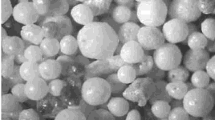

The results of the preparation of strengthened syntactic carbon materials that can be used for industrial-grade heat insulation in conditions of heightened pressures and temperatures are presented. Strengthened syntactic carbon material is obtained by mixing hollow carbon microspheres, pre-treated with vanadium (III) chloride catalyst, with a phenol-formaldehyde binder with the addition of fine polydimethylsilane, molding the composition at low pressure, soaking the mold at 150°C for 2 h, followed by heat treatment in an inert environment at 375°C and final carbonization in combination with carbidization when the temperature rises at a rate of 100 K/h to 900°C. The physicomechanical and thermophysical characteristics were studied. Syntactic material can be used for the manufacture of heat-insulation products operating at high temperatures.

Similar content being viewed by others

References

K. R. Dando, W. M. Cros, M. J. Robinson, et al., “Production and characterization of epoxy syntactic foams highly loaded with thermoplastic microballoons,” J. Cellular Plastics, 54(3), 499 – 514 (2017). DOI: https://doi.org/10.1177/0021955X17700093

Chandar J. Vishnu, D. Mutharasu, K. Mohamed, et al., “High thermal conductivity, UV-stabilized poly(3-hydroxybutyrateco-3-hydroxyvalerate) hybrid composites for electronic applications: effect of different hybrid fillers on structural, thermal, optical, and mechanical properties,” Polymer-Plastics Technol. Mater., 60(12), 1273 – 1291 (2021). DOI: https://doi.org/10.1080/25740881.2021.1888990

E. E. Mastalygina, V. A. Ovchinnikov, and V. Yu. Chukhlanov, “Light heat-resistant polymer concretes based on oligooxyhydridesilmethylensiloxysilane and hollow spherical fillers,” Magazine Civil Eng., 90(6), 37 – 46 (2019). DOI: https://doi.org/10.18720/MCE.90.4

E. M. Wouterson, F. Y. Boey, X. Hu, et al., “Specific properties and fracture toughness of syntactic foam: Effect of foam microstructures,” Comp. Sci. Technol., No. 65, 1840 – 1847 (2005).

Q. A. Hemn, K. J Dilshad, and A. Y. Sinan, “Flexural strength and failure of geopolymer concrete beams reinforced with carbon fibre-reinforced polymer bars,” Constr. Build. Mater., No. 231, 117185 (2020). DOI: https://doi.org/10.1016/j.conbuildmat.2019.117185

M. S. A. Rahaman, A. F. Ismail, and A. Mustafa, “A review of heat treatment on polyacrylonitrile fiber polymer,” Degradation and Stability, 92(8), 1421 – 1432 (2007). DOI: https://doi.org/10.1016/j.polymdegradstab.2007.03.023

H. Q. Ly, R. Taylor, and R. J. Day, “Conversion of polycarbosilane (PCS) to SiC-based ceramic. Part I, Characterization of PCS and Curing product,” J. Mater. Sci., No. 36, 4037 – 4043 (2001). DOI:https://doi.org/10.1023/A:1017942826657

D. Frazer, M. D. Abad, D. Krumwiede, et al., “Localized mechanical property assessment of SiC/SiC composite materials,” Composites Pt. A: Appl. Sci. Manuf., No. 70, 93 – 101 (2015). DOI: https://doi.org/10.1016/j.compositesa.2014.11.008

C. G. Anirudh, A. A. Jayalakshmi, Kandasubramanian Balasubramanian, et al. “Epoxy/hollow glass microsphere syntactic foams for structural and functional application – A review,” Eurp. Polymer J., 171, 111163 (2022). DOI: https://doi.org/10.1016/j.eurpolymj.2022.111163

S. Yajima, Y. Hasegawa, K. Okamura, et al., “Development of high tensile strength silicon carbide fibre using an organosilicon polymer precursor,” Nature, No. 273(5663), 525 – 527 (1978). DOI:https://doi.org/10.1038/273525a0

Thermal Conductivity Measuring Device ITP-MG4. Operating Manual E 12.102.010RE [in Russian], SKB “Stroipribor,” Chelyabinsk (2020).

C. M. Zheng, X. D. Li, H. Wang, et al., “Thermal stability and curing kinetics of polycarbosilane fibers,” Trans. Nonfer. Met. Soc. China, No. 16, 44 – 48 (2006). DOI: https://doi.org/10.1016/S1003-6326(06)60008-3

This work was performed as part of the state assignment in the field of scientific activity of the Ministry of Science and Higher Education of the Russian Federation (topic FZUN-2020-0015, state assignment of VlSU). The research was performed using the equipment of the interregional multidisciplinary and interdisciplinary center for the collective use of promising and competitive technologies in the areas of development and application in industry/mechanical engineering of domestic achievements in the field of nanotechnology (agreement No. 075-15-2021-692 of August 5, 2021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 9, pp. 44 – 49, September, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chukhlanov, V.Y., Smirnova, N.N., Krasilnikova, I.A. et al. Ceramic-Forming Organosilicon Polymer as a Modifier of Heat-Insulating Syntactic Material. Glass Ceram 80, 385–388 (2024). https://doi.org/10.1007/s10717-023-00618-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-023-00618-1