Abstract

Grain, flour and bread quality parameters were investigated in one Polish and three Ukrainian triticale cultivars, selected as the most suitable for production of bread. The studies revealed large differences in some bread-making parameters. The farinographic parameters of the Ukrainian triticale cultivars were not worse than those of wheat, but the bread loaf volume was lower. The best triticale bread was obtained from the Polish cultivar Panteon, loaf volume and crumb porosity were the highest, in spite of weak results of the farinographic test. Reliability of parameters used for prediction of wheat bread quality in application to triticale is discussed. The laboratory baking is recommended for bakers, breeders and for cultivar testing as the safest method of the evaluation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Triticale (X Triticosecale Wittm. ex A. Camus) is an artificially obtained species of grain crop resulting from crossing of wheat Triticum aestivum (n = 42, genomes ABD) and rye Secale cereale (n = 14, genome R). The aim of the breeders and scientists was to combine beneficial traits of both parents: quality of wheat and wide adaptation of rye. However, in triticale, the D genome of wheat, mostly responsible for baking quality traits, has been replaced with the R–rye genome. It is related to the still existing difficulties in rising the baking quality parameters to the wheat level. In recent years, numerous studies have been conducted, in which the usefulness of triticale grain for human consumption has been confirmed (Szulyndin 1981; Woś and Brzeziński 2015; Wrigley and Bushuk 2017; Shchipak 2019; Shchipak and Shchipak 2022; Mihaly-Lango et al. 2022; Hegart et al. 2022). The studies indicate that the flour obtained from this grain can also be used for the production of good quality bread, both by direct dough management (Szulyndin 1981; Shchipak 2019; Tohver et al. 2005; Woś and Brzeziński 2015; Fraś et al. 2016) as well as with the use of leaven (Galoburda et al. 2020; Lango et al. 2016). The nutritious properties of breads produced from triticale flour are highly competitive to the wheat bread. In our investigation of the Polish and Ukrainian forms protein content in grain was similar to that of wheat and varied between 12.5 and 14.3%, exceeding the range 9–14% reported for modern hexaploid winter triticale by Randhawa et al. (2015). If to consider better amino-acids composition than in wheat, higher digestibility than in rye, the high health promoting value of triticale grain is evident. Considering taste preferences of local consumers in middle Europe, rising the baking quality parameters to the wheat level is neither necessary nor recommended. In Poland mostly consumed bread is produced from blended flours; bakers usually mix 70% of wheat and 30% of rye flour. Triticale bread could be baked from one batch of triticale grain and one should not look for another batch of wheat or rye grain that would meet specific flour parameters. In other countries, mixtures of wheat and triticale flour were also used to make dough and bake bread (Schulyndin 1981; Acs et al. 2016; Shchipak 2019; Shchipak and Shchipak 2022). Bona et al. (2013) concluded that the “inappropriate nature of triticale per se flours for baking industry seems to hinder the human utilization”. Thus, blends wheat-triticale may be an alternative suitable way to use triticale grain in milling and baking products at larger scale in food industry.

High amylase activity is a serious restricting factor for baking bread; thus, triticale grain is mainly used as a feed crop. Among great variety of the existing triticale genotypes only several ones appeared with distinctly higher suitability for bread production. The four cultivars selected for this study should be also classified to this group. The publication contains results of more profound analysis of the baking parameters (those used for wheat cultivars assessment) for one Polish and three Ukrainian cultivars. Significance of the revealed diversity is discussed, both for baking industry and for reliability of the Polish cultivar testing procedures.

Materials and methods

Experimental material

The studied triticale grain material consisted of one Polish and three Ukrainian cultivars showing best results in baking trials. The Polish cultivar Panteon (strain BOH1512 from the Plant Breeding Company Strzelce, Poland) was registered in 2015. It was selected among doubled haploid recombinants of the cross BOH16-4 × DH265, the both parental lines originated from forms showing high falling number. The winter line BOH16-4 was described earlier (Woś and Brzeziński 2015). The line DH265 parentage includes the Polish winter triticale Krakowiak and a line from the earlier cross (spring triticale MAH1596 x winter triticale Presto WR4/1R.1D5+10–2). The Presto line was a carrier of the 1R.1D translocation called Valdy, derived in the California University Riverside by means of chromosomal engineering. The Gli-D1 and Glu-D1 loci, which determine high baking value, were transferred from the wheat 1D chromosome into the 1R chromosome of rye (Lukaszewski 2006). However, no Gli-D1 and Glu-D1 loci were found in Panteon cultivar (Brzeziński W. unpublished data). On the other hand, high falling number, high protein content, high test weight as well as other desirable properties such as good winter hardiness and good disease resistance were maintained.

