Abstract

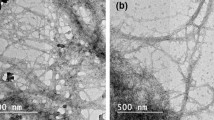

Developing a sustainable separation membrane is imperative due to the growing environmental pollution caused by petrochemical-based polymers. Cellulose-based materials, including bacterial cellulose (BC), have exhibited potential as separation materials. Here, a novel BC membrane (BCM) is in-situ fabricated via microbial fermentation and physical post-treatment. Owing to the randomly assembled BC nanofibers and abundant hydroxyls on their surface, the obtained BCMs possess three-dimensional network structure with strong hydrophilicity. The BCMs properties can be manipulated by adjusting fermentation and drying conditions, satisfying different purposes for practical use. Extending fermentation time from 3 to 10 days, bacteria secret more BC nanofibers and form a denser membrane structure. Freeze-dried BCMs have the most porous structure and exhibit the highest flux (up to 52 L m−2 h−1) and molecular weight cut-off (up to 1000 KDa) under 2 bar. Press-dried BCMs obtain the highest tensile strength (up to 241.16 MPa) and BSA retention (up to 94.44%). Heat-dried BCMs show good prospects in the pressure-driven membrane process considering flux and retention and demonstrate favorable stability and flux recovery ratios (85.51%~96.43%). Modification of BCMs by carboxymethyl cellulose further promotes membrane hydrophilicity but causes denser structures than original BCMs. The present study proposes a sustainable cellulose membrane manufacturing strategy and demonstrates BCMs can be favorable alternatives to petrochemical-based membranes.

Similar content being viewed by others

Data availability

All data generated during this study are included in this published article.

Reference

Asad A, Rastgar M, Sameoto D, Sadrzadeh M (2021) Gravity assisted super high flux microfiltration polyamide-imide membranes for oil/water emulsion separation. J Membr Sci 621:119019. https://doi.org/10.1016/j.memsci.2020.119019

Choudhury RR, Sahoo SK, Gohil JM (2020) Potential of bioinspired cellulose nanomaterials and nanocomposite membranes thereof for water treatment and fuel cell applications. Cellulose 27:6719–6746. https://doi.org/10.1007/s10570-020-03253-z

Dalwani M, Benes NE, Bargeman G, Stamatialis D, Wessling M (2010) A method for characterizing membranes during nanofiltration at extreme pH. J Membr Sci 363:188–194. https://doi.org/10.1016/j.memsci.2010.07.025

Dayal MS, Catchmark JM (2016) Mechanical and structural property analysis of bacterial cellulose composites. Carbohydr Polym 144:447–453. https://doi.org/10.1016/j.carbpol.2016.02.055

de Lima Fontes M, Meneguin AB, Tercjak A, Gutierrez J, Cury BSF et al (2018) Effect of in situ modification of bacterial cellulose with carboxymethylcellulose on its nano/microstructure and methotrexate release properties. Carbohydr Polym 179:126–134. https://doi.org/10.1016/j.carbpol.2017.09.061

de Oliveira Barud HG, da Silva RR, da Silva Barud H, Tercjak A, Gutierrez J et al (2016) A multipurpose natural and renewable polymer in medical applications: bacterial cellulose. Carbohydr Polym 153:406–420. https://doi.org/10.1016/j.carbpol.2016.07.059

Fan T, Miao J, Li Z, Cheng B (2019) Bio-inspired robust superhydrophobic-superoleophilic polyphenylene sulfide membrane for efficient oil/water separation under highly acidic or alkaline conditions. J Hazard Mater 373:11–22. https://doi.org/10.1016/j.jhazmat.2019.03.008

Fang Q, Zhou X, Deng W, Zheng Z, Liu Z (2016) Freestanding bacterial cellulose-graphene oxide composite membranes with high mechanical strength for selective ion permeation. Sci Rep 6:33185. https://doi.org/10.1038/srep33185

Fu L, Zhang J, Yang G (2013) Present status and applications of bacterial cellulose-based materials for skin tissue repair. Carbohydr Polym 92:1432–1442. https://doi.org/10.1016/j.carbpol.2012.10.071

Galdino CJS, Maia AD, Meira HM, Souza TC, Amorim JDP et al (2020) Use of a bacterial cellulose filter for the removal of oil from wastewater. Process Biochem 91:288–296. https://doi.org/10.1016/j.procbio.2019.12.020

