Abstract

Cellulose has been developed as an alternative to petrochemical materials. By comparison with refined nanofibers (RCNFs), lignocellulose nanofibers (LCNFs) show particular promise because it is produced from biomass using only mild pretreatment. The mechanical properties of LCNFs depend on the contained lignin. However, the microscopic location of the lignin contained in LCNFs has not been determined. Thus, we developed two methods to detect and visualize lignin. One uses a scanning transmission electron microscope (STEM) equipped with an energy dispersive X-ray spectroscopy detector. The other method uses an atomic force microscope (AFM) equipped with a cantilever coated with an aromatic molecule. Both methods revealed that the lignin in LCNFs covers a thin cellulose fiber and is precipitated in a grained structure. In particular, the AFM system was able to determine the nanoscopic location of lignin-rich areas. The present study establishes a strong tool for analyzing the characteristics of lignin-containing materials.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the past two decades, materials manufactured using petrochemicals are being converted to sustainable materials via the use of chemistry that is considered “green” from the viewpoint of environmental conservation. Cellulose has attracted attention for its utility as an alternative to petrochemical materials. This is happening because cellulose is the most abundant biomass in nature. Also, cellulose has excellent mechanical properties and thermal stability (Nishino et al. 2004) as well as the advantage of low density and properties that allow it to be easily processed. Furthermore, unlike engineered plastics, cellulose is biodegradable, which means the oceans and the soil are not polluted by debris when cellulose decomposes (Nishino and Arimoto 2007; Fujisawa et al. 2013).

Cellulose nanofibers are considered a beneficial use of cellulose (Nogi et al. 2009; Liu et al. 2016). Cellulose nanofibers (CNFs) exhibit desirable mechanical properties (Saito et al. 2013), transparency (Fukuzumi et al. 2009), and gas-barrier properties (Fukuzumi et al. 2009; Yang et al. 2012). Therefore, CNFs are expected to be applied for the reinforcement of glass (Nogi and Yano 2008), as packaging for foods and medical supplies (Fukuzumi et al. 2009; Azeredo et al. 2017), and as gas-separation membranes (Fukuzumi et al. 2013).

CNFs are produced from sources such as bamboo, wood, rice and wheat straw, hemp, potatoes, bagasse, and kenaf. Sorghum (Sorghum bicolor (L.) Moench) is a C4-species crop and is considered to be a dedicated biorefinery feedstock due to its high productivity (Rooney et al. 2007). Among hybrid forage sorghum cultivars, Tentaka (F1 hybrid) is the top yielding cultivar per unit of land (40.3 t ha−1 y−1) (Venuto and Kindiger 2008).

CNFs are classified as either refined cellulose nanofibers (RCNFs) or lignocellulose nanofibers (LCNFs) based on differences in their chemical composition. LCNFs contain a rich fraction of lignin compared with RCNFs. General lignocellulosic biomass is composed of cellulose, hemicellulose, starch, xylan, and lignin. The lignin and hemicellulose are removed via chemical pretreatment. To produce RCNF, the lignin is completely removed via processes that include several pulping procedures (Gierer 1985) and treatment with sodium chlorite (NaClO2) (the Wise method) (Wise et al. 1946). Hemicellulose can be removed via alkaline treatment (Wise and Ratliff 1947). RCNFs are produced from lignocellulosic biomass using a double process of alkaline treatment and the Wise method (Nobuta et al. 2016). LCNFs are produced via a mild delignification process that includes treatment with dilute sulfuric acid (Teramura et al. 2016) and with an organic acid (Espinosa et al. 2019). After pretreatment for removing lignin and hemicellulose, the biomass is subjected to chemical or mechanical fibrillation. To accomplish mechanical fibrillation, several methods are considered: grinding (Taniguchi and Okamura 1998), aqueous counter collision (Kose and Kondo 2011), and twin-screw extrusion (Baati et al. 2017; Rol et al. 2017).