Three varieties from the Ukrainian state trials, Timofiej (variety registered in 2017), Elan (variety registered in 2018) and Pudik (variety registered in 2018) were obtained from the Plant Production Institute named after V.Ya. Yuriev of NAAS of Ukraine in Kharkiv. They come from the same cross combination made in 2008 between the winter triticale cultivar Raritiet, characterized by improved baking quality and high winter hardiness (bred by prof. G.V. Shchipak) and the line XAD7 with high protein content (Shchipak 2019). Triticale XAD7 was characterized by high bread making quality but had insufficient winter hardiness.

The studied triticale cultivars were bred by means of normal recombination breeding, with the goal to create quality triticale adapted to the local soil and weather conditions.

Additionally, wheat grain was included to the investigation as a reference species, in relation to the fact that all methods and parameters applied for the triticale were identical with those used for bread wheat. Wheat was represented by two winterhardy cultivars with high baking quality: Sailor from Secobra Saatzucht-Germany (harvest in 2019) and Euforia from Polish Plant Breeding Company Strzelce (Poland) (harvest in 2020). The grain of all triticale and wheat objects originated from multiplications grown in 2019 and 2020 on the same field located in Poland in the Wielkopolskie Voivodeship, at the conventional cultivation practices typical for triticale.

The research on the quality of grain and flour as well as bread baking the bread quality assessment were carried out at the Institute of Food Technology and Nutrition of the University of Rzeszów (Poland).

Quality assessment of grain

In commodity assessment, the grain was examined for the test weight (TW), expressed as kg/hl (ISO 2019). The thousand kernel weight (TKW) of the examined varieties was determined using a grain counter (Sadkiewicz Instruments, Bydgoszcz, Poland) by deducting 500 grains in 3 replications, weighting and calculating the TKW, taking into account grain moisture. The glassiness of the examined grain was determined according to ICC Standard Method No. 129 (ICC 1980). The determination was carried out by cutting 50 grains in a glassiness measuring device (Sadkiewicz Instruments, Bydgoszcz, Poland), then counting the number of grains with glassy or predominantly glassy cross-section; the result was their percentage of all grains cut (0–100%).

Grain milling process

The wheat and triticale grains were moistened to a moisture content of 14.5% and then crushed in a Quadrumat Junior Mill (Brabender, Duisburg, Germany). The product obtained was separated into flour and bran by means of a conical sifter with the mesh of 212 µm in diameter according to AACC Method No 26–50.01(AACC 2009). The flour yield (%) was calculated as the amount of flour obtained due to milling 100 g of grain. The dry matter content (d.m.) of the grains was determined according to the AOAC method No 925.10 (AOAC 2006). The grains of the examined variety were milled into flour in three repetitions, then the flour samples of this variety were combined and thoroughly mixed.

Quality assessment of flour

Flour obtained due to milling of wheat and triticale grains was examined for its chemical composition in terms of the content of: dry matter, according to AACC Method No. 44–15.02 (AACC 2009); total ash, according to ICC Standard No. 104/1 (ICC 2005); and nitrogen converted to crude protein content (N × 6.25), according to AACC Method No. 46–11.02 (AACC 2009). The wet gluten content in flour was determined according to ISO 21415–1:2006 (ISO 2006) and expressed as the weight of flour with a moisture content of 14%. The falling number of flour was measured according to ISO 3093:2009 (ISO 2009), using a Falling Number apparatus, model 1800 (Perten Instruments, Huddinge, Sweden). The aforementioned determinations were performed in 3 replications.

