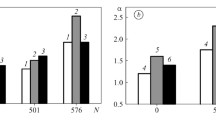

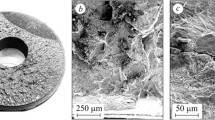

An assessment of the survivability time was performed for the following two parts made of 10Kh9MFB-Sh steel at 600°C and maximum allowable metal stresses: a pipe measuring 630 mm in diameter and having a wall thickness of 25 mm, and a pipe billet produced by electroslag remelting (ESR) technique. The specific feature of the proposed procedure consists in testing samples containing an extra deep and sharp notch. To determine the time to breaking, the notch opening rate was registered at an increased frequency of 0.003 h. It is shown that metal of the billet produced by the ESR technique has an advantage of longer service life in comparison with the hot-worked pipe. A simplified version of the procedure featuring fixed parameters of the breaking conditions is proposed for the base and weld metal.

Similar content being viewed by others

References

V. I. Gladshteyn, “Express-assessment of metal characteristics of high-temperature parts of turbines and steam lines made of high-chromium steel,” Élektr. Stantsii, No. 5, 27 – 33 (2010).

L. V. Dub and V. N. Skorobogatykh, “Material science and technology basis for creating an advanced thermal power equipment,” Teploénergetika, No. 4, 7 – 13 (2012).

TU 14-3P-55–2001. Steel Seamless Pipes for Boilers and Pipelines [in Russian].

TU 1301-039-00212179–2010. Seamless Pipes Made of Carbonaceous and Alloyed Steel, Produced by the ESR Method, for Pipelines of Thermal and Nuclear Power Plants [in Russian].

V. I. Gladshteyn, “Procedure for predicting long-term strength of steel and alloys by continuity variation diagram under continuous loading,” Zavod. Lab., 62(4), 55 – 60 (1996).

L. M. Kachanov, Fundamentals of Fracture Mechanics [in Russian], Nauka, Moscow (1974).

V. I. Gladshtein, Microdamaging of Metal of High-Temperature Components of the Power Equipment [in Russian], Mashinostroenie, Moscow (2014).

STO 70238424.27.100.005–2008. Basic Elements of Boilers, Turbines, and Pipelines of Thermal Power Plants. Metal Condition Control. Norms and Requirements [in Russian], RAO “UES of Russia,” Moscow (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Électricheskie Stantsii, No. 1, January 2019, pp. 8 – 15.

Rights and permissions

About this article

Cite this article

Gladshtein, V.I., Troitskii, A.I. Prediction of Survivability Time for Express Assessment of Long-Term Performance of Steam Line Metal Parts Made of Steel 10Kh9MFB-Sh. Power Technol Eng 53, 200–207 (2019). https://doi.org/10.1007/s10749-019-01060-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10749-019-01060-6