Abstract

Nanocellulose has emerged as a widely utilized building block in nanostructured materials due to its availability, sustainability, large surface area, and high stiffness and aspect ratio. The wet or dry elastoplastic properties of these materials are determined by the fibrils' stiffness, chemical properties, hemicellulose content, and the number of fibril contacts. However, the specific contributions and relative importance of each factor remain unclear. Therefore, this work was devoted to systematically comparing the material properties of gels, aerogels, and wet and dry sheets prepared from CNFs with different aspect ratios, chemical functionality, and hemicellulose content. The fibrils were prepared by chemical and mechanical processing of different pulps. By preserving the native structure as much as possible, higher aspect ratio fibrils can be obtained, which allows for the development of more mechanically robust materials. The results demonstrate that higher aspect ratios lead to more interconnected networks at a lower solids concentration, resulting in a more evenly distributed stress and longer-range stress transfer, yielding stiffer and more ductile materials. The most important finding was that the aspect ratio influences the network formation, resulting in different network topologies. The results were also compared to earlier published data and integrated into a theoretical beam-bending model for a complete elastoplastic description of the network properties, including the influence of fibril aspect ratio and chemical functionality. This information improves our understanding and description of nanofibril networks for which general models have been missing. It can be used to optimize nanofibril preparation and, hence, the resulting eco-friendly materials.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Nanocelluloses have emerged as a sustainable component for the design of nanostructured materials (Li et al. 2021). Nanocelluloses are divided into two primary types: short, rod-like cellulose nanocrystals (CNCs) and long, slender, and more flexible cellulose nanofibrils (CNFs) (Klemm et al. 2011; Benselfelt et al. 2023). The distinguishing characteristic between these types is their aspect ratio (\(a=L/w\)), where L is the contour length, and w is the characteristic width of the fibril. The aspect ratio of CNCs typically falls below 100, while for CNFs, it can reach up to ~ 1000 depending on the source of cellulose and the treatment. These vast differences in aspect ratio lead to quite different uses. When forming networks in materials, a high aspect ratio results in long-range stress transfer due to more contacts per fibril, making CNFs the preferred choice for strong and ductile materials (Walther and Benitez 2017). However, high aspect ratio fibrils are also more difficult to process since they form networks even at low solid concentrations (Solomon and Spicer 2010; Xu et al. 2020; Benselfelt et al. 2023). Nonetheless, CNF networks surpass CNCs in creating materials of high tensile and shear strength and have been recently shown to stabilize and incorporate other types of particles in continuous superstructure constructs (Walther and Benitez 2017; Mattos et al. 2020; Nordenström et al. 2022; Rostami et al. 2022). The considerable surface charge of the nanocelluloses is necessary to keep them colloidally stable, and careful control of the colloidal chemical properties of the nanocelluloses is necessary to tailor and control their self-assembly.

The availability and increased utilization of cellulose nanofibrils motivate the development of more detailed models for the behavior of their networks. Unlike statistical entropy-elastic polymer networks, nanofibril networks behave more like macroscale mechanical objects while also being strongly affected and controlled by intermolecular and colloidal forces. Recent models show that nanofibril networks deform via bending and sliding fibril contacts (Mittal et al. 2018; Östmans et al. 2023; Östmans et al. 2024). This results in a stick-slip-stick behavior where fibrils can release from contacts, slide with friction, and then reattach due to intermolecular interactions when the stress is released. For nanoscale objects in aqueous dispersions, the repulsion from charged groups can influence network properties similarly to their bending stiffness. A chemical term must be added to the balance of pressures within the networks (Östmans et al. 2023). There are two types of hydrated networks: (1) colloidal glasses with repulsion between fibrils due to charged groups or (2) colloidal gels with attraction between fibrils (Solomon and Spicer 2010), leading to two types of elastoplastic models for fibril networks (Östmans et al. 2023, 2024).

Based on the above discussions, the fibrils' stiffness, chemical properties, and the number of fibril contacts determine the elastoplastic properties of fibril networks. Since the number of contacts is proportional to the aspect ratio, and fibril stiffness is related to the chemical modification and processing, the aspect ratio and chemical functionality are the main properties that influence the mechanical behavior of nanocellulose materials. Although CNFs have been characterized in great detail (Usov and Mezzenga 2015; Usov et al. 2015; Isogai et al. 2018), and the influence of length and degree of polymerization has been investigated primarily for dried sheets (Henriksson et al. 2008; Fukuzumi et al. 2013), few studies comprehensively link the fibril properties to the mechanical properties of a broad range of nanocellulose-based materials. To systematically investigate this relationship, gels, aerogels, and wet and dry sheets prepared from CNFs with different aspect ratios and chemical functionality were compared experimentally and theoretically. Hydrated networks were given more attention as the fibril properties are less influential in dense dried sheets. There is also a need for a complete theoretical model to describe the elastoplastic behavior of wet nanofibril networks. Even though the details differ for different types of materials, the approach to understanding and describing their mechanical behavior is the same. This systematic study shows the importance of preserving the high aspect ratio of native cellulose and the influence of remaining hemicellulose, which can be used to develop the ideal fibrils for specific applications.

Theory

The behavior of networks of stiff fibrils is primarily influenced by the volume fraction (ϕ) of the network, along with the chemical properties and aspect ratio of the fibrils (\(a\)). The volume fraction depends on the material's application, leaving the aspect ratio and chemical functionality as the primary influencers of the mechanical properties.

Concentration regimes that dictate the properties of nanofibril networks

The crowding factor (N3D) is used to describe different concentration regimes of fiber and fibril suspensions or networks and is defined as

It quantifies the average number of fibrils inside the volume spanned by a rotating fibril pivoted at its center (Kerekes et al. 1985; Kerekes and Schell 1992). N3D = 1, that is \(\phi =1.5{a}^{-2}\), represents the overlap concentration. Below this threshold, in the dilute regime, fibril–fibril contacts are rare. However, the geometrical model behind the crowding factor does not identify a clear transition in physical behavior of fiber suspensions; that threshold has been experimentally identified at a volume fraction of N3D = 16, that is, \(\phi =24{a}^{-2}\) (Solomon and Spicer 2010; Geng et al. 2018). The crowding range of 1 < N3D < a (Benselfelt et al. 2023), represents the semi-dilute regime with properties of viscous liquid. At N3D ~ a, that is \(\phi \approx {a}^{-1}\), the concentrated regime with a volume-spanning arrested state (VAS) ensues, also known as colloidal glasses for repulsive fibril interactions (Solomon and Spicer 2010; Nordenström et al. 2017) Similarly, the VAS transition can be described by a 2-dimensional crowding (Benselfelt et al. 2023), also referred to as the dimensionless concentration (Onsager 1949; Xu et al. 2020), given by

This random solid network exists until roughly \(\phi =5.4{a}^{-1}\), after which a random network cannot fit into the sample volume, implying that the fibrils must orient or ultimately align (Solomon and Spicer 2010). Figure 1a shows these regimes for rods of different aspect ratios.