Gao Q, Shen X, Lu X (2011) Regenerated bacterial cellulose fibers prepared by the NMMO·H2O process. Carbohydr Polym 83:1253–1256. https://doi.org/10.1016/j.carbpol.2010.09.029

Gigault J, Hadri HE, Nguyen B, Grassl B, Rowenczyk L et al (2021) Nanoplastics are neither microplastics nor engineered nanoparticles. Nat Nanotechnol 16:501–507. https://doi.org/10.1038/s41565-021-00886-4

Guo Y, Zhang X, Hao W, Xie Y, Chen L et al (2018) Nano-bacterial cellulose/soy protein isolate complex gel as fat substitutes in ice cream model. Carbohydr Polym 198:620–630. https://doi.org/10.1016/j.carbpol.2018.06.078

Hatanaka D, Yamamoto K, Kadokawa J (2014) Preparation of chitin nanofiber-reinforced carboxymethyl cellulose films. Int J Biol Macromol 69:35–38. https://doi.org/10.1016/j.ijbiomac.2014.05.022

Hou Y, Duan C, Zhu G, Luo H, Xu JJJoMS, (2019) Functional bacterial cellulose membranes with 3D porous architectures: conventional drying, tunable wettability and water/oil separation. J Membr Sci 591:117312. https://doi.org/10.1016/j.memsci.2019.117312

Huang HC, Chen LC, Lin SB, Hsu CP, Chen HH (2010) In situ modification of bacterial cellulose network structure by adding interfering substances during fermentation. Bioresour Technol 101:6084–6091. https://doi.org/10.1016/j.biortech.2010.03.031

Huang S, Chen Y, Wang X, Guo J, Li Y et al (2022) Preparation of antifouling ultrafiltration membranes from copolymers of polysulfone and zwitterionic poly(arylene ether sulfone)s. Chin J Chem Eng 11:100–110. https://doi.org/10.1016/j.cjche.2022.06.025

Kang Y, Obaid M, Jang J, Kim IS (2019) Sulfonated graphene oxide incorporated thin film nanocomposite nanofiltration membrane to enhance permeation and antifouling properties. Desalination 470:114125. https://doi.org/10.1016/j.desal.2019.114125

Kim JF, Székely G, Valtcheva IB, Livingston AG (2014) Increasing the sustainability of membrane processes through cascade approach and solvent recovery—pharmaceutical purification case study. Green Chem 16:133–145. https://doi.org/10.1039/c3gc41402g

Kingkaew J, Kirdponpattara S, Sanchavanakit N, Pavasant P, Phisalaphong M (2014) Effect of molecular weight of chitosan on antimicrobial properties and tissue compatibility of chitosan-impregnated bacterial cellulose films. Biotechnol Bioprocess Eng 19:534–544. https://doi.org/10.1007/s12257-014-0081-x

Lacin NT (2014) Development of biodegradable antibacterial cellulose based hydrogel membranes for wound healing. Int J Biol Macromol 67:22–27. https://doi.org/10.1016/j.ijbiomac.2014.03.003

Li J-F, Xu Z-L, Yang H, Yu L-Y, Liu M (2009) Effect of TiO2 nanoparticles on the surface morphology and performance of microporous PES membrane. Appl Surf Sci 255:4725–4732. https://doi.org/10.1016/j.apsusc.2008.07.139

Li S-L, Guan Y, Qin Y, Chen Y, Cheng D, Gong G, Hu Y (2023) An antifouling loose nanofiltration membrane prepared by cross-linking HPAN ultrafiltration membrane with zwitterionic polymer PEI-CA for efficient dye desalination. Desalination 549:116354. https://doi.org/10.1016/j.desal.2022.116354

Lin WC, Lien CC, Yeh HJ, Yu CM, Hsu SH (2013) Bacterial cellulose and bacterial cellulose-chitosan membranes for wound dressing applications. Carbohydr Polym 94:603–611. https://doi.org/10.1016/j.carbpol.2013.01.076

Lin D, Liu Z, Shen R, Chen S, Yang X (2020) Bacterial cellulose in food industry: current research and future prospects. Int J Biol Macromol 158:1007–1019. https://doi.org/10.1016/j.ijbiomac.2020.04.230