LCNFs are materials that have the potential for a “greener” status than that of RCNFs because LCNFs are produced via pretreatment using simple and mild conditions (Hassan et al. 2018; Smullen et al. 2019). Currently, the primary industrial applications of LCNFs include use as a filler of polymer materials (Travalini et al. 2019) and as sheets and fibers that can be applied to products (Iwamoto and Endo 2015; Oliaei et al. 2021). The mechanistic properties of LCNFs depend on their residual lignin content (Iwamoto et al. 2008; Karimi et al. 2014). In addition to the content, the location of lignin also could affect the properties of LCNFs, because lignin is known to locate between plant fibers and in cell walls, which forms a complex lignin-carbohydrate linkage (Zoghlami and Paës 2019). The location of lignin in lignocellulosic biomass has been studied using microscopic techniques that include the use of a confocal laser scanning microscope (Liao et al. 2022), CLSM with immunolabeling (Hou et al. 2013), Fourier transmission infra-red imaging (Li et al. 2018), and Raman imaging (Sasani et al. 2021). Electron microscopes offer a spatial resolution that is superior to that of optical microscopes, and electron microscopes have also been employed for biomass that is mercurialized (Westermark et al. 1988) and reacted with potassium permanganate (Hepler and Fosket 1970; Hou et al. 2013). Atomic force microscopes (AFM) have also been employed to observe lignocellulosic materials on a nanoscopic scale (Lambert et al. 2019). AFMs scan the sharp-tipped probe of a cantilever on the surface of a material of interest to generate a morphology map (Binnig et al. 1986). As an adaptation of AFM, chemical force microscopy (CFM) is able to gain information about the chemical surface variations and the magnitude of chemical forces. CFM uses a probe modified with specific ligand molecules. Several groups reported a heterogeneous distribution of interactive forces between a self-assembled monolayer of a hydrophobic molecule and lignocellulosic surfaces (Arslan et al. 2015; Elinski et al. 2017; Gusenbauer et al. 2020). However, the variety of the molecules modified on the probe was limited and the nanoscopic location of the lignin in LCNFs is not determined using this process.

In the present study, we applied two techniques to visualize and quantify the lignin contained in LCNFs on either a microscopic or nanoscopic scale. The first involved the use of a scanning transmission electron microscope (STEM) equipped with an energy dispersive X-ray spectrometry (EDS) detector. In this process, the lignin in LCNFs was electron-stained with KMnO4; lignin molecules are oxidized by KMnO4, and conversely, the permanganate anion is reduced to manganese dioxide, which then precipitates and indicates the site of the reaction (Fig. 1a). The second process involved the use of an atomic force microscope (AFM) with a cantilever modified with an arbitrary ligand molecule. AFM detects an interactive force between the ligand and the material’s surface via a system of force-distance curve measurements, which allows force-curve mapping (FCM) (Dufrêne et al. 2013). Lignin molecules are composed of three building blocks of aromatic molecules (Fig. 1b). Thus, we attempted to detect the lignin on LCNFs by using an AFM equipped with a cantilever coated with aromatic molecules to ensure an affinity for the aromatic rings in lignin molecules that would result in hydrophobic and π–π interactions (Fig. 1c).

The detection methods of lignin deposited on cellulose nanofibers (CNFs) that are reported in the present study, involved a a scanning transmission electron microscope equipped with an energy-dispersive X-ray spectroscopy (EDS) detector and c an atomic force microscope equipped with a cantilever modified with an aromatic molecule. b Building blocks of a lignin molecule

Hypothesis

STEM-EDS with KMnO4 staining and AFM equipped with a cantilever modified with thiophenol may visualize and determine the location of lignin on cellulose nanofibers in a nanoscopic scale.

Materials and methods

Biomass-derived materials

Two kinds of materials were prepared from the hybrid sorghum cultivar Tentaka (Venuto and Kindiger 2008). This sorghum was grown in 2013 at an experimental field in Okinawa, Japan. After harvest, a fine powder was prepared with the previous reported method of purification and degreasing (Teramura et al. 2016). Then, the materials were pretreated with two different methods: sulfuric acid treatment (Teramura et al. 2016) and refining (a combination of the Wise method and alkaline treatment, Nobuta et al. 2016). Then, water dispersion samples were prepared via fibrillation by passing the pretreated biomass through a high-pressure homogenizer (LM-20-30 Microfluidizer®, Microfluidics International Co.) ten times at 207 MPa. These two materials are referred to as LCNFs and RCNFs, respectively.

As a reference sample of pure lignin, organosolv-treated lignin was prepared via a previously reported method using 1-butanol (Teramura et al. 2016). Organosolv treatment is a practical methodology that is based on sulfuric acid treatment with the addition of a solvent for the isolation of high-quality lignin and high-purity cellulose. Acetone was used to adjust the pure lignin solution to 10 g/L (Nacalai Tesque, Kyoto, Japan). Then, 40 µL of this solution was applied to the cover glass (φ13 mm glass; Matsunami Glass Industries, Osaka), which then was spin-coated at 3000 rpm for 1 min. To assess the nonspecific interaction of the probe, a cellulose acetate membrane (C020A047A; Advantec, Tokyo, Japan) was used as a control sample.

Chemical composition analysis

The chemical compositions of these materials were determined according to analysis based on the National Renewable Energy Laboratory (referred to as NREL) method (Sluiter et al. 2012). In brief, the polysaccharide composition was calculated based on the monomer content after two-step acid hydrolysis. First, each 300 mg of a sample was added into 3 mL of 72% (w/w) sulfuric acid, followed by incubation at 30 oC for 2 h. Second, the reacted sample was diluted to 4% (w/w) using deionized water, after which it was autoclaved at 121 oC for 1 h. The hydrolysis sample was neutralized to pH 5.0 using calcium hydroxide. Finally, the sugar content of the liquid hydrolysate was determined via GCMS-QP2010 SE (Shimadzu, Kyoto, Japan). The acid-soluble lignin content was determined by measuring the optical density at 240 nm.