Farinographic test

Water absorption of the flour of the wheat and triticale varieties as well as the rheological properties of the dough (dough development time, dough stability time, dough softening, and farinograph quality number (FQN) were assessed at a maximum consistency of 500 FU, using the Farinograph E (Brabender, Duisburg, Germany), according to ICC Standard Method 115/1 (ICC 2003a, b). The flour doses weighted were equivalents to the dry matter content in 50 g of flour with a moisture content of 14%.

Bread baking procedure

The method of bread baking applied in the study is popularly called the single-phase method or “wheat method”. It has been chosen because it is laboratory test method, a well-known among bakers too and is readily used as the time effective one.

Preparation of the dough, its fermentation and baking were performed according to ICC Standard Method 131 (ICC 2003a, b). The dough, prepared according to Jakubczyk and Haber (1983), was composed of: flour with a weight equivalent to the dry matter content in 300 g of flour with a moisture content of 14%; pressed baking yeast (3% of flour weight); table salt (1.5%); and tap water in the amount enough to give a dough consistency of 350 FU. The resulting dough was fermented in a fermentation chamber (Sveba Dahlen, Fristadt, Sweden) for 1 h at 30 °C and a relative air humidity of 85%, whereby the dough was punched after 30 min of fermentation. The dough was then divided into chunks (250 g), formed into a ball and placed in the greased baking pans. The prepared dough chunks underwent fermentation under the above-mentioned conditions, until the optimal rise was achieved. The process of baking was conducted at 230 °C for 30 min in a baking chamber of a Classic electric oven (Sveba Dahlen, Fristadt, Sweden). After baking, the hot loaves were removed from the pans, weighted and allowed to cool on metal grids. Dough preparation and bread baking were repeated three times, and the obtained loaves were three production batches.

Quality assessment of bread

The main baking quality indicators of wheat and triticale bread, such as dough yield, total baking loss and bread yield, were calculated 24 h after baking (Jakubczyk and Haber 1983; Alvarez-Jubete et al. 2010). The specific volume of the bread was calculated from the measurement of loaf weight and volume, according to AACC Method No. 01/10/01 (AACC 2009), using a Sa-Wa bread volumeter (Sadkiewicz Instruments, Bydgoszcz, Poland). The crumb porosity (porosity coefficient) of the examined bread was assessed using the Dallmann scale, where 30 points means the worst crumb porosity, while 100 points means the best porosity (Dallmann 1981). The crumb moisture was determined according to AACC Method No. 44–15.02 (AACC 2009). The crumb hardness of the investigated bread was determined using the EZ Test EZ-LX testing device and dedicated the Trapezium software (Shimadzu, Kyoto, Japan). A cube-shaped crumb sample (a = 30 mm) was compressed twice to 50% of its height by a cylindrical probe (d = 25 mm), moving at a speed of v = 1 mm⋅s−1. Measurements were made in 6 replications for each examined bread from each production batch.

Statistical analysis

All laboratory tests, unless otherwise stated, were performed in triplicate. Statistical analysis of the obtained results was performed using the Statistica ver. 13 (TIBCO Software Inc, Palo Alto, CA, USA) software. The results were subjected to the one-way analysis of variance, and the differences between the mean values were assessed by Duncan’s test at the significance level of p ≤ 0.05.

Results and discussion

Quality assessment of wheat and triticale grains

The physical parameters and chemical composition of the grain determine its technological suitability, and the results of studies provide information to establish direction in which the examined grain may be used. The results of the research on the quality of winter wheat and winter triticale grain from the 2019 and 2020 harvests are presented in Fig. 1.

