Abstract

Wood extractives are known to cause problems during the production of pulp and paper and to impact their mechanical properties. In the present work, we systematically explored whether minute residual amounts of extractives that reprecipitate on the fiber surface in the final stages of the pulping process would lower the thermal resilience of softwood Kraft pulp. Pulp samples subjected to different extraction methods were characterized by means of thermogravimetric analysis. The compound classes constituting the respective extracts were identified and quantified via gas chromatography-mass spectrometry/flame ionization detector (GC-MS/FID) and the influence of the individual compound classes on the thermal stability of the samples was investigated separately. Soxhlet extraction with an ethanol/toluene solvent system clearly led to increased thermal stability. Besides fatty acids and resin acids also sterols and sterol esters that do not carry carboxylic acid functionalities contributed to the deterioration of the thermal pulp properties. Lateral order indices derived from Fourier transformed infrared spectra and crystallinity indices derived from solid-state 13C nuclear magnetic resonance spectra indicate that upon thermal degradation, the presence of even minute amounts of extractives leads to an increased degree of supramolecular disorder. Moreover, the characterization of the samples’ carbohydrate composition by means of acidic hydrolysis showed a tendency towards facilitated pyrolysis of the hemicelluloses if extractives were present in the pulp.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Extractives are a class of nonstructural wood components characterized by low molecular weights and high lipophilicity (Sjöström 1993). Extractives are a blend of terpenes, terpenoids such as sterols, sterol esters, and resin acids, as well as fatty acids, waxes, fats, phenols, and tannins (Koch 2006; Sixta et al. 2006). These compounds can either be extracted by organic or aqueous-organic solvent systems. Extractives do not contribute to the mechanical properties of wood but protect the tree against the attack of insects and fungi (Sjöström 1993). During highly alkaline Kraft pulping, extractives are largely removed from wood chips since most of these substances are soluble in alkaline solutions (Sixta et al. 2006). Under the prevailing pulping conditions, free unsaturated fatty acids, resin acids and esters undergo isomerization reactions and saponification, respectively. Waxes and fats are readily hydrolyzed whereas sterol esters seem to be more reluctant towards hydrolysis under the given conditions. A certain extractive fraction re-precipitates on the pulp fiber surfaces in the final stage of the Kraft cook when the pH is lowered (Hubbe et al. 2020). These re-precipitated compounds can cause problems during paper manufacturing. They decrease inter-fiber bonding due to their hydrophobicity, impair the mechanical or optical properties (Sundberg et al. 2000; Kokkonen et al. 2002; Koljonen et al. 2004; Hubbe et al. 2020) of the products due to their color or contribute to chromophore formation, cellulose hydrolysis upon aging and accelerated brightness reversion if they contain reactive carbonyl or carboxyl groups (Rosenau et al. 2004; Korntner et al. 2015; Ahn et al. 2019).

The motivation for this study was to explore whether these extractive residues, and extractives in general, also affect the thermal stability of pulp fibers, in connection to our previous studies on the thermal stability of papers in power transformers and the analysis of the thermal effects (Jusner et al. 2021, 2022a, 2022b). It has been proposed that extractives found in wood are likely to have a deteriorating effect on the thermal stability of wood fibers (Shebani et al. 2008, 2009; Poletto et al. 2012; Chen et al. 2014; Poletto 2016; Hamada et al. 2017). However, to the best of our knowledge, it has never been systematically examined whether the minute quantities of residual extractives adsorbed on the Kraft pulp fibers affect the thermal degradation of pulp and paper products. This question is of relevance for the utilization of paper for electrical insulation purposes in power transformers or other applications where paper would be exposed to elevated temperatures, such as baking parchment. In this work, softwood Kraft pulp samples were subjected to different extraction methods and subsequently characterized by means of thermogravimetric analysis (TGA). The compound classes in the respective extracts were identified and quantified via gas chromatography-mass spectrometry/flame ionization detector (GC-MS/FID) and the influence of the individual compound classes on the thermal stability of the samples was investigated separately.

Materials and methods

Sample material and chemicals

The investigated pulp was unbleached softwood Kraft pulp which was kindly provided by Mondi Frantschach GmbH, Austria. The moisture content (MC) of the pulp stored in the laboratory was between 7 and 9 wt% which was determined with a Sartorius Moisture Analyzer MA 35 (Sartorius Weighing Technology, Germany). All solvents and reactants for analytical procedures and sample preparation were obtained commercially of the highest purity available.