Scanning electron microscope (SEM) observation

The water dispersions of RCNF and LCNF were vacuum filtered and dried in vacuo at 50 °C for 12 h to obtain the RCNF and LCNF sheets. The surfaces of the CNF sheets were observed using a JSM-7100 F (JEOL, Tokyo, Japan) at 2 kV following the application of a Pt–Pd coating.

STEM observation and EDS analysis

The dispersion samples were separated from the dispersion by centrifugation (4000 g, 2 min, RT). Then, these samples were stained with a 1% (w/v) potassium permanganate (KMnO4) (Nacalai Tesque, Kyoto, Japan) solution for 5 min followed by washing with distilled water 4 times, and were again dispersed in water. Finally, the stained samples were drop cast on 900-mesh copper grids and dried to form a thin film of CNFs. Unstained samples were prepared according to the same procedure without KMnO4 staining.

Each observation sample was mounted on a grid and examined using a JEM-2100 F (JEOL, Tokyo, Japan) equipped with a scanning transmission electron microscopy (STEM) mode, a high-angle annular dark-field (HAADF) detector (JEOL), and an energy dispersive X-ray spectrometer (EDS) (JED-2300T; JEOL), at an accelerating voltage of 200 kV. For statistical analysis, the percentages of Mn atom content in five random fields of view for each sample were calculated using Analysis Station and Analysis Program (JEOL) software under the assumption that the sample consisted of only carbon, oxygen, and manganese.

AFM imaging and force curve measurement analysis

A silicon cantilever (Olympus Co. Ltd., Tokyo, Japan, OMCL-TR400PB-1, spring constant: 0.09 N/m, tip radius: < 40 nm, tip angle: < 70 deg., Au coated) was used in this study, and chemical modification was performed using a previously reported method (Takenaka et al. 2015, 2017) with only minor modification. In brief, the cantilever was treated with ultraviolet light irradiation for 1.5 h to clear the organic compounds that may have previously adhered to the cantilever surface. The concentration of thiophenol (Wako pure chemical industries, Osaka, Japan) was adjusted to 20 mM via the use of 99.5% ethanol (Nacalai Tesque, Kyoto, Japan). The treated cantilever was dipped into the 20 mM thiophenol solution with shading for 30 min. The reacted cantilever was washed with 99.5% ethanol and then with distilled water.

Water-dispersion samples (100 mL) were dropped onto poly-L-lysine-coated glass (Matsunami Glass Industries, Osaka). Then, these samples were dried in an oven at 80 °C for 2 h.

A SPA400-Nanonavi AFM unit (Hitachi High-Tech Science, Tokyo, Japan) was used to perform all measurements in distilled water. The measurements and mapping were performed using previously reported methods (Takenaka et al. 2015, 2017). In brief, the sample surface was imaged at a resolution of 64 × 64 pixels, which allowed the simultaneous measurement of force via a force-distance curve. The force-distance curve was recorded in 512 steps with a dwell time of 10 msec. The forces between the cantilever and each sample were analyzed using three random field-of-view (FOV) that contained 4096 data points. The force-curve mapping was visualized using FlexPro7 software (Hulinks, Tokyo, Japan).

To evaluate the non-specific interaction between the cantilever probes and polysaccharides, force-curve measurements were conducted on a cellulose acetate membrane filter. To verify the π–π interaction between the thiophenol-modified probe and aromatic molecules, force-curve measurements were performed on a thiophenol-modified gold substrate using a thiophenol-modified cantilever. The gold substrate underwent the same thiophenol modification conditions as those used for the cantilever.

Results and discussion

Chemical compositions of RCNFs and LCNFs

RCNFs and LCNFs were prepared from raw biomass according to the scheme in Fig. 1a. The chemical compositions of the samples were evaluated via analysis based on the National Renewable Energy Laboratory (NREL) method (Sluiter et al. 2012). RCNFs are 74.2% cellulose, 13.8% hemicellulose, and 17.8% lignin—of which, 3.72% are acid-soluble and 14.1% are acid-insoluble. LCNFs are approximately 64.7% cellulose, 3.52% hemicellulose, and 39.9% lignin—of which, 32.8% are acid-soluble and 7.12% are acid-insoluble. The lignin content of LCNFs was approximately twice that of RCNFs.

