Abstract

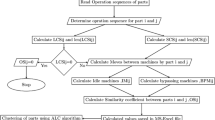

Reconfigurable manufacturing system (RMS) is designed around part family providing exact production function and capacity in cost-effective way when needed. Besides the grouping accuracy of part family impacting the responsiveness of RMS, the efficiency problem of RMS resulting from the difference of process time and capacity demand should be solved. Therefore, a similarity coefficient method for RMS part family grouping considering process time and capacity demand is proposed. First, the longest common subsequence (LCS) among different part process routes is extracted and the shortest composite supersequence (SCS) of parts is constructed. Idle machine (IM) and bypass move (BPM) are analyzed based on SCS. Then, the process time (T) and capacity demand (D) are used as characteristic value of operation. And characteristic value sequences of process route, LCS, SCS, IM and BPM are gained, that is, TDP, TDLCS, TDSCS, TDIM and TDBPM respectively. By analyzing the relationships between TDLCS and TDSCS, the characteristic value sequences of TDLCS, TDIM and TDBPM are used to calculate the similarity between parts. Based on the similarity matrix, the netting clustering algorithm is used for clustering to complete the part family grouping. Finally, a case study is presented to implement the proposed method and validate the effectiveness.

Reproduced with permission from Wang et al. (2016)

Similar content being viewed by others

References

Abdi MR (2012) Product family grouping and selection for reconfigurability using analytical network process. Int J Prod Res 50(17):4908–4921. https://doi.org/10.1080/00207543.2012.657976

Abdi MR, Labib AW (2003) A design strategy for reconfigurable manufacturing systems (RMSs) using analytical hierarchical process (AHP): a case study. Int J Prod Res 41(10):2273–2299. https://doi.org/10.1080/0020754031000077266

Ashraf M, Hasan F (2015) Product family grouping based on multiple product similarities for a reconfigurable manufacturing system. Int J Model Oper Manag 5(3–4):247–265. https://doi.org/10.1504/IJMOM.2015.075800

Askin RG, Zhou M (1998) Grouping of independent flow-line cells based on operation requirements and machine capabilities. IIE Trans 30(4):319–329. https://doi.org/10.1080/07408179808966472

Balakrishnan J, Jog PD (1995) Manufacturing cell grouping using similarity coefficients and a parallel genetic TSP algorithm: formulation and comparison. Math Comput Model 21(12):61–73. https://doi.org/10.1016/0895-7177(95)00092-G

Battaïa O, Dolgui A (2013) A taxonomy of line balancing problems and their solution approaches. Int J Prod Econ 142(2):259–277. https://doi.org/10.1016/j.ijpe.2012.10.020

Choobineh F (1988) A framework for the design of cellular manufacturing systems. Int J Prod Res 26(7):1161–1172. https://doi.org/10.1080/00207548808947932

ElMaraghy HA (2005) Flexible and reconfigurable manufacturing systems paradigms. Int J Flex Manuf Syst 17(4):261–276

Galan R, Racero J, Eguia I, Garcia JM (2007) A systematic approach for product families grouping in reconfigurable manufacturing systems. Robot Comput Integr Manuf 23(5):489–502. https://doi.org/10.1016/j.rcim.2006.06.001

Goyal KK, Jain PK, Jain M (2013a) A comprehensive approach to operation sequence similarity based part family grouping in the reconfigurable manufacturing system. Int J Prod Res 51(6):1762–1776. https://doi.org/10.1080/00207543.2012.701771

Goyal KK, Jain PK, Jain M (2013b) A novel methodology to measure the responsiveness of RMTs in reconfigurable manufacturing system. J Manuf Syst 32(4):724–730. https://doi.org/10.1016/j.jmsy.2013.05.002

Gupta A, Jain PK, Kumar D (2012) Grouping of part family in reconfigurable manufacturing system using principle component analysis and K-means algorithm. Paper presented at the annals of DAAAM for 2012 and proceedings of the 23rd international DAAAM symposium

Hasan F, Jain PK, Kumar D (2014) 24th Daaam international symposium on intelligent manufacturing and automation, 2013 service level as performance index for reconfigurable manufacturing system involving multiple part families. Procedia Eng 69:814–821. https://doi.org/10.1016/j.proeng.2014.03.058

Ho YC, Lee CC, Moodie CL (1993) Two sequence-pattern, matching-based, flow analysis methods for multi-flowlines layout design. Int J Prod Res 31(7):1557–1578. https://doi.org/10.1080/00207549308956809

Kashkoush M, ElMaraghy H (2014) Product family formation for reconfigurable assembly systems. Procedia CIRP 17:302–307. https://doi.org/10.1016/j.procir.2014.01.131

Keeling KB, Brown EC, James TL (2007) Grouping efficiency measures and their impact on factory measures for the machine-part cell formation problem: a simulation study. Eng Appl Artif Intell 20(1):63–78. https://doi.org/10.1016/j.engappai.2006.04.001