Theoretical predictions of the behavior of nanofibril networks. a A Solomon and Spicer-inspired plot (Solomon and Spicer 2010) of different concentration regimes and their transitions as a function of the aspect ratio of straight rods. A more detailed explanation of the different relationships characterizing the different phases is given in the text. b The number of fibril contacts as a function of the aspect ratio for different volume fractions. c Elastoplastic models of fibril contacts in nanofibril glasses and gels. The entire glass/gel is described by many of these elements in parallel (Östmans et al. 2023, 2024)

Another critical concentration is the 3-point contact, introduced as the rigidity threshold of a rod network (Celzard et al. 2009), given by

Note that the above equations are based on ideal circular rods, and CNFs are known to have rectangular cross-sections and kinks that would influence their observed behaviors.

Number of contacts

The number of contacts per fibril (nc) in a random fibril network is in the most straightforward geometrical calculation given by (Sampson 2001)

More advanced equations exist and are compared in the work by Sampson (2001). Figure 1b shows the number of contacts per fibril for a nanofibril network of different aspect ratios at different volume fractions. The number of contacts is essential for the mechanical properties of the network at a given volume fraction. Fibrils with a high aspect ratio enhance the performance of materials, provided that they can be processed into homogeneous networks.

Charged fibrils in a dispersion, such as CNFs, will repel each other and have a higher effective diameter due to the counterion cloud surrounding the charged fibrils. The effective diameter is approximated by adding a Debye length to the radius of the fibril or by calculating the effective width according to Stroobants, Lekkerkerker, and Odijk (SLO) theory (Stroobants et al. 1986; Dong et al. 1996). The effective aspect ratio of the fibrils thus depends on charge density, electrolyte concentration, and concentration of fibrils, which adds to the complexity of the phase and self-associative behavior of the fibrils.

Glasses and gels

In addition to the colloidal glasses previously mentioned, nanofibrils can also form colloidal gels by adding inorganic or organic acids or bases, which screens or alters the charge of groups through protonation or deprotonation. In this respect, the counterion concentration also has a significant role as it will affect the Debye length and may lead to attraction depending on the type of ion (Shimizu et al. 2016; Benselfelt et al. 2019a, b). Colloidal gels can be formed at significantly lower concentrations than colloidal glasses, provided the fibrils overlap and form an ordered structure instead of random networks (Östmans et al. 2024). Here, ordered networks refer to the situation where fibrils can organize to form a network due to attractive interactions. While the aspect ratio of fibrils significantly affects random networks in glasses, this influence is less pronounced in colloidal gels, where the impact of the ordered network structure tends to dominate over individual fibril properties.

The simplest elastoplastic models for nanofibril glasses and gels are shown in Fig. 1c. The mode of deformation is an initial bending of fibrils and then sliding of fibril contacts at a limiting yield stress. Glasses have a second spring from the double-layer repulsion due to charged groups. For nanoscale objects, this repulsion can be significant in relation to the mechanical network stiffness and is thus a crucial component in nanoscale elastoplastic models of charged fibril networks in water (Östmans et al. 2023).

An elastoplastic model at higher concentrations

Fibril networks at higher concentrations (\(a\phi \gg 1\)) can be described by a beam-bending model (Benselfelt et al. 2019a, b). For fibrils with a square cross-section, the volume fraction is given by

where \({n}_{f}\) is the number density of fibrils with contour length \(L\) and width w. The area moment of inertia of these fibrils is

Assuming a linear elastic fibril material, the fibril stiffness is

where \(k_{1} \,{ \lesssim }\,1\) and \(E_{c}\) is the Young's modulus of cellulose (138 GPa) (Nishino et al. 1995). The flexural rigidity of such fibril is hence

Having identified the mechanical properties of individual fibrils, the network structure is considered to arrive at an estimate of the network stiffness. In a random network, the number of contacts per unit volume is

where \({c}_{t}\) is a dimensionless parameter dependent on the network's topology, that is, how the network is organized depending on the assembly method or the aspect ratio or shape of the fibrils (Corte and Kallmes 1962). The network has a characteristic mesh size, that is, the average free distance between two contacts along a fibril contour, given by

where the first equality follows from the observation that each contact bisects two fibrils, and the second equality follows from Eq. (9). The mesh size is often used in equations for the mechanical properties of fibril networks (Prince and Kumacheva 2019). The wet network modulus, Ew, is thus described by the flexural rigidity of the fibrils and the mesh size according to

where \(k_{2}\) is a parameter that depends on the interaction between fibrils and hence their surface chemistry. Assuming that the topological parameter \(c_{t} = c_{t} \left( a \right)\) depends mainly on the aspect ratio of fibrils, a parameter \(c\left( {a;k_{1} ,k_{2} } \right)\), can be introduced to describe this relationship (11) according to

By plotting the right-hand side against the aspect ratio, \(c\left(a;{k}_{1},{k}_{2}\right)\) can be determined from experimental data and describes the influence of the aspect ratio on the network topology. Equation (12) identifies how \(c\left(a;{k}_{1},{k}_{2}\right)\) scales with the prefactor \({k}_{2}^{1/4}\) in response to changes in surface chemistry of the fibrils.

Results

Properties of prepared fibrils

The aspect ratio of CNFs depends on the source of cellulose and the chemical treatment before the disintegration of fibers into fibrils. Three different pulps were used to produce the CNFs for this study (the carbohydrate analysis is summarized in Table 1). The Domsjö pulp is a dissolving grade sulphite pulp with a high cellulose content of 96%. These fibers have been extensively bleached to remove all the hemicellulose and lignin, and this will also negatively affect the degree of polymerization of the glucan polymers. The Nordic paper pulp is a more gently treated sulphite pulp with a more preserved cellulose structure and 13–14% remaining hemicelluloses. A mild peracetic acid delignification process for specifically prepared wood chips was also used to prepare Holo cellulose fibers with a highly preserved native state of the cellulose-containing ~ 30% hemicellulose (Yang and Berglund 2021).

Wood chips cooked under milder conditions, as for Nordic paper pulp, resulted in less damaged glucan chains observed as a higher viscosity, a higher hemicellulose content, and a preserved fibril structure (Table 1). The hemicelluloses block cellulose-cellulose contacts, preventing fibril association, which preserves the native dimensions of cellulose fibrils. Under harsher processing conditions during the preparation of Domsjö pulp, fibrils are damaged, and most hemicelluloses are removed, leading to slightly wider fibril aggregates when fibrils can associate (Hult et al. 2001). The molecular mechanism behind the increased width of fibrils in pulps with high cellulose content has not yet been established.

During chemical modification to introduce charges to the fibrils' surface, a higher hemicellulose content between and around the fibrils will increase fiber swelling, allowing the chemical reaction to access the fibril surfaces. The result is less damaged fibrils that can efficiently be extracted from the fiber wall. By utilizing a high hemicellulose content, Yang et al. showed that it was possible to reduce the energy required for fibrillating the fibers into fibrils and replacing the commonly used high-energy homogenization with a low-energy kitchen blender (Yang et al. 2018; Yang et al. 2020). This development was an insight for achieving industrial scalability in nanocellulose production while ensuring profitability and efficiency.

