Abstract

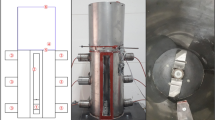

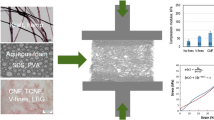

This research was aimed at fibrillating wood (Aspen) particles using ultra-fine friction grinding, facilitated by a sodium hydroxide pretreatment step. Its objective was to examine the effect of grinding on the extent of fibrillation and the rheological behaviors of the products. The morphology of the ground samples were characterized by optical (OM) and scanning electron microscopy. The extent of fibrillation was evaluated by measurements of particle size distribution (PS), specific surface area, and water retention value. The rheological behavior of the sample suspension was examined by oscillatory and rotational flow testing. Morphological results revealed a reduction in particle size with increasing mechanical fibrillation. The fibrillated samples contained micro- and nano-sized fibers of approximately 50–1000 nm in width, and lengths between hundreds of nanometers to micrometers. Rheological results revealed an increase in storage moduli (G′) and loss moduli (G″) of the fibrillated samples as the grinding was more severe. A shift in the cross-over point (G′ = G″) towards higher strains was also observed, indicating a more stable network structure with a higher extent of grinding. The fibrillated samples showed shear thinning (reduced viscosity) and a decreased thixotropic behavior when subjected to increasing shear rates. A higher extent of fibrillation led to aqueous suspensions of higher shear viscosity, which would also increase when increasing the solid content of the measured suspension. Overall, this study offers a low-cost and simple means for producing fibrillated particles from wood materials, and also benefits their downstream processing through the acquired understanding of their rheological behavior.

Similar content being viewed by others

References

Abdul Khalil HPS, Davoudpour Y, Islam MN, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr Polym 99(1):649–665

Agoda-Tandjawa G, Durand S, Berot S, Blassel C, Gaillard C, Garnier C, Doublier J-L (2010) Rheological characterization of microfibrillated cellulose suspensions after freezing. Carbohydr Polym 80(3):677–686

Bali G, Meng X, Deneff JI, Sun Q, Ragauskas AJ (2015) The effect of alkaline pretreatment methods on cellulose structure and accessibility. Chemsuschem 8(2):275–279

Dimic-Misic K, Salo T, Paltakari J, Gane PAC (2014) Comparing the rheological properties of novel nanofibrillar cellulose-formulated pigment coating colours with those using traditional thickener. Nord Pulp Pap Res J 29(2):253–270

Duncan S, Jing Q, Katona A, Kazlauskas RJ, Shilling J, Tschirner U, AlDajani WW (2010) Increased saccharification yields from Aspen biomass upon treatment with enzymatically generated peracetic acid. Appl Biochem Biotechnol 160(6):1637–1652

Fan LT, Gharpuray MM, Lee Y-H (1987) Cellulose hydrolysis, vol 3. Springer, Berlin, pp 1–68

Hoeger IC, Nair SS, RagauskasAJ DengY, Rojas OJ, Zhu YJ (2013) Mechanical deconstruction of lignocellulose cell walls and their enzymatic saccharification. Cellulose 20(2):807–818

Iotti M, Gregersen ØW, Moe S, Lenes M (2011) Rheological studies of microfibrillar cellulose water dispersions. J Polym Environ 19(1):137–145

Iwamoto S, Nakagaito AN, Yano H, Nogi M (2005) Optically transparent composites reinforced with plant fiber-based nanofibers. Appl Phys A Mater Sci Process 81:1109–1112

Josefsson G, Tanem BS, Li Y, Vullum PE, Gamstedt EK (2013) Prediction of elastic properties of nanofibrillated cellulose from micromechanical modeling and nano-structure characterization by transmission electron microscopy. Cellulose 20(2):761–770

Kamel S (2007) Nanotechnology and its applications in lignocellulosic composites, a mini review. Express Polym Lett 1(9):546–575

Karppinen A, Saarinen T, Salmela J, Laukkanen A, Nuopponen M, Seppälä J (2012) Flocculation of microfibrillated cellulose in shear flow. Cellulose 19(6):1807–1819

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50(24):5438–5466

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90(2):735–764

Liu D, Chang PR, Chen M, Wu Q (2011) Chitosan colloidal suspension composed of mechanically dissembled nanofibers. J Colloid Interface Sci 354:637–643

Luo X, Wang X (2017) Preparation and characterization of nanocellulose fibers from NaOH/urea pretreatment of oil palm fibers. BioResources 12(3):5826–5837

Mirahmadi K, Kabir MM, Jeihanipour A, Karimi K, Taherzadeh M (2010) Alkaline pretreatment of spruce and birch to improve bioethanol and biogas production. BioResources 5(2):928–938

Nechyporchuk O, Belgacem MN, Pignon F (2014) Rheological properties of micro-/nanofibrillated cellulose suspensions: wall-slip and shear banding phenomena. Carbohydr Polym 112(4):432–439

