Abstract

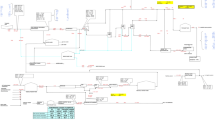

In the present study, a techno-economic analysis for the reclamation of wastewater in a midstream petrochemical factory (the Miaoli factory of the China Petrochemical Development Company in Taiwan) was investigated. Caprolactam is the main product in this factory. The wastewater to be reclaimed and recycled as cooling water replenishment was the effluent from organic- and inorganic-based wastewater treatment plants, the concentrate from cooling tower units, and water for rinsing use from other units. In addition to the current primary treatment process (Scheme 1), other treatment methods involving various combinations of membrane-based processes of microfiltration (MF), ultrafiltration (UF), reverse osmosis (RO), and electrodialysis reversal (EDR) were proposed, depending on the quality of the wastewater. The three schemes include the combination of MF and EDR (Scheme 2), UF and RO (Scheme 3), and MF, UF and RO (Scheme 4). Based on the capacities and operating costs of various membrane modules, an economic analysis on Schemes 2–4 by the net present worth method demonstrated that Scheme 3 was the best choice under the range of source water price studied (U$ 0.45–0.62/m3). In this case, the total amount of wastewater reclaimed notably increased from 6.6% by the current treatment scheme (Scheme 1) to 30.9% by Schemes1 and 3. Moreover, Scheme 3 had an advantage over Scheme 1 when the source water price exceeds U$ 0.51/m3.

Similar content being viewed by others

Data availability

The data will be provided upon request.

Abbreviations

- CMH:

-

Cubic meter per hour (m3/h)

- DCF:

-

Discounted cash flow

- EDR:

-

Electrodialysis reversal

- MARR:

-

Minimum attractive rate of return

- MF:

-

Microfiltration

- NPW:

-

Net present worth method

- RO:

-

Reverse osmosis

- UF:

-

Ultrafiltration

- COD:

-

Chemical oxygen demand

- TDS:

-

Total dissolved solids

- SS:

-

Suspended solids

References

Aljuwaisseri, A., Aleisa, E., & Alshayji, K. (2022). Environmental and economic analysis for desalinating seawater of high salinity using reverse osmosis: A life cycle assessment approach. Environment, Development and Sustainability. https://doi.org/10.1007/s10668-022-02214-9

Allison, R. P. (1995). Electrodialysis reversal in water reuse applications. Desalination, 103(1), 11–18. https://doi.org/10.1016/0011-9164(95)00082-8

Baker, R. W. (2012). Reverse osmosis. In Membrane technology and applications, Chapter 5 (3rd Ed.). Wiley. ISBN: 978-0-470-74372-0.

Broens, L., Liebrand, N., Futselaar, H., & De Armas Torrent, J. C. (2004). Effluent reuse at Barranco Seco (Spain): A 1000 m3/h case study. Desalination, 167, 13–16. https://doi.org/10.1016/j.desal.2004.06.106

Ciardelli, G., Corsi, L., & Marcucci, M. (2001). Membrane separation for wastewater reuse in the textile industry. Resources, Conservation and Recycling, 31(2), 189–197. https://doi.org/10.1016/S0921-3449(00)00079-3

Chao, Y. M., & Liang, T. M. (2008). A feasibility study of industrial wastewater recovery using electrodialysis reversal. Desalination, 221(1), 433–439. https://doi.org/10.1016/j.desal.2007.04.065

Hammenecker, J. (2010). International statistics for water services 2010, the IWA specialist group on statistics and economics. London, UK: IWA.

Hammenecker, J., & Bijnens, A. (2018). International statistics for water services 2018, the IWA specialist group on statistics and economics. London, UK: IWA.

Henny, L., Thorncroft, C. D., Hsu, H. H., & Bosart, L. F. (2021). Extreme rainfall in Taiwan: Seasonal statistics and trends. Journal of Climate, 34(12), 4711–4731. https://doi.org/10.1175/JCLI-D-20-0999.1

Ji, S., & Ma, S. (2021). The effects of industrial pollution on ecosystem service value: A case study in a heavy industrial area, China. Environment, Development and Sustainability. https://doi.org/10.1007/s10668-021-01728-y

Liang, J., Mai, W., Tang, J., & Wei, Y. (2019). Highly effective treatment of petrochemical wastewater by a super-sized industrial scale plant with expanded granular sludge bed bioreactor and aerobic activated sludge. Chemical Engineering Journal, 360, 15–23. https://doi.org/10.1016/j.cej.2018.11.167