In the present work, charges were added by TEMPO-oxidation (TO) or carboxymethylation (CM) to introduce carboxylate groups. The average diameter, length, charge density, and aspect ratio of the fibrils are reported in Table 2. Figure 2a, d, g shows AFM images and (Fig. 2b–c, e–f, h–i) histograms of the size distribution. High aspect ratio CNFs had a narrow thickness distribution (Fig. 2e), whereas low aspect ratio CNFs contained wider fibrils (Fig. 2b), and Holo CNFs also contained a considerable amount of fibril aggregates (Fig. 2h). High aspect ratio CNFs were also found to be thinner following previous studies (Rostami et al. 2022; Östmans et al. 2023). However, accurately measuring the thickness of nano-sized fibrils is challenging. With this reservation, the average thickness is around 2 nm, consistent with the 18-chain model as the native state of plant-based cellulose and some stripping of surface chains during chemical modification due to solubilization (Song et al. 2020). The lengths distributions in Fig. 2c, f, i are relatively broad with the most important difference that fibrils from the dissolving pulp is significantly shorter (Fig. 2c). The aspect ratio was around 250, 500, and 600 for low aspect ratio, high aspect ratio, and Holo CNFs, respectively, showing that a milder treatment that does not damage the cellulose and also preserves more of the hemicelluloses results in longer fibrils after chemical modification and processing into fibrils. However, it is essential to note that different processing steps, such as defibrillation and dispersing methods, will also influence the final dimensions and properties of the fibrils (Yang et al. 2020; Lim et al. 2023). In this work, Holo CNFs were dispersed by high shear mixing, while the others were prepared by high-pressure homogenization.

Dimensions of different types of fibrils presented as AFM images and histograms of width and length. a–c TO- and CM-CNFs with low aspect ratio. d–f TO- and CM-CNFs with high aspect ratio. g–i TO- and CM-Holo CNFs. The lines are smoothed density plots using kernel smoothing. Measurements of fibril lengths from AFM images have a bias towards shorter fibrils due to their higher probability to be isolated and stick to the surface. However, this is a semi-established procedure and there is currently no better alternative (Usov and Mezzenga 2015)

Mechanical properties of fibril-based wet sheets

Anisotropic CNF sheets were formed by vacuum filtration and drying. The nanofibril networks enter the ordered phase (Fig. 1a) during the filtration and are thus highly anisotropic, with fibrils aligning with the plane. Their mechanical properties were tested in both the dry and rewet states, where the latter required locking the CNF sheets by ion exchange of Na+ to Ca2+ during rewetting (Dong et al. 2013; Shimizu et al. 2016; Benselfelt et al. 2019a, b; Zhao et al. 2023). The rewet sheets swell due to double layer repulsion between fibrils, and as they have a high concentration, they should be considered colloidal glasses (Fig. 1c). However, close contacts are formed during drying, and a better description is probably an attractive glass, meaning that the concentration and organization are similar to those of a glass while there is attraction between some of the fibrils. Figure 3a displays representative stress–strain curves for the wet CNF sheets. It can be observed that the samples organized into three different groups related to the aspect ratio of the fibrils. The low aspect ratio CNF sheets exhibited the highest wet tensile strengths and tensile moduli, followed by the high aspect ratio and Holo-CNF sheets. The networks formed from high aspect ratios and Holo CNFs had lower tensile strength but higher ductility.

Mechanical properties of different fibril-based materials. Rewet sheets locked by Ca2+: a tensile stress–strain curves, b tensile strength and stiffness as a function of volume fraction of fibrils, and c specific tensile strength and stiffness for wet sheets locked by Ca2+. CNF gels locked by HCl addition: d rheological storage and loss moduli at 1 Hz, e maximum shear strain in each creep-recovery cycle as a function of applied stress, and f critical oscillation stress before reaching the nonlinear region. Aerogels: g compressive stress–strain curves and h compressive yield strain and stress. Dry sheets: i tensile strength and strain at break. Error bars are 95% confidence intervals

Based on the theory of the importance of fibril contacts in Eqs. 10 and 11, a higher aspect ratio should result in more contacts per fibril and stronger networks (Fig. 1b, Eq. 4). However, the counterintuitive nature of these results is due to the fact that the volume fraction of fibrils is not accounted for in the normalization of tensile data. Figure 3b shows the volume fraction of fibrils in the wet sheets, which is inversely proportional to the aspect ratio. Shorter fibrils can pack more densely upon sheet formation, which leads to a lower equilibrium swelling in the presence of Ca2+. Longer fibrils create a more entangled network that can more easily open up and swell in water.

Figure 3b also shows that the tensile strength and stiffness are proportional to the volume fraction, similar to the densification of macroscopic fiber networks in paper. What is shown in Fig. 3b is, hence, an equilibrium network that depends on the aspect ratio of the fibrils. The stiffness and strength were normalized with the network density, in this case, volume fraction, to account for the different water contents presented as the specific moduli and strengths (Fig. 3c). The normalized properties are more similar owing to the nature of CNF networks at different solidities. However, there are some differences. For the carboxymethylated samples, a lower aspect ratio results in stiffer sheets due to dense packing and better utilization of each fibril. However, this trend is not as clear for TO-CNFs. The Holo CNFs display the lowest specific moduli for both chemical functionalities due to the hemicellulose-rich coating acting as a lubricant in the fibril contacts (Yang et al. 2020). The specific wet tensile strength was highest for the CM- and TO-high aspect ratio, which is related to better stress transfer in the networks, leading to a more ductile network.

Mechanical properties of fibril-based colloidal gels

Colloidal gels were formed by locking 1 g/L CNF dispersions with HCl. These networks are formed below the glass threshold (Fig. 1a) due to attraction between fibrils when the carboxylate groups are neutralized (Fig. 1c). Figure 3d shows the storage and loss modulus for gels locked with HCl at a frequency of 1 Hz. High aspect ratio CNFs exhibited the highest storage modulus, although TO-high aspect ratio, CM-Holo, and TO-low aspect ratio displayed similar properties. The storage and loss moduli are significantly lower for CM-low aspect ratio and TO-Holo. A hypothetical explanation for the low stiffness of TO-Holo gels is the reduced degree of polymerization of polysaccharides known to occur during TEMPO oxidation (Isogai et al. 2011). Hemicelluloses would probably be more sensitive to hydrolysis, forming a lubricating low molecular weight layer around the fibrils. An observed trend is that an increased aspect ratio of the fibrils increases the storage modulus of the gels. However, this did not apply to Holo-CNF gels that were less stiff than their aspect ratio would suggest due to lubricating hemicellulose that allows sliding of fibril contacts at a lower yield force.

Creep experiments were conducted to further study the sliding between fibrils after yielding fibril contacts. Different shear stresses were applied and the resulting strain was measured over time, followed by relaxation upon removal of the stress. Figure 3e shows that Holo CNFs exhibited extensive plastic deformation of the hydrogel network structure upon applied stress. In contrast, the CM-high aspect ratio hydrogel network demonstrated the highest ability to recover and resist plastic network deformation. This trend in yielding behavior progresses from Holo-CNFs, which are most susceptible to the applied shear stress, through those with a low aspect ratio, to the high aspect ratio CNFs showing the least plastic deformation. All CM-CNFs endured one more stress-relaxation cycle than the TO-CNFs before the network structure fully yielded. This trend shows that carboxymethylation produces fibrils that lead to stronger interactions and networks upon gelation than TEMPO-oxidized fibrils. These results show that both the chemical functionality of the surface and the aspect ratio are essential for fibrillar hydrogel networks.

Figure 3f shows the critical oscillation stress in the strain sweeps, corresponding to the highest stress applied to the material during the test before the material exhibits a significant deviation from a linear relationship between strain and stress, which is another manifestation of yielding. The trend is that a higher aspect ratio of the fibrils increases the critical oscillation stress that can be applied to the sample before nonlinearity ensues.

