Abstract

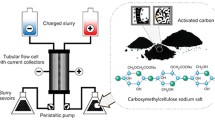

Carbon slurries as “flowable electrodes” have been used recently in a few electrochemical systems, e.g., electrochemical flow capacitors (EFCs) for energy storage and flow-electrode capacitive deionization (FCDI) for water treatment. These slurries typically have three parts: activated carbon particles, a conductive additive such as carbon black, and an aqueous electrolyte solution. Previously, a particle-based computational model that employs Stokesian dynamics was developed to describe the particle motion and interaction, while simultaneously solving for the charge transfer inside an electrical network of moving particles. In this work, we develop a unified expression of the dynamically varying electrical network. Furthermore, we incorporate a group of smaller particles as the conductive additive, whose effect on the charge transfer of the slurry is studied. The results suggest that at lower concentrations, the small particles may enhance charge transfer by filling interstitial spaces and bridging contacts of large particles; however, at higher concentrations, the benefits are not as clear since direct contacts of the large particles play the dominant role in charge transfer.

Similar content being viewed by others

References

Presser V, Dennison CR, Campos J, Knehr KW, Kumbur EC, Gogotsi Y (2012) The electrochemical flow capacitor: a new concept for rapid energy storage and recovery. Adv Energy Mater 2(7):895–902

Dennison CR, Beidaghi M, Hatzell KB, Campos JW, Gogotsi Y, Kumbur EC (2014) Effects of flow cell design on charge percolation and storage in the carbon slurry electrodes of electrochemical flow capacitors. J Power Sources 247:489–496

Hatzell KB, Boota M, Gogotsi Y (2015) Materials for suspension (semi-solid) electrodes for energy and water technologies. Chem Soc Rev 44(23):8664–8687

Si Jeon, Hr Park, Jg Yeo, Yang S, Cho CH, Han MH, Kim DK (2013) Desalination via a new membrane capacitive deionization process utilizing flow-electrodes. Energ Environ Sci 6(5):1471

Suss ME, Porada S, Sun X, Biesheuvel PM, Yoon J, Presser V (2015) Water desalination via capacitive deionization: what is it and what can we expect from it? Energy Environ Sci 8(8):2296–2319

Hoyt NC, Wainright JS, Savinell RF (2015a) Mathematical modeling of electrochemical flow capacitors. J Electrochem Soc 162(4):A652–A657

Hoyt NC, Wainright JS, Savinell RF (2015b) Current density scaling in electrochemical flow capacitors. J Electrochem Soc 162(6):A1102–A1110

Karzar-Jeddi M, Luo H, Cummings PT, Hatzell KB (2019) Computational modeling of particle hydrodynamics and charging process for the flowable electrodes of carbon slurry. J Electrochem Soc 166(12):A2643–A2653

Kirk TL, Evans J, Please CP, Chapman SJ (2020) Modelling electrode heterogeneity in lithium-ion batteries: unimodal and bimodal particle-size distributions. arXiv preprint arXiv:2006.12208

Marquis SG, Timms R, Sulzer V, Please CP, Chapman SJ (2020) A suite of reduced-order models of a single-layer lithium-ion pouch cell. J Electrochem Soc 167(14):140513

Brady JF, Bossis G (1985) The rheology of concentrated suspensions of spheres in simple shear flow by numerical simulation. J Fluid Mech 155:105

Brady JF, Morris JF (1997) Microstructure of strongly sheared suspensions and its impact on rheology and diffusion. J Fluid Mech 348:S0022112097006320

Karzar-Jeddi M, Luo H, Cummings PT (2018) Mobilities of polydisperse hard spheres near a no-slip wall. Comput Fluids 176:40–50

Durlofsky L, Brady JF, Bossis G (1987) Dynamic simulation of hydrodynamically interacting particles. J Fluid Mech 180(1987):21–49

Brady JF, Bossis G (1988) Stokesian dynamics. Annu Rev Fluid Mech 20(1):111–157

Chang C, Powell RL (1993) Dynamic simulation of bimodal suspensions of hydrodynamically interacting spherical particles. J Fluid Mech 253:1–25

