Abstract

Investigation of dynamic fracture of elastomers can still be considered to be a relatively open area. When a sheet of elastomer is stretched in a tensile machine and a crack is introduced, the crack propagates at a speed that depends on the initial stretch level. There are instances where this speed is noted to exceed the shear wave speed based on the elastic modulus under high imposed stretches. Such cracks are called transonic cracks. It was usually hypothesized that either the hyperelastic or viscoelastic stiffening of the bulk material raises the wave speeds resulting in crack speeds entering the transonic regime. This article revisits the experiments performed on Polyurethane elastomers in Corre et al. (Int J Fract 224(1):83–100, 2020) to study the implications of both these hypotheses. Crack propagation has not been explicitly modeled, but the crack speeds are implicitly imposed on the geometry using the boundary conditions extracted from the experimental data. It has been determined that the viscoelasticity in the bulk is needed to describe and understand the transonic cracks in polyurethane elastomer. The inclusion of viscoelasticity results in the notions of ‘rubbery’ and ‘glassy’ wave speeds and hence, the transonic regime is defined considering the rubbery wave speed.

Similar content being viewed by others

Change history

27 July 2021

A Correction to this paper has been published: https://doi.org/10.1007/s10704-021-00573-4

References

Abaqus UM (2014) Abaqus theory guide. Version 6(14)

Atkinson C, Popelar C (1979) Antiplane dynamic crack propagation in a viscoelastic strip. J Mech Phys Solids 27(5–6):431–439. https://doi.org/10.1016/0022-5096(79)90024-3

Boulanger P, Hayes M (2001) Finite-amplitude waves in Mooney–Rivlin and Hadamard materials, January 2001. https://doi.org/10.1007/978-3-7091-2582-3

Buehler MJ, Abraham FF, Gao H (2003) Hyperelasticity governs dynamic fracture at a critical length scale. Nature 426(6963):141–146. https://doi.org/10.1038/nature02096

Chen CH, Zhang HP, Niemczura J, Ravi-Chandar K, Marder M (2011) Scaling of crack propagation in rubber sheets. EPl. https://doi.org/10.1209/0295-5075/96/36009

Coret M, Corre T (2017) Investigation of dynamic fracture of elastomers—I. https://doi.org/10.5281/zenodo.4034638

Corre T (2018) Rupture dynamique de membranes élastomères : étude expérimentale par mesure de champs. PhD thesis

Corre T, Coret M, Verron E, Leblé B, Le Lay F (2020) Experimental full field analysis for dynamic fracture of elastomer membranes. Int J Fract 224(1):83–100. https://doi.org/10.1007/s10704-020-00447-1

Fisher GMC, Gurtin ME (1965) Wave propagation in the linear theory of viscoelasticity. Q Appl Math 23(3):257–263. https://doi.org/10.1090/qam/191196

Freund L (1979) The mechanics of dynamic shear crack propagation. J Geophys Res 84(B5):2199. https://doi.org/10.1029/JB084iB05p02199

Freund L (1990) Dynamic fracture mechanics. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511546761

Gent AN, Marteny P (1982) Crack velocities in natural rubber. J Mater Sci 17(10):2955–2960. https://doi.org/10.1007/BF00644675

Geubelle PH, Danyluk MJ, Hilton HH (1998) Dynamic mode III fracture in viscoelastic media. Int J Solids Struct 35(9–10):761–782. https://doi.org/10.1016/S0020-7683(97)00084-X

Gori M, Rubino V, Rosakis AJ, Lapusta N (2018) Pressure shock fronts formed by ultra-fast shear cracks in viscoelastic materials. Nat Commun 9(1):4754. https://doi.org/10.1038/s41467-018-07139-4

Graham GAC, Walton JR (1995) Crack and contact problems for viscoelastic bodies

Guo G, Yang W, Huang Y (2003) Supersonic crack growth in a solid of upturn stress-strain relation under anti-plane shear. J Mech Phys Solids 51(11–12):1971–1985. https://doi.org/10.1016/j.jmps.2003.09.028

Hilber HM, Hughes TJR (1976) Taylor RL (1977) Improved Numerical Dissipation For Time Integration Algorithms in Structural Dynamics. Earthquake Eng Struct Dynam 5:283–292

Huang Y, Gao H (2001) Intersonic crack propagation-part I: the fundamental solution. J Appl Mech 68(2):169. https://doi.org/10.1115/1.1357871

Knowles James K (2002) Impact-induced tensile waves in a rubberlike material. SIAM J Appl Math 62(4):1153–1175. https://doi.org/10.1137/S0036139901388234

Kadir A, Thomas AG (1984) Tearing of Unvulcanized natural rubber. J Polymer Sci A 2 Polymer Phys 22(9):1623–1634

Mai TT, Okuno K, Tsunoda K, Urayama K (2020) Crack-tip strain field in supershear crack of elastomers. ACS Macro Lett 9(5):762–768. https://doi.org/10.1021/acsmacrolett.0c00213

Marder M (2006) Supersonic rupture of rubber. J Mech Phys Solids 54(3):491–532. https://doi.org/10.1016/j.jmps.2005.10.002

