Abstract

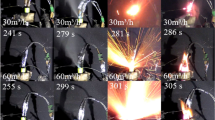

There is a poor blocking effect of the paper diaphragm used in the transportation package of lithium-ion batteries. Hence, researches on barrier materials are necessary. In this study, the thermal runaway (TR) was triggered by a heating rod and propagated horizontally between battery packs, and the tests were conducted in a self-designed chamber to investigate the blocking effect of aerogel felt thickness on the TR propagation of 18,650 lithium-ion batteries with 30% SOC and 100% SOC. And a simplified model of TR propagation was established to illustrate the heat propagation between batteries. The results showed that when the barrier thickness of aerogel felt increased from 1 to 10 mm, the number of batteries with TR decreased, the total heat release rate (THR) triggering time was longer, and the blocking effect of TR propagation was better. Besides, the aerogel felt the thickness of 1 mm had a poor effect on the prevention and control of TR, and there was a threshold between the barrier thickness of 6 mm and 10 mm to prevent TR. Simultaneously, there was a slight fluctuation in the parameters of heat release rate (HRR), battery surface temperature, and peak concentrations of CO and CO2. And the concentrations of O2, CO2, and CO are related to the SOC and the number of TR of lithium-ion batteries. When the thickness of aerogel felt increased to a certain value, the difference between mass loss and the force effect produced by TR will be smaller, and the THR will be more. These results provide valuable proposals and inspiration for packaging in civil aviation transportation.

Similar content being viewed by others

Data Availability

All the relevant data are included in the paper. Source data are provided with this paper.

References

Spotnitz RM, Weaver J, Yeduvaka G (2007) Simulation of abuse tolerance of lithium-ion battery packs. J Power Sources 163:1080–1086. https://doi.org/10.1016/j.jpowsour.2006.10.013

Ouyang DX, Liu JH, Chen MY, Weng JW, Wang J (2018) An experimental study on the thermal failure propagation in lithium-ion battery pack. J Electrochem Soc 165:2184–2193. https://doi.org/10.1149/2.0721810jes

Zhao R, Liu J, Gu JJ (2016) Simulation and experimental study on lithium-ion battery short circuit. Appl Energy 173:29–39. https://doi.org/10.1016/j.apenergy.2016.04.016

Li SL, Ai XP, Yang HX, Cao YL (2009) A polytriphenylamine-modified separator with reversible overcharge protection for 3.6 V-class lithium-ion battery. J Power Sources 189:771–774. https://doi.org/10.1016/j.jpowsour.2008.08.006

Spotnitz R, Franklin J (2003) Abuse behavior of high-power, lithium-ion cells. J Power Sources 113:81–100. https://doi.org/10.1016/S0378-7753(02)00488-3

FAA SAFO (2021) Federal aviation administration. Li-Batt. Thermal events April to date.pdf (faa.gov). Accessed 6 May 2021

FAA SAFO (2013) Risks in transporting lithium batteries in cargo by aircraft. https://www.faa.gov/news/press_releases/media/safo10017.pdf. Accessed 6 May 2021

Yuan CC, Wang QS, Wang Y, Zhao Y (2019) Inhibition effect of different interstitial materials on thermal runaway propagation in the cylindrical lithium-ion battery module. Appl Therm Eng 153:39–50. https://doi.org/10.1016/j.applthermaleng.2019.02.127

Andreas MM, Boxia L, Carlos Z, Magnus R, Hans JS (2016) Modeling and simulation of the thermal runaway behavior of cylindrical Li-ion cells-computing of critical parameters. Energies 9:292. https://doi.org/10.1149/MA2016-01/4/425

Abraham DP, Roth EP, Kostecki R, McCarthy K, MacLaren S, Doughty DH (2006) Diagnostic examination of thermally abused high-power lithium-ion cells. J Power Sources 161:648–657. https://doi.org/10.1016/j.jpowsour.2006.04.088

Dong HJ, Seung MB (2011) Thermal modeling of cylindrical lithium-ion battery during discharge cycle. Energy Convers Manage 52:2973–2981. https://doi.org/10.1016/j.enconman.2011.04.013

Chen XT, Zhang X, Wang HB, Jia JY, Xie S, Zhi MY, Fu J, Sun Q (2020) Influence of ambient pressure and heating power on the thermal runaway features of lithium-ion battery. J Electrochem 18:1–24. https://doi.org/10.1115/1.4049316

Liu JK, Wang ZR, Gong JH, Liu K, Wang H, Guo LS (2017) Experimental study of thermal runaway process of 18650 lithium-ion battery. Materials 10:230. https://doi.org/10.3390/ma10030230

Liao ZH, Zhang S, Li K, Zhao MY, Qiu JZ, Han D, Zhang GQ, Thomas GH (2020) Hazard analysis of thermally abused lithium-ion batteries at different states of charges. J Energy Storage 27:101065. https://doi.org/10.1016/j.est.2019.101065

Li WF, Wang HW, Zhang YJ, Ouyang MG (2019) Flammability characteristics of the battery vent gas: a case of NCA and LFP lithium-ion batteries during external heating abuse. J Energy Storage 24:100775. https://doi.org/10.1016/j.est.2019.100775

