Abstract

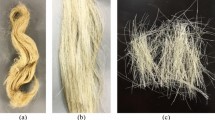

Cellulose pulps in cementitious matrix have been investigated because of their high tensile strength, which improves the mechanical properties of the composites. Nonetheless, the material's hydrophilic nature could impair cement and potentially diminish the durability of the compound. In this work, to improve physical-mechanical performance of fiber cement produced with cellulose, the surface of the cellulose pulp was modified by sulfur hexafluoride (SF6) plasma treatment at different conditions (0.1, 0.3, 0.5 and 0.7 Torr). Fiber cement composite was subsequently produced from treated pulps. Theoretical calculations suggested that cellulose interacts with SF6 molecules through adsorption. The cellulose pulps were evaluated using spectroscopy, diffractometry and water affinity techniques. The physical and mechanical properties of the composites produced were evaluated before and after accelerated ageing cycles. The surface modification of cellulose pulp by SF6 plasma treatment was viable and suitable. FTIR and Raman spectroscopy showed the presence of specific bands related to C-Fx bonds. An exchange of behavior of the cellulose pulp occurred, transitioning from hydrophilic to hydrophobic. After 192 hours of analysis, moisture absorption was reduced by 15.28%, 13.99%, 8.30%, and 14.05% for the 0.1SF6, 0.3SF6, 0.5SF6, and 0.7SF6 treatments, respectively. Only the 0.1SF6 treatment yielded satisfactory results for all mechanical properties assessed, including rupture modulus (MOR), elasticity modulus (MOE), limit of proportionality (LOP), and toughness, when compared to untreated cellulose pulp. The positive results were particularly evident following accelerated ageing cycles, as the properties were either maintained (MOR, LOP) or improved (MOE, toughness). Therefore, this treatment is recommended for the intended application.

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

ABNT - Associação Brasileira de Normas Técnicas (2014) NBR 7581-2: Fiber cement corrugated sheet - Part 2: Tests, 17p

ABNT - Associação Brasileira de Normas Técnicas (2018) NBR 16697: Portland cement - Requirements, 12p

ABNT - Associação Brasileira de Normas Técnicas (2021) NBR 15498: Fibre-cement flat sheets reinforced with fibres, thread, filaments or mesh - Requirements and test methods, 7p

Agarwal UP (2017) Raman spectroscopy in the analysis of cellulose nanomaterials. ACS Symp Ser 1251:75–90

Alrekabi S, Cundy AB, Lampropoulos A et al (2017) Mechanical performance of novel cement-based composites prepared with nano-fibres, and hybrid nano- and micro-fibres. Compos Struct 178:145–156. https://doi.org/10.1016/j.compstruct.2017.06.045

Antoniazzi JP, Mohamad G, Casali JM et al (2020) Ação dos aditivos estabilizador de hidratação e incorporador de ar em pastas de cimento Portland. Ambient Constr 20:249–262. https://doi.org/10.1590/s1678-86212020000300427

ASTM (2023a) G154-23: Standard practice for operating fluorescent ultraviolet (uv) lamp apparatus for exposure of materials. 14.04. 12p

ASTM (2023b) C948-81: Standard test method for dry and wet bulk density, water absorption, and apparent porosity of thin sections of glass-fiber reinforced concrete, 2p

Bader RFW (1994) Atoms in molecules: a quantum theory. Clarendon press, Oxford

Ballesteros JEM, dos Santos V, Mármol G et al (2017) Potential of the hornification treatment on eucalyptus and pine fibers for fiber-cement applications. Cellulose 24:2275–2286. https://doi.org/10.1007/s10570-017-1253-6

Choi H, Choi YC (2021) Setting characteristics of natural cellulose fiber reinforced cement composite. Constr Build Mater 271:121910. https://doi.org/10.1016/j.conbuildmat.2020.121910

Cortés-Guzmán F, Bader RFW (2005) Complementarity of QTAIM and MO theory in the study of bonding in donor–acceptor complexes. Coord Chem Rev 249:633–662. https://doi.org/10.1016/J.CCR.2004.08.022

Curosu I, Liebscher M, Mechtcherine V et al (2017) Tensile behavior of high-strength strain-hardening cement-based composites (HS-SHCC) made with high-performance polyethylene, aramid and PBO fibers. Cem Concr Res 98:71–81. https://doi.org/10.1016/j.cemconres.2017.04.004

da Costa Correia V, Santos SF, Soares Teixeira R, Savastano Junior H (2018) Nanofibrillated cellulose and cellulosic pulp for reinforcement of the extruded cement based materials. Constr Build Mater 160:376–384. https://doi.org/10.1016/j.conbuildmat.2017.11.066