Ougiya H, Hioki N, Watanabe K, Morinaga Y, Yoshinaga F, Samejima M (1998) Relationship between the physical properties and surface area of cellulose derived from adsorbates of various molecular sizes. Biosci Biotechnol Biochem 62(10):1880–1884

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941

Pahimanolis N, Salminen A, Penttilä PA, Korhonen JT, Johansson L-S, Ruokolainen J, Serimaa R, Seppälä J (2013) Nanofibrillated cellulose/carboxymethyl cellulose composite with improved wet strength. Cellulose 20(3):1459–1468

Ratna T, Philipp S, Paul Q (2010) Effect of nanoparticle concentration on zeta-potential measurement results and reproducibility. Particuology 8(3):279–285

Saarikoski E, Saarinen T, Salmela J, Seppälä J (2012) Flocculated flow of microfibrillated cellulose water suspensions: an imaging approach for characterisation of rheological behaviour. Cellulose 19(3):647–659

Saito T, Nishiyama Y, Putaux J, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7(6):1687–1691

Samyn P, Taheri H (2016) Rheology of fibrillated cellulose suspensions after surface modifications by organic nanoparticle deposits. J Mater Sci 51(21):9830–9848

Schenker M, Schoelkopf J, Mangin P, Gane P (2016) Rheological investigation of complex micro and nanofibrillated cellulose (MNFC) suspensions: discussion of flow curves and gel stability. Tappi J 15(6):405–416

Schenker M, Schoelkopf J, Gane P, Mangin P (2018a) Influence of shear rheometer measurement systems on the rheological properties of microfibrillated cellulose (MFC) suspensions. Cellulose 25(2):961–976

Schenker M, Schoelkopf J, Gane P, Mangin P (2018b) Quantification of flow curve hysteresis data: a novel tool for characterising microfibrillated cellulose (MFC) suspensions. Appl Rheol 28:22945

Schenker M, Schoelkopf J, Gane P, Mangin P (2018c) Rheology of microfibrillated cellulose (MFC) suspensions: influence of the degree of fibrillation and residual fibre content on flow and viscoelastic properties. Cellulose. https://doi.org/10.1007/s10570-018-2117-4

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494

Szczęsna-Antczak M, Kazimierczak J, Antczak T (2012) Nanotechnology-methods of manufacturing cellulose nanofibers. Fiber Text East Eur 2(91):8–12

TAPPI UM 256 (2011) Water retention value (WRV), TAPPI useful test methods, TAPPI

Uetani K, Yano H (2011) Nanofibrillation of wood pulp using a high-speed blender. Biomacromolecules 12(2):348–353

Wang QQ, Zhu JY, Gleisner R, Kuster TA, Baxa U, McNeil SE (2012) Morphological development of cellulose fibrils of a bleached eucalyptus pulp by mechanical fibrillation. Cellulose 19(5):1631–1643

Wang J, Li Y, Wang Z, Li Y, Liu N (2016) Influence of pretreatment on properties of cotton fiber in aqueous NaOH/urea solution. Cellulose 23(3):1–11

Yano H, Nakahara S (2004) Bio-composites produced from plant microfiber bundles with a nanometer unit web-like network. J Mater Sci 39(5):1635–1638

Yoshimura A, Prud’homme RK (1988) Wall slip corrections for Couette and parallel disk viscometers. J Rheol 32:53–67

Acknowledgments

The authors thank Prof. Schilling J (University of Minnesota, UMN) for the supply of the alkaline pretreated wood and use of the spectrophotometer, Prof. Abbas A (UMN) for the use of optical microscope, Prof. Zucolotto V (University of Sao Paulo) for the use of Zetasizer, Dr. Schenker M (FiberLean Technologies) for discussing the rheology methods, and Dr. Plotegher F and Dr. Moreira FKV (Embrapa) for the use of rheometer. Parts of this work were carried out in the University of Minnesota’s Characterization Facility (scanning electron microscopy) and Minnesota Nano Center (laser diffraction), which receive partial support from the National Science Foundation through, respectively, the Materials Research Science and Engineering Center (MRSEC) and National Nanotechnology Coordinated Infrastructure Network (NNCI; Award No. ECCS-1542202). The authors also acknowledge CAPES (Project Nanobiotec No. 13; MCB postdoctoral scholarship process number 6290-13-2), the United States Department of Agriculture’s National Institute of Food and Agriculture Grant (No. 2011-67009-20063) and its McIntire Stennis Project (No. MIN-12-053; under Accession No. 1010000) for financial supports.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Branciforti, M.C., Yang, HS., Hafez, I. et al. Morphological and rheological behaviors of micro-nanofibrillated NaOH-pretreated Aspen wood. Cellulose 26, 4601–4614 (2019). https://doi.org/10.1007/s10570-019-02389-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02389-x