Liu J, Chen P, Qin D, Jia S, Jia C et al (2020) Nanocomposites membranes from cellulose nanofibers, SiO2 and carboxymethyl cellulose with improved properties. Carbohydr Polym 233:115818. https://doi.org/10.1016/j.carbpol.2019.115818

Ma T, Zhao QQ, Ji KH, Zeng B, Li GQ (2014) Homogeneous and porous modified bacterial cellulose achieved by in situ modification with low amounts of carboxymethyl cellulose. Cellulose 21:2637–2646. https://doi.org/10.1007/s10570-014-0316-1

Mautner A, Lee KY, Lahtinen P, Hakalahti M, Tammelin T, Li K, Bismarck AJCC (2014) Nanopapers for organic solvent nanofiltration. Chem Commun 50:5778–5781. https://doi.org/10.1039/c4cc00467a

Mautner A, Lee K-Y, Tammelin T, Mathew AP, Nedoma AJ, Li K, Bismarck A (2015) Cellulose nanopapers as tight aqueous ultra-filtration membranes. React Funct Polym 86:209–214. https://doi.org/10.1016/j.reactfunctpolym.2014.09.014

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994. https://doi.org/10.1039/c0cs00108b

Muhamad MS, Salim MR, Lau W-J (2015) Preparation and characterization of PES/SiO2 composite ultrafiltration membrane for advanced water treatment. Korean J Chem Eng 32:2319–2329. https://doi.org/10.1007/s11814-015-0065-3

Paximada P, Koutinas AA, Scholten E, Mandala IG (2016) Effect of bacterial cellulose addition on physical properties of WPI emulsions comparison with common thickeners. Food Hydrocoll 54:245–254. https://doi.org/10.1016/j.foodhyd.2015.10.014

Salari M, Sowti Khiabani M, Rezaei Mokarram R, Ghanbarzadeh B, Samadi Kafil H (2018) Development and evaluation of chitosan based active nanocomposite films containing bacterial cellulose nanocrystals and silver nanoparticles. Food Hydrocoll 84:414–423. https://doi.org/10.1016/j.foodhyd.2018.05.037

Shenvi S, Ismail AF, Isloor AM (2014) Enhanced permeation performance of cellulose acetate ultrafiltration membranes by incorporation of sulfonated Poly(1,4-phenylene ether ether sulfone) and Poly(styrene-co-maleic anhydride). Indust Eng Chem Res 53:13820–13827. https://doi.org/10.1021/ie502310e

Stumpf TR, Yang X, Zhang J, Cao X (2018) In situ and ex situ modifications of bacterial cellulose for applications in tissue engineering. Mater Sci Eng C 82:372–383. https://doi.org/10.1016/j.msec.2016.11.121

Suratago T, Taokaew S, Kanjanamosit N, Kanjanaprapakul K, Burapatana V, Phisalaphong M (2015) Development of bacterial cellulose/alginate nanocomposite membrane for separation of ethanol–water mixtures. J Indust Eng Chem 32:305–312. https://doi.org/10.1016/j.jiec.2015.09.004

Tang N, Zhang S, Si Y, Yu J, Ding B (2019) An ultrathin bacterial cellulose membrane with a Voronoi-net structure for low pressure and high flux microfiltration. Nanoscale 11:17851–17859. https://doi.org/10.1039/c9nr06028f

Ullah H, Santos HA, Khan T (2016) Applications of bacterial cellulose in food, cosmetics and drug delivery. Cellulose 23:2291–2314. https://doi.org/10.1007/s10570-016-0986-y

Vatanpour V, Madaeni SS, Rajabi L, Zinadini S, Derakhshan AA (2012) Boehmite nanoparticles as a new nanofiller for preparation of antifouling mixed matrix membranes. J Membr Sci 401–402:132–143. https://doi.org/10.1016/j.memsci.2012.01.040

Vilarinho F, Sanches Silva A, Vaz MF, Farinha JP (2018) Nanocellulose in green food packaging. Crit Rev Food Sci Nutr 58:1526–1537. https://doi.org/10.1080/10408398.2016.1270254

Waheed S, Ahmad A, Khan SM, Gul S-e, Jamil T, Islam A, Hussain T (2014) Synthesis, characterization, permeation and antibacterial properties of cellulose acetate/polyethylene glycol membranes modified with chitosan. Desalination 351:59–69. https://doi.org/10.1016/j.desal.2014.07.019