As far as we could ascertain, the present study is the first to compare the chemical compositions of CNFs treated by two different methods. Previously, although the material was made from kenaf, the chemical composition of RCNF sheets was reported to be 85% cellulose, 9.4% hemicellulose, and 5.5% lignin (Nobuta et al. 2016). On the other hand, the chemical composition of the biomass pretreated with sulfuric acid (as LCNFs before fibrillation) was reported as 53.0% cellulose, 12.6% hemicellulose, and 36% lignin (Teramura et al. 2016). The results show that the proportions of the constituents were not significantly changed by fibrillation. Residual lignin did not be extracted to a water phase even with the use of destructive shear force, because the chemical pretreatment had fully penetrated the biomass powder.

SEM observation

Before the detection of lignin, the surfaces of CNF sheets were observed via SEM to inspect the topology of CNFs. RCNFs were uniformly fibrillated into < 10 nm fibers (Fig. 2c). The primary fibers became entangled or crystallized into clumps in places. LCNFs were fibrillated into variable thick fibers (< 100 nm) (Fig. 2d). In addition to fibers, we found grained structures and smooth sections that varied in diameters from < 10 nm to as much as 500 nm. Notably, only fibers were found in RCNFs, although it is 14% acid-soluble lignin. Acid-soluble lignin is hydrophilic and thus might co-exist with cellulose fiber rather than forming a separate structure. Thus, the grains in LCNFs are derived from acid-insoluble lignin. A part of acid-insoluble lignin should be alkaline-soluble lignin that is free of associated polysaccharides and is composed mainly of the aromatic building blocks of lignin (Sun et al. 2000). Because these aromatic molecules are relatively hydrophobic, acid-insoluble lignin forms a grained structure in LCNFs. Some previous researchers have reported that lignin forms a grained structure in pretreated biomass, which is based on the hypothesis that lignin is melted by the heat of pretreatment, which causes it to migrate out of a biomass matrix (Selig et al. 2007; Schmetz et al. 2019).

a Schematic method for the production of cellulose nanofiber from biomass. b Carbohydrate and lignin composition of refined cellulose nanofibers (RCNFs) and sulfuric acid treated cellulose nanofibers (LCNFs). The data are indicated as the mean of 3 different runs. Scanning electron microscope image of c LCNFs and d RCNFs. Scale bar: 500 nm

Lignin detection using STEM observation and EDS analysis

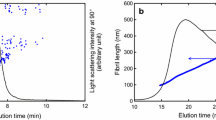

First, we performed lignin detection in RCNFs and LCNFs using STEM-EDS with KMnO4 staining. MnO4− is reduced by lignin building blocks and is precipitated at lignin sites as MnO2. The deposited MnO2 thus indicates the location of lignin, which allows quantification. For statistical analysis, the percentages of Mn atom content in five random fields of view for each sample were calculated under the assumption that the sample consisted of only carbon, oxygen, and manganese. The manganese content in LCNFs was significantly higher than that in RCNFs (Fig. 3a). No manganese was detected in the unstained CNF samples. RCNFs and LCNFs stained with KMnO4 contained a median of 0.13 atom% and 8.4 atom%, respectively. Atomic mapping images produced with STEM-EDS also revealed differences in the manganese content between RCNFs (Fig. 3b(i)) and LCNFs (Fig. 3b(ii)). HAADF represents a typical STEM image where the object appears to be white. The topographical images of both RCNFs and LCNFs corresponded to the SEM images discussed above. Only fiber was found in RCNFs that were not stained with manganese. In LCNFs, the fibers not stained with manganese were covered by obscure and hazy structures that were stained with manganese. Manganese stained the grained structures. KMnO4 staining indicated that the hazy structures and distinct grains could have been lignin. Rather than manganese, carbon was detected in the LCNF fibers, which could exist in cellulose without lignin as it does in RCNFs. The thick fiber found in the SEM image of LCNFs could be thin cellulose fibers coated by lignin (Fig. 2d). Lignin was detected in only LCNFs. The amount of lignin in RCNFs, however, is approximately half that in LCNFs. This inconsistency could derive from the difference in lignin characteristics between the conditions of acid-soluble and acid-insoluble. As mentioned above, acid-insoluble lignin is rich in aromatic building blocks that react with a permanganate ion. Thus, the lignin detection method using STEM-EDS with KMnO4 could be applied to the detection of acid-insoluble lignin. This is the first report to detect and visualize lignin in CNFs using STEM-EDS with KMnO4 staining.

a Manganese content in refined cellulose nanofibers (RCNFs) and lignocellulose nanofibers (LCNFs) with and without treatment of potassium permanganate (KMnO4) measured by STEM-EDS. Each experiment was performed with 4 different runs. b Visualization of lignin in (i) RCNFs and (ii) LCNFs with KMnO4 staining using STEM-EDS. HAADF: high-angle annular dark-field image, C: carbon, O: oxygen, Mn: manganese