Among the triticale, the highest test weight (TW) the grain of the cultivar Panteon (71.9 kg/hL) and only this cultivar had this value above 71 kg/hL. The triticale test weight of the cultivars harvested in 2020 was higher than the values determined in 2019, however, in each of the 2 years, this value in winter wheat grain was significantly the higher. The wheat results looked consistent in spite of the cultivar differences; thus, it was stated that they sufficiently represent the wheat species as the reference object. The impact of the cultivation year on grain quality was also observed in the thousand kernel weight (TKW); the triticale grain derived from the second-year harvest (2020) was assessed as heavier. Compared to wheat grain of the Sailor cv. in 2019, all examined varieties differed from winter triticale significantly larger (TKW); whereas, a comparison of grains harvested in 2020, showed that Euforia cv. grain had the highest value of this parameter (TKW = 44.9). Other authors (Dekić et al. 2014) also reported very significant differences in the yield of triticale grain between the years of research and highly significant differences in the TKW and test weight. In the examined triticale cultivars, glassines of the triticale grain also varied markedly in two depending on the year of investigation (Fig. 1). The average grain glassiness of the Elan cv. was about 65%, while for the Panteon cv. it was about 37%, glassiness of the Pudik was 25% and the Timofei—21%. In 2019, protein content in triticale grain was comparable to that of the wheat cultivar Sailor, while in 2020 was significantly lower than in the previous year; although, was still higher than that of the Euforia wheat standard. The highest average crude protein content was found for the cultivar Timofiej. According to Alaru et al. (2003), the protein content in the triticale grain depends on the variety, weather conditions and nitrogen fertilization, while according to Brzozowska et al. (2009), weather conditions during plant growth do not affect the total content of essential amino acids in the triticale grain protein.

Quality assessment of flour and dough

The average yield of triticale flour was significantly lower (66.5–68.1%) than that of wheat flour (about 75%). The result is in agreement with studies of other authors, e.g., Aprodu and Banu (2016) report lower yield of triticale flour compared to wheat flour. On the other hand, according to Woś H. (unpublished data), in a small industrial mill near Kraków (Poland), a flour yield of 70% was obtained for the Krakowiak cultivar triticale grain. In earlier studies, other authors (Dennett and Trethowan 2013; Pattison and Trethowan 2013) found that yield of the grain milling of contemporary triticale varieties is higher with lower moisture, regardless of the grain hardness; however, as in the case of wheat grain, the ash content in the flour increases as a result. Similar relationships were also reported by Fraś et al. (2016).

The protein and ash content of flour are the fundamental criteria for the classification of flour and, together with the knowledge about the wet gluten content, are the basis for assessing the baking value of wheat flour. The crude protein content in the examined triticale flours was similar to that of the wheat flour of the two investigated varieties (Table 1). The highest average protein content in triticale flour was found in the cultivar Timofiej (15.6%) and in the wheat flour—in the Sailor cv. (17.6%). It should be emphasized that all triticale varieties had a relatively high protein content in flour, which should ensure a high-quality bread. Most often, the protein content in triticale grain is in the range of 14.4–15.6%, which is also confirmed by other authors (Ceglińska and Haber 2001; Boros et al. 2013; Fraś et al. 2016). The wet gluten content of the examined triticale flours did not correspond to the protein content of the flour and was at the same time significantly lower than the value of this parameter for the examined wheat flours (Table 1). The cultivar Panteon was rated best for the average wet gluten content, as showed by the highest values of this parameter in each year of the study. Similar results were reported in previous studies on the flour obtained from selected triticale varieties (Kaszuba et al. 2017, 2021).

When assessing the suitability of triticale grain for consumption purposes, especially for milling and bread-making, the importance of the resistance of triticale varieties to preharvest sprouting is indicated. Some triticale cultivars are characterized by a much lower than average amylolytic activity of the resulting flour (Woś and Brzeziński 2015; Fraś et al. 2018; Kaszuba et al. 2017, 2021). Flour of the examined triticale varieties, obtained in 2019, varied significantly in terms of the falling number (Table 1). In the majority of cultivars, it was about 100 s, while that of the Panteon cultivar (248 s) was rated the best. Triticale flours obtained from the grain milled in 2020 had a falling number of over 200 s and the Panteon variety (333 s) was again rated highest. Moreover, as indicated by the findings of other authors (Alaru and Laur 2005), the falling number depended on the variety and weather conditions in a given year. A comparison of the falling number values of triticale flours, given in Table 1 showed that the Panteon variety is the most stable in terms of this characteristic, as was already found in previous studies (Woś and Brzeziński 2015; Fraś et al. 2016; Kaszuba et al. 2021).