Generally, three mechanisms cause nonlinearity in rheology measurements: (1) finite elastic deformation (weak nonlinearity), (2) reversible structure changes (strong nonlinearity), and (3) breaking or phase transitions induced by deformation (severe nonlinearity) (Malkin 1995). These nonlinearities commonly act together to determine the rheological behavior. Holo CNFs showed the highest critical stress while yielding most easily in creep experiments, indicating that finite elastic deformation is not the cause of nonlinearity. Reversible structural changes would be the most plausible explanation since networks of longer fibrils can deform more before the ability to restore the network is lost. Creep tests probably do not resolve this behavior, as the stress steps are too large. However, even with large stress steps, the results in Fig. 3e indicate that low aspect ratio CNF gels start to encounter irreversible structural changes at a lower stress of 12 Pa. Mechanism 3, which is severe nonlinearity due to fracture, would also make sense since the gel ductility would be proportional to the aspect ratio of the fibrils. Slippage between the plates and the gel might be a problem. However, since stiffer gels than the ones used here did not show this phenomenon and since special plates were utilized, this problem can be neglected for the present evaluation (Östmans et al. 2023). In conclusion, irreversible structural changes most likely explain the nonlinearity detected for the gels. These structural changes can be due to a reorganization of the network or local fracture since there were no observable large-scale fractures in the gels.

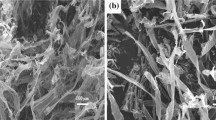

Mechanical properties of fibril-based aerogels

Aerogels were prepared using a previously reported freeze-thawing procedure (Rostami et al. 2021). First, mixtures with CNFs, alginate, and CaCO3 particles with the same final solid concentration were prepared with different CNFs. Since the aerogels were prepared from CNF gels with higher concentrations, the Holo CNFs contained nanofibrils and some macroscopic aggregates. The mixtures were then frozen in a conventional freezer, allowing for the formation of ice crystals. As the crystals grow, the solid materials condense around the crystals, forming cell walls and an interconnected porous network. The highly porous frozen hydrogels were then subjected to acetic acid containing acetone, which dissolved the CaCO3 particles, releasing Ca2+ ions and CO2 gas. The Ca2+ ions crosslink the network, primarily due to interactions between carboxylic acid groups of the alginate, leading to the formation of wet-stable aerogels (Rostami et al. 2021). The acetone exchanges with the water in the frozen aerogel networks, leading to acetone-soaked aerogels. Acetone has significantly lower surface tension, and the aerogels can be air-dried without significant collapse due to the lower capillary forces.

The highly porous aerogels were then compressed by 90% to evaluate the mechanical properties. Figure 3g shows that aerogels from TO-high aspect ratio fibrils had the highest compressive modulus of 84 ± 15 kPa, followed by TO-low aspect ratio aerogels and TO-Holo aerogels with a compressive modulus of 66 ± 15 and 51 ± 2, respectively. Normalizing the compressive modulus with the density results in a specific compressive modulus of 7.1 ± 1.1, 5.4 ± 0.9 and 4.4 ± 0.2 kPa m3 kg−1 for TO-high aspect ratio, TO-low aspect ratio and TO-Holo, respectively.

Higher aspect ratio fibrils form a more entangled gel network at a much lower critical overlap concentration than lower aspect ratio fibrils. In practice, the fibrils start interacting at a much lower concentration, leading to increased contact points for the high aspect ratio fibrils, more efficient long-range stress transfer, and a more evenly distributed stress throughout the system. Recent work by Tang et al. (2023) showed that longer fibrils lead to stiffer low-density aerogels. In contrast, longer fibrils performed worse at higher density, probably due to the impact on the processing into homogeneous materials at higher volume fractions. In the present work, the TO-high aspect ratio aerogels showed the highest specific compressive modulus and yield stress (Fig. 3h), indicating an efficient process of translating fibril length into mechanical properties. The TO-Holo aerogels, however, had the lowest yield stress and compressive modulus. Notably, some fibril aggregates were still present in the aerogel sample, which may impact the performance, although they were removed by centrifugation before the sheets and gels were prepared. The lubricating effect of the hydrated hemicelluloses on the Holo-CNFs could explain the low yield stress and strain of aerogels from these fibrils (Fig. 3h).

Mechanical properties of fibril-based dry sheets

Figure 3i shows the tensile strength and strain-at-break of dry anisotropic CNF sheets. TO-Holo and TO-low aspect ratio led to sheets with lower tensile strength and strain at break, making them more brittle than sheets from the other CNFs. Generally, a high aspect ratio of the fibrils resulted in the highest tensile strength. However, the moduli of the sheets were similar, considering experimental errors.

Holo CNFs without chemical modification have been shown to significantly improve sheets' strength and stiffness due to cellulose's preserved molecular weight and hemicelluloses acting as binding agents (Yang et al. 2020). However, as shown in Fig. 3i, their beneficial properties are lost when the hemicelluloses are further modified, especially with TEMPO oxidation. These results also indicate that the functionality and properties of the surface polymers seem more critical for dried sheets than the aspect ratio of the fibrils. Still, a higher aspect ratio with better long-range stress transfer can mitigate some of these effects.

Due to the minor differences in the mechanical properties of dry sheets and aerogels, the fibril properties are less important in high-density networks. There are already many contacts per fibril to achieve an efficient stress transfer. Thus, the present work focused on wet nanofibril networks where the influence of fibril properties is considerable. However, as observed for sheets, the aspect ratio may influence the processing into networks. For example, longer fibrils have a lower concentration limit for efficient processing, and the influence of this should be studied in detail.

The importance of the fibril aspect ratio—combining experiments and theory

Figure 3b shows a linear relationship between volume fraction and stiffness of wet sheets. Equation 12 and previous reports, however, show a highly nonlinear relationship between volume fraction and stiffness (\({E}_{w}\propto {\phi }^{4}\)) for wet CNF sheets locked by different multivalent ions (Benselfelt et al. 2019a, b). An exponent of 4 indicates that the bending of fibrils is the primary deformation mode. The linear relationship observed in this work for a fixed ion species, Ca2+, is because the aspect ratio influences the network topology through \(c\left(a\right)\) in Eq. 12. In contrast, the highly nonlinear relationship for CNFs locked by different multivalent ions is based on the initial network topology determined by the fibril properties.