Enrichment of softwood Kraft pulp with extractive model compounds

Several softwood Kraft pulp samples enriched with different extractive model substances were prepared. These model substances were stearic acid (CAS Nr.: 57-11-4, Sigma Aldrich), linoleic acid (CAS Nr.: 60-33-3, Sigma Aldrich), α-linolenic acid (CAS Nr.: 463-40-1, Sigma Aldrich), abietic acid (CAS Nr.: 514-10-3, kindly provided by Lenzing AG, Austria), β-sitosterol (CAS Nr.: 83-46-5, kindly provided by Lenzing AG, Austria), and cholesteryl palmitate (CAS Nr.: 601-34-3, Sigma Aldrich). 5 to 6 mg (mass based on pure substance) of each model compound were weighed into a 4 mL vial using an analytical balance (Sartorius CPA225D-OCE, Sartorius Weighing Technology, Germany). The model compounds were dissolved in 3 mL of dichloromethane (DCM). The model compound concentration of the solution was adjusted to 0.16 mg/mL by adding the respective volume of ethanol. 1 g (dry equivalent, MC = 7 to 9 wt%) of softwood Kraft pulp was placed into a 50 mL round bottom flask. The pulp was completely immersed in 20 mL of ethanol and left for 1 h. Subsequently, 12.5 mL of the model compound solution (= 2 mg of the respective model substance) were added, the round bottom flask was wrapped in aluminum foil, and left for 24 h on a laboratory shaker. Finally, the solvent (ethanol/dichloromethane) was evaporated under reduced pressure. The water bath temperature was set to 40 °C. Before further analysis, these samples were exposed to the laboratory atmosphere at room temperature (RT, ca. 20 °C) until the equilibrium MC was in the same range as in case of the untreated reference material (MC = 7 to 9 wt%).

Soxhlet extraction

Three gram (dry equivalent, MC = 7 to 9 wt%) of pulp were placed into a cellulosic extraction thimble and inserted into a 250 mL Soxhlet extraction chamber which was mounted on a 500 mL round bottom flask filled with 300 mL of an ethanol/toluene (2:1 v/v) mixture, as recommended by Willför et al. (2006). The oil bath temperature was set to 130 °C. Continuous extraction was performed for 24 h, in the course of which the maximum temperature in the extraction chamber varied between 41.8 and 55.0 °C. After 24 h, the ethanol/toluene mixture was replaced with 300 mL ethanol to remove residual traces of toluene from the pulp and the extraction was continued for 4 h. Afterwards the pulp was washed with deionized water over a Büchner-funnel and dried under vacuum at 40 °C overnight. Before further analysis, the extracted pulp samples were exposed to ambient atmosphere at RT until the equilibrium MC was in the same range as in case of the untreated reference material (MC = 7 to 9 wt%). The extractives were isolated by transferring the ethanol/toluene extracts into a 500 mL round bottom flask and evaporating the solvents under reduced pressure at 40 °C. The remainder was re-dissolved in ca. 3 mL of DCM. This solution was transferred into a 4 mL vial of which the mass had been accurately determined before. Finally, the DCM was evaporated under a constant N2 stream and the extractive yield was determined gravimetrically.

Accelerated solvent extraction (ASE)

A sequential ASE was carried out in triplicate using an ASE 350 system (Dionex Corporation, USA). Per extraction, 10 g of pulp (dry equivalent, MC = 7 to 9 wt%) were placed into a 34 mL extraction cell. Each sample was at first extracted with n-hexane followed by an extraction with a mixture of acetone and deionized water (v/v = 9:1). The ASE system settings were chosen as recommended by Willför et al. (2006): temperature = 120 °C, heating time = 6 min, four extraction cycles per solvent, static extraction time = 15 min, purge time = 60 s, and rinse volume = 40%. The pressure in the extraction cell reached up to 115 bar during the static extraction phase. Before further analysis, the extracted pulp samples were exposed to ambient atmosphere at RT until the equilibrium MC was in the same range as in case of the untreated reference material (MC = 7 to 9 wt%). The extractives were isolated by transferring the n-hexane and acetone/water extracts into 250 mL round bottom flasks, evaporating the solvents under reduced pressure at a water bath temperature of 40 °C., and re-dissolving the remainder in ca. 3 mL of DCM. The solution was transferred into a 4 mL vial of which the mass had been accurately determined before. Finally, the DCM was evaporated under a constant N2 stream and the extractive yield was determined gravimetrically.

Thermogravimetric analysis (TGA)

The instrument used for all TGA measurements was a Netzsch TG209 F1 (NETZSCH-Gerätebau GmbH, Germany). Each sample (10 ± 0.5 mg) was placed into Al2O3 crucibles covered by a lid made of the same material. All measurements were performed in triplicate unless stated otherwise. The MC of analyzed samples was 7 to 9 wt%. The measurements were conducted in N2 atmosphere (flow rate = 20 mL/min) or in a mixture of N2 and O2 (flow rate = 20 mL/min, N2:O2 = 80:20, v/v) with a N2 purge flow applied (flow rate = 8 mL/min). The samples were heated from 24 to 600 °C at a rate of 10 K/min. In case of isothermal TG measurements, the samples were heated from 24 to 250 °C at a rate of 10 K/min. Subsequently, the samples were held at a temperature of 250 °C for 1 h.

