Abstract

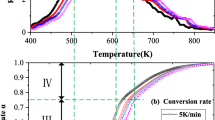

Uttarakhand has the maximum potential of pine of about 20 lakh tonnes/year including reserved forests and van panchayat which makes pine needle an abundant resource. The analysis of the pine needles reveals it a potential biomass feedstock for gasification to produce electricity. This manuscript deals with the combustion study of Pine needles (Pinusroxburghii) biomass using a thermogravimetric analyzer to investigate the thermal degradation behavior and kinetic parameters. The pine needles were heated in the presence of air at four different heating rates 5, 10, 25 and 50 °C/min, and the degradation phenomenon was studied. From the proximate and ultimate analysis of pine needles, it was observed that the biomass could be a potential feedstock for gasification. The TG-DTG curves revealed that the main decomposition was between 190 and 450 °C with the release of 80–84% volatiles. It was observed that as the heating rate increases, the maximum decomposition temperature also increases and the peak shifts to the right. The obtained thermal data were used to calculate the kinetic parameters using Kissinger–Akharia–Sunose, Ozawa-Flynn-Wall, Friedman and Kissinger. The average values obtained from the above methods are 190.74, 190.75, 199.48 and 172 kJ/mol and 2.749 × 1022, 5.13 × 1022, 4.21 × 1021 and 4.14 × 106/min, respectively. The model fitting method and Coats–Redfern method were used to determine the kinetic triplet (A, E and n). The above model-free methods and model fitting methods predicts the progress of gasification at different positions along the reactor. Considering proximate analysis and heating value, pine needles could be considered as a potential feedstock for energy production through gasification process. The estimated results help as a source to understand the thermal degradation of biomass during the gasification process and be used to design the systems.

Similar content being viewed by others

References

Arora, S., et al. (2011). Comparative degradation kinetic studies of three biopolymers: chitin, chitosan and cellulose. Arch Appl Sci Res, 3(3), 188–201.

Basu, P. (2010). Biomass gasification and pyrolysis: practical design and theory. Cambridge: Academic Press.

Bisht, A. S., Singh, S., & Kumar, M. (2014). Pine needles a source of energy for Himalayan Region. International Journal of Scientific & Technology Research, 3(12), 161–164.

Cerc Korošec, R., et al. (2009). Thermogravimetry as a possible tool for determining modification degree of thermally treated Norway spruce wood. Journal of Thermal Analysis and Calorimetry, 98(1), 189–195.

Ceylan, S., Topcu, Y., & Ceylan, Z. (2014). Thermal behaviour and kinetics of alga Polysiphonia elongata biomass during pyrolysis. Bioresource Technology, 171, 193–198.

Chan, J., & Balke, S. (1997). The thermal degradation kinetics of polypropylene: Part III. Thermogravimetric analyses. Polymer degradation and stability, 57(2), 135–149.

Channiwala, S., & Parikh, P. (2002). A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel, 81(8), 1051–1063.

Chauhan, A., & Saini, R. (2015). Renewable energy based off-grid rural electrification in Uttarakhand state of India: Technology options, modelling method, barriers and recommendations. Renewable and Sustainable Energy Reviews, 51, 662–681.

Claoston, N., et al. (2014). Effects of pyrolysis temperature on the physicochemical properties of empty fruit bunch and rice husk biochars. Waste Management and Research, 32(4), 331–339.

Coats, A. W., & Redfern, J. (1964). Kinetic parameters from thermogravimetric data. Nature, 201(4914), 68.

Demirbaş, A. (1997). Calculation of higher heating values of biomass fuels. Fuel, 76(5), 431–434.

Din, Z. U., & Zainal, Z. (2016). Biomass integrated gasification–SOFC systems: Technology overview. Renewable and Sustainable Energy Reviews, 53, 1356–1376.

Doyle, C. (1962). Kinetic analysis of thermogravimetric data. Journal of Applied Polymer Science, 6(19), 120.

El-Sayed, S. A., & Mostafa, M. (2014). Pyrolysis characteristics and kinetic parameters determination of biomass fuel powders by differential thermal gravimetric analysis (TGA/DTG). Energy Conversion and Management, 85, 165–172.

Fisher, T., et al. (2002). Pyrolysis behavior and kinetics of biomass derived materials. Journal of Analytical and Applied Pyrolysis, 62(2), 331–349.

Font, R., et al. (2009). Kinetics of pyrolysis and combustion of pine needles and cones. Journal of Analytical and Applied Pyrolysis, 85(1–2), 276–286.

Friedman, H. L. (1964). Kinetics of thermal degradation of char‐forming plastics from thermogravimetry. Application to a phenolic plastic. Journal of Polymer Science Part C: Polymer Symposia. Wiley Online Library.

García, R., et al. (2013). Biomass proximate analysis using thermogravimetry. Bioresource Technology, 139, 1–4.