de Camargo JSG, de Menezes AJ, da Cruz NC et al (2017) Morphological and chemical effects of plasma treatment with oxygen (O2) and sulfur hexafluoride (SF6) on cellulose surface. Mater Res 20:842–850. https://doi.org/10.1590/1980-5373-MR-2016-1111

de Souza JDGT, Motta LA de C, Pasquini D et al (2017) Modificação química superficial de fibras de bucha vegetal visando à compatibilização e aplicação como reforço em matriz cimentícia. Ambiente Construído 17:269–283. https://doi.org/10.1590/s1678-86212017000200157

de Siqueira MC(2017) Modificação superficial de nanocristais de celulose obtidos do bagaço de cana-de-açúcar para formulação de nanocompósitos de matriz polimérica. 620.11 S618m CD-ROM. Dissertation. Universidade Estadual do Norte Fluminense Darcy Ribeiro. Campos dos Goytacazes, RJ, 58p

Fan M, Ndikontar MK, Zhou X, Ngamveng JN (2012) Cement-bonded composites made from tropical woods: compatibility of wood and cement. Constr Build Mater 36:135–140. https://doi.org/10.1016/j.conbuildmat.2012.04.089

Ferreira DF (2014) Sisvar: a Guide for its Bootstrap procedures in multiple comparisons. Ciência e Agrotecnologia 38:109–112. https://doi.org/10.1590/S1413-70542014000200001

Ferreira VA (2018) Mathematical model and experimental study of a SF6 process. T/UNICAMP F413m. Dissertation. Universidade Estadual de, Campinas Campinas, SP, 136p

Filho NT de A, Dantas CP, Leal AF et al (2012) Resistência mecânica de compósitos cimentícios leves utilizando resíduos industriais e fibras de sisal. Revista Brasileira de Engenharia Agrícola e Ambiental 16:894–902

Filomeno RH, Rodier LB, Ballesteros JEM et al (2020) Optimizing the modified atmosphere parameters in the carbonation process for improved fiber-cement performance. J Build Eng 32:101676. https://doi.org/10.1016/j.jobe.2020.101676

Fischer S, Schenzel K, Fischer K, Diepenbrock W (2005) Applications of FT Raman spectroscopy and micro spectroscopy characterizing cellulose and cellulosic biomaterials. Macromol Symp 223:41–56. https://doi.org/10.1002/masy.200550503

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 20:583–588. https://doi.org/10.1007/s10570-012-9833-y

Frisch MJ, Trucks GW, Schlegel HB et al (2009) Gaussian 09. Gaussian, Inc., Wallingford CT

Gierlinger N, Luss S, König C et al (2010) Cellulose microfibril orientation of Picea abies and its variability at the micron-level determined by Raman imaging. J Exp Bot 61:587–595. https://doi.org/10.1093/jxb/erp325

Guignone GC, Vieira GL, Zulcão R et al (2020) Performance of concrete with the incorporation of waste from the process of stoning and polishing of glass as partial replacement of cement. Revista IBRACON de Estruturas e Materiais 13:613–627. https://doi.org/10.1590/s1983-41952020000300011

Hodak SK, Supasai T, Paosawatyanyong B et al (2008) Enhancement of the hydrophobicity of silk fabrics by SF 6 plasma. Appl Surf Sci 254:4744–4749. https://doi.org/10.1016/j.apsusc.2008.01.110

Hofstrand AD, Moslemi AA, Garcia JF (1984) Curing characteristics of particles from nine northern Rocky Mountain species mixed with portland cement. For Prod J 34:57–61

Hosokawa RS (2016) Delineação de padrões na superfície da poliamida por processo de plasma. Dissertarion. Universidade Estadual Paulista, Sorocaba, SP

Hua ZQ, Sitaru R, Denes F, Young RA (1997) Mechanisms of oxygen- and argon-RF-plasma-induced surface chemistry of cellulose. Plasmas Polym 2:199–224. https://doi.org/10.1007/BF02766154

Kamlangkla K, Paosawatyanyong B, Pavarajarn V et al (2010) Mechanical strength and hydrophobicity of cotton fabric after SF 6 plasma treatment. Appl Surf Sci 256:5888–5897. https://doi.org/10.1016/j.apsusc.2010.03.070

Keith TA (2011) AIM ALL, TK Gristmill software. Overland Park KS, AIMAll (Version 11.05.16). http://aim.tkgristmill.com/

Kim JH, Han JH, Hong S et al (2021) Effect of plasma surface modification on pullout characteristics of carbon fiber-reinforced cement composites. Carbon Trends 3:100030. https://doi.org/10.1016/j.cartre.2021.100030

Koch U, Popelier PLA (1995) Characterization of C-H-O hydrogen bonds on the basis of the charge density. J Phys Chem 99:9747–9754. https://doi.org/10.1021/j100024a016

Kumar A, Gupta D (2016) Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash-soil mixtures. Geotext Geomembr 44:466–474. https://doi.org/10.1016/j.geotexmem.2015.07.010