The raw data was exported with Proteus 6.1.0 software (NETZSCH-Gerätebau GmbH, Germany) whereas for data processing and evaluation the Microsoft Excel (Microsoft Office Professional Plus 2016, Microsoft Corporation, USA) and OriginPro 2020 (OriginLab Corporation, USA) software packages were used. The 1st derivative of the TG curve (DTA) was calculated after applying a Lowess smoothing algorithm (span = 0.05) in OriginPro 2020. The maximum value of the 1st derivative (i.e., the value closest to zero as all values are negative) was defined as the final constant mass, and the corresponding point of each TGA curve was set as the reference point for the mass loss calculations, e.g., the temperature of 5% mass loss (T(5% ml.l.)) and temperature of 10% mass loss (T(10% m.l.)). The temperature corresponding to the onset of the pyrolytic decomposition (T(onset)) is equal to the abscissa value of the point of intersection of tangents drawn through the point of constant weight (maximum value of the 1st derivative) and the point of steepest slope of the TGA curve (minimum value of the 1st derivative) as described by Ávila Ramírez et al. (2014). The corresponding temperature (abscissa value) of the point of steepest slope of the TGA curve is the temperature of the maximum mass loss rate (T(dm max)).

Fourier transformed infrared (FTIR) spectroscopy

Attenuated total reflection (ATR) FTIR spectra were recorded with a PerkinElmer Frontier IR single-range spectrometer (PerkinElmer Inc., USA) in the range of 4000 and 500 cm−1. The system comprised a ZnSe ATR crystal and a LiTaO3-detector. Eight scans per spectra were recorded at a resolution of 4 cm−1. The obtained spectra were baseline corrected using the Spectragryph software (Spectragryph Version 1.2.8., Dr. Friedrich Menges, Germany) by setting the coarseness value of the advanced baseline correction function to 25% and normalizing the band at 1030 cm−1 to a value of 1.

The lateral order index (LOI) was determined following an established and frequently applied procedure to characterize cellulosic samples (O'Connor et al. 1958; Evans et al. 1995; Odabas et al. 2016). The LOI is defined as the ratio of the height of the band at 1428 cm−1 (H1428) and the height of the band at 896 cm−1 (H896). H1428 was determined, first, by drawing a baseline from the local minimum at 1490 cm−1 to the local minimum at 1395 cm−1 and second, by subtracting the baseline ordinate value at 1428 cm−1 from the maximum absorption at 1428 cm−1. H896 was determined analogously by drawing the baseline from the local minimum at 915 cm−1 to the local minimum at 870 cm−1.

Nuclear magnetic resonance (NMR) spectroscopy

Solid state 13C cross-polarization/magic angle spinning (CP/MAS) NMR spectra were recorded on a Bruker Avance III HD 400 spectrometer (Bruker, Germany) with a resonance frequency of 1H at 400.13 MHz and 13C at 100.61 MHz. The system was equipped with a 4 mm dual broadband CP/MAS probe. 13C spectra were recorded by applying the total sideband suppression (TOSS) sequence at room temperature (20 °C) with a MAS rate of 5 kHz, a CP contact time of 2 ms, a recycle delay of 2 s, and SPINAL-64 1H decoupling. The acquisition time was set to 49 ms, and the spectral width was fixed to 250 ppm. All 13C chemical shifts were referenced externally against the carbonyl signal of glycine at 176.03 ppm. Due to the small sample amount (10 mg ± 0.5 mg) of material subjected to isothermal TG, the usually applied swelling of the sample in H2O prior to spectra recording was skipped.

The raw data was processed with the Bruker TopSpin 4.0.7. software (Bruker, Germany) and the C4 (91–79 ppm) deconvolution was carried out with the Dmfit 19.12.11 software (CEMHTI CNRS UPR3079, France) according to Wickholm et al. (1998) and Zuckerstätter et al. (2013). Crystallinity indices (CI) and lateral crystallite dimensions were obtained as described by Jusner et al. (2022a).

Identification and quantification of extractives via gas-chromatography-mass spectrometry/flame ionization detector (GC-MS/FID)

Extractives were quantified according to Barbini et al. (2021). 3 to 5 mg of the dry extracts were accurately weighed in a 1.5 mL GC vial using an analytical balance. The n-hexane fraction of the ASE extract was highly viscous and of a yellowish color; the acetone/water fraction of the ASE extract and the Soxhlet extracts were of dark-brown color. All ASE factions and Soxhlet extracts were analyzed in triplicate. To each sample 0.2 mL of an internal standard stock solution was added. The internal standards used for quantification of extractives were n-heptadecanoic acid (CAS Nr.: 506-12-7, purity ≥ 98%, Alfa Aesar), cholesterol (CAS Nr.: 57-88-5, purity > 99%, Sigma Aldrich), cholesteryl palmitate (CAS Nr.: 601-34-3, purity > 98%, Sigma Aldrich), and glyceryl triheptadecanoate (CAS Nr.: 2438–40-6, purity > 99%, Sigma Aldrich). The standard stock solutions were obtained by dissolving 9 to 10 mg of each standard (analytical balance) in 30 mL of chloroform resulting in a final concentration of each standard of approx. 0.33 mg per mL chloroform. The chloroform of the stock solution added to the samples was evaporated under a constant N2 stream. Subsequently, the dry samples were derivatized with the binary silylating agent N,O-bis(trimethylsilyl)-trifluoroacetamide (BSTFA)/trimethyl-chlorosilane (TMCS). 0.2 mL of BSTFA containing 10% TMCS was added to each sample followed by heating to 70 °C for 1 h. The sample was transferred to a glass insert and 1 μL was injected (cold multimode inlet split injection, injector temperature program: 65 °C for 6 s followed by heating to 380 °C at a rate of 500 K/min and held for 5 min, split ratio of 15:1), using a GC-MS/FID apparatus (Agilent 5975C, Agilent Technologies Inc., USA) which was equipped with a high temperature GC column (Agilent J&W DB-5HT capillary column: 30 m * 250 µm * 0.1 µm, Agilent Technologies Inc., USA). The initial column temperature of 60 °C was kept isothermally for 5 min. Then, the column was heated to 380 °C (10 K/min) and kept isothermally for 8 min. Helium was used as a carrier gas at a flow rate of 2.5 mL/min. A splitter after the column allowed to record synchronized MS and FID spectra (1/3rd for MS and 2/3rd for FID). The MS detector worked in electron impact mode at 70 eV and a temperature of 280 °C. The operating temperature of the FID was set to 400 °C with a H2 flow of 30 mL/min, an air flow of 400 mL/min, and a combined makeup flow of 25 mL/min.

