Abstract

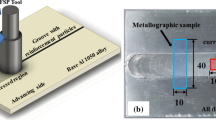

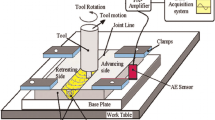

In this paper, aluminum composites reinforced by the Ti2SC MAX phase were fabricated through friction stir processing (FSP). The effects of FSP and the addition of Ti2SC MAX phase on the electrochemical behavior of the surface composite were studied in a 3.5 wt. % NaCl solution. Optical microscopy (OM) and scanning electron microscopy, along with energy-dispersive spectroscopy (SEM–EDS), were employed to investigate the microstructure of the samples. The corrosion behavior of the base metal and FSPed samples with and without Ti2SC-reinforcement particles was examined by different electrochemical methods such as cyclic voltammetry (CV), potentiodynamic polarization, and electrochemical impedance spectroscopy (EIS). Microstructural studies revealed that FSP leads to fine grain structure and reduction in Al2CuMg strengthening precipitates content. The corrosion behavior of Al2024 depends on microstructural characteristics such as grain size, Ti2SC-reinforcement particle size, and distribution of Al2CuMg precipitates. The dissolution of second phase particles (Al2CuMg) present in Al2024 aluminum increases the corrosion resistance of the Al2024 alloy. Also, adding the Ti2SC MAX phase improved the corrosion resistance of the surface composites.

Graphic abstract

Similar content being viewed by others

References

Polmear I, St John D, Nie J-F, Qian M (2017) Light alloys: metallurgy of the light metals, 5th edn. Elsevier Inc., Amsterdam

Melchers RE (2015) Time dependent development of aluminium pitting corrosion. Adv Mater Sci Eng 2015:1–10. https://doi.org/10.1155/2015/215712

Revie RW (2011) Uhlig’s corrosion handbook, 3rd edn. Wiley, New Jersey

Koli DK, Agnihotri G, Purohit R (2014) A review on properties, behaviour and processing methods for Al-Nano Al2O3 composites. Procedia Mater Sci 6:567–589. https://doi.org/10.1016/j.mspro.2014.07.072

Kumar S, Reddy SK, Joshi SV (2017) Microstructure and performance of cold sprayed Al-SiC composite coatings with high fraction of particulates. Surf Coatings Technol 318:62–71. https://doi.org/10.1016/j.surfcoat.2016.11.047

Ramgopal T, Gouma PI, Frankel GS (2002) Role of grain-boundary precipitates and solute-depleted zone on the intergranular corrosion of aluminum alloy 7150. Corrosion 58:687–697. https://doi.org/10.5006/1.3287699

Ma ZY (2008) Friction stir processing technology: a review. Metall Mater Trans A Phys Metall Mater Sci 39(3):642–658. https://doi.org/10.1007/s11661-007-9459-0

Chanakyan C, Sivasankar S, Meignanamoorthy M et al (2020) Friction stir processing (FSP) of numerical study based on design of experiment-review. Mater Today Proc 27:748–751. https://doi.org/10.1016/j.matpr.2019.12.035

Paidar M, Ojo OO, Ezatpour HR, Heidarzadeh A (2019) Influence of multi-pass FSP on the microstructure, mechanical properties and tribological characterization of Al/B4C composite fabricated by accumulative roll bonding (ARB). Surf Coatings Technol 361:159–169. https://doi.org/10.1016/j.surfcoat.2019.01.043

Moustafa E (2017) Effect of multi-pass friction stir processing on mechanical properties for AA2024/Al2O3 nanocomposites. Materials (Basel) 10:1053. https://doi.org/10.3390/ma10091053

Sharma R, Singh AK, Arora A et al (2019) Effect of friction stir processing on corrosion of Al-TiB2 based composite in 3.5 wt.% sodium chloride solution. Trans Nonferrous Met Soc China 29:1383–1392. https://doi.org/10.1016/S1003-6326(19)65045-4

Soleymani S, Abdollah-zadeh A, Alidokht SA (2012) Microstructural and tribological properties of Al5083 based surface hybrid composite produced by friction stir processing. Wear 278–279:41–47. https://doi.org/10.1016/j.wear.2012.01.009

Surekha K, Murty BS, Rao KP (2008) Microstructural characterization and corrosion behavior of multipass friction stir processed AA2219 aluminium alloy. Surf Coatings Technol 202:4057–4068. https://doi.org/10.1016/j.surfcoat.2008.02.001

Rao AG, Katkar VA, Gunasekaran G et al (2014) Effect of multipass friction stir processing on corrosion resistance of hypereutectic Al-30Si alloy. Corros Sci 83:198–208. https://doi.org/10.1016/j.corsci.2014.02.013