Lignin detection via AFM imaging and force-measurement analysis

To detect lignin in RCNFs and LCNFs, we developed a cantilever modified with a probe molecule that detects lignin with specificity via force measurement using an AFM. An Au-coated cantilever was modified with thiophenol via thiol-gold interaction. An aromatic ring bound on a cantilever would have an affinity for other aromatic compounds such as the building blocks of lignin. For a proof of concept, the thiophenol-modified cantilever was first used to detect the interaction with a thiophenol-modified gold substrate surface. Force-curve measurement was taken at 12,288 different points for each samples. The strong interaction was observed between the thiophenol-modified probe and the thiophenol modified gold substrate, compared to the bare gold substrate (Fig. S1). The positive interaction would be due to π–π interactions. A film of pure lignin that was extracted from biomass via organosolv treatment was also used to demonstrate the interaction with the thiophenol-modified cantilever and the lignin. Compared with a bare cantilever, the modified cantilever showed a stronger interaction with pure lignin (Fig. 4a(i)). The detected interactive forces did not change during and after the FCM (Fig. S2). It was suggested that the probe surface was not degraded by the measurements. Then, RCNFs and LCNFs were tested with the AFM system for the specific detection of lignin. The repeated force measurements at each of the 12,288 different points showed that the median of detected force was larger in LCNFs than in RCNFs (Fig. 4a(ii)). Although the difference in median values appeared small, the number of points representing strong affinity was significantly high. Since the CNF sample surface was not uniform and the places with strong interactions were limited, the averaged data reflected little change between RCNFs and LCNFs. It is possible that the AFM system could detect not only acid-insoluble lignin but also acid-soluble lignin, which is not within the capacity of the STEM-EDS and KMnO4 methods. In addition, nonspecific interaction of the thiophenol-modified probe tip was assessed using a polysaccharide surface. The FCM conducted on a cellulose acetate membrane revealed that the interaction force between the cellulose acetate and the thiophenol-modified tip was slightly lower compared to that with the bare tip. The modification of AFM tips did not provoke non-specific interactions with polysaccharides (Fig. S3).

Local images of both topology and FCM provided rather comprehensive results. In FCM, only the points with an affinity force above 100 pN were spotted. The topographical image of RCNFs showed isolated thin fibers and no other significant structure (Fig. 4b(i)). The FCM of RCNFs showed few points that would represent a strong interaction (Fig. 4b(ii)). The merged image confirmed no correspondence between the topology and the FCM (Fig. 4b(iii)). In LCNFs, thick fibers and grained structures were found in the topographical image (Fig. 4b(iv)). The FCM showed locally dense points that represent high affinity (Fig. 4b(vi)). The points were located in smooth areas that had no fiber but did show grains. Thus, the AFM system indicated that the smooth coverage on the nanofiber and on the grained structure was lignin, which corresponded to the results of the lignin detection using STEM-EDS. Subsequently, high-magnification observation was performed in limited areas in the topographical image of LCNFs, and these are indicated as X and Y in Fig. 4b(iv). The X area shows many grained structures (Fig. 4b(vii)). The corresponding FCM shows an area on the left edge of the spherical structure expressed a high level of interaction with the cantilever modified with thiophenol (Fig. 4b(viii), (ix)). The Y area displays thick fibers with sub-µm diameters (Fig. 4b(x)). Strong interactions were detected on the left edge of the fibers, similar to those observed in the grained structures (Fig. 4b(xi), (xii)). It was investigated whether the lignin was actually deposited on one side of the structures, or this was an artifact derived from the sweep direction of the AFM probe. FCM was conducted on LCNFs using a thiophenol-modified cantilever, and the scan direction of the probe was reversed for additional FCM within the same FOV. Consequently, strong interactions were detected from the left side of the fibers, regardless of the probe’s scan direction (Fig. S4). This suggests that lignin is indeed asymmetrically deposited onto LCNFs. The anisotropic deposition of lignin may have occurred during the drying process of the samples.

Few previous reports have used AFM to study the lignin on CNFs. Lignin precipitated on a Kraft pulp surface has been observed using AFM only from a topographical point of view (Maximova et al. 2001; Gidh et al. 2006; Gilli et al. 2012). Hydrophobic CFM was able to detect lignin selectively. In the present study, a modification of an AFM probe with an aromatic molecule indicated the nanoscopic location of lignin on CNFs utilizing π-π interactions.

a Interactive force measured by AFM on (i) the lignin thin film using a bare cantilever or a thiophenol-modified cantilever and on (ii) the refined cellulose nanofibers (RCNFs) and lignocellulose nanofibers (LCNFs). Each measurement was performed on 12,288 different points. b AFM imaging and force-curve mapping (FCM) of (i–iii) RCNFs and (iv–xii) LCNFs. Magnified image of (vii–ix) area X and (x–xii) area Y (iv). (i, iv, vii, x) topographical image. (ii, v, viii, xi) FCM image. (iii, vi, ix, xii) merged topographical and FCM image