Wahid F, Zhao XJ, Duan YX, Zhao XQ, Jia SR, Zhong C (2021) Designing of bacterial cellulose-based superhydrophilic/underwater superoleophobic membrane for oil/water separation. Carbohydr Polym 257:117611. https://doi.org/10.1016/j.carbpol.2020.117611

Wang T, Wang Y-Q, Su Y-L, Jiang Z-Y (2006) Antifouling ultrafiltration membrane composed of polyethersulfone and sulfobetaine copolymer. J Membr Sci 280:343–350. https://doi.org/10.1016/j.memsci.2006.01.038

Wang X, Ullah N, Sun X, Guo Y, Chen L, Li Z, Feng X (2017) Development and characterization of bacterial cellulose reinforced biocomposite films based on protein from buckwheat distiller’s dried grains. Int J Biol Macromol 96:353–360. https://doi.org/10.1016/j.ijbiomac.2016.11.106

Wang H, Yan B, Hussain Z, Wang W, Chang N (2022) Chemically graft aminated GO onto dehydro-fluorinated PVDF for preparation of homogenous DF-PVDF/GO-NH2 ultrafiltration membrane with high permeability and antifouling performance. Surf Interfaces 33:102255. https://doi.org/10.1016/j.surfin.2022.102255

Xiang W, Guo Z (2022) Nonflammable, robust and recyclable hydrophobic zeolitic imidazolate frameworks/sponge with high oil absorption capacity for efficient oil/water separation. Coll Surf A Physicochem Eng Aspects 650:129570. https://doi.org/10.1016/j.colsurfa.2022.129570

Xu W, Sun X, Huang M, Pan X, Huang X, Zhuang H (2020) Novel covalent organic framework/PVDF ultrafiltration membranes with antifouling and lead removal performance. J Environ Manag 269:110758. https://doi.org/10.1016/j.jenvman.2020.110758

Yagoub H, Zhu L, Shibraen MHMA, Xu X, Babiker DMD, Xu J, Yang S (2019) Complex membrane of cellulose and chitin nanocrystals with cationic guar gum for oil/water separation. J Appl Polym Sci 136:47947. https://doi.org/10.1002/app.47947

Yu L, Zhang Y, Zhang B, Liu J, Zhang H, Song C (2013) Preparation and characterization of HPEI-GO/PES ultrafiltration membrane with antifouling and antibacterial properties. J Membr Sci 447:452–462. https://doi.org/10.1016/j.memsci.2013.07.042

Yu Q, Jiang Z, Yu Y, Yang H, Sun X, Wang C, Ho SH (2021) Synchronous removal of emulsions and organic dye over palladium nanoparticles anchored cellulose-based membrane. J Environ Manag 288:112402. https://doi.org/10.1016/j.jenvman.2021.112402

Zhang X, Yang W, Wang Q, Huang F, Gao C, Xue L (2021) Tuning the nano-porosity and nano-morphology of nano-filtration (NF) membranes: Divalent metal nitrates modulated inter-facial polymerization. J Membr Sci 640:119780. https://doi.org/10.1016/j.memsci.2021.119780

Zhu J, Zheng J, Zhang Q, Zhang S (2016) Antifouling ultrafiltration membrane fabricated from poly (arylene ether ketone) bearing hydrophilic hydroxyl groups. J Appl Polym Sci 133:n/a-n/a. https://doi.org/10.1002/app.42809

Acknowledgments

The authors gratefully acknowledge the funding support by Key R&D Plan of Shaanxi Province, China (Project No: 2022NY-006).

Funding

This work was supported by Key R&D Plan of Shaanxi Province, China [Project No: 2022NY-006].

Author information

Authors and Affiliations

Contributions

Y.G. and Y.W. contributed equally to this work. Z.L.: Funding acquisition, conceptualization, writing—review & editing. Y.G., Y.W.: Investigation, experiments, data collection and analysis, visualization and writing—original draft. F.J., S.L.: Partial data collection, investigation. S.L., S.S., W.Y.: Formal analysis, writing—review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent for publication

All authors were informed and agreed to publish in Cellulose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, Y., Wang, Y., Jia, F. et al. Microbial fabrication of cellulose nanofiber-based ultrafiltration membrane: a sustainable strategy for membrane manufacture. Cellulose 30, 5001–5017 (2023). https://doi.org/10.1007/s10570-023-05201-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05201-z