065. https://doi.org/10.1016/j.apcatb.2022.121065

Yang Y, Chen Y, Li Z, Tang S, Li Y, Fu Z, Yang S, Yang M, Xie H (2022) Homojunction type of carbon nitride as a robust photo-catalyst for reduction conversion of CO2 in water vapor under visible light. Chem Eng J 430:132668. https://doi.org/10.1016/j.cej.2021.132668

Jin Z, Yanbing Li XH (2021) Ni, Co-based selenide anchored g-C3N4 for boosting photocatalytic hydrogen evolution. Acta Phys -Chim Sin 37:1912033

Luo F, Gao K, Pang X, Yang H, Qiao L, Wang Y (2008) Characterization of the mechanical properties and failure modes of hard coatings deposited by RF magnetron sputtering. Surf Coat Technol 202:3354–3359

Pang X, Gao K, Volinsky AA (2007) Microstructure and mechanical properties of chromium oxide coatings. J Mater Res 22:3531–3537

Hong S, Kim E, Kim D-W, Sung T-H, No K (1997) On measurement of optical band gap of chromium oxide films containing both amorphous and crystalline phases. J Non Cryst Solids 221:245–254

Khamlich S, Manikandan E, Ngom BD, Sithole J, Nemraoui O, Zorkani I, McCrindle R, Cingo N, Maaza M (2011) Synthesis, characterization, and growth mechanism of α-Cr2O3 monodispersed particles. J Phys Chem Solids 72:714–718

Mougin J, Bihan TL, Lucazeau G (2001) High-pressure study of Cr2O3 obtained by high-temperature oxidation by X-ray diffraction and Raman spectroscopy. J Phys Chem 62:553–563

Ogwu AA, Oje AM, Kavanagh J (2016) Corrosion, ion release and Mott-Schottky probe of chromium oxide coatings in saline solution with potential for orthopaedic implant applications. Mater Res Express 3:45401

Edgar A, Jairo O, Cubillos G (2012) Thin film growth through sputtering technique and its applications. Cryst - Sci Technol 23:11–12

Gilmer GH, Huang H, Roland C (1998) Thin Film deposition: fundamentals and modeling. Comput Mater Sci 12:354–380

Kavanagh JG (2012) The effect of RF sputtering deposition parameters on the functional properties of chromium oxide thin films (Ph.D. Thesis, School of Engineering and Computing, University of the West of Scotland, United Kingdom)

Oje AM, Ogwu AA, Oje AI, Tsendzughul N, Rahman SU (2020) A comparative study of the corrosion and ion release behaviour of chromium oxide coatings exposed to saline, Ringer’s and Hank’s physiological solutions. Corros Sci 167:108533

Oje AM, Ogwu AA, Kavanagh J, Gibson D, Mirzaeian M (2015) The effect of growth conditions on the surface energy, optical properties and saline corrosion resistance of amorphous chromium oxide thin films prepared by reactive magnetron sputtering. In: 58th annual technical conference proceedings, Santa Clara, CA April 25–30, pp 1–7

Ogwu AA, Hellwig T (2014) Boron phosphide protective coatings for hazardous radioactive waste and geothermal power applications. Int J Electrochem Sci 9:8299–8319

Jackson MJ, Ahmed W (2012) Surface engineered surgical tools and medical devices. Springer, Boston

Oje AI, Ogwu AA, Mirzaeian M, Oje AM, Tsendzughul N (2019) Silver thin film electrodes for supercapacitor application. Appl Surf Sci 488:142–150

Oje AI, Ogwu AA, Oje AM (2021) Effect of temperature on the electrochemical performance of silver oxide thin films supercapacitor. J Electroanal Chem 882:115015

Oje AI, Ogwu AA, Mirzaeian M, Tsendzughul N, Oje AM (2019) Pseudo-capacitance of silver oxide thin film electrodes in ionic liquid for electrochemical energy applications. J Sci Adv Mater Devices 4:213–222. https://doi.org/10.1016/j.jsamd.2019.04.003

Li H, Jiang Z, Feng H, Wang Q, Zhang W, Fan G, Li G (2015) Electrochemical corrosion characteristics of super duplex stainless steel S32750 in LT-MED environment. Int J Electrochem Sci 10:1616–1631

Hakiki NE, Montemor MF, Ferreira MGS, da Cunha Belo M (2000) Semiconducting properties of thermally grown oxide films on AISI 304 stainless steel. Corros Sci 42:687–702

Hakiki NB, Boudin S, Rondot B, Da Cunha Belo M (1995) The electronic structure of passive films formed on stainless steels. Corros Sci 37:1809–1822

Ferreira MGS, Da Cunha Belo M, Hakiki NE, Goodlet G, Montemor MF, Simõesa AMP (2002) Semiconducting properties of oxide and passive films formed on AISI 304 stainless steel and Alloy 600. J Braz Chem Soc 13:433–440

Ferreira MGS, Hakiki NE, Goodlet G, Faty S, Simoes AMP, Belo MD (2001) Influence of the temperature of film formation on the electronic structure of oxide films formed on 304 stainless steel. Electrochim Acta 46:3767–3776

Ogwu AA, Okpalugo TIT, Ali N, Maguire PD, McLaughlin JAD (2008) Endothelial cell growth on silicon modified hydrogenated amorphous carbon thin films. J Biomed Mater Res B 85:105–113

Kim JS, Lägel B, Moons E, Johansson N, Baikie ID, Salaneck WR, Friend RH, Cacialli F (2000) Kelvin probe and ultraviolet photoemission measurements of indium tin oxide work function: a comparison. Synth Met 111:311–314

Fujii R, Gotoh Y, Liao MY, Tsuji H, Ishikawa J (2006) Work function measurement of transition metal nitride and carbide thin films. Vacuum 80:832–835

Greiner MT, Chai L, Helander MG, Tang WM, Lu ZH (2012) Transition metal oxide work functions: the influence of cation oxidation state and oxygen vacancies. Adv Funct Mater 22:4557–4568

Funding

We received no funding for the study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare we have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Oje, A.M., Ogwu, A.A. & Oje, A.I. An investigation of the work function and stability of chromium oxide thin films deposited by reactive magnetron sputtering. J Appl Electrochem 52, 1551–1562 (2022). https://doi.org/10.1007/s10800-022-01718-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-022-01718-6