To demonstrate this further, CM-high aspect ratio sheets were locked by Cu2+ and Fe3+ and compared to the previous TO-low aspect ratio data from Benselfelt et al. (2019a, b) in Fig. 4a. Sheets treated with Cu2+ or Fe2+ resulted in lower volume fraction and stiffer sheets. However, the increase in volume fraction starts from different base levels induced by Ca2+ depending on the aspect ratio, which means that CNFs of different aspect ratios resulted in different network topologies formed by vacuum filtration. A log–log plot in Fig. 4b again shows the relationship: \({E}_{w}\propto {\phi }^{4}\) after treatment with different multivalent ions but starting at different volume fractions.

a CM-high aspect ratio treated with Cu2+ and Fe3+ and compared to the previous TO-low aspect ratio data from Benselfelt et al. (2019a, b), that is, an aspect ratio of 250 compared to 500. b Log–log plot that shows the relationship \({E}_{w}\propto {\phi }^{4}\) after treatment with different multivalent ions. c The beam-bending model for CNF networks at high concentration (\(a\phi \gg 1\)) in Eq. 12 can be validated by fitting this data. A linear relationship appears by plotting the right-hand side of Eq. 12 as a function of the aspect ratio

The beam-bending model for CNF networks at high concentration (\(a\phi \gg 1\)) in Eq. 12 can be validated by fitting this data. A linear relationship appears in Fig. 4c by plotting the right-hand side of Eq. 12 as a function of the aspect ratio. Despite their chemical and physical complexity, this relationship means that a microscopic beam-bending model is surprisingly suitable for nanofibril networks. Note that sheets locked with different multivalent ions end up in the same position, meaning that different ions do not significantly influence the strength of fibril contacts or friction during contact sliding. Different ions only determine the equilibrium volume fraction due to long-range interactions, in line with previous observations (Benselfelt et al. 2019b). With the assumption that the parameters of fibril modulus (\({k}_{1}\)) and surface chemistry (\({k}_{2}\)) are unchanging in the experiments contributing only to the variability, so that \(c\left(a;{k}_{1},{k}_{2}\right)=c(a)\), the fitting leads to the equation \(c\left(a\right)=a/620+0.5\). The intercept is of little physical importance as the model is designed for highly anisotropic beams, supposedly \(a\gg 10\). \(a/620\) shows that the network topology is relatively insensitive to the aspect ratio. Still, according to Eq. 12, the wet stiffness is proportional to \(c{\left(a\right)}^{4}\) which means that small topology differences, specifically in the number density of fibril contacts, have significant effects on the wet mechanical properties, as observed in Fig. 4a.

According to our theory, the residuals associated with the linear fit of c(a) in Fig. 4c are associated with variations in k1 and k2, including measurement errors. That is, the effects of k1 (effective elastic modulus of cellulose) and k2 (cross-link properties) are limited to this modest variation.

Comparison to previously published data

The data of the present work was compared to previously published data to establish a more general view of the influence of aspect ratio and chemical functionality on material properties. The dimensionless concentration or 2D crowding factor was used as normalization to compare materials influenced by different aspect ratios and volume fractions of CNFs. This relationship is important as the dimensionless concentration is the minimum determining factor for the number of contacts in a nanofibril network (Fig. 1b, Eq. 4), which are crucial in forming efficient load-bearing networks. Figure 5 shows a general trend for materials over vast concentration and aspect ratio ranges. In an isotropic material, or in the plane of a transversely isotropic material, the elastic (E) and shear (G) moduli are related by \(G=E/(2(1+\nu ))\), where ν is the Poisson ratio. Hydrogels are typically assumed to deform isochorically, implying that \(\nu =0.5\). That is, \(G=E/3\). A comparison of the elastic modulus results in a slope of 2.4 in a log–log plot, which means that the stiffness of CNF materials can be broadly described with the relationship

Literature data of the stiffness of CNF materials as a function of the dimensionless concentration. The dimensionless concentration allows the comparison of materials with influence from both the aspect ratio and volume fraction of fibrils. The materials range from very dilute gels or glasses to dense, dry sheets (Saito et al. 2009; Fukuzumi et al. 2013; Shafeiei-Sabet et al. 2013; Li et al. 2015; Tanaka et al. 2016; Lu et al. 2017; Sharma et al. 2018; Arcari et al. 2020; Yang et al. 2020; Leppänen et al. 2022)

However, this relationship is crude, and deviations are due to different CNF functionality that affects the interaction between fibrils, different locking mechanisms, errors in assessing aspect ratio or volume fraction, or the influence of larger aggregates. Gels and glasses should also deviate since they form different types of networks (Östmans et al. 2023). A true value between 2 and 2.5 is perhaps a more nuanced description. On a grander scale, the dimensionless concentration can still be used to compare different materials. However, the geometrical meaning of exponent 2.4 has yet to be uncovered. Future work should be dedicated to identifying the underlying mechanism behind this relationship.

Figure 5 also shows a region without data: CNF materials that are too stiff for rheology and too soft for tensile tests. New methods need to be used for this region, such as indentation or tensile machines with specialized clamps that do not damage soft gels.

Conclusions

This work systematically investigated how cellulose fibril properties influence the material properties of wet and dry sheets, gels, and aerogels. The result can be used to understand and optimize nanocellulose-based materials based on the properties of the building blocks.

There is generally some interdependence between the charge density and fibril dimensions since higher degrees of oxidation reduces the degree of polymerization of glucan chains. Still, it is possible to prepare fibrils of similar charge densities but with different lengths depending on the hemicellulose content of the raw material. The preservation of hemicelluloses in the chemically modified fibrils displayed similar effects for the water-swollen materials and the aerogels, that is, a lubricating effect that resulted in lower stiffness and suggested to cause greater fibril sliding in the networks upon applied stress. However, concerning unmodified hemicellulose, it has previously been shown to significantly improve the fibril contacts, where the hemicellulose may act as a binding agent and consequently increase the strength and stiffness of CNF sheets (Yang et al. 2020; Östmans et al. 2023). Describing the lubricating mechanism of hemicelluloses depending on added charges and their chemistry is an interesting future direction.

The results show that the aspect ratio of the CNFs influences the material's mechanical properties since it determines the number of contact points and the initial topology of the network. Although aspect ratio is more influential than chemical functionality, carboxymethylated fibrils generally performed better than TEMPO-oxidized. A hypothesis for future investigation is that the spacer between the sugar ring and the carboxylate group for carboxymethylated fibrils leads to more stable and strongly interacting fibril surfaces.

A significant finding of the present work is that a beam-bending model can accurately describe the network mechanics for CNF networks at higher volume fractions. Fitting this model to experimental data showed that the aspect ratio determines the network topology during its formation. It also shows that multivalent ions only influence the network’s volume fraction relative to this topology and not due to a direct influence on fibril contacts. The range at which the beam-bending model is suitable for CNF networks needs quantification.

A comparison of the stiffness of CNF materials as a function of the dimensionless concentration based on literature data highlights a regime of CNF materials that is difficult to characterize mechanically. The stiffnesses in this region fall in a range that poses difficulty for measurements using traditional methods like rheology and tensile testing. New characterization methods for this region are needed. Fitting this data in a log–log yields a slope of 2.4, which can be used to describe the stiffness of CNF-based materials in a broader sense. In future work, this should be studied in depth to provide a more detailed explanation behind the value of 2.4.

Experimental

Chemicals

Monochloroacetic acid ≥ 99.0%, peracetic acid 38–40%, potassium phosphate monobasic (KH2PO4), sodium chlorite (NaClO2), sodium hydroxide (NaOH), iron (III) chloride (97%), copper (II) chloride (97%) and 2,2,6,6-tetramethyl-1-piperidinyloxy (TEMPO, free radical), Polydiallyldimethylammonium chloride solution (Mw 400,000–500,000, 20 wt%), and (3-Aminopropyl)triethoxysilane were purchased from Sigma-Aldrich AB (Sweden). Sodium hypochlorite (NaClO) 14%, ethanol (96% and absolute) and 2-propanol were purchased from VWR International AB (Sweden). Hydrochloric acid (HCl) 37%, methanol, alginic acid sodium salt (high viscosity) and zinc chloride (98.5%) were purchased from Thermo Fisher Scientific. Sodium bicarbonate ≥ 99.7% was purchased from Honeywell Fluka. Anhydrous calcium chloride (CaCl2) and anhydrous sodium carbonate (Na2CO3) were purchased from Merck. SYLGARD 184 Silicone Elastomer Kit was purchased from DOW. Milli-Q water (Merck Milli-Q 18.2 MΩ/cm) or deionized (DI) water was used throughout all experiments.