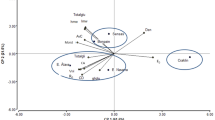

Among the bread-making quality parameters water absorption of the flour is important, as necessary to achieve the desired consistency of the bread dough. Bakers are interested in the varieties characterized by high water absorption for economic reasons. The results of the farinographic analysis of the dough of the investigated wheat and triticale varieties are presented in Table 2; their graphical presentation as the consistency curve is given in Fig. 2.

Results from the Tables 3 and 4 indicate significant differences of baking quality parameters related to the studied cultivars of triticale and wheat. Schulyndin (1981) wrote for the first time in his monograph that triticale flour can be an enhancer for wheat flour to achieve a very good bread porosity. The very good triticale bread obtained in this study (Photo 1) had also very good porosity, which is one of the most important quality indicators of bread. In addition, the crumb of triticale bread from the Panteon cv. was characterized by a lower hardness (Table 4). This feature, together with the highest crumb humidity, probably contributed to the largest bread volume and dough yield, not forgetting the high gluten content. The Ukrainian triticale varieties had a very strong flour gluten, which could have led to a greater crumb hardness of the bread (Table 4), which and made impossible to obtain a greater bread volume. Różyło (2010) claims that in the case of dough with strong gluten, modification of the dough processing parameters could improve the baking results.

The volume of bread obtained from 100 g of flour was the largest in the case of wheat breads, while among triticale breads, the greatest volume had the bread made of the Panteon cultivar. Wheat breads had the highest specific volume. Of the triticale breads baked from grain flour from the harvest in 2019, the bread from the Panteon cv. achieved the largest specific volume (2.99 cm3/g) and at the same time showed a very good porosity (Table 4). These results may reflect the highest wet gluten content, the lowest amylolytic activity of the flour (Table 1) and the high water absorption of the flour (Table 2); they do not, however, correlate with the indirect parameters of the dough evaluation indicated in the farinographic analysis (Table 2), which is very important only for the assessment of the wheat flour suitability. Moreover, as was noted for the triticale Panteon cv., the crumb of the bread with a very good porosity was also characterized by a lower crumb hardness.

As reported other authors (Navarro-Contreras et al. 2014; Fraś et al. 2016), the discussed quality features of the triticale breads varied (Table 4) and to a large extent were determined by the cultivar genotype.

Reliable indicators of the baking value of the examined triticale flour

The cultivar Panteon was characterized by a high gluten content (33%) and a very high falling number as for triticale flour about 300 s; whereas, this parameter was significantly lower for the Ukrainian cultivars. This may be due to the fact that, under Polish conditions, there is more rainfall and it is easier to select forms resistant to preharvest sprouting, which is correlated with a high falling number. The cultivar Panteon had also the highest water absorption of flour, similar to that of wheat, and much higher than that of the flours from the Ukrainian cultivars (Table 2). On the other hand, the parameters of the farinographic analysis of triticale dough from the Ukrainian cultivars, such as the dough development time and dough stability were even higher than these obtained for the examined wheat cultivars. The dough softening was relatively low but still better than that determined for the examined wheat dough, which is unusual with regard to triticale dough characteristics. Unfortunately, the dough made from the cultivar Panteon showed the highest softening, about 200 FU, while in the case of wheat and triticale doughs obtained from the Ukrainian cultivars, the dough softening was about 20 FU. The cultivar Panteon reached also the lowest farinograph quality number (35), while for the wheat cultivar Sailor, the FQN was 200 (2020) and for Ukrainian triticale cultivars accounted for 170 (2020). The research results discussed in this paper show that some quality parameters used in wheat quality assessment may be not reliable in the similar assessment of triticale. The following parameters proved to be reliable for both wheat and triticale: falling number, protein content, wet gluten content, water absorption and crumb porosity. Their application is recommended for triticale breeders, bakers and cultivar testing authorities.

The indirect methods and farinographic analysis of dough may be much useful in application to the selected Ukrainian triticale materials, however fail in case of the Polish cv. Panteon, which despite the unsatisfactory dough characteristics, achieved the best baking results. Such cultivar could be rejected during selection if testing is based on farinographic analysis. The results are in agreement with those collected earlier in studies including this cultivar (Woś and Brzeziński 2015).