Conclusion

We used two methods to detect and visualize lignin on LCNFs, which were produced from sorghum biomass via dilute sulfuric acid pretreatment. STEM-EDS with KMnO4 staining showed that acid-insoluble lignin in LCNFs covers thin cellulose fibers and is precipitated in a grained structure. An AFM equipped with a cantilever modified with thiophenol also detected acid-insoluble lignin in LCNFs via a π–π interaction between thiophenol and lignin building blocks. These lignin detection methods could reveal the prospective mechanical characteristics of various LCNF materials by determining the amounts and locations of lignin.

References

Arslan B, Ju X, Zhang X, Abu-Lail NI (2015) Heterogeneity and specificity of nanoscale adhesion forces measured between self-assembled monolayers and lignocellulosic substrates: a chemical force microscopy Study. Langmuir 31:10233–10245. https://doi.org/10.1021/acs.langmuir.5b02633

Azeredo HMC, Rosa MF, Mattoso LHC (2017) Nanocellulose in bio-based food packaging applications. Ind Crops Prod 97:664–671. https://doi.org/10.1016/j.indcrop.2016.03.013

Baati R, Magnin A, Boufi S (2017) High solid content production of nanofibrillar cellulose via continuous extrusion. ACS Sustain Chem Eng 5:2350–2359. https://doi.org/10.1021/acssuschemeng.6b02673

Binnig G, Quate CF, Gerber C (1986) Atomic force microscope. Phys Rev Lett 56:930–933. https://doi.org/10.1201/9781420075250

Dufrêne YF, Martínez-Martín D, Medalsy I et al (2013) Multiparametric imaging of biological systems by force-distance curve-based AFM. Nat Methods 10:847–854. https://doi.org/10.1038/nmeth.2602

Elinski MB, Menard BD, Liu Z, Batteas JD (2017) Adhesion and friction at graphene/self-assembled monolayer interfaces investigated by atomic force microscopy. J Phys Chem C 121:5635–5641. https://doi.org/10.1021/acs.jpcc.7b00012

Espinosa E, Rol F, Bras J, Rodríguez A (2019) Production of lignocellulose nano fi bers from wheat straw by different fi brillation methods. Comparison of its viability in cardboard recycling process. J Clean Prod 239:118083. https://doi.org/10.1016/j.jclepro.2019.118083

Fujisawa S, Saito T, Kimura S et al (2013) Surface engineering of ultrafine cellulose nanofibrils toward polymer nanocomposite materials. Biomacromol 14:1541–1546. https://doi.org/10.1021/bm400178m

Fukuzumi H, Fujisawa S, Saito T, Isogai A (2013) Selective permeation of hydrogen gas using cellulose nanofibril film. Biomacromol 14:1705–1709. https://doi.org/10.1021/bm400377e

Fukuzumi H, Saito T, Iwata T et al (2009) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromol 10:162–165. https://doi.org/10.1021/bm801065u

Gidh AV, Decker SR, See CH et al (2006) Characterization of lignin using multi-angle laser light scattering and atomic force microscopy. Anal Chim Acta 555:250–258. https://doi.org/10.1016/j.aca.2005.09.023

Gierer J (1985) Chemistry of delignification: part 1: general concept and reactions during pulping. Wood Sci Technol 19:289–312. https://doi.org/10.1007/BF00350807

Gilli E, Schmied F, Diebald S et al (2012) Analysis of lignin precipitates on ozone treated kraft pulp by FTIR and AFM. Cellulose 19:249–256. https://doi.org/10.1007/s10570-011-9612-1

Gusenbauer C, Nypelö T, Jakob DS et al (2020) Differences in surface chemistry of regenerated lignocellulose fibers determined by chemically sensitive scanning probe microscopy. Int J Biol Macromol 165:2520–2527. https://doi.org/10.1016/j.ijbiomac.2020.10.145

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour Technol 262:310–318. https://doi.org/10.1016/j.biortech.2018.04.099

Hepler PK, Fosket DE (1970) Lignification during secondary wall formation in coleus: an electron microscopic study. Am J Bot 57:85–96

Hou XD, Li N, Zong MH (2013) Renewable bio ionic liquids-water mixtures-mediated selective removal of lignin from rice straw: visualization of changes in composition and cell wall structure. Biotechnol Bioeng 110:1895–1902. https://doi.org/10.1002/bit.24862

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromol 9:1022–1026. https://doi.org/10.1021/bm701157n

Iwamoto S, Endo T (2015) 3 Nm thick lignocellulose nano fibers obtained from esterified wood with maleic anhydride. ACS Macro Lett 4:80–83. https://doi.org/10.1021/mz500787p