Pozrikidis C (1992) Boundary integral and singularity methods for linearized viscous flow. Cambridge University Press, Cambridge

Swan JW, Brady JF (2007) Simulation of hydrodynamically interacting particles near a no-slip boundary. Phys Fluids 19(11):113306

Corless RM, Jeffrey DJ (1988) Stress moments of nearly touching spheres in low Reynolds number flow. Zeitschrift für angewandte Mathematik und Physik ZAMP 39(6):874–884

Jeffrey D, Corless R (1988) Forces and stresslets for the axisymmetric motion of nearly touching unequal spheres. PhysicoChem Hydrodyn 10(4):461–470

Jeffrey DJ, Onishi Y (1984) Calculation of the resistance and mobility functions for two unequal rigid spheres in low-Reynolds-number flow. J Fluid Mech 139(1):261–290

Cooley MDA, O’Neill ME (1969) On the slow motion generated in a viscous fluid by the approach of a sphere to a plane wall or stationary sphere. Mathematika 16(01):37

Goldman A, Cox R, Brenner H (1967) Slow viscous motion of a sphere parallel to a plane wall-II Couette flow. Chem Eng Sci 22(4):653–660

Singh A, Mari R, Denn MM, Morris JF (2018) A constitutive model for simple shear of dense frictional suspensions. J Rheol 62(2):457–468

Wyart M, Cates M (2014) Discontinuous shear thickening without inertia in dense non-brownian suspensions. Phys Rev Lett 112(9):098302

Pozrikidis C (2002) A practical guide to boundary element methods with the software library BEMLIB. CRC Press, Boca Raton

Chang C, Powell RL (1994) The rheology of bimodal hard-sphere dispersions. Phys Fluids 6(5):1628–1636

Farris R (1968) Prediction of the viscosity of multimodal suspensions from unimodal viscosity data. Trans Soc Rheol 12(2):281–301

Shapiro AP, Probstein RF (1992) Random packings of spheres and fluidity limits of monodisperse and bidisperse suspensions. Phys Rev Lett 68(9):1422

Pednekar S, Chun J, Morris JF (2018) Bidisperse and polydisperse suspension rheology at large solid fraction. J Rheol 62(2):513–526

Acknowledgements

This work was supported by an NSF Grant (CBET-1921320). Prof. Kelsey B. Hatzell’s help in this work is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

In addition to the verification in Karzar-Jeddi et al. [13], we have done further tests of the SD code against the BEM calculations using a code previously developed by Prof. Pozrikidis [26]. In this test, the particle ratio \(a_2/a_1\) = 5 is used to match the bimodal particle interactions in the present SD simulation. A total of 1294 triangular elements with 7 Gaussian integration points (6 integration points for singular elements) were used in the BEM for each particle. Figure 6a displays the normalized wall-normal particle velocity versus the normalized gap distance between the two particles, while Fig. 6b displays the inline particle velocity. The calculations from the SD simulation we employ agree well with the BEM method, especially at a gap distance greater than \(a_2\). At lower gaps, the inline velocity shows more pronounced differences for the smaller particle, but the error is still within 15%. Similar to Karzar-Jeddi et al. [13], further mesh refinement in the BEM shows that this discrepancy persists. Thus, the lubrication approximation in the Stokesian dynamics likely has caused the error.

In order to verify the statistical results, a comparison of three, five, and eight simulations was performed on the \(N_b\) = 25 case for the three volume concentrations. This comparison, as seen in Fig. 7, shows that the charge contours are consistent among these calculations and thus ensures that the number of simulations used to provide the data for Fig. 4 is sufficient.

Rights and permissions

About this article

Cite this article

Stacks, B., Luo, H. & Li, D. Charging of flowable electrodes with bimodal distribution of carbon particles. J Eng Math 131, 8 (2021). https://doi.org/10.1007/s10665-021-10177-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10665-021-10177-5