There are serious economic reasons to consider triticale as a crop competitive to wheat, at least in some regions. Poland is the largest triticale cultivation area in the world with an average of 1.2–1.3 million hectares (Niewinska et al. 2022; Woś and Brzeziński 2015). The crop is better adapted to the most typical local soils where it yields more grain than wheat. Triticale shows relatively high resistance to soil acidification and drought (Arseniuk 2015; Randhawa et al. 2015). In Poland, over 60% of arable soils are acid or very acid. Under such soil conditions, aluminium toxicity is regarded as the most important yield—limiting factor (Budzianowski and Woś 2004). Moreover, for cultivation of triticale less nitrogen is used than in wheat. Therefore, the crop is recommended for organic farming. Almost all triticale grain is used in livestock feeding, and the green matter is useful in the form of silage, pasture grazing and hay for fodder of beef cattle, dairy cattle, sheep, swine and poultry (Eudes 2015). Other than bread cereals foods gain popularity as an essential part of the daily diet (due to contents of protein, carbohydrate, dietary fiber and texture). It is also an unexploited area for triticale grain utilization. As the population becomes more health conscious, the current trend to try new products has increased consumers’ interest in triticale (Lango et al. 2016).

Breeding and cultivation of quality triticale for acid and less fertile soils would increase total production of grain for bread. Currently, the crop is less economically feasible because farmers receive more money for grain of quality wheat.

Conclusions

-

(1)

A significant variation of grain, flour and bread quality parameters was found among the four investigated triticale cultivars selected as the most suitable for bread production.

-

(2)

Baking quality parameters of the investigated Ukrainian triticale cultivars were not worse than those of wheat, but the bread loaf volume was lower.

-

(3)

Triticale bread baked from Panteon flour was the largest with excellent porosity.

-

(4)

There are at least two different types of triticale suitable for bread production. The Ukrainian type, represented by the cultivars Elan, Pudik and Timofiej, may be tested with the use of methods accepted for wheat bread quality assessment, contrary to the other type represented by the Polish cultivar Panteon.

-

(5)

The parameters used for prediction of wheat bread quality, especially the farinographic ones, are deceptive if applied to triticale, thus the method of laboratory baking is recommended for bakers, breeders and for cultivar testing.

Data availability

The data that support the findings of this study are available from the corresponding authora upon reasonable request.

References

AACC (2009) AACC International approved methods of analysis. (11th ed.). American Association of Cereal Chemists (AACC) International St. Paul, MN, USA

Acs E, Bona L, Lango B, Acs K, Veha A, Pepo P, Petroczi IM (2016) Effects of fertilizer active agents on quality parameters of Hungarian triticale varieties in long-term fertilization trials. In: Book of abstracts, 9th international trtiticale symposium, Szeged, Hungary, 23–27 May 2016, p 77

Alaru M, Laur Ü (2005) About winter triticale cultivation in Estonia. J Agr Sci 16(2):80–84

Alaru M, Lau Ü, Jaama E (2003) Influence of nitrogen and weather conditions on the grain quality of winter triticale. Agron Res 1(1):3–10

Alvarez-Jubete L, Auty M, Arendt EK, Gallagher E (2010) Baking properties and microstructure of pseudocereal flours in gluten-free bread formulations. Eur Food Res Technol 230(3):437–445. https://doi.org/10.1007/s00217-009-1184-z

AOAC (2006) Official methods of analysis, method 925.10. Solids (Total) and moisture in flour, 18th ed.; Gaithersburg Association of Official Analytical Chemists International, Gaithersburg, MD, USA

Aprodu I, Banu I (2016) Comparative analyses of physicochemical and technological properties of triticale, rye and wheat. Ann Univ Dunarea Jos Galati Fascicle VI: Food Technol 40(2):31–39

Arseniuk E (2015) Triticale abiotic stresses—an overview. Triticale. Springer, Cham, pp 69–81

Bona L, Acs E, Lantos C, Purnhauser L, Lango B, Tomoskozi S (2013) Human utilization of triticale: technological and nutritional features, milling and baking experiments. In: Abstract book of the 8th international triticale symposium, Ghent, Belgium, 10–14 June 2013, p 47