Materials

Never-dried fully bleached sulphite pulps were kindly provided by Aditya Birla Domsjö Fabriker AB (Sweden) and Nordic Paper AB (Sweden). Spruce chips were kindly provided by SCA Forest Products AB (Sweden).

Determination of carbohydrate composition

Carbohydrate composition was determined according to the SCAN-CM 71:09 using a high-performance anion-exchange chromatography system, Dionex ICS-5000, coupled to a Dionex CarboPac PA1 column (Dionex, Sweden) and a pulsed amperometric detector (HPAEC-PAD). Calibration was done against external standards of each carbohydrate.

Pulp fiber analysis

Average fiber lengths and widths were determined according to the standard “ISO 16065–2 Determination of fiber length by automated optical analysis” using a PULP EYE analyzer at More Research Örnsköldsvik, Sweden.

Delignification of spruce

Holocellulose (Holo) fibers were prepared by a mild peracetic acid (PAA) delignification of spruce wood following the procedure by Yang et al. 2020. The wood chips were cut into fine sticks with a width of a few mm and immersed in a PAA solution (~ 4 wt% in water), which was adjusted to pH 4.8 prior to the reaction with a 20 wt% NaOH solution. 47.5 g PAA was used to treat a 100 g of dry wood chips. The delignification was performed in rounds of 1 h at ~ 85°C. After each round, the wood sticks were drained and treated with a new PAA solution. A total of 5–6 rounds of PAA treatments were performed until the individual fibers were liberated. Finally, the fibers were suspended in a 0.01 M NaOH solution for 2 h before washing with DI water to a conductivity below 5 μS/cm.

Preparation of carboxymethylated (CM) fibers

Carboxymethylation of fibers were performed based on an established procedure (Wågberg et al. 2008). The fibers (30 g, dry mass) were solvent-exchanged four times in ethanol (~ 250 ml) for approximately 15 min. After each solvent-exchange step, the excess ethanol was filtered off. The fibers were then impregnated in a solution of Chloroacetic acid (4.4 g) dissolved in isopropanol (155 ml) for 30 min. NaOH pellets (5.3 g) were dissolved in Methanol (155 ml) and then added to preheated isopropanol (555 ml. 85 °C). The Chloroacetic acid-impregnated fibers were added to the solvent mixture, and the reaction continued for 60 min. The chemically modified fibers were then washed with DI water (~ 5000 mL), followed by placing the fibers in a dilute HCl solution (0.01 M, ~ 5000 mL, 30 min) and again DI water (~ 5000 mL). The fibers were soaked in a sodium bicarbonate solution (5 wt%, 2000 mL, pH 9, 30 min) to convert the counterions to the sodium form. Finally, the modified fibers were washed with DI water until the filtrate water had a conductivity below 5 µS/cm.

The amounts of the reagents and solvents were varied according to Table 3, aimed to obtain a charge density of around 500 µeq/g for the fibrils,

Preparation of TEMPO-oxidized (TO) fibers

TEMPO-mediated oxidation under neutral conditions was performed on fibers with different hemicellulose contents according to the procedure established by Saito et al. (2009). The fibers (30 g, dry mass) were suspended in a phosphate buffer (0.05 M, pH 6.8, 2700 mL, 60 °C) followed by the addition of sodium chlorite (300 mmol), TEMPO (3 mmol) and sodium hypochlorite (30 mmol). To obtain the high aspect ratio CNFs, a 25% increase in reagents was used to oxidize the fibers. The suspension was continuously stirred throughout the reaction, which proceeded for 5.5 h (low aspect ratio CNF), 6 h (high aspect ratio CNF), and 8.5 h (Holo). After the reaction, the oxidized pulps were washed in DI water, followed by suspending the fibers in an HCl solution (0.01 M, ~ 2000 mL, 30 min). The suspensions were then filtrated and washed with deionized water until the conductivity was below 5 μS/cm. The fibers were subsequently placed in a sodium bicarbonate solution (0.01 M, 2000 mL, pH 9, 30 min) before washing below 5 μS/cm again.

Disintegration of fibers into fibrils

CM or TO fibers were homogenized into CNFs by one time using 400/200 μm chambers (~ 1000 bar) and three times using 200/100 μm chambers (~ 1650 bar) in a high-pressure microfluidizer (Microfluidizer M-110EH, Microfluidics Corp.). The TO or CM Holo fibers were mechanically fibrillated to CNFs using a kitchen blender (Blendtech Classic 575. USA) at high speed for 5 rounds, each 50 s long, since it was found that the high-pressure homogenization was not needed due to the ease of fibril release from these modified fibers.

Preparation of CNF dispersion

CNF gels (~ 1 wt%) were diluted in MilliQ water, aiming for a final concentration of 0.12 wt%. The low and high aspect ratio CNFs were dispersed using an Ultra Turrax disperser (IKA, Staufen, Germany) for 15 min at 12 000 rpm. Holo-CNF gels were diluted to 0.15 wt% dispersions and mixed with a kitchen blender (Blendtech Classic 575, USA) at high speed for 5 rounds, each of being 50 s long. Subsequently, the Holo-CNF dispersions were centrifuged at 4800 rpm for 1 h to remove unfibrillated parts.

Preparation of calcium carbonate particles

The CaCO3 particle suspension (1.2 wt%, 100 mL) was prepared by adding Na2CO3 solution (1.325 g in 50 g MilliQ water) dropwise to a CaCl2 solution (1.367 g in 50 g Milli Q water) under vigorous stirring. The formed suspension was then placed in an ice bath and further homogenized (12 000 rpm, 20 min) using an Ultra-Turrax T25® high-shear mixer (IKA, Staufen, Germany).

Preparation of aerogels

According to a previous protocol, mixtures of CNF gel, alginate solution and CaCO3 suspension (33 g mixture) were prepared in centrifuge tubes (Rostami et al. 2021). First, alginate solution was added to CNF gel in a dry mass ratio of 1:40 ratio, where the final concentration of the CNF gel and alginate solution was 0.5 wt% and 0.0125 wt%, respectively. CaCO3 suspension was then added to the mixture in a dry mass ratio of 1:6, with regards to dry mass of CNF gel and alginate solution, resulting in a final concentration of 0.085 wt% for CaCO3 particles. Using an Ultra-Turrax high-shear mixer, the mixtures were homogenized (12 000 rpm, 5 min) and then aliquoted into polystyrene petri dishes (35 mm wide and 10 mm high, 10 g mixture per mold). The mixtures were then put in a freezer overnight (~ − 18 °C) and solvent exchanged the following day. The solvent exchange procedure was as followed: the frozen mixtures were put in acidic acetone (10 wt% acetic acid in acetone, 50 mL solution/frozen aerogel) and kept in the solution for 1 h. The solution was then discarded of and replaced with fresh pure acetone (3 × 20 min, 100 mL/aerogel). After the solvent exchange procedure, the aerogels were left to air-dry.