Mason P (1963) Finite elastic wave propagation in rubber. Proc R Soc A 272(1350):315–330. https://doi.org/10.1098/rspa.1963.0056

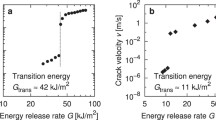

Morishita Y, Tsunoda K, Urayama K (2016) Velocity transition in the crack growth dynamics of filled elastomers: contributions of nonlinear viscoelasticity. Phys Rev E. https://doi.org/10.1103/PhysRevE.93.043001

Needleman A (1999) An Analysis of Intersonic Crack Growth Under Shear Loading. J Appl Mech 66(4):847. https://doi.org/10.1115/1.2791788

Niemczura J, Ravi-Chandar K (2011a) On the response of rubbers at high strain rates-I. Simple waves. J Mech Phys Solids 59(2):423–441. https://doi.org/10.1016/j.jmps.2010.09.006

Niemczura J, Ravi-Chandar K (2011b) On the response of rubbers at high strain rates-III. Effect of hysteresis. J Mech Phys Solids 59(2):457–472. https://doi.org/10.1016/j.jmps.2010.09.009

Petersan PJ, Deegan RD, Marder M, Swinney HL (2004) Cracks in rubber under tension exceed the shear wave speed. Phys Rev Lett 93(1):015504-1. https://doi.org/10.1103/PhysRevLett.93.015504

Ravi-Chandar K, Knauss W (1984) An experimental investigation into dynamic fracture: I. Crack initiation and arrest. Int J Fract 25(4):247–262. https://doi.org/10.1007/BF00963460

Rivlin RS, Saunders DW (1951) Large elastic deformations of isotropic materials VII. Experiments on the deformation of rubber. Philosoph Trans R Soc Lond Ser A 243(865):251–288

Rosakis AJ (2002) Intersonic shear cracks and fault ruptures. Adv Phys 51(4):1189–1257. https://doi.org/10.1080/00018730210122328

Rosakis AJ, Samudrala O, Coker D (2000) Intersonic shear crack growth along weak planes. Mater Res Innov 3(4):236–243. https://doi.org/10.1007/s100190050009

Sharon E, Gross SP, Fineberg J (1996) Energy dissipation in dynamic fracture. Phys Rev Lett 76(12):2117–2120. https://doi.org/10.1103/PhysRevLett.76.2117

Simo JC (1987) On a fully three-dimensional finite-strain viscoelastic damage model: formulation and computational aspects. Comput Methods Appl Mech Eng 60(2):153–173. https://doi.org/10.1016/0045-7825(87)90107-1

Stevenson A, Thomas AG (1979) On the bursting of a balloon. J Phys D Appl Phys 12(12):2101–2109. https://doi.org/10.1088/0022-3727/12/12/012

Taylor RL, Pister KS, Goudreau GL (1970) Thermomechanical analysis of viscoelastic solids. Int J Numer Methods Eng 2:45–59

VIC-2D CS (2009) Software; correlated solutions. https://www.correlatedsolutions.com/vic-2d/

Washabaugh PD, Knauss W (1994) A reconciliation of dynamic crack velocity and Rayleigh wave speed in isotropic brittle solids. Int J Fract 65(2):97–114. https://doi.org/10.1007/BF00032282

Willis J (1967) Crack propagation in viscoelastic media. J Mech Phys Solids 15(4):229–240. https://doi.org/10.1016/0022-5096(67)90013-0

Acknowledgements

VK thanks Thomas Corre, Erwan Verron and Julien Réthoré for various discussions held on this subject.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: FE simulations for a different data extraction location

Appendix A: FE simulations for a different data extraction location

For the results of FE simulations presented in earlier sections, the boundary conditions were extracted along a line just above the crack path (green line in Fig. 5). To examine the effect of the location of data extraction line on the observed results, some more analyses have been performed where the data is extracted from the middle of the top half of the specimen instead of just above the crack path (purple line in Fig. 5). The new data extraction location is about 10 mm from the crack path in the undeformed configuration.

The analyses in the previous sections are then repeated with new data as boundary conditions. The results can be seen in Figs. 21 and 22.

Even in this case, the results of FE simulations with viscoelastic model can be seen to be closer to the experiments. In the case of horizontal displacements from Fig. 21, a bean shaped profile can be seen in the experimental result and the FE simulation with viscoelasticity. The case with just hyperelastic model does not exhibit this distinct profile. It shall be noted that the experimental result does not include the data near the top edge of the specimen.

Similarly, the velocity magnitudes from experiment and viscoelastic FE simulation are closer while hyperelastic result is not. This demonstrates the robustness of the viscoelastic model used and also indicates the presence of viscoelastic effects in regions far from the crack tip.

Rights and permissions

About this article

Cite this article

Kamasamudram, V., Coret, M. & Moës, N. The role played by viscoelasticity in the bulk material during the propagation of a dynamic crack in elastomers. Int J Fract 231, 43–58 (2021). https://doi.org/10.1007/s10704-021-00561-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-021-00561-8