The MS spectra were analyzed with the Agilent MassHunter Workstation—Unknown Analysis software (Agilent Technologies Inc., USA) to identify the retention times corresponding to the extractive class borders, using the Wiley10 and NIST11 library. The FID chromatograms were processed and evaluated by using the free software environment R (Core_Team_R 2019). For baseline correction, the “fill peaks” algorithm was applied up to a retention time of 35 min, the “rolling ball” algorithm from 35 to 45 min, which was developed by Kneen and Annegarn (1996) and translated into R by Liland et al. (2010). The width of the local window for minimization/maximization was set to 700 (wm) and the width of the local window for smoothing was set to 175 (ws). The respective spectra intervals corresponding to the extractive classes were integrated by means of trapezoidal integration in R.

Acidic methanolysis and quantification of low molecular weight carbohydrates via GC-FID

The composition of low molecular weight carbohydrates was quantified according to Sundberg et al. (1996) and Becker et al. (2013, 2021). 8 to 9 mg of freeze-dried sample material was weighed into a 10 mL test tube. A 2 M HCl solution in anhydrous methanol was added (4 mL), vortexed for 2 min at RT, and heated to 100 °C for 5 h. Every 15 min the samples were vortexed. After the samples were cooled to RT, 0.4 mL of anhydrous pyridine was added, followed by another vortex treatment. Then, 0.1 mL of a D-sorbitol solution in anhydrous methanol (c = 5 mg/mL, CAS Nr.: 50-70-4, purity ≥ 98%, Sigma Aldrich) was added which served as the internal standard. Subsequently, the methanol was evaporated under a constant N2 stream and the samples were freeze-dried. 0.2 mL of anhydrous pyridine was added, the samples were vortexed, and left for equilibration for 1 h. Then, 0.2 mL of anhydrous pyridine containing 1.5 mg 4-dimethylaminopyridine per mL of pyridine was added as well as 0.4 mL of BSTFA containing 10% of TMCS. The samples were vortexed at RT, heated to 70 °C for 2 h, and stored at − 20 °C for 15 min. The sample mixtures were diluted with 0.4 mL of ethyl acetate, vortexed at RT, and centrifuged. Xylan standards were treated analogously to determine the recovery rate (90.25%), which was considered for calculation of the results.

The samples were transferred into 1.5 mL GC vials and 1 μL was injected (injector temperature: 260 °C, split ratio of 10:1) into the GC-FID system (Agilent 7890B, Agilent Technologies Inc., Canada). For the analysis, a HP1 methyl siloxane column (Agilent 19091Z-413: 30 m * 320 µm * 0.25 µm, Agilent Technologies Inc., USA) was used and H2 as carrier gas at a follow rate of 2 mL/min. Initially, the oven temperature was kept at 140 °C for 1 min, then increased to 210 °C at a rate of 4 K/min, and further increased to 260 °C at a rate of 30 K/min with a hold time of 5 min. The detector temperature was kept at 280 °C. The FID temperature was maintained at 320 °C with a H2 flow of 30 mL/min. The retention time of the derivatized monosaccharides was calibrated by means of commercially available standards of the highest purity. The FID signal was evaluated utilizing Agilent ChemStation software (Agilent Technologies Inc., USA).

Results and discussion

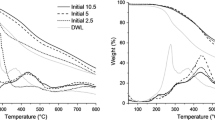

Figure 1 shows the TGA curves of untreated softwood Kraft pulp and the Soxhlet-extracted counterpart (extraction time: 24 h). All samples were heated from 24 up to 600 °C at a heating rate of 10 K/min. The extracted pulp showed a delayed onset of the pyrolytic degradation. This effect was visible in both a N2/O2 atmosphere (simulating air) and in a N2 atmosphere but was more pronounced in the former.