Karimi S, Tahir PM, Karimi A et al (2014) Kenaf bast cellulosic fibers hierarchy: a comprehensive approach from micro to nano. Carbohydr Polym 101:878–885. https://doi.org/10.1016/j.carbpol.2013.09.106

Kose R, Kondo T (2011) Favorable 3D-network formation of chitin nanofibers dispersed in water prepared using aqueous counter collision. SEN’I GAKKAISHI 67:91–95

Lambert E, Aguié-Béghin V, Dessaint D et al (2019) Real time and quantitative imaging of lignocellulosic films hydrolysis by atomic force microscopy reveals lignin recalcitrance at nanoscale. Biomacromol 20:515–527. https://doi.org/10.1021/acs.biomac.8b01539

Li X, Wei Y, Xu J et al (2018) Biotechnology for biofuels quantitative visualization of lignocellulose components in transverse sections of moso bamboo based on FTIR macro – and micro – spectroscopy coupled with chemometrics. Biotechnol Biofuels. https://doi.org/10.1186/s13068-018-1251-4

Liao K, Han L, Yang Z et al (2022) A novel in-situ quantitative profiling approach for visualizing changes in lignin and cellulose by stained micrographs. Carbohydr Polym 297:119997. https://doi.org/10.1016/j.carbpol.2022.119997

Liu C, Li B, Du H et al (2016) Properties of nanocellulose isolated from corncob residue using sulfuric acid, formic acid, oxidative and mechanical methods. Carbohydr Polym 151:716–724. https://doi.org/10.1016/j.carbpol.2016.06.025

Maximova N, Österberg M, Koljonen K, Stenius P (2001) Lignin adsorption on cellulose fibre surfaces: effect on surface chemistry, surface morphology and paper strength. Cellulose 8:113–125. https://doi.org/10.1023/A:1016721822763

Nishino T, Arimoto N (2007) All-cellulose composite prepared by selective dissolving of fiber surface. Biomacromolecules 8:2712–2716. https://doi.org/10.1021/bm0703416

Nishino T, Matsuda I, Hirao K (2004) All-cellulose composite. Macromolecules 37:7683–7687. https://doi.org/10.1021/ma049300h

Nobuta K, Teramura H, Ito H et al (2016) Characterization of cellulose nanofiber sheets from different refining processes. Cellulose 23:403–414. https://doi.org/10.1007/s10570-015-0792-y

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 21:1595–1598. https://doi.org/10.1002/adma.200803174

Nogi M, Yano H (2008) Transparent nanocomposites based on cellulose produced by bacteria offer potential innovation in the electronics device industry. Adv Mater 20:1849–1852. https://doi.org/10.1002/adma.200702559

Oliaei E, Lindström T, Berglund LA (2021) Sustainable development of hot-pressed all-lignocellulose composites—comparing wood fibers and nanofibers. Polymer (Basel). https://doi.org/10.3390/polym13162747

Rol F, Karakashov B, Nechyporchuk O et al (2017) Pilot-scale twin screw extrusion and chemical pretreatment as an energy-efficient method for the production of nanofibrillated cellulose at high solid content. ACS Sustain Chem Eng 5:6524–6531. https://doi.org/10.1021/acssuschemeng.7b00630

Rooney WL, Blumenthal J, Bean B, Mullet JE (2007) Designing sorghum as a dedicated bioenergy feedstock. Biofuels Bioprod Biorefin 1:147–157. https://doi.org/10.1002/bbb.15

Saito T, Kuramae R, Wohlert J et al (2013) An ultrastrong nanofibrillar biomaterial: the strength of single cellulose nanofibrils revealed via sonication-induced fragmentation. Biomacromolecules 14:248–253. https://doi.org/10.1021/bm301674e

Sasani N, Bock P, Felhofer M, Gierlinger N (2021) Raman imaging reveals in – situ microchemistry of cuticle and epidermis of spruce needles. Plant Methods. https://doi.org/10.1186/s13007-021-00717-6

Schmetz Q, Teramura H, Morita K et al (2019) Versatility of a dilute acid/butanol pretreatment investigated on various lignocellulosic biomasses to produce lignin, monosaccharides and cellulose in distinct phases. ACS Sustain Chem Eng 7:11069–11079. https://doi.org/10.1021/acssuschemeng.8b05841

Selig MJ, Viamajala S, Decker SR et al (2007) Deposition of lignin droplets produced during dilute acid pretreatment of maize stems retards enzymatic hydrolysis of cellulose. Biotechnol Prog 23:1333–1339. https://doi.org/10.1021/bp0702018

Sluiter A, Hames B, Ruiz R et al (2012) NREL/TP-510-42618 analytical procedure: determination of structural carbohydrates and lignin in Biomass. Lab Anal Proced. 1617(1):1–16

