Abstract

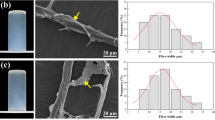

There is a growing demand for the development of new renewable materials and the replacement of fossil fuel based polymers with bio-based polymers and composites. Cellulose nanofibres (CNF) is an emerging nano-reinforcement agent for polymers to improve mechanical properties. The preparation and properties of bionanocomposites consisting of spinifex cellulose nanofibres and bio-based polyamide 11 are reported. The freeze-dried nanofibres derived from a native Australian grass, Triodia pungens (spinifex), and wood were first premixed with the polymer at low concentration (0.1–0.5 wt%) using a jet mill, prior to melt-compounding via extrusion and injection-moulding of test specimens. The thermal and decomposition behaviours, as characterised by TGA and DSC, remained mostly unchanged. DSC and XRD show that crystallinity is largely unaffected by the presence of CNF, and thus all property changes may be attributed solely to the reinforcement effect of the fibres. Product specimens reinforced with CNF produced from spinifex (SCNF), showed an increase in tensile strength (+ 23%), toughness (+ 61%) and impact strength (+ 67%).

Similar content being viewed by others

References

Amiralian N, Annamalai PK, Memmott P, Martin DJ (2015a) Isolation of cellulose nanofibrils from triodia pungens via different mechanical methods. Cellulose 22(4):2483–2498

Amiralian N, Annamalai PK, Memmott P, Taran E, Schmidt S, Martin DJ (2015b) Easily deconstructed, high aspect ratio cellulose nanofibres from triodia pungens; an abundant grass of australia’s arid zone. RSC Adv 5:32124–32132

Aoyagi Y, Yamashita K, Doi Y (2002) Thermal degradation of poly[(r)-3-hydroxybutyrate], poly[\(\epsilon\)-caprolactone], and poly[(s)-lactide]. Polym Degrad Stab 76(1):53–59

Bicu I, Mustata F (2011) Cellulose extraction from orange peel using sulfite digestion reagents. Bioresour Technol 102(21):10013–10019

Cho SY, Yun YS, Jin HJ (2014) Carbon nanofibers prepared by the carbonization of self-assembled cellulose nanocrystals. Macromol Res 22(7):753–756

Elanthikkal S, Gopalakrishnapanicker U, Varghese S, Guthrie JT (2010) Cellulose microfibres produced from banana plant wastes: isolation and characterization. Carbohydr Polym 80(3):852–859

Grassie N, Murray E, Holmes P (1984) The thermal degradation of poly(-(d)-\(\beta\)-hydroxybutyric acid): part 1—identification and quantitative analysis of products. Polym Degrad Stab 6(1):47–61

Hablot E, Bordes P, Pollet E, Avérous L (2008) Thermal and thermo-mechanical degradation of poly(3-hydroxybutyrate)-based multiphase systems. Polym Degrad Stab 93(2):413–421

Heitzmann MT, Veidt M, Ng CT, Lindenberger B, Hou M, Truss R, Liew CK (2012) Single-plant biocomposite from ricinus communis: preparation, properties and environmental performance. J Polym Environ 21(2):366–374

Huang S, Wang M, Liu T, Zhang W-D, Tjiu WC, He C, Lu X (2009) Morphology, thermal, and rheological behavior of nylon 11/multi-walled carbon nanotube nanocomposites prepared by melt compounding. Polym Eng Sci 49(6):1063–1068

Inoue M (1963) Studies on crystallization of high polymers by differential thermal analysis. J Polym Sci Part A Gen Pap 1(8):2697–2709

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromolecules 9(3):1022–1026 PMID: 18247566

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10(9):2571–2576 PMID: 19645441

Khalil HPSA, Ismail H, Rozman HD, Ahmad MN (2001) The effect of acetylation on interfacial shear strength between plant fibres and various matrices. Eur Polym J 37:1037–1045

Khalil HA, Bhat A, Yusra AI (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87(2):963–979