Charge density determination

The charge densities of all the CNF dispersions were measured by polyelectrolyte titration at pH 6–7 against polydiallyldimethylammonium chloride using a ParticleMetrix Stabino (Germany) system assuming that all charges on the fibrils were available for the polyelectrolyte. At least three replicates were taken for each dispersion, and the average value was reported.

AFM characterization

The dimensions of the CNFs were measured using Atomic Force Microscopy (AFM) (Multimode 8. Bruker. Santa Barbara. USA) in tapping mode. The samples were prepared by adsorbing APTES (1 g/L) on a freshly cleaved mica surface for around 30 s followed by rinsing with MilliQ water and drying with nitrogen gas. Then the CNF dispersion (1.5 g/L) was allowed to adsorb on the treated surface for 1 min before rinsing with MilliQ and drying with nitrogen gas. The thickness and length of over 100 fibrils for each type of CNF were measured manually using Gwydion and ImageJ. Due to the very long dimensions of the HOLO CNFs. the length of only ~ 60 fibrils was measured.

Hydrogel formation

The CNF dispersion (1 g/L, 1.15 mL) was added to the PDMS mold designed for the samples to have the exact dimensions to fit the rheometer plate and its gap. A dilute HCl solution (115 µL, 0.1 M) was added to the dispersion via a membrane (Durapore, PVDF, Hydrophilic, 0.65 μm) placed on top of the dispersion. The amount of HCl solution added corresponds to a final pH of 2 in the gel. To avoid evaporation of water from the sample, a lid was placed on top of the dispersion. To ensure a homogeneous pH throughout the hydrogel the sample was left to equilibrate for approximately 18 h before rheological measurements.

Rheology

Rheological characterization was carried out using a DHR-2 rheometer (TA Instruments. New Castle. DE. USA) with a sandblasted plate-plate geometry (25 mm in diameter) in order to avoid wall slip between the plate and sample. The hydrogel sample was transferred from the PDMS mold directly to the measurement position in the rheometer to avoid damaging the macroscopic structure of the sample and then the plate was lowered to the measurement gap (1900 µm). Time sweeps were measured under 900 s at a constant strain of 0.1% and angular frequency of 10 rad/s. Frequency sweeps were measured between 0.1 and 120 rad/s at a constant strain of 0.1%. Strain sweeps were measured between 0.1 and 500% at a constant angular frequency of 10 rad/s. In the cyclic creep tests, the applied stress was increased in steps from 0.5 to 20 Pa, and the strain response was measured over time. A constant stress was applied to the sample for 90 s (the creep). Then the stress was released, and the material was allowed to recover its structure for 180 s (creep recovery) before the next creep recovery cycle was initiated.

Preparation of CNF sheets

Sheets with a diameter of 8 cm were formed, with a dry content of approximately 250 mg CNF, using vacuum filtration overnight with membrane filters (Durapore, PVDF, Hydrophilic, 0.65 μm) followed by drying in a Rapid Köthen sheet dryer for 15 min at 93 °C under a reduced pressure of 95 kPa. For wet mechanical analysis, the dried films were treated with a 1 wt% calcium chloride solution for 24 h, then washed and equilibrated for 72 h in Milli-Q water before measurement.

Mechanical properties

Tensile properties of CNF sheets were measured using an Instron 5944 with a load cell of 500 N. Samples of 3 mm by 50–60 mm in size were measured with a gauge length of 20 mm and a strain rate of 2 mm min−1. The best practice for measuring wet mechanical properties has been summarized (Walther et al. 2020). If the samples have high enough concentration they can be tested in the same way as dry samples since they are strong enough to be clamped. The impact of evaporation of water during the measurement was minimized by keeping the samples wet as long as possible.

Dry samples were conditioned at 50% relative humidity for 72 h and the wet samples treated with CaCl2 were equilibrated in Milli-Q water for 72 h before the tensile tests. All measurements were performed at 50% relative humidity and 23 ̊ C according to standards for conditioning and mechanical testing of cellulosic materials, such as ASTM D685, Tappi 402 and ISO 1924. The dimensions of the dry and swollen samples were measured using a caliper and thickness gauge. The modulus of the dry films was calculated as the slope of the curve in the strain interval 0–0.5% and for wet samples 0–0.1%. For wet samples, the moduli and strengths were normalized with the network density to account for different water content. The volume fractions were determined by the difference in thickness of dry and wet sheets, assuming that the dry samples are nonporous and that the density of the CNFs is 1.5 g/cm3.

All aerogels were conditioned at 50% relative humidity for 72 h before the mass was recorded. The dimensions of the aerogels were measured using a caliper. Since the shape and surface of the aerogels were uneven, only average values were used for height and diameter to conduct the measurements. Using an Instron 5944 equipped with a 500 N load cell, the mechanical properties were assessed under compression. The aerogels were compressed to 90%, with regards to average height input. A pre-load of 0.05 N was used and the load rate was 10% min−1.

References

Arcari M et al (2020) Structure–property relationships of cellulose nanofibril hydro-and aerogels and their building blocks. Nanoscale 12(21):11638–11646

Benselfelt T et al (2019a) Ion-induced Assemblies of Highly Anisotropic Nanoparticles are Governed by Ion–ion Correlation and Specific Ion Effects. Nanoscale 11(8):3514–3520

Benselfelt T et al (2019b) Explaining the exceptional wet integrity of transparent cellulose nanofibril films in the presence of multivalent ions—suitable substrates for biointerfaces. Adv Mater Interfaces 6(13):1900333

Benselfelt T et al (2023) The colloidal properties of nanocellulose. Chemsuschem 16(8):e202201955

Celzard A et al (2009) Flocculation of cellulose fibres: new comparison of crowding factor with percolation and effective-medium theories. Cellulose 16(6):983–987

Corte H, Kallmes O (1962) Statistical geometry of a fibrous network. In: The formation and structure of paper, pp 13–46

Dong XM et al (1996) Effects of ionic strength on the isotropic−chiral nematic phase transition of suspensions of cellulose crystallites. Langmuir 12(8):2076–2082

Dong H et al (2013) Cation-induced hydrogels of cellulose nanofibrils with tunable moduli. Biomacromol 14(9):3338–3345

Fukuzumi H et al (2013) Influence of TEMPO-oxidized cellulose nanofibril length on film properties. Carbohyd Polym 93(1):172–177

Geng L et al (2018) Understanding the mechanistic behavior of highly charged cellulose nanofibers in aqueous systems. Macromolecules 51(4):1498–1506

Henriksson M et al (2008) Cellulose nanopaper structures of high toughness. Biomacromol 9(6):1579–1585

Hult EL et al (2001) Cellulose fibril aggregation—an inherent property of kraft pulps. Polymer 42(8):3309–3314

Isogai A et al (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3(1):71–85

Isogai A et al (2018) Review: catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions. Prog Polym Sci 86:122–148

Kerekes R, Schell C (1992) Regimes by a crowding factor. J Pulp Pap Sci 18:J32–J38

Kerekes R et al (1985) The flocculation of pulp fibres. In: Papermaking raw materials: their interaction with the production process and their effect on paper properties-transactions of the eighth fundamental research symposium held at Oxford: September 1985

Klemm D et al (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50(24):5438–5466