The characteristic values derived from the TGA measurements, as summarized in Table 1, allow quantifying the delayed pyrolytic degradation after Soxhlet extraction of the pulp samples. Upon heating, the point corresponding to a mass loss of 5% (relative to the constant sample mass) was postponed by 8.3 °C in a N2/O2 atmosphere and by 6.6 °C in a N2 atmosphere. The point corresponding to 10% mass loss was moved backwards by 6.2 °C in N2/O2 and by 5.5 °C in N2. Also, the point corresponding to the onset of the pyrolysis was postponed by 3.4 and 3.0 °C, respectively.

The shift of T(5% m.l.), T(10% m.l.), and T(onset) towards higher temperatures clearly suggests a higher thermal stability of the Soxhlet-extracted pulp sample (extraction time: 24 h) compared to the untreated reference. This was additionally confirmed by isothermal TG measurements where the samples were heated up to 250 °C at a rate of 10 K/min and kept at this temperature for 1 h (cf. Fig. 2). In both N2/O2 atmosphere and N2 atmospheres, the Soxhlet-extracted samples evidently degraded more slowly, or to a smaller extent at a given time.

However, the beneficial effect of Soxhlet extraction on the thermal stability of the Kraft pulp was reduced as the extraction time was reduced (cf. Fig. 3). The samples extracted for 12 h under otherwise identical conditions still had an improved thermal stability compared to the untreated reference, but featured lower characteristic values than the samples extracted for 24 h. Presumably, this is due to the lower extraction yield at shorter extraction times (cf. Fig. 4b). Kraft pulp extracted by means of sequential accelerated solvent extraction (ASE) featured a lower thermal stability than the untreated reference material. This is a consequence of the rather harsh ASE parameters used (T = 120 °C, p = 115 bar, t = 4 × 15 min) with partial dissolution and extraction of lignin during the acetone/water extraction sequence.

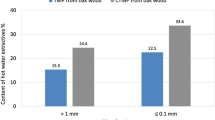

Sequential ASE delivered a gravimetric extractive yield of 4.9 mg/g which is slightly lower than that obtained by Soxhlet extraction for 12 h (6.3 mg/g; cf. Fig. 4b). Soxhlet extraction for 24 h delivered a much larger extractive yield of 13.4 mg/g. In all extracts analyzed, low molecular weight compounds (LMW), such as low molecular weight carboxylic acids, terpenes, phenolics, or traces of monosaccharide degradation products, were the biggest fraction (cf. Fig. 4a). Also free fatty acids, resin acids, sterols, and sterol esters were found in significant amounts.

The next step was to choose appropriate extractive model compounds to see whether a certain compound class could be identified as the primary cause of the faster thermal degradation of the untreated reference pulp. Stearic acid (a saturated fatty acid), α-linoleic acid (an unsaturated fatty acid with two C=C double bonds), and linolenic acid (unsaturated fatty acid with three C=C double bonds) were selected as fatty acid model compounds. The acidic diterpenoid abietic acid was chosen as a resin acid representative, and β-sitosterol was used as model compound to explore the effect of sterols on the thermal stability. Furthermore, we chose cholesteryl palmitate as a sterol ester representative. Although cholesteryl palmitate is not present in plants, it seemed appropriate as a sterol ester model compound since high-purity grades were commercially available. Then, a series of Kraft pulp samples enriched with 2 mg/g of each model compound was prepared and studied by TGA. Each pulp sample was enriched with only one model compound. Regardless of whether the added compounds had carboxylic acid functions or C=C double bonds, all of them lowered the softwood Kraft pulp's thermal stability (cf. Fig. 5). Especially the characteristic values T(5% mass loss) and T(10% mass loss) (cf. Fig. 5a and 5b, respectively), revealed slight differences regarding the compounds’ effect of the thermal stability. In the initial stage, stearic acid, linoleic acid, β-sitosterol, and cholesteryl palmitate contributed most significantly to the accelerated thermal decomposition of the sample material. In later stages of the pyrolytic decomposition, the differences were largely levelled out (cf. Fig. 5c, d).

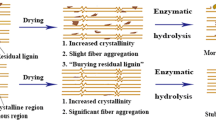

The significant negative impact of β-sitosterol and cholesteryl palmitate on the sample’s thermal stability indicates that other mechanisms than simple acid-catalyzed degradation contribute to the observed phenomenon. Direct catalysis of thermally induced carbohydrate/polysaccharide dehydration by the extractives does not seem very likely because the compounds largely lack any potentially active functional groups. One possibly relevant mechanism has been evoked as the major driver in the deterioration of mechanical properties of paper triggered by lipophilic extractives: It has been observed that the friction between fibers of handsheets enriched with extractives was significantly reduced (Sundberg et al. 2000; Kokkonen et al. 2002). The surface-adsorbed extractives increased the surface hydrophobicity and thus prevented inter-fiber hydrogen bonding to some extent. The increased molecular mobility caused by this lubrication effect is likely to contribute to the lower thermal stability also of our extractive-enriched pulp samples. In general, higher molecular mobility implies higher susceptibility to thermal degradation processes (Hosoya and Sakaki 2013; Hosoya et al. 2014; Liebner et al. 2010).