Boros D, Jabłonka O, Myszka K (2013) Triticale as a source of nutrients and bioactive components—study based on chemical characteristics of 29 varieties currently registered in Poland. In: Abstract book of the 8th international triticale symposium, Ghent, Belgium, 10–14 June 2013, p 47

Brzozowska I, Brzozowski J, Hruszka M (2009) Effect of various methods of weed control and nitrogen fertilisation on biological value of winter triticale grain protein. Fragm Agron 26(2):16–25

Budzianowski G, Woś H (2004) The effect of single D-genome chromosomes on aluminum tolerance of triticale. Euphytica 137:165–172

Ceglińska A, Haber T (2001) Wartość technologiczna wybranych odmian pszenżyta ozimego. Biul IHAR 218(219):315–332

Dallmann H (1981) Porentabelle. Detmold. Moritz Schäfer, Verlag Moriz Schafer, Germany

Đekić V, Milovanović M, Popović V, Milivojević J, Staletić M, Jelić M, Perišić V (2014) Effects of fertilization on yield and grain quality in winter triticale. Rom Agric Res 31:175–183

Dennett AL, Trethowan RM (2013) Milling efficiency of triticale grain for commercial flour production. J Cereal Sci 57(3):527–530. https://doi.org/10.1016/j.jcs.2013.03.002

Eudes F (2015) Preface. Triticale. Springer, pp 83–108

Fraś A, Gołębiewska K, Gołębiewski D, Mańkowski DR, Boros D, Szecówka P (2016) Variability in the chemical composition of triticale grain, flour and bread. J Cereal Sci 71:66–72. https://doi.org/10.1016/j.jcs.2016.06.016

Fraś A, Gołębiewski D, Gołębiewska K, Mańkowski DR, Gzowska M, Boros D (2018) Triticale-oat bread as a new product rich in bioactive and nutrient components. J Cereal Sci 82:146–154. https://doi.org/10.1016/j.jcs.2018.05.001

Galoburda R, Straumite E, Sabovics M, Kruma Z (2020) Dynamics of volatile compounds in triticale bread with sourdough: from flour to bread. Foods 9(12):1837. https://doi.org/10.3390/foods9121837

Hegarty JM, Shchipak GV, Nichiporuk YA, Shchipak VG, Relina LI, Dubcovsky J (2022) Triticale grain: it’not just for animals anymore! Biul IHAR 297(2022):38

ICC (1980) Standard method No. 129: method for the determination of the vitreousness of durum wheat. International Association for Cereal Science and Technology (ICC), Vienna, Austria

ICC (2003) Standard method no. 115/1: method for using the brabender farinograph; International Association for Cereal Science and Technology (ICC), Vienna, Austria

ICC (2003) Standard method no. 131: method for test baking of wheat flours. International Association for Cereal Science and Technology (ICC), Vienna, Austria

ISO (2006) International Organization for Standardization (ISO)ISO 21415–1:2006. Wheat and wheat flour—gluten content—Part 1: determination of wet gluten by a manual method. International Organization for Standardization (ISO), Geneva, Switzerland

ISO (2009) (ISO). ISO 3093:2009. Wheat, rye and their flours, durum wheat and durum wheat semolina—determination of the falling number according to Hagberg-Perten. International Organization for Standardization (ISO), Geneva, Switzerland

ISO (2019) International Organization for Standardization (ISO). ISO 7971–3:2019. Cereals: Determination of bulk density, called mass per hectolitre - Part 3: Routine method, International Organization for Standardization (ISO): Geneva, Switzerland.

