Abstract

As the cutting stone is a wear process, performing this process with diamond pieces' aid can be considered the wear of stone particles bypassing diamond grains on its surface. To better understand this process as well as the conditions governing the cutting diamond grain, it is necessary to be familiar with the cutting mechanism along with affecting parameters. In this case, forecasting the quantity of bead consumption is crucial for calculating manufacturing costs and mapping out the locations of the construction stone mines. In order to calculate the consumption of diamond cutting wire beads, this article used data collected from carbonate and granite stones. To do so, two methods, namely support vector regression (SVR) and genetic algorithm + Multilayer perceptron (GA-MLP), were chosen using MATLAB software toolboxes to estimate the bead wear. In each of above algorithms, a low-pass smoothing filter called Savitzky-Golay was used on the data. For this purpose, three rock properties, including uniaxial compressive strength (UCS), Schmiazek abrasivity factor (SFa), and Young's modulus (YM), were employed as the model's input. Then, twelve models were constructed, and the bead wear was estimated as well. At last, the accuracy of above models was assessed using the coefficient of determination (\({R}^{2}\)), mean square error (MSE), root mean square error (RMSE), mean absolute error (MAE), mean absolute percentage error (MAPE), and variance account for (VAF). According to obtained results, it can be concluded that SVR approach and the Savitzky-Golay filter with Polynomial Kernel could better estimate the wear rate of diamond cutting wire bead.

Similar content being viewed by others

Availability of data and material

Not applicable.

Notes

American Telephone & Telegraph.

References

Agus M, Bortolussi A, Careddu N, Ciccu R, Grosso B, Massacci G (2003) Influence of stone properties on diamond wire performance. In: Fourth international conference on computer applications in the minerals industries (CAMI 2003)

Almasi SN, Bagherpour R, Mikaeil R, Ozcelik Y (2017) Analysis of bead wear in diamond wire sawing considering the rock properties and production rate. Bull Eng Geol Environ 76(4):1593–1607. https://doi.org/10.1007/s10064-017-1057-9

Ataei M, Mikaiel R, Sereshki F, Ghaysari N (2012) Predicting the production rate of diamond wire saw using statistical analysis. Arab J Geosci 5(6):1289–1295. https://doi.org/10.1007/s12517-010-0278-z

Ataei M (2009) Building stones. Shahroud University of Technology Publications, Shahroud, Iran

Bagherpour R, Khademian A, Almasi SN, Aalaei M (2014) Optimum cutting wire assembly in dimension stone quarries. J Mining Metall Section a: Mining 50(1):1–8

Brown ET (1981) Rock characterization, testing & monitoring: ISRM suggested methods. International Society for Rock Mechanics, Oxford

Burges CJ (1998) A tutorial on support vector machines for pattern recognition. Data Min Know Discov 2(2):121–167. https://doi.org/10.1023/A:1009715923555

Cai O, Careddu N, Mereu M, Mulas I (2007) The influence of operating parameters on the total productivity of diamond wire in cutting granite. Ind Diamond Rev 67(3):25–32

Careddu N, Perra ES, Masala O (2019) Diamond wire sawing in ornamental basalt quarries: technical, economic and environmental considerations. Bull Eng Geol Environ 78(1):557–568. https://doi.org/10.1007/s10064-017-1112-6

Holland JH (1992) Adaptation in natural and artificial systems. MIT Press, US

Huang G, Xu X (2013) Sawing performance comparison of brazed and sintered diamond wires. Chin J Mech Eng 26(2):393–399. https://doi.org/10.3901/CJME.2013.02.393

Jain S, Rathore SS (2011) Prediction of cutting performance of diamond wire saw machine in quarrying of marble: a neural network approach. Rock Mech Rock Engin 44(3):367–371. https://doi.org/10.1007/s00603-011-0137-6

Jalil K, Raza S (2019) Cost estimation for bench drilling phase of diamond wire sawing technique for granite mining. Int J Sci Res Public 9(3):2250–3153

Kumar A, Suresh Y (2016) Multilayer feed forward neural network to predict the speed of wind. 2016 International Conference on Computation System and Information Technology for Sustainable Solutions (CSITSS). IEEE. https://doi.org/10.1109/CSITSS.2016.7779372

Luo J, Ying K, Bai J (2005) Savitzky-golay smoothing and differentiation filter for even number data. Sig Process 85(7):1429–1434. https://doi.org/10.1016/j.sigpro.2005.02.002

Mikaeil R, Haghshenas SS, Ozcelik Y, Gharehgheshlagh H (2018) Performance evaluation of adaptive neuro-fuzzy inference system and group method of data handling-type neural network for estimating wear rate of diamond wire saw. Geotech Geol Eng 36(6):3779–4379. https://doi.org/10.1007/s10706-018-0571-2

Özçelik Y (2005) Optimum working conditions of diamond wire cutting machines in the marble industry IDR. Indus Diam Rev 1:58–64

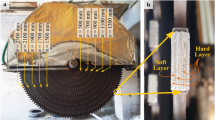

Ozcelik Y, Bayram F (2004) Optical investigations of bead wear in diamond wire cutting. IDR Ind Diam Rev 3:60–65

Ozcelik Y, Yilmazkaya E (2011) The effect of the rock anisotropy on the efficiency of diamond wire cutting machines. Int J Rock Mech Min Sci 48:626–636

Özcelik Y, Kulaksız S, Cetin MC (2002) Assessment of the wear of diamond beads in the cutting of different rock types by the ridge regression. J Mater Process Technol 127:392–400

Savitzky A, Golay MJ (1964) Smoothing and differentiation of data by simplified leas squares procedures. Analy Chem 36:1627–1639. https://doi.org/10.1021/ac60214a047

Smola AJ, Schölkopf B (2004) A tutorial on support vector regression. Stat Comput 14(3):199–222. https://doi.org/10.1023/B:STCO.0000035301.49549.88

Yilmazkaya E, Dagdelenler G, Ozcelik Y, Sonmez H (2018) Prediction of mono-wire cutting machine performance parameters using artificial neural network and regression models. Engin Geolog 239:96–108. https://doi.org/10.1016/j.enggeo.2018.03.009

Yilmazkaya E, Ozcelik Y (2016) The effects of operational parameters on a mono-wire cutting system: efficiency in marble processing. Rock Mech Rock Engin 49:523–539. https://doi.org/10.1007/s00603-015-0743-9

Zhang JS, Wang Z (2004) Technical parameters and wear resistibility of diamond wire-saw in granite cutting. In: Key engineering materials.Trans Tech, Zurich, pp 122–126

Zhang H, Zhang J, Chen M, An Q (2019) The effect of operational parameters on diamond tools of frame sawing system: Wear characteristics and optimization in stone processing. Int J Refrac Met Hard Mater 84:105019. https://doi.org/10.1016/j.ijrmhm.2019.105019

Zhong Z, Carr TR (2016) Application of mixed kernels function (MKF) based support vector regression model (SVR) for CO2–Reservoir oil minimum miscibility pressure prediction. Fuel 184:590–603. https://doi.org/10.1016/j.fuel.2016.07.030

Funding

There is no funding for this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that researchers have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Babajan, O.J., Bagherpour, R. Estimating the Wear Rate of Diamond Cutting Wire Bead in Building Stone Cutting Using SVR and GA_MLP System. Geotech Geol Eng 40, 5841–5853 (2022). https://doi.org/10.1007/s10706-022-02253-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-022-02253-z