Forestier C, Lecocq A, Zantman A, Grugeon S, Sannier L, Marlair G, Laruelle S (2020) Study of the role of LiNi1/3Mn1/3Co1/3O2/graphite li-ion pouch cells confinement, electrolyte composition and separator coating on thermal runaway and off-gas toxicity. J Electrochem Soc 167:090513. https://doi.org/10.1149/1945-7111/ab829e

Ye JN, Chen HD, Wang QS, Huang PF, Sun JH, Lo SM (2016) Thermal behavior and failure mechanism of lithium-ion cells during overcharge under adiabatic conditions. Appl Energy 182:464–474. https://doi.org/10.1016/j.apenergy.2016.08.124

Lu TY, Chiang CC, Wu SH, Chen KC, Lin SJ, Wen CY, Shu CM (2013) Thermal hazard evaluations of 18650 lithium-ion batteries by an adiabatic calorimeter. J Therm Anal Calorim 114:1083–1088. https://doi.org/10.1007/s10973-013-3137-9

Li H, Kong XB, Liu CY, Zhao JB (2019) Study on the thermal stability of nickel-rich/silicon-graphite large capacity lithium-ion battery. Appl Therm Eng 161:114144. https://doi.org/10.1016/j.applthermaleng.2019.114144

Lai X, Wang SY, Wang HB, Zheng YJ, Feng XN (2021) Investigation of thermal runaway propagation characteristics of lithium-ion battery modules under different trigger modes. Int J Heat Mass Transf 171:121080. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121080

Wu TQ, Chen HD, Wang QS, Sun JH (2018) Comparison analysis on the thermal runaway of lithium-ion battery under two heating modes. J Hazard Mater 344:733–741. https://doi.org/10.1016/j.jhazmat.2017.11.022

Weng JJ, Ouyang DX, Yang XQ, Chen MY, Zhang GQ, Wang J (2019) Alleviation of thermal runaway propagation in thermal management modules using aerogel felt coupled with flame-retarded phase change material. Energy Conv Manag 200:112071. https://doi.org/10.1016/j.enconman.2019.112071

Lopez CF, Jeevarajan JA, Mukherjee PP (2015) Characterization of lithium-ion battery thermal abuse behavior using experimental and computational analysis. J Electrochem Soc 162:2163–2173. https://doi.org/10.1149/2.0751510jes

Lamb J, Orendorff CJ, Steele LAM, Spangler SW (2015) Failure propagation in multi-cell lithium-ion batteries. J Power Sources 283:517–523. https://doi.org/10.1016/j.jpowsour.2014.10.081

Larsson F, Anderson J, Andersson P, Mellander BE (2016) Thermal modeling of cell-to-cell fire propagation and cascading thermal runaway failure effects for lithium-ion battery cells and modules using fire walls. J Electrochem Soc 163:2854–2865. https://doi.org/10.1149/2.0131614jes

Liu QY, Yi XY, Han X (2020) Effect of different arrangement on thermal runaway characteristics of 18650 lithium ion batteries under the typical pressure in civil aviation transportation. Fire Technol 56:2509–2523. https://doi.org/10.1007/s10694-020-00984-0

Deng Y (2020) Study on the thermal runaway domino effect of lithium-ion batteries for air transportation. Thesis, Civil Aviation University of China. https://doi.org/10.27627/d.cnki.gzmhy.2020.000410 (in Chinese)

Zhao JB (2019) Experimental study on thermal runaway propagation of lithium-ion batteries at different distances. Thesis, Hefei University of Technology. https://doi.org/10.27101/d.cnki.ghfgu.2019.000456 (in Chinese)

Eshetu GG, Grugeon S, Laruelle S, Boyanov S, Lecocq A, Bertrand JP, Marlair G (2013) In-depth safety-focused analysis of solvents used in electrolytes for large scale lithium-ion batteries. Phys Chem Chem Phys 15:9145–9155. https://doi.org/10.1039/c3cp51315g

Fu YY (2017) Study on combustion characteristics of typical lithium-ion batteries and electrolytes and the mechanism of influence of air transportation environment on them. Dissertation, University of Science and Technology of China. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CDFD&dbname=CDFDLAST2017&filename=1017178966.nh&uniplatform=NZKPT&v=BQsB9bPp1RpFFM4KeCogjnJGYTbk2rlWAwxr72BAPfp4HghByaTiJ-v_lEa3TIaH (in Chinese)

Acknowledgements

We thank the key project of National Natural Science Foundation of China [U2033206] and the funding of Civil Aircraft Fire Science and Safety Engineering Key Laboratory of Sichuan Province [NO: MZ2022JB01] for supporting our work.

Funding

This work was financially supported by the National Natural Science Foundation of China [NO: U2033206] and the funding of Civil Aircraft Fire Science and Safety Engineering Key Laboratory of Sichuan Province [NO: MZ2022JB01].

Author information

Authors and Affiliations

Contributions

All authors contributed equally to the work, discussing and analyzing the data. XY and WZ were primarily responsible for carrying out and validation of the experiments; QL conceptualized the ideas and provided guidance and insights as well as the funding; QZ wrote and revised the manuscript and assisted with material characterization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Q., Zhu, Q., Zhu, W. et al. Study on the Blocking Effect of Aerogel Felt Thickness on Thermal Runaway Propagation of Lithium-Ion Batteries. Fire Technol 59, 381–399 (2023). https://doi.org/10.1007/s10694-022-01336-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-022-01336-w