Khanna K, Kumar R (2017) Part family and operations group formation for RMS using bond energy algorithm. Int J Eng Technol 9(2):1365–1373. https://doi.org/10.21817/ijet/2017/v9i2/170902273

Koren Y (2013) The rapid responsiveness of RMS. Int J Prod Res 51(23–24):6817–6827. https://doi.org/10.1080/00207543.2013.856528

Koren Y, Heisel U, Jovane F, Moriwaki T, Pritschow G, Ulsoy G, Van Brussel H (1999) Reconfigurable manufacturing systems. CIRP Ann Manuf Technol 48(2):527–540. https://doi.org/10.1016/S0007-8506(07)63232-6

Koren Y, Wang WC, Gu X (2017) Value creation through design for scalability of reconfigurable manufacturing systems. Int J Prod Res 55(5):1227–1242. https://doi.org/10.1080/00207543.2016.1145821

Liang FJ, Ning RX (2003) Theoretical research of reconfigurable manufacturing system. Chin J Mech Eng 39(6):36–43. https://doi.org/10.3901/JME.2003.06.036

Lozano S, Canca D, Guerrero F, García JM (2001) Machine grouping using sequence-based similarity coefficients and neural networks. Robot Comput Integr Manuf 17(5):399–404. https://doi.org/10.1016/S0736-5845(01)00015-1

Luo Z, Sheng H, Zhao B, Zhao X, Liu R, Jiang J (2000) Rapidly reconfigurable manufacturing systems. China Mech Eng 11(3):300–303

Ma LM, Li JY, Liu JP (2011) Product family partition of reconfigurable manufacturing systems (RMS) based on improved hierarchical clustering algorithm. Mach Des Manuf 8:78–80

Mehrabi MG, Ulsoy AG, Koren Y (2000) Reconfigurable manufacturing systems: key to future manufacturing. J Intell Manuf 11(4):403–419. https://doi.org/10.1023/a:1008930403506

Mehrabi MG, Ulsoy AG, Koren Y, Heytler P (2002) Trends and perspectives in flexible and reconfigurable manufacturing systems. J Intell Manuf 13(2):135–146. https://doi.org/10.1023/a:1014536330551

Seifoddini H, Djassemi M (1995) Merits of the production volume based similarity coefficient in machine cell grouping. J Manuf Syst 14(1):35–44. https://doi.org/10.1016/0278-6125(95)98899-H

Spicer P, Koren Y, Shpitalni M, Yip-Hoi D (2002) Design principles for machining system configurations. CIRP Ann Manuf Technol 51(1):275–280. https://doi.org/10.1016/S0007-8506(07)61516-9

Tam KY (1990) An operation sequence based similarity coefficient for part families groupings. J Manuf Syst 9(1):55–68. https://doi.org/10.1016/0278-6125(90)90069-T

Vakharia AJ, Wemmerlov U (1990) Designing a cellular manufacturing system: a materials flow approach based on operation sequences. IIE Trans 22(1):84–97. https://doi.org/10.1080/07408179008964161

Wang GX, Huang SH, Shang XW, Yan Y, Du JJ (2016) Formation of part family for reconfigurable manufacturing systems considering bypassing moves and idle machines. J Manuf Syst 41:120–129. https://doi.org/10.1016/j.jmsy.2016.08.009

Yamada Y, Ookoudo K, Komura Y (2003) Layout optimization of manufacturing cells and allocation optimization of transport robots in reconfigurable manufacturing systems using particle swarm optimization. Paper presented at the intelligent robots and systems, 2003 (IROS 2003). https://doi.org/10.1109/iros.2003.1248968

Yin Y, Yasuda K (2005) Similarity coefficient methods applied to the cell grouping problem: a comparative investigation. Comput Ind Eng 48(3):471–489. https://doi.org/10.1016/j.cie.2003.01.001

Zhang XH, Qiu M (2008) Problem of classification of product family for reconfigurable manufacturing systems. Machinery 35(7):47–51

Zhao X, Wang J, Luo Z (2000) A stochastic model of a reconfigurable manufacturing system part 1: a framework. Int J Prod Res 38(10):2273–2285. https://doi.org/10.1080/00207540050028098

Acknowledgements

The authors are grateful to the anonymous reviewers for their comments, which have helped to improve this paper. All authors have approved to submit to your journal, and there is no conflict of interest regarding the publication of this manuscript. The authors acknowledge the supporting funds, the National Natural Science Foundation, China (No. 51375049) and Graduate technological innovation project of Beijing institute of technology (Project No. 2017CX10040).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, S., Yan, Y. Part family grouping method for reconfigurable manufacturing system considering process time and capacity demand. Flex Serv Manuf J 31, 424–445 (2019). https://doi.org/10.1007/s10696-018-9322-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-018-9322-1