Salehi M, Saadatmand M, Aghazadeh Mohandesi J (2012) Optimization of process parameters for producing AA6061/SiC nanocomposites by friction stir processing. Trans Nonferrous Met Soc China 22:1055–1063. https://doi.org/10.1016/S1003-6326(11)61283-1

Mazaheri Y, Heidarpour A, Jalilvand MM, Roknian M (2019) Effect of friction stir processing on the microhardness, wear and corrosion behavior of Al6061 and Al6061/SiO2 nanocomposites. J Mater Eng Perform 28:4826–4837. https://doi.org/10.1007/s11665-019-04260-3

Sun ZM (2011) Progress in research and development on MAX phases: a family of layered ternary compounds. Int Mater Rev 56:143–166. https://doi.org/10.1179/1743280410Y.0000000001

Manochehrian A, Heidarpour A, Mazaheri Y, Ghasemi S (2019) On the surface reinforcing of A356 aluminum alloy by nanolayered Ti3AlC2 MAX phase via friction stir processing. Surf Coatings Technol 377:124884. https://doi.org/10.1016/j.surfcoat.2019.08.013

Hosseini SM, Heidarpour A, Ghasemi S (2020) Effects of ball milling sequences on the in-situ reactive synthesis of the Ti2SC MAX phase. Adv Appl Ceram 119:204–211. https://doi.org/10.1080/17436753.2020.1732637

Hodder KJ, Izadi H, McDonald AG, Gerlich AP (2012) Fabrication of aluminum-alumina metal matrix composites via cold gas dynamic spraying at low pressure followed by friction stir processing. Mater Sci Eng A 556:114–121. https://doi.org/10.1016/j.msea.2012.06.066

Ghanbari D, Kasiri Asgarani M, Amini K, Gharavi F (2017) Influence of heat treatment on mechanical properties and microstructure of the Al2024/SiC composite produced by multi–pass friction stir processing. Meas J Int Meas Confed 104:151–158. https://doi.org/10.1016/j.measurement.2017.03.024

Abdi behnagh R, Besharati Givi MK, Akbari M (2012) Mechanical properties, corrosion resistance, and microstructural changes during friction stir processing of 5083 aluminum rolled plates. Mater Manuf Process 27:636–640. https://doi.org/10.1080/10426914.2011.593243

Surekha K, Murty BS, Prasad Rao K (2011) Comparison of corrosion behaviour of friction stir processed and laser melted AA 2219 aluminium alloy. Mater Des 32:4502–4508. https://doi.org/10.1016/j.matdes.2011.03.033

Karimi S, Ghahreman A, Rashchi F (2018) Kinetics of Fe(III)-Fe(II) redox half-reactions on sphalerite surface. Electrochim Acta 281:624–637. https://doi.org/10.1016/j.electacta.2018.05.132

Wei YK, Luo XT, Ge Y et al (2019) Deposition of fully dense Al-based coatings via in-situ micro-forging assisted cold spray for excellent corrosion protection of AZ31B magnesium alloy. J Alloys Compd 806:1116–1126. https://doi.org/10.1016/j.jallcom.2019.07.279

Rahsepar M, Jarahimoghadam H (2016) The influence of multipass friction stir processing on the corrosion behavior and mechanical properties of zircon-reinforced Al metal matrix composites. Mater Sci Eng A 671:214–220. https://doi.org/10.1016/j.msea.2016.05.056

Khatami R, Fattah-alhosseini A, Keshavarz MK (2017) Effect of grain refinement on the passive and electrochemical behavior of 2024 Al alloy. J Alloys Compd 708:316–322. https://doi.org/10.1016/j.jallcom.2017.03.031

Li JF, Ziqiao Z, Na J, Chengyu T (2005) Localized corrosion mechanism of 2×××-series Al alloy containing S(Al2CuMg) and θ′(Al2Cu) precipitates in 4.0% NaCl solution at pH 6.1. Mater Chem Phys 91:325–329. https://doi.org/10.1016/j.matchemphys.2004.11.034

Guillaumin V, Mankowski G (1998) Localized corrosion of 2024 T351 aluminium alloy in chloride media. Corros Sci 41:421–438. https://doi.org/10.1016/S0010-938X(98)00116-4

Mahmoud TS (2008) Effect of friction stir processing on electrical conductivity and corrosion resistance of AA6063-T6 Al alloy. Proc Inst Mech Eng Part C J Mech Eng Sci 222:1117–1123. https://doi.org/10.1243/09544062JMES847

Flores JF, Neville A, Kapur N, Gnanavelu A (2012) Corrosion and erosion-corrosion processes of metal-matrix composites in slurry conditions. J Mater Eng Perform 21:395–405. https://doi.org/10.1007/s11665-011-9926-z