Jakubczyk T, Haber T (eds) (1983) Analiza zbóż i przetworów zbożowych: praca zbiorowa. Wydawnictwo SGGW-AR, Warszawa, Poland (in Polish)

Kaszuba J, Pycia K, Wiśniewski R, Jaworska G, Kuźniar P (2017) Effect of selected oil-bearing plant seed contained in triticale bread on its quality. Food Sci Technol Qual 24:90–102. https://doi.org/10.15193/zntj/2017/113/213

Kaszuba J, Jaworska G, Krochmal-Marczak B, Kogut B, Kuźniar P (2021) Effect of bran addition on rheological properties of dough and quality of triticale bread. J Food Process Preserv 45(1):e15093. https://doi.org/10.1111/jfpp.15093

Lango B, Acs E, Tomoskozi S, Bona L (2016) Triticale end-use: nutritional and technological properties of Hungarian genotypes. In: Book of abstracts 9th international triticale symposium, May 23–27,2016. Szeged, Hungary, p 72

Lukaszewski AJ (2006) Cytogenetically engineered rye chromosomes 1R to improve bread-making quality of hexaploid triticale. Crop Sci 46:2183–2194

Mihaly-Lango B, Erika A, Purgel S, Tomoskozi S, Bona L (2022) Resent results on food-use quality of Hungarian triticale genotypes: nutrional and technological aspects. Biul IHAR 297(2022):36

Navarro-Contreras AL, Chaires-González CF, Rosas-Burgos EC, Borboa-Flores J, Wong-Corral FJ, Cortez-Rocha MO, Cinco-Moroyoqui FJ (2014) Comparison of protein and starch content of substituted and complete triticales (X Triticosecale Wittmack): contribution to functional properties. Int J Food Prop 17(2):421–432. https://doi.org/10.1080/10942912.2011.642440

Niewinska M, Lugowska B, Pojmaj M, Bogacki J, Brukwiński W, Kaźmierczak P, Kurleto D, Banaszak K, Czerwińska E, Krysztofik R, Haremza J, Fornalczyk A, Konieczny M, Katanska-Kaczmarek A, Paszkowski E, Bielerzewska-Kazmierczak H, Kaczmarek J, Urbańczyk P (2022) New plant variety breeding of triticale (X Triticosecale Wittm. Ex A. camus) based on innovative biotechnological methods. Biul IHAR 297/2022:49

Pattison AL, Trethowan RM (2013) Characteristics of modern triticale quality: commercially significant flour traits and cookie quality. Crop Pasture Sci 64(9):874–880. https://doi.org/10.1071/CP13056

Randhawa HS, Bona L, Graf RJ (2015) Triticale breeding—progress and prospect. Triticale. Springer, Cham, pp 15–32

Różyło R (2010) Wpływ parametrów obróbki ciasta na cechy fizyczne chleba pszennego. Acta Agroph 16(1[181]):149–161 (in Polish)

Schulyndin AF (1981) Triticale new species of grain and green mass. Kijev, pp1–49

Shchipak GV (2019) Triticale and wheat breeding for adaptability, yield and quality. Kijev, pp 1–480

Shchipak GV, Shchipak VG (2022) Hexaploid triticale breeding for adaptability, yield and quality. Biul IHAR 297(2022):24

Tohver M, Kann A, Täht R, Mihhalevski A, Hakman J (2005) Quality of triticale cultivars suitable for growing and bread-making in northern conditions. Food Chem 89(1):125–132. https://doi.org/10.1016/j.foodchem.2004.01.079

Woś H, Brzeziński W (2015) Triticale for food—the quality driver. Triticale. Springer, Cham, pp 213–232

Wrigley C, Bushuk W (2017) Triticale: grain-quality characteristics and management of quality requirements. Cereal grains. Woodhead Publishing, pp 179–194

Funding

This work was financed by a subsidy of the Ministry of Education and Science for the University of Rzeszów in 2021 (research project PB/ZOTZiŻC/2021) and Dr. Henryk Woś, Private Breeding Program, Nowe Borówko 29, 64-020 Czempiń, Poland.

Author information

Authors and Affiliations

Contributions

Conceptualization, HW, GS; methodology, HW, GS, JK; investigation, HW, JK, GS; writing—original draft preparation, HW, JK, GS; writing—review and editing, HW, JK.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no financial or non-financial interests that are directly or indirectly related to the work submitted for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kaszuba, J., Woś, H. & Shchipak, G.V. Bread making quality parameters of some Ukrainian and Polish triticale cultivars. Euphytica 220, 15 (2024). https://doi.org/10.1007/s10681-023-03272-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10681-023-03272-4