Abstract

Sheet metals subjected to biaxial plane stress loading typically fail due to localized necking in the thickness direction. Classical plasticity models using a smooth yield surface and the normality flow rule cannot predict localized necking at realistic strain levels when both the in-plane principal strains are tensile. In this paper, a recently developed multi-surface model for porous metal plasticity is used to show that the development of vertices on the yield surface at finite strains due to microscopic void growth, and the resulting deviations from plastic flow normality, can result in realistic predictions for the limit strains under biaxial tensile loadings. The shapes of the forming limit curves predicted using an instability analysis are in qualitative agreement with experiments. The effect of constitutive features such as strain hardening and void nucleation on the predicted ductility are discussed.

Similar content being viewed by others

References

Anand L, Kim K, Shawki T (1987) Onset of shear localization in viscoplastic solids. J Mech Phys Solids 35(4):407–429

Azrin M, Backofen WA (1970) The deformation and failure of a biaxially stretched sheet. Metall Trans 1:2857–2865

Bai Y, Wierzbicki T (2008) A new model of metal plasticity and fracture with pressure and lode dependence. Int J Plasticity 24(6):1071–1096

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J of Mech Sci 46(81):81–98

Benzerga AA (2002) Micromechanics of Coalescence in Ductile Fracture. J Mech Phys Solids 50:1331–1362

Benzerga AA, Leblond JB (2014) Effective yield criterion accounting for microvoid coalescence. J App Mech 81:031009

Benzerga AA, Besson J, Pineau A (2004) Anisotropic ductile fracture. Part II: theory. Acta Mater 52:4639–4650

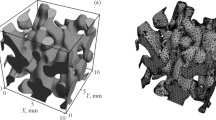

Chouksey M, Keralavarma SM (2023) Mesoscopic unit cell analysis of ductile failure under plane stress conditions. Int J Plast 165:103607

Chouksey M, Keralavarma SM, Basu S (2019) Computational investigation into the role of localisation on yield of a porous ductile solid. J Mech Phys Solids 130:141–164

Chu C, Needleman A (1980) Void nucleation effects in biaxially stretched sheets. J Eng Mat Tech 102:249–256

Drucker DC (1966) Continuum theory of plasticity on macroscale and microscale. J Mater 1(4):873

Gurson AL (1977) Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I- Yield Criteria and Flow Rules for Porous Ductile Media. J Eng Mat Tech 99:2–15

Hill R (1948) A theory of yielding and plastic flow of anisotropic solids. Proc Roy Soc London A 193:281–297

Hill R (1952) On discontinuous plastic states, with special reference to localized necking in thin sheets. J Mech Phys Solids 1:19–30

Hill R (1958) A general theory of uniqueness and stability in elastic-plastic solids. J Mechan Phys Solids 6(3):236–249

Hutchinson J (1970) Elastic-plastic behaviour of polycrystalline metals and composites. Proc R Soc Lond A Math Phys Sci 319(1537):247–272

Hutchinson J, Neale K (1978) Sheet necking-iii. strain-rate effects. In: Mechanics of sheet metal forming: material behavior and deformation analysis, pp 269–285

Keralavarma SM (2017) A multi-surface plasticity model for ductile fracture simulations. J Mech Phys Solids 103:100–120

Keralavarma SM, Chockalingam S (2016) A criterion for void coalescence in anisotropic ductile materials. Int J Plasticity 82:159–176

Keralavarma SM, Reddi D, Benzerga AA (2020) Ductile failure as a constitutive instability in porous plastic solids. J Mech Phys Solids 139:103917

Koplik J, Needleman A (1988) Void growth and coalescence in porous plastic solids. Int J Solids Struct 24(8):835–853

Kuwabara T, Kuroda M, Tvergaard V, Nomura K (2000) Use of abrupt strain path change for determining subsequent yield surface: experimental study with metal sheets. Acta materialia 48(9):2071–2079

Leblond JB, Mottet G (2008) A theoretical approach of strain localization within thin planar bands in porous ductile materials. C R Mecanique 336:176–189

Marciniak Z, Kuczyński K (1967) Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci 9:609–620

Mohr D, Marcadet SJ (2015) Micromechanically-motivated phenomenological hosford-coulomb model for predicting ductile fracture initiation at low stress triaxialities. Int J Solids Struct 67:40–55

Morin L, Leblond JB, Benzerga AA, Kondo D (2016) A unified criterion for the growth and coalescence of microvoids. J Mech Phys Solids

Needleman A, Triantafyllidis N (1978) Void growth and local necking in biaxially stretched sheets. J Eng Mat Tech 100:164–169

Pardoen T, Hutchinson JW (2000) An extended model for void growth and coalescence. J Mech Phys Solids 48:2467–2512

Reddi D, Areej VK, Keralavarma SM (2019) Ductile failure simulations using a multi-surface coupled damage-plasticity model. Int J Plasticity

Rice J (1976) The localization of plastic deformation. In: Koiter W (ed) 14th int. cong. Theoretical and Applied Mechanics, North–Holland, Amsterdam, pp 207–220

Rice JR, Tracey DM (1969) On the enlargement of voids in triaxial stress fields. J Mech Phys Solids 17:201–217

Rudnicki JW, Rice JR (1975) Conditions for the localization of deformation in pressure-sensitive dilatant materials. J Mech Phys Solids 23:371–394

Simo J, Hughes T (1998) Computational Inelasticity. Springer, New York

Stören S, Rice JR (1975) Localized necking in thin sheets. J Mech Phys Solids 23:421–441

Thomason PF (1985) A three-dimensional model for ductile fracture by the growth and coalescence of microvoids. Acta Metall 33(6):1087–1095

Torki M, Benzerga AA (2022) Ductile fracture in plane stress. J Appl Mechan 89(1):011001

Torki ME, Benzerga AA, Leblond JB (2015) On void coalescence under combined tension and shear. J App Mech 82:071005

Torki M, Keralavarma S, Benzerga A (2021) An analysis of lode effects in ductile failure. J Mech Phys Solids 153:104468

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32:157–169

Vishwakarma V, Keralavarma SM (2019) Micromechanical modeling and simulation of the loading path dependence of ductile failure by void growth to coalescence. Int J Solids Struct

Wierzbicki T, Bao Y, Lee YW, Bai Y (2005) Calibration and evaluation of seven fracture models. Int J Mechan Sci 47(4–5):719–743

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sidharth, R., Keralavarma, S.M. Porous plasticity modeling of local necking in sheet metals. Int J Fract (2024). https://doi.org/10.1007/s10704-024-00764-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10704-024-00764-9