The samples subjected to isothermal TGA (cf. Fig. 2) were examined in more detail by means of ATR FTIR after exposure to 250 °C for 1 h to study how the presence of residual extractives would affect the course of sample degradation. Slight differences between Soxhlet-extracted (extraction time: 24 h) and untreated samples were detected regarding the chemical nature of fiber surfaces (cf. Fig. 6), mainly in regions allocated to C=O stretching (around 1720 cm−1) and conjugated C=C systems (around 1600 cm−1) (Ahn et al. 2018; Völkel et al. 2022). For samples exposed to 250 °C in N2 atmosphere this difference was less expressed than for samples heated in a N2/O2 atmosphere (Fig. 6, insets).

When comparing the lateral order index (LOI), derived from ATR FTIR spectra, of samples subjected to 250 °C for 1 h in an N2 atmosphere and reference samples, a reduced degree of order was determined for the thermally stressed samples (cf. Table 2). The LOI of thermally stressed softwood Kraft pulp (1.05) was lower than the LOI of thermally stressed extracted softwood Kraft pulp (1.09). This observation was confirmed by the samples’ crystallinity index (CI) derived from solid-state 13C CP/MAS NMR spectra. The CIs suggested reduced crystallinity and reduced lateral crystallite dimension of the thermally stressed samples compared to the reference. Also here, the extracted sample featured higher values (0.53 and 3.81 nm) than the untreated thermally stressed sample (0.49 and 3.77 nm). The presence of extractives precipitated on fiber surfaces appeared to promote a greater degree of thermally induced supramolecular disorder upon slow pyrolysis. A reduction of crystallinity and crystallite dimensions upon pyrolysis of comparable sample material (softwood fibers) in inert atmosphere (He gas) has been observed before (Zickler et al. 2007). That this is clearly facilitated by surface-adsorbed extractive compounds is a novel observation, but obviously requires further clarification with regard to the underlying mechanisms.

After recording ATR FTIR and solid-state 13C CP/MAS NMR spectra we subjected the samples to acidic methanolysis to study their carbohydrate composition (cf. Fig. 7). In Fig. 7a, the untreated softwood Kraft pulp sample and the extracted sample are compared before isothermal TGA. Only some minute differences regarding the glucose content were detected. Nevertheless, it can be stated that Soxhlet extraction did not affect the carbohydrate composition of the sample, as expectable.

Upon thermal stress, a significant reduction of xylose and arabinose was detected for both sample types in both experimental settings (N2/O2 atmosphere and N2 atmosphere). For the untreated softwood Kraft pulp, the xylose content reduction was − 39.4% in a N2/O2 atmosphere and − 21.7% in a N2 atmosphere. The corresponding arabinose content reduction was − 67.9 and − 53.0%, respectively. For the Soxhlet extracted sample, the decrease in xylose content was − 34.9% in a N2/O2 atmosphere and − 17.45% in a N2 atmosphere, the values for arabinose being − 63.2 and − 50.6%, respectively. The decrease in the pentose contents was consistently lower for the extracted samples: the extraction evidently impeded the thermal degradation of the hemicelluloses to furanoids, once more confirming the beneficial effect of the extraction with regard to thermostability.

The results for the hemicellulose-derived hexoses, mannose and galactose, were similar. For the untreated softwood Kraft pulp, the mannose (galactose) content reduction was − 16.0% (− 62.7%) in a N2/O2 atmosphere and − 10.5% (− 38.0%) in a N2 atmosphere. For the Soxhlet extracted sample, the mannose (galactose) content differences were − 4.5% (− 60.4%) in N2/O2 and + 9.6% (− 34.7%).

These findings suggest that the arabinoxylan fraction of softwood Kraft pulp is thermally less stable than the galactoglucomannan fraction. This is in accordance with recently published results obtained by the analysis of paper strips made of Kraft pulp aged in transformer oil at 170 °C (Jusner et al. 2022a, 2022b). In general, the presence of extractives facilitates the pyrolytic decomposition of the hemicellulose fraction in softwood Kraft pulps.

The strong increase of glucose susceptible to acidic methanolysis after sample exposure to 250 °C for 1 h is the result of oligomeric cellulose degradation products, due to thermal degradation. Acidic methanolysis reports low molecular weight carbohydrates, such as hemicelluloses and degraded cellulose, while intact cellulose, especially in crystalline areas, is not covered and would require harsher conditions like those of sulfuric acid hydrolysis (Becker et al. 2021).

Conclusions

In this study, clear evidence of a negative, decomposition-promoting effect of the small amounts of extractives contained in softwood Kraft pulp (few mg/g) on the thermal stability was presented. While this effect can be easily understood for fatty acids and resin acids which feature carboxylic acid functionalities and would promote cellulose hydrolysis, surprisingly, also sterols and sterol esters clearly contribute to lowering the onset temperature of the pyrolytic sample degradation. Thus, also other mechanisms besides acid-catalyzed hydrolytic processes must be operative. We presented indications that even very low extractive contents (13.4 mg/g, cf. Fig. 4b) lead to a higher degree of supramolecular disorder upon thermal degradation. This would, at least partly, proceed via a facilitated thermal degradation of hemicelluloses in the sample.