Ni DR, Xiao BL, Ma ZY et al (2010) Corrosion properties of friction-stir processed cast NiAl bronze. Corros Sci 52:1610–1617. https://doi.org/10.1016/j.corsci.2010.02.026

Narimani M, Lotfi B, Sadeghian Z (2015) Investigating the effect of tool dimension and rotational speed on microstructure of Al-B4C surface composite layer produced by friction stir processing (FSP). J Adv Mater Process 3:61–70

Jalilvand MM, Mazaheri Y, Heidarpour A, Roknian M (2019) Development of A356/Al2O3+SiO2 surface hybrid nanocomposite by friction stir processing. Surf Coatings Technol 360:121–132. https://doi.org/10.1016/j.surfcoat.2018.12.126

Navaser M, Atapour M (2017) Effect of friction stir processing on pitting corrosion and intergranular attack of 7075 aluminum alloy. J Mater Sci Technol 33:155–165. https://doi.org/10.1016/j.jmst.2016.07.008

Surekha K, Murty BS, Prasad Rao K (2009) Effect of processing parameters on the corrosion behaviour of friction stir processed AA2219 aluminum alloy. Solid State Sci 11:907–917. https://doi.org/10.1016/j.solidstatesciences.2008.11.007

Buchheit RG, Grant RP, Hlava PF et al (1997) Local dissolution phenomena associated with s phase (Al2CuMg) particles in aluminum alloy 2024–T3. J Electrochem Soc 144:2621–2628. https://doi.org/10.1149/1.1837874

Liu Z, Chong PH, Skeldon P et al (2006) Fundamental understanding of the corrosion performance of laser-melted metallic alloys. Surf Coatings Technol 200:5514–5525. https://doi.org/10.1016/j.surfcoat.2005.07.108

Esmailzadeh S, Aliofkhazraei M, Sarlak H (2018) Interpretation of cyclic potentiodynamic polarization test results for study of corrosion behavior of metals: a review. Prot Met Phys Chem Surfaces 54:976–989. https://doi.org/10.1134/S207020511805026X

Argade GR, Panigrahi SK, Mishra RS (2012) Effects of grain size on the corrosion resistance of wrought magnesium alloys containing neodymium. Corros Sci 58:145–151. https://doi.org/10.1016/j.corsci.2012.01.021

Domínguez-Crespo MA, Torres-Huerta AM, Rodil SE et al (2010) XPS and EIS studies of sputtered Al-Ce films formed on AA6061 aluminum alloy in 3.5% NaCl solution. J Appl Electrochem 40:639–651. https://doi.org/10.1007/s10800-009-0039-4

Zhang Z, Liu F, Han EH, Xu L (2020) Mechanical and corrosion properties in 3.5% NaCl solution of cold sprayed Al-based coatings. Surf Coatings Technol 385:135539. https://doi.org/10.1016/j.surfcoat.2020.125372

Dong CF, Sheng H, An YH et al (2010) Corrosion of 7A04 aluminum alloy under defected epoxy coating studied by localized electrochemical impedance spectroscopy. Prog Org Coatings 67:269–273. https://doi.org/10.1016/j.porgcoat.2009.11.004

Burstein SH (2020) The chemistry, biology and pharmacology of the cyclopentenone prostaglandins. Prostaglandins Other Lipid Mediat 148:106408. https://doi.org/10.1016/j.prostaglandins.2020.106408

Liu J, Zhao K, Yu M, Li S (2018) Effect of surface abrasion on pitting corrosion of Al-Li alloy. Corros Sci 138:75–84. https://doi.org/10.1016/j.corsci.2018.04.010

Cao M, Liu L, Yu Z et al (2019) Electrochemical corrosion behavior of 2A02 Al alloy under an accelerated simulation marine atmospheric environment. J Mater Sci Technol 35:651–659. https://doi.org/10.1016/j.jmst.2018.09.060

Zhang W, Frankel GS (2003) Transitions between pitting and intergranular corrosion in AA2024. Electrochim Acta 48:1193–1210. https://doi.org/10.1016/S0013-4686(02)00828-9

Liu Y, Meng GZ, Cheng YF (2009) Electronic structure and pitting behavior of 3003 aluminum alloy passivated under various conditions. Electrochim Acta 54:4155–4163. https://doi.org/10.1016/j.electacta.2009.02.058

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heidarpour, A., Mousavi, Z.S., Karimi, S. et al. On the corrosion behavior and microstructural characterization of Al2024 and Al2024/Ti2SC MAX phase surface composite through friction stir processings. J Appl Electrochem 51, 1123–1136 (2021). https://doi.org/10.1007/s10800-021-01567-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-021-01567-9