Latorraca JVF, Iwakiri S, Lelis RCC (1999) Efeito Inibidor de cinco espécies Florestais sobre a cura do compósito cimento-madeira. Floresta e Ambiente 6:75–82

Lisboa FJN, Scatolino MV, de Paula PT et al (2020) Lignocellulosic materials for production of cement composites: valorization of the alkali treated soybean pod and eucalyptus wood particles to obtain higher value-added products. Waste Biomass Valor 11:2235–2245. https://doi.org/10.1007/s12649-018-0488-2

Machado PJC, dos Reis A, Ferreira R, de Castro A, Motta L, Pasquini D (2020) Characterization and properties of cementitious composites with cellulose fiber, silica fume and latex. Constr Build Mater 257:119602. https://doi.org/10.1016/j.conbuildmat.2020.119602

Mármol G, Savastano H (2017) Study of the degradation of non-conventional MgO-SiO2 cement reinforced with lignocellulosic fibers. Cem Concr Compos 80:258–267. https://doi.org/10.1016/j.cemconcomp.2017.03.015

Mendes RF (2014) Desempenho de fibrocimentos extrudados produzidos com polpas celulósicas modificadas com silanos. Thesis. Universidade Federal de Lavras, Lavras, MG, 158p

Mendes LM, Loschi FAP, Paula LE de R e et al (2011) Potencial de utilização da madeira de clones de Eucalyptus urophylla na produção de painéis cimento-madeira. CERNE 17:69–75. https://doi.org/10.1590/S0104-77602011000100008

Mendes RF, Mendes LM, de Oliveira JE et al (2015) Modification of eucalyptus pulp fiber using silane coupling agents with aliphatic side chains of different length. Polym Eng Sci 55:1273–1280. https://doi.org/10.1002/pen.24065

Mori FA, Lopes YLV, Mendes LM, de Latorraca JV, F, (2007) Estudo da compatibilidade entre a madeira e as cascas de Eucalyptus grandis e cimento portland. Ciência Florestal 17:257. https://doi.org/10.5902/198050981957

Navarro F, Dávalos F, Denes F et al (2003) Highly hydrophobic sisal chemithermomechanical pulp (CTMP) paper by fluorotrimethylsilane plasma treatment. Cellulose 10:411–424. https://doi.org/10.1023/A:1027381810022

Neville AM (2016) Propriedades do Concreto. Bookman

Okino EYA, de Souza MR, Santana MAE et al (2004) Cement-bonded wood particleboard with a mixture of eucalypt and rubberwood. Cem Concr Compos 26:729–734. https://doi.org/10.1016/S0958-9465(03)00061-1

Owens DK, Wendt RC (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13:1741–1747. https://doi.org/10.1002/app.1969.070130815

Page J, Khadraoui F, Gomina M, Boutouil M (2019) Influence of different surface treatments on the water absorption capacity of flax fibres: Rheology of fresh reinforced-mortars and mechanical properties in the hardened state. Constr Build Mater 199:424–434. https://doi.org/10.1016/j.conbuildmat.2018.12.042

Pedroso M, Flores-Colen I (2020) The influence of dimension and content of natural organic fibrous materials on the multi-performance of cement-based composites: a statistical approach. Constr Build Mater 231:117175. https://doi.org/10.1016/j.conbuildmat.2019.117175

Pereira TGT, Silva DW, Eugênio TMC et al (2019) Coconut fibers and quartzite wastes for fiber-cement production by extrusion. Mater Today Proc 31:S309–S314. https://doi.org/10.1016/j.matpr.2020.01.394

Proniewicz LM, Paluszkiewicz C, Wesełucha-Birczyńska A et al (2002) FT-IR and FT-Raman study of hydrothermally degraded groundwood containing paper. J Mol Struct 614:345–353. https://doi.org/10.1016/S0022-2860(02)00275-2

Rangel EC, Bento WCA, Kayama ME et al (2003) Enhancement of polymer hydrophobicity by SF6 plasma treatment and argon plasma immersion ion implantation. Surf Interface Anal 35:179–183. https://doi.org/10.1002/sia.1518

RILEM Technical Committee (1984) 049 TFR: Testing methods for fibre reinforced cement-based composites. 17(102):441–456

Ruiz E, Cirera J, Alvarez S (2005) Spin density distribution in transition metal complexes. Coord Chem Rev 249:2649–2660. https://doi.org/10.1016/J.CCR.2005.04.010

Santos AEF, Bastos DC, da Silva MLVJ et al (2012) Chemical analysis of a cornstarch film surface modified by SF 6 plasma treatment. Carbohydr Polym 87:2217–2222. https://doi.org/10.1016/j.carbpol.2011.10.049