Smullen E, Finnan J, Dowling D, Mulcahy P (2019) The environmental performance of pretreatment technologies for the bioconversion of lignocellulosic biomass to ethanol. Renew Energy 142:527–534. https://doi.org/10.1016/j.renene.2019.04.082

Sun R, Tomkinson J, Sun XF, Wang NJ (2000) Fractional isolation and physico-chemical characterization of alkali- soluble lignins from fast-growing poplar wood. Polymer (Guildf) 41:8409–8417. https://doi.org/10.1016/S0032-3861(00)00190-7

Takenaka M, Kobayashi T, Inokuma K et al (2017) Mapping of endoglucanases displayed on yeast cell surface using atomic force microscopy. Colloids Surf B Biointerfaces 151:134–142. https://doi.org/10.1016/j.colsurfb.2016.12.014

Takenaka M, Miyachi Y, Ishii J et al (2015) The mapping of yeast’s G-protein coupled receptor with an atomic force microscope. Nanoscale 7:4956–4963. https://doi.org/10.1039/c4nr05940a

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47:291–294. https://doi.org/10.1002/(SICI)1097-0126(199811)47:3%3c291::AID-PI11%3e3.0.CO;2-1

Teramura H, Sasaki K, Oshima T et al (2016) Organosolv pretreatment of sorghum bagasse using a low concentration of hydrophobic solvents such as 1 – butanol or 1 – pentanol. Biotechnol Biofuels 9:1–11. https://doi.org/10.1186/s13068-016-0427-z

Travalini AP, Lamsal B, Magalhães WLE, Demiate IM (2019) Cassava starch films reinforced with lignocellulose nanofibers from cassava bagasse. Int J Biol Macromol 139:1151–1161. https://doi.org/10.1016/j.ijbiomac.2019.08.115

Venuto B, Kindiger B (2008) Forage and biomass feedstock production from hybrid forage sorghum and sorghum-sudangrass hybrids. Grassl Sci 54:189–196. https://doi.org/10.1111/j.1744-697x.2008.00123.x

Westermark U, Lidbrandt O, Eriksson I (1988) Lignin distribution in spruce (Picea abies) determined by mercurization with SEM-EDXA technique. Wood Sci Technol 22:243–250. https://doi.org/10.1007/BF00386019

Wise LE, Maxine M, D’Addieco A (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Pap Trade J 122:35–43

Wise LE, Ratliff EK (1947) Quantitative isolation of hemicelluloses and the summative analysis of wood. Anal Chem 19:459–462. https://doi.org/10.1021/ac60007a010

Yang Q, Fujisawa S, Saito T, Isogai A (2012) Improvement of mechanical and oxygen barrier properties of cellulose films by controlling drying conditions of regenerated cellulose hydrogels. Cellulose 19:695–703. https://doi.org/10.1007/s10570-012-9683-7

Zoghlami A, Paës G (2019) Lignocellulosic biomass: understanding recalcitrance and predicting hydrolysis. Front Chem 7:874. https://doi.org/10.3389/fchem.2019.00874

Acknowledgments

This work was supported by the Advanced Low Carbon Technology Research and Development Program from the Japan Science and Technology Agency (JST-ALCA), Japan. This study was partially supported by JSPS KAKENHI Grant Numbers: 20K22533 (K.M.); 21K14471 (K.M.); 23K13610 (K.M.), ENEOS TONENGENERAL RESEARCH/DEVELOPMENT ENCOURAGEMENT & SCHOLARSHIP FOUNDATION, and NAKATANI Foundation.I would like to thank the members of Research Facility Center for Science and Technology, Kobe University.

Funding

Open access funding provided by Kobe University.

Author information

Authors and Affiliations

Contributions

KM: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Validation, Visualization, Writing - original draft, review & editing. MT: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Software, Validation, Visualization, Writing - original draft. KT: Investigation, Methodology, Validation. JI: Resources, Supervision. HK: Conceptualization, Funding acquisition, Investigation, Methodology, Project administration, Writing - original draft. DM: Investigation. HA: Investigation. MF: Investigation. TM: Resources, TM: Data curation, Investigation, Methodology, Visualization, Supervision. TN: Conceptualization, Funding acquisition, Methodology, Project administration, Resources, Supervision. CO: Conceptualization, Funding acquisition, Methodology, Project administration, Resources, Supervision, Writing - review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Consent for publication

All authors agreed with the publication.

Ethics approval

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Morita, K., Takenaka, M., Tomita, K. et al. Nanoscopic lignin mapping on cellulose nanofibers via scanning transmission electron microscopy and atomic force microscopy. Cellulose 30, 11357–11367 (2023). https://doi.org/10.1007/s10570-023-05514-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05514-z