Leppänen I et al (2022) Hybrid films from cellulose nanomaterials—properties and defined optical patterns. Cellulose 29(16):8551–8567

Li M-C et al (2015) Cellulose nanoparticles: structure–morphology–rheology relationships. ACS Sustain Chem Eng 3(5):821–832

Li T et al (2021) Developing fibrillated cellulose as a sustainable technological material. Nature 590(7844):47–56

Lim JH et al (2023) Structural anisotropy governs the kink formation in cellulose nanocrystals. J Phys Chem Lett 14(16):3961–3969

Lu H et al (2017) Effects of different manufacturing processes on TEMPO-oxidized carboxylated cellulose nanofiber performance as binder for flexible lithium-ion batteries. ACS Appl Mater Interfaces 9(43):37712–37720

Malkin AY (1995) Non-linearity in rheology—an essay of classification. Rheol Acta 34(1):27–39

Mattos BD et al (2020) Nanofibrillar networks enable universal assembly of superstructured particle constructs. Sci Adv 6(19):7328

Mittal N et al (2018) Multiscale control of nanocellulose assembly: transferring remarkable nanoscale fibril mechanics to macroscale fibers. ACS Nano 12:6378–6388

Nishino T et al (1995) Elastic modulus of the crystalline regions of cellulose polymorphs. J Polym Sci Part B Polym Phys 33(11):1647–1651

Nordenström M et al (2017) Formation of colloidal nanocellulose glasses and gels. Langmuir 33(38):9772–9780

Nordenström M et al (2022) The structure of cellulose nanofibril networks at low concentrations and their stabilizing action on colloidal particles. Carbohyd Polym 297:120046

Onsager L (1949) The effects of shape on the interaction of colloidal particles. Ann N Y Acad Sci 51(4):627–659

Östmans R et al (2023) Immobilized water at room temperature with tailored fluidic channels by using highly anisotropic cellulose nanofibrils. Available at SSRN 4647146

Östmans R et al (2023) Elastoplastic behavior of anisotropic, physically crosslinked hydrogel networks comprising stiff, charged fibrils in an electrolyte. Soft Matter 19(15):2792–2800

Östmans R et al (2024) Solidified water at room temperature hosting tailored fluidic channels by using highly anisotropic cellulose nanofibrils. Mater Today Nano 100476

Prince E, Kumacheva E (2019) Design and applications of man-made biomimetic fibrillar hydrogels. Nat Rev Mater 4(2):99–115

Rostami J et al (2021) Hierarchical build-up of bio-based nanofibrous materials with tunable metal–organic framework biofunctionality. Mater Today 48:47–58

Rostami J et al (2022) Shaping 90 wt% NanoMOFs into robust multifunctional aerogels using tailored bio‐based nanofibrils. Adv Mater 2204800

Saito T et al (2009) Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions. Biomacromolecules 10(7):1992–1996

Sampson W (2001) The structural characterisation of fibre networks in papermaking processes—a review. In: Proceedings of the transactions of 12th fundamental resource symposium, Oxford

Shafeiei-Sabet S et al (2013) Influence of degree of sulfation on the rheology of cellulose nanocrystal suspensions. Rheol Acta 52:741–751

Sharma PR et al (2018) High aspect ratio carboxycellulose nanofibers prepared by nitro-oxidation method and their nanopaper properties. ACS Appl Nano Mater 1(8):3969–3980

Shimizu M et al (2016) Water-resistant and high oxygen-barrier nanocellulose films with interfibrillar cross-linkages formed through multivalent metal ions. J Membr Sci 500:1–7

Sjostrom E (2013) Wood chemistry: fundamentals and applications. Elsevier

Solomon MJ, Spicer PT (2010) Microstructural regimes of colloidal rod suspensions, gels, and glasses. Soft Matter 6(7):1391–1400

Song B et al (2020) Direct measurement of plant cellulose microfibril and bundles in native cell walls. Front Plant Sci 11:479

Stroobants A et al (1986) Effect of electrostatic interaction on the liquid crystal phase transition in solutions of rodlike polyelectrolytes. Macromolecules 19(8):2232–2238

Tanaka R et al (2016) Viscoelastic properties of core–shell-structured, hemicellulose-rich nanofibrillated cellulose in dispersion and wet-film states. Biomacromol 17(6):2104–2111

Tang R et al (2023) Critical impact of nanocellulose on the synthesis of porous cellulose monolith with oriented microchannels: Structure control, mechanics, and mass transport. Nano Res 16(5):8018–8024

Usov I, Mezzenga R (2015) FiberApp: an open-source software for tracking and analyzing polymers, filaments, biomacromolecules, and fibrous objects. Macromolecules 48(5):1269–1280

Usov I et al (2015) Understanding nanocellulose chirality and structure–properties relationship at the single fibril level. Nat Commun 6:7564

Wågberg L et al (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24(3):784–795

Walther A, Benitez A (2017) Cellulose nanofibril nanopapers and bioinspired nanocomposites: a review to understand the mechanical property space. J Mater Chem A

Walther A et al (2020) Best practice for reporting wet mechanical properties of nanocellulose-based materials. Biomacromol 21(6):2536–2540

Xu Y et al (2020) A review of nanocrystalline cellulose suspensions: rheology, liquid crystal ordering and colloidal phase behaviour. Adv Coll Interface Sci 275:102076

Yang X, Berglund LA (2021) Structural and ecofriendly holocellulose materials from wood: microscale fibers and nanoscale fibrils. Adv Mater 33(28):2001118

Yang X et al (2018) Preserving cellulose structure: delignified wood fibers for paper structures of high strength and transparency. Biomacromol 19(7):3020–3029

Yang X et al (2020) Eco-Friendly Cellulose Nanofibrils Designed by Nature: Effects from Preserving Native State. ACS Nano 14(1):724–735

Zhao M et al (2023) Counterion-dependent material properties of phosphorylated nanocellulose. Biomacromol 24(4):1881–1887

Funding

Open access funding provided by Royal Institute of Technology. The Knut and Alice Wallenberg Foundation is thanked for funding through the Wallenberg Wood Science Center (WWSC) and an individual fellowship for Tobias Benselfelt (KAW 2021.0210). Jowan Rostami acknowledges VR, the Swedish Research Council, for financial support. Stefan B. Lindström thanks Svenska Cellulosa AB (SCA) and the research profile Neopulp financed by the Knowledge foundation for financial support.

Author information

Authors and Affiliations

Contributions

RÖ—data curation, formal analysis, investigation, methodology, resources, validation, writing—original draft. FAS—data curation, formal analysis, investigation, methodology, resources, validation, writing—original draft. JR—data curation, formal analysis, investigation, methodology, resources, validation, writing—original draft. MCR—data curation, formal analysis. SL—validation, formal analysis, data curation, writing review and editing. LW—funding acquisition, supervision, resources, conceptualization, validation, writing review and editing. TB—supervision, conceptualization, methodology, formal analysis, validation, data curation, visualization, writing original draft.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

Not applicable.

Availability of data and materials

Available from the corresponding author upon reasonable request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sellman, F.A., Rostami, J., Östmans, R. et al. Influence of fibril aspect ratio, chemical functionality, and volume fraction on the mechanical properties of cellulose nanofibril materials. Cellulose (2024). https://doi.org/10.1007/s10570-024-06084-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10570-024-06084-4