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Silverstein RM, Webster FX, Kiemle DJ (2005) Spectrometric Identification of organic compounds, 7th edn. Wiley, Hoboken

Szymańska-Chargot M, Cybulska J, Zdunek A (2011) Sensing the structural differences in cellulose from apple and bacterial cell wall materials by Raman and FT-IR Spectroscopy. Sensors 11:5543–5560. https://doi.org/10.3390/s110605543

Teixeira RS, Tonoli GHD, Santos SF et al (2018) Nanoindentation study of the interfacial zone between cellulose fiber and cement matrix in extruded composites. Cem Concr Compos 85:1–8. https://doi.org/10.1016/j.cemconcomp.2017.09.018

Teixeira RS, Santos SF, Christoforo AL et al (2019) Extrudability of cement-based composites reinforced with curauá (Ananas erectifolius) or polypropylene fibers. Constr Build Mater 205:97–110. https://doi.org/10.1016/j.conbuildmat.2019.02.010

Teixeira JN, Silva DW, Vilela AP et al (2020) Lignocellulosic materials for fiber cement production. Waste Biomass Valor 11:2193–2200. https://doi.org/10.1007/s12649-018-0536-y

Thiry D, Konstantinidis S, Cornil J, Snyders R (2016) Plasma diagnostics for the low-pressure plasma polymerization process: a critical review. Thin Solid Films 606:19–44. https://doi.org/10.1016/j.tsf.2016.02.058

Thygesen A, Oddershede J, Lilholt H et al (2005) On the determination of crystallinity and cellulose content in plant fibres. Cellulose 12:563–576. https://doi.org/10.1007/s10570-005-9001-8

Tonoli GHD, Belgacem MN, Bras J et al (2012) Impact of bleaching pine fibre on the fibre/cement interface. J Mater Sci 47:4167–4177. https://doi.org/10.1007/s10853-012-6271-z

Tonoli GHD, Mendes RF, Siqueira G et al (2013) Isocyanate-treated cellulose pulp and its effect on the alkali resistance and performance of fiber cement composites. Holzforschung 67:853–861. https://doi.org/10.1515/hf-2012-0195

Wiley JH, Atalla RH (1987) Raman spectra of celluloses. In: The structures of cellulose, pp 151–168. https://link.springer.com/article/10.1557/PROC-197-89

Won JP, Hong BT, Choi TJ et al (2012) Flexural behaviour of amorphous micro-steel fibre-reinforced cement composites. Compos Struct 94:1443–1449. https://doi.org/10.1016/j.compstruct.2011.11.031

Zanini S, Massini P, Mietta M et al (2008) Plasma treatments of PET meshes for fuel-water separation applications. J Colloid Interface Sci 322:566–571. https://doi.org/10.1016/j.jcis.2008.04.012

Acknowledgments

The authors would like to thank the Technological Plasma Laboratory (LaPTec) of the São Paulo State University “Júlio de Mesquita Filho” (UNESP), the Crystallography Laboratory of the Federal University of Alfenas (UNIFEI), the Physics Laboratory, Wood Anatomy Laboratory, Nanotechnology Laboratory, Laboratory of Electron Microscopy and Ultra-structural Analysis (LME) and Laboratory of Computational Chemistry at Federal University of Lavras (UFLA) for enabling the production, treatment and characterization of the samples. The authors would also like to thank the financial support of Fundação de Amparo à Pesquisa do Estado de Minas Gerais – FAPEMIG (CAG - APQ - 01644-15) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - CAPES.

Funding

This research work was funded by Fundação de Amparo à Pesquisa do Estado de Minas Gerais – FAPEMIG (CAG – APQ – 01644-15) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - CAPES.

Author information

Authors and Affiliations

Contributions

Schiavi, L.S. de O. developed all stages of the research work reported here, wrote the text, prepared figures and participated in the review process. Gonçalves, M. A. and Ramalho, T. C. developed the theoretical simulation analysis involved in the work, together with Schiavi, L.S. de O., participated in the writing of the text concerning this stage of the work and in the revision process. Silva, A. de O. D., Rangel, E. C. provided laboratory infrastructure for the application of plasma in the studied samples, participated in the discussions and guidance of the investigative methodological process. Mendes, R. F. provided laboratory infrastructure for the preparation of studied samples, evaluation of mechanical characteristics, actively participated in the discussions and guidance of the investigative methodological process and also in the writing of the text concerning this stage of the work, as well as in the review process.

Vaz, L. E. V. de S. B. guided the research work described, participating in each stage of conducting, discussions, writing and reviewing the text.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Schiavi, L., Gonçalves, M.A., Delgado-Silva, A. et al. Properties of fiber cement reinforced with cellulose pulp modified by plasma treatment with sulfur hexafluoride (SF6). Cellulose (2024). https://doi.org/10.1007/s10570-024-05885-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10570-024-05885-x