Abstract

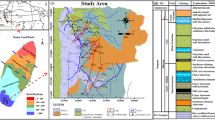

Nowadays, in the coal mining industry, achieve to goals such as high production rates and efficiency with increasing safety and reducing production costs needs to using mechanized mining methods and advanced equipment. As case studies, Takht coal mine and Tazareh coal mine in north-eastern of Iran and Tabas coal mine in mid-Eastern Iran were selected. In total, 17 coal seams with the potential for mechanization from three mentioned mines were studied. In this present study in order to evaluating these coal mines potential of mechanization, important and influential factors such as seam inclination, seam thickness, roof strength, seam uniformity condition, seam extension, bearing capacity and water at the working face were investigated. In this study, it was tried to select the best seams between studied seams with potential for mechanization based on the mentioned factors, by using Preference Ranking Organization Method for Enrich Evaluation method. Finally, Tabas and K11 seam from Takht mine were selected as the top options for mechanization.

Similar content being viewed by others

References

Afrouz A, Hassani FP, Scoble MJ (1988) Geotechnical assessment of the bearing capacity of coal mine floors. Int J Min Geol Eng 6(4):297–312

Ardejani FD, Shokri BJ, Moradzadeh A, Soleimani E, Jafari MA (2008) A combined mathematical geophysical model for prediction of pyrite oxidation and pollutant leaching associated with a coal washing waste dump. Int J Environ Sci Technol 5(4):517–526

Ataei M, Khalokakaei R, Hossieni M (2009) Determination of coal mine mechanization using fuzzy logic. Min Sci Technol (China) 19(2):149–154

Bin Y (2010) Study on fully mechanized coal mining technology in passed 40 years in Datong mining area. J China Coal Soc 35(11):1772–1777

Brans JP, Vincke P, Mareschal B (1986) How to select and how to rank projects: the PROMETHEE method. Eur J Oper Res 24(2):228–238

Ghadernejad S, Lalegani Dezaki S, Rajaty MH (2016) Classification of mechanization capability of Tazareh coal mine stopes using analytical hierarchy process. In: 3rd national Iranian coal congress, vol 3, 30–31 Aug 2016. Shahrood University of Technology, pp 1–5

Ghadernejad S, Jafarpour A, Ahmadi P (2019) Optimal coal seam selection for mine mechanization using an integrated decision-making approach based on FDAHP and PROMETHEE method (case study: Tazareh coal mine complex, Iran). Int J Min Geo-Eng. https://doi.org/10.22059/ijmge.2018.255070.594727

Hattingh TS, Sheer TJ, Du Plessis AG (2010) Human factors in mine mechanization. In: The 4th international platinum conference, platinum in transition ‘boom or bust”. The South African Institute of Mining and Metallurgy

Hosseini SAA, Ataei M, Hosseini SM, Akhyani M (2012) Application of fuzzy logic for determining of coal mine mechanization. J Coal Sci Eng (China) 18(3):225–231

Hwang CL, Lin MJ (2012) Group decision making under multiple criteria: methods and applications, vol 281. Springer, Berlin

Ishikawa A, Amagasa M, Shiga T, Tomizawa G, Tatsuta R, Mieno H (1993) The max-min Delphi method and fuzzy Delphi method via fuzzy integration. Fuzzy Sets Syst 55(3):241–253

Kaufmann A, Gupta MM (1988) Fuzzy mathematical models in engineering and management science. Elsevier, Amsterdam

Liu YC, Chen CS (2007) A new approach for application of rock mass classification on rock slope stability assessment. Eng Geol 89(1–2):129–143

Mehdi HS, Reza M, Mohammad A, Khalokakaei R (2013) Development a new classification for assessing the coal mine mechanization/Opracowanie nowej klasyfikacji dla oceny mechanizacji w kopalniach węgla. Arch Min Sci 58(1):217–226

Özfırat MK (2012) A fuzzy method for selecting underground coal mining method considering mechanization criteria. J Min Sci 48(3):533–544

Saaty TL (1980) The analytic hierarchy process. McGraw-Hill, New York

Saaty TL (1994) How to make a decision: the analytic hierarchy process. Interfaces 24(6):19–43

Sheng GJ, Sun QS, Song HL (2007) The innovational mining technology of fully mechanized mining on thin coal seam. J China Coal Soc 32(3):230–234

Wang G, Jiao S, Cheng G (2011) Fully mechanized coal mining technology for thin coal seam under complicated geological conditions. Energy Explor Exploit 29(2):169–177

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mikaeil, R., Gharahasanlou, E.J. & Jafarpour, A. Ranking and Evaluating the Coal Seam Mechanization Based on Geological Conditions. Geotech Geol Eng 38, 3307–3329 (2020). https://doi.org/10.1007/s10706-020-01200-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-020-01200-0