Lyu, S., Chen, W., Zhang, W., Fan, Y., & Jiao, W. (2016). Wastewater reclamation and reuse in China: Opportunities and challenges. Journal of Environmental Sciences, 39, 86–96. https://doi.org/10.1016/j.jes.2015.11.012

Mahbub, P., & Sharma, A. (2019). Investigation of alternative water sources for fish farming using life cycle costing approach: A case study in North West Tasmania. Journal of Hydrology, 579, 124215. https://doi.org/10.1016/j.jhydrol.2019.124215

Marques, A. C., Veras, C. E., & Rodriguez, D. A. (2022). Assessment of water policies contributions for sustainable water resources management under climate change scenarios. Journal of Hydrology, 608, 127690. https://doi.org/10.1016/j.jhydrol.2022.127690

Park, C. S. (2016). Present worth analysis. In Contemporary engineering economics, Chapter 5 (6th Ed., pp. 208–269). Pearson Education, Inc. ISBN: 978-0-134-10559-8

Pérez, E. M., & Martín, N. (2015). π–π interactions in carbon nanostructures. Chemical Society Reviews, 44(18), 6425–6433. https://doi.org/10.1039/C5CS00578G

Subramani, A., & Jacangelo, J. G. (2015). Emerging desalination technologies for water treatment: A critical review. Water Research, 75, 164–187. https://doi.org/10.1016/j.watres.2015.02.032

Sullivan, W. S., Wicks, E. M., & Koelling, C. P. (2020). Evaluating a single project, Chapter 5. In Engineering economy (17th ed., pp. 210–257). Pearson Education, Inc. ISBN: 978-1-292-26490-5.

Tchobanoglous, G., Burton, F. L., & Stensel, H. D. (2003). Wastewater Engineering: Treatment and Reuse (4th ed.). New York: Metcalf & Eddy Inc.

Tian, X., Song, Y., Shen, Z., Zhou, Y., Wang, K., Jin, X., Han, Z., & Liu, T. (2020). A comprehensive review on toxic petrochemical wastewater pretreatment and advanced treatment. Journal of Cleaner Production, 245, 118692. https://doi.org/10.1016/j.jclepro.2019.118692

Tung, Y. T., & Pai, T. Y. (2015). Water management for agriculture, energy, and social security in Taiwan. Clean–soil Air and Water, 43, 627–632. https://doi.org/10.1002/clen.201300275

Van der Bruggen, B., Vandecasteele, C., Van Gestel, T., Doyen, W., & Leysen, R. (2003). A review of pressure-driven membrane processes in wastewater treatment and drinking water production. Environmental Progress, 22(1), 46–56. https://doi.org/10.1002/ep.670220116

Vergili, I., Kaya, Y., Sen, U., Gönder, Z. B., & Aydiner, C. (2012). Techno-economic analysis of textile dye bath wastewater treatment by integrated membrane processes under the zero liquid discharge approach. Resources, Conservation and Recycling, 58, 25–35. https://doi.org/10.1016/j.resconrec.2011.10.005

Wang, D. H. M., & Huang, C. Y. (2018). Construction and application of water resource accounting information system in Taiwan. International Journal of Business, Economics and Management, 5(1), 1–15. https://doi.org/10.18488/journal.62.2018.51.1.15

Weerasooriya, R. R., Liyanage, L. P. K., Rathnappriya, R. H. K., Bandara, W. B. M. A. C., Perera, T. A. N. T., Gunarathna, M. H. J. P., & Jayasinghe, G. Y. (2021). Industrial water conservation by water footprint and sustainable development goals: A review. Environment, Development and Sustainability, 23(9), 12661–12709. https://doi.org/10.1007/s10668-020-01184-0

Wintgens, T., Melin, T., Schäfer, A., Khan, S., Muston, M., Bixio, D., & Thoeye, C. (2005). The role of membrane processes in municipal wastewater reclamation and reuse. Desalination, 178(1), 1–11. https://doi.org/10.1016/j.desal.2004.12.014

Wu, J., Zhang, Y., Wang, J., Zheng, X., & Chen, Y. (2021). Municipal wastewater reclamation and reuse using membrane-based technologies: A review. Desalination and Water Treatment, 224, 65–82. https://doi.org/10.5004/dwt.2021.27175

Acknowledgements

Financial support for this work through a grant from the National Science and Technology Council, Taiwan (No. 111-2221-E-182-002) is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is not any conflicts of interest regarding this publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, CW., Tran, H.N. & Juang, RS. Reclamation and reuse of wastewater by membrane-based processes in a typical midstream petrochemical factory: a techno-economic analysis. Environ Dev Sustain 26, 5419–5430 (2024). https://doi.org/10.1007/s10668-022-02880-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-022-02880-9