Garcia-Maraver, A., et al. (2015). Determination and comparison of combustion kinetics parameters of agricultural biomass from olive trees. Renewable Energy, 83, 897–904.

Gil, M., Teruel, E., & Arauzo, I. (2014). Analysis of standard sieving method for milled biomass through image processing. Effects of particle shape and size for poplar and corn stover. Fuel, 116, 328–340.

Guo, Q., Chen, X., & Liu, H. (2012). Experimental research on shape and size distribution of biomass particle. Fuel, 94, 551–555.

Joshi, K., Sharma, V., & Mittal, S. (2015). Social entrepreneurship through forest bioresidue briquetting: An approach to mitigate forest fires in Pine areas of Western Himalaya, India. Renewable and Sustainable Energy Reviews, 51, 1338–1344.

Katre, D., & Gupta, M. (2011). Expert usability evaluation of 28 state government web portals of India. International Journal of Public Information Systems, 7(3), 1–16.

Kok, M. V., & Özgür, E. (2013). Thermal analysis and kinetics of biomass samples. Fuel Processing Technology, 106, 739–743.

Kurose, K., Okamura, D., & Yatagai, M. (2007). Composition of the essential oils from the leaves of nine Pinus species and the cones of three of Pinus species. Flavour and fragrance journal, 22(1), 10–20.

Leoni, E., et al. (2003). Thermal degradation of pinus pinaster needles by dsc, part 2: Kinetics of exothermic phenomena. Journal of Fire Sciences, 21(2), 117–130.

Li, Y., Zhou, L., & Wang, R. (2017). Urban biomass and methods of estimating municipal biomass resources. Renewable and Sustainable Energy Reviews, 80, 1017–1030.

Lu, C., Song, W., & Lin, W. (2009). Kinetics of biomass catalytic pyrolysis. Biotechnology Advances, 27(5), 583–587.

Naik, S., et al. (2010). Characterization of Canadian biomass for alternative renewable biofuel. Renewable Energy, 35(8), 1624–1631.

Ozawa, T. (1965). A new method of analyzing thermogravimetric data. Bulletin of the chemical society of Japan, 38(11), 1881–1886.

Perlack, R. D. (2005). Biomass as feedstock for a bioenergy and bioproducts industry: The technical feasibility of a billion-ton annual supply. Oak Ridge: Oak Ridge National Laboratory.

Safi, M., Mishra, I., & Prasad, B. (2004). Global degradation kinetics of pine needles in air. Thermochimica Acta, 412(1–2), 155–162.

Saravanan, A. P., et al. (2018). Biofuel policy in India: a review of policy barriers in sustainable marketing of biofuel. Journal of Cleaner Production, 193, 734–747.

Senneca, O. (2007). Kinetics of pyrolysis, combustion and gasification of three biomass fuels. Fuel Processing Technology, 88(1), 87–97.

Smidt, E., & Schwanninger, M. (2005). Characterization of waste materials using FTIR spectroscopy: Process monitoring and quality assessment. Spectroscopy Letters, 38(3), 247–270.

Statheropoulos, M., et al. (1997). Thermal degradation of Pinus halepensis pine-needles using various analytical methods. Journal of Analytical and Applied Pyrolysis, 43(2), 115–123.

Susastriawan, A., & Saptoadi, H. (2017). Small-scale downdraft gasifiers for biomass gasification: A review. Renewable and Sustainable Energy Reviews, 76, 989–1003.

Vigneault, C., Rothwell, T., & Bourgeois, G. (1992). Hammermill grinding rate and energy requirements for thin and conventional. Canadian Agricultural Engineering, 34(2), 203.

Vyazovkin, S., & Wight, C. A. (1999). Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochimica Acta, 340, 53–68.

Wang, X.-R., & Szmidt, A. E. (1993). Chloroplast DNA-based phylogeny of AsianPinus species (Pinaceae). Plant Systematics and Evolution, 188(3–4), 197–211.

White, J. E., Catallo, W. J., & Legendre, B. L. (2011). Biomass pyrolysis kinetics: a comparative critical review with relevant agricultural residue case studies. Journal of Analytical and Applied Pyrolysis, 91(1), 1–33.

Wilburn, F. (1989). Introduction to thermal analysis, techniques and applications: Michael E. Brown, published by Chapman and Hall, London, 1988, ISBN 0 412 30230 6, xx + 211 p.; price£ 17.50. Elsevier.

Williams, O., et al. (2016). Influence of mill type on densified biomass comminution. Applied Energy, 182, 219–231.

Xu, R.-B., et al. (2012). Chemical composition and antioxidant activities of three polysaccharide fractions from pine cones. International Journal of Molecular Sciences, 13(11), 14262–14277.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Havilah, P.R., Sharma, P.K. & Sharma, A.K. Characterization, thermal and kinetic analysis of Pinusroxburghii. Environ Dev Sustain 23, 8872–8894 (2021). https://doi.org/10.1007/s10668-020-01001-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-020-01001-8