Of course, further research is required to validate these findings also for other pulp types to prove their generality. For example, clarifying the interactions of extractives with the lignin fraction upon thermal stress appears an important issue that will be addressed in future studies. Another important research topic that results from the findings is the development of environmentally benign and efficient methods to remove extractives from pulps which are intended for applications with high thermal stress. This could be an elegant way to improve the thermal resilience of pulp and paper products without the addition of amino-group bearing stabilizers or other chemical modification (Jusner et al. 2021). Soxhlet extraction, while advantageous in the research lab, is certainly not applicable on the required large scale, but extraction with supercritical CO2, already established on industrial level, could become a viable alternative on the long run.

Data availability

Data available from the authors upon request.

Code availability

Not applicable.

References

Ahn K, Schedl A, Zweckmair T, Rosenau T, Potthast A (2018) Fire-induced structural changes and long-term stability of burned historical rag papers. Sci Rep 8:12036

Ahn K, Zaccaron S, Zwirchmayr NS, Hettegger H, Hofinger H, Bacher M, Henniges U, Hosoya T, Potthast A, Rosenau T (2019) Yellowing and brightness reversion of celluloses: CO or COOH, who is the culprit? Cellulose 26:429–444

Ávila Ramírez JA, Suriano CJ, Cerrutti P, Foresti ML (2014) Surface esterification of cellulose nanofibers by a simple organocatalytic methodology. Carbohydr Polym 114:416–423

Barbini S, Sriranganadane D, España Orozco S, Kabrelian A, Karlström K, Rosenau T, Potthast A (2021) Tools for bark biorefineries: studies toward improved characterization of lipophilic lignocellulosic extractives by combining supercritical fluid and gas chromatography. ACS Sustain Chem Eng 9(3):1323–1332

Becker M, Zweckmair T, Forneck A, Rosenau T, Potthast A, Liebner F (2013) Evaluation of different derivatisation approaches for GC/MS analysis of carbohydrates in complex matrices of biological and synthetic origin. J Chromatogr A 1281:115–126

Becker M, Ahn K, Bacher M, Xu C, Sundberg A, Willför S, Rosenau T, Potthast A (2021) Comparative hydrolysis analysis of cellulose samples and aspects of its application in conservation science. Cellulose 28:8719–8734

Chen Y, Tshabalala MA, Gao J, Stark NM, Fan Y, Ibach RE (2014) Thermal behavior of extracted and delignified pine wood flour. Thermochim Acta 591:40–44

CORE_TEAM_R (2019) R: a language and environment for statistical computing. R Foundation for Statistical Computing: Vienna, Austria

Evans R, Newman RH, Roick UC, Suckling ID, Wallis AFA (1995) Changes in cellulose crystallinity during Kraft pulping-comparison of infrared, X-ray-diffraction and solid-state NMR results. Holzforschung 49:498–504

Hamada J, Pétrissans A, Mothe F, Ruelle J, Pétrissans M, Gérardin P (2017) Intraspecific variation of European oak wood thermal stability according to radial position. Wood Sci Technol 51:785–794

Hosoya T, Sakaki S (2013) Levoglucosan formation from crystalline cellulose: importance of a hydrogen bonding network in the reaction. ChemSusChem 6:2356–2368

Hosoya T, Takano T, Kosma P, Rosenau T (2014) Theoretical foundation for the presence of oxacarbenium ions in chemical glycoside synthesis. J Org Chem 79(17):7889–7894

Hubbe MA, Mclean DS, Stack KR, Lu X, Strand A, Sundberg A (2020) Self-assembly of alkyl chains of fatty acids in papermaking systems: a review of related pitch issues, hydrophobic sizing, and pH effects. BioResources 15:4591–4635

Jusner P, Bacher M, Simon J, Bausch F, Khaliliyan H, Schiehser S, Sumerskii I, Schwaiger E, Potthast A, Rosenau T (2022a) Analyzing the effects of thermal stress on insulator papers by solid-state 13C NMR spectroscopy. Cellulose 29:1081–1095

Jusner P, Bausch F, Schiehser S, Schwaiger E, Potthast A, Rosenau T (2022b) Protocol for characterizing the molar mass distribution and oxidized functionality profiles of aged transformer papers by gel permeation chromatography (GPC). Cellulose 29:2241–2256

Jusner P, Schwaiger E, Potthast A, Rosenau T (2021) Thermal stability of cellulose insulation in electrical power transformers—a review. Carbohydrate Polym 252:117196

Kneen MA, Annegarn HJ (1996) Algorithm for fitting XRF, SEM and PIXE X-ray spectra backgrounds. Nucl Instrum Meth B 109–110:209–213

Koch G (2006) Raw material for pulp. In: Sixta H (ed) Handbook of pulp. Wiley, Weinheim

Kokkonen P, Korpela A, Sundberg A, Holmbom B (2002) Effects of different types of lipophilic extractives on paper properties. Nord Pulp Pap Res J 17:382–386

Koljonen K, Österberg M, Kleen M, Fuhrmann A, Stenius P (2004) Precipitation of lignin and extractives on kraft pulp: effect on surface chemistry, surface morphology and paper strength. Cellulose 11:209–224

Korntner P, Hosoya T, Dietz T, Eibinger K, Reiter H, Spitzbart M, Röder T, Borgards A, Kreiner W, Mahler AK, Winter H, French AD, Henniges U, Potthast A, Rosenau T (2015) Chromophores in lignin-free cellulosic materials belong to three compound classes. Cellulose 22(2):1053–1062

Liebner F, Ebner G, Becker E, Potthast A, Rosenau T (2010) Thermal aging of 1-alkyl-3-methylimidazolium ionic liquids and its effect on dissolved cellulose. Holzforschung 64:161–166

Liland KH, Almøy T, Mevik BH (2010) Optimal choice of baseline correction for multivariate calibration of spectra. Appl Spectrosc 64:1007–1016

Newman RH (1999) Estimation of the lateral dimensions of cellulose crystallites using 13C NMR signal strengths. Solid State Nucl Mag Reson 15:21–29

O’Connor RT, Dupré EF, Mitcham D (1958) Applications of infrared absorption spectroscopy to investigations of cotton and modified cottons. Textile Res J 28:382–392

Odabas N, Amer H, Bacher M, Henniges U, Potthast A, Rosenau T (2016) Properties of cellulosic material after cationization in different solvents. ACS Sustain Chem Eng 4:2295–2301

Oehme DP, Downton MT, Doblin MS, Wagner J, Gidley MJ, Bacic A (2015) Unique aspects of the structure and dynamics of elementary Iβ cellulose microfibrils revealed by computational simulations. Plant Physiol 168:3–17

Poletto M (2016) Effect of extractive content on the thermal stability of two wood species from Brazil. Maderas Cienc Tecnol 18:435–442

Poletto M, Zattera AJ, Forte MM, Santana RM (2012) Thermal decomposition of wood: influence of wood components and cellulose crystallite size. Biores Technol 109:148–153

Rosenau T, Potthast A, Milacher W, Hofinger A, Kosma p, (2004) Isolation and identification of residual chromophores in cellulosic materials. Polymer 45(19):6437–6443

Shebani AN, Van Reenen AJ, Meincken M (2008) The effect of wood extractives on the thermal stability of different wood species. Thermochim Acta 471:43–50

Shebani AN, Van Reenen AJ, Meincken M (2009) The effect of wood extractives on the thermal stability of different wood-LLDPE composites. Thermochim Acta 481:52–56

Sixta H, Potthast A, Krotschek AW (2006) Chemical pulping processes: sections 4.1–4.2.5. In: Sixta H (ed) Handbook of pulp. Wiley, Weinheim

Sjöström E (1993) Chapter 5-extractives. In: Sjöström E (ed) Wood chemistry. Academic Press, USA

Sundberg A, Holmbom B, Willför S, Pranovich A (2000) Weakening of paper strength by wood resin. Nord Pulp Pap Res J 15:46–53

Sundberg A, Sundberg K, Lillandt C, Holmhom B (1996) Determination of hemicelluloses and pectins in wood and pulp fibres by acid methanolysis and gas chromatography. Nord Pulp Pap Res J 11:216–219

Völkel L, Rusakov D, Kontturi E, Beaumont M, Rosenau T, Potthast A (2022) Manufacturing heat-damaged papers as model materials for evaluating conservation methods. Cellulose 29:6373–6391

Wickholm K, Larsson PT, Iversen T (1998) Assignment of non-crystalline forms in cellulose I by CP/MAS 13C NMR spectroscopy. Carbohydr Res 312:123–129

Willför S, Hemming J, Leppänen AS (2006) Analysis of extractives in different pulps–Method development, evaluation, and recommendations. Report B1, Åbo Akademi University

Zickler GA, Wagermaier W, Funari SS, Burghammer M, Paris O (2007) In situ X-ray diffraction investigation of thermal decomposition of wood cellulose. J Analyt Appl Pyrol 80:134–140

Zuckerstätter G, Terinte N, Sixta H, Schuster KC (2013) Novel insight into cellulose supramolecular structure through 13C CP-MAS NMR spectroscopy and paramagnetic relaxation enhancement. Carbohydr Polym 93:122–128

Acknowledgments

The financial support by the Austrian Biorefinery Center Tulln (ABCT) is gratefully acknowledged.

Funding

Open access funding provided by University of Natural Resources and Life Sciences Vienna (BOKU). The financial support by the Austrian Biorefinery Center Tulln (ABCT) is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

PJ, AP, and TR: contributed to the study conception and design; All authors: Material preparation, data collection and analysis were performed; PJ and TR: the first draft of the manuscript was written; All authors: commented on previous versions of the manuscript; All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflicts of interest

None.

Consent to participate

Not applicable.

Consent for publication

All authors agreed to the publication in the submitted form.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jusner, P., Barbini, S., Schiehser, S. et al. Impact of residual extractives on the thermal stability of softwood Kraft pulp. Cellulose 29, 8797–8810 (2022). https://doi.org/10.1007/s10570-022-04807-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04807-z