Kohan MI (ed) (1995) Nylon plastics handbook. Munich, Munich

Kvien I, Tanem BS, Oksman K (2005) Characterization of cellulose whiskers and their nanocomposites by atomic force and electron microscopy. Biomacromolecules 6(6):3160–3165 PMID: 16283741

Latko P, Kolbuk D, Kozera R, Boczkowska A (2015) Microstructural characterization and mechanical properties of PA11 nanocomposite fibers. J Mater Eng Perform 25(1):68–75

Liu S, Yu Y, Cui Y, Zhang H, Mo Z (1998) Isothermal and nonisothermal crystallization kinetics of nylon-11. J Appl Polym Sci 70(12):2371–2380

Liu T, Lim KP, Tjiu WC, Pramoda K, Chen Z-K (2003) Preparation and characterization of nylon 11/organoclay nanocomposites. Polymer 44(12):3529–3535

Mago G, Kalyon DM, Fisher FT (2011) Nanocomposites of polyamide-11 and carbon nanostructures: development of microstructure and ultimate properties following solution processing. J Polym Sci Part B Polym Phys 49(18):1311–1321

Marchessault R (1962) Application of infra-red spectroscopy to cellulose and wood polysaccharides. Pure Appl Chem 5(1–2):107–130

Mathias LJ, Powell DG, Autran JP, Porter RS (1990) Nitrogen-15 nmr characterization of multiple crystal forms and phase transitions in polyundecanamide (nylon 11). Macromolecules 23(4):963–967

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Nair SS, Ramesh C, Tashiro K (2006) Crystalline phases in nylon-11: studies using HTWAXS and HTFTIR. Macromolecules 39(8):2841–2848

Nayak P (2000) Natural oil-based polymers: opportunities and challenges. J Macromol Sci Part C 40(1):1–21

Nazari B, Bousfield D (2016) Cellulose nanofibers influence on properties and processing of paperboard coatings. Nordic Pulp Pap Res J 31(3):511–520

Ng H-M, Sin LT, Tee T-T, Bee S-T, Hui D, Low C-Y, Rahmat A (2015) Extraction of cellulose nanocrystals from plant sources for application as reinforcing agent in polymers. Compos B Eng 75:176–200

Oksman K, Aitomäki Y, Mathew AP, Siqueira G, Zhou Q, Butylina S, Tanpichai S, Zhou X, Hooshmand S (2016) Review of the recent developments in cellulose nanocomposite processing. Compos Part A Appl Sci Manuf 83:2–18 (Special Issue on Biocomposites)

Panaitescu DM, Frone AN, Nicolae C (2013) Micro- and nano-mechanical characterization of polyamide 11 and its composites containing cellulose nanofibers. Eur Polym J 49(12):3857–3866

Panaitescu DM, Gabor RA, Frone AN, Vasile E (2015) Influence of thermal treatment on mechanical and morphological characteristics of polyamide 11/cellulose nanofiber nanocomposites. J. Nanomater 2015:4:4

Peng Y, Gardner DJ, Han Y, Cai Z, Tshabalala MA (2013) Influence of drying method on the surface energy of cellulose nanofibrils determined by inverse gas chromatography. J Colloid Interface Sci 405:85–95

Peng Y, Gardner DJ, Han Y (2015) Characterization of mechanical and morphological properties of cellulose reinforced polyamide 6 composites. Cellulose 22(5):3199–3215

Poletto M, Zattera AJ, Santana RMC (2012) Thermal decomposition of wood: kinetics and degradation mechanisms. Bioresour Technol 126:7–12

Poletto M, Ornaghi Júnior HL, Zattera AJ (2014) Native cellulose: structure, characterization and thermal properties. Materials 7(9):6105–6119

Qua E, Hornsby P (2011) Preparation and characterisation of nanocellulose reinforced polyamide-6. Plast Rubber Compos 40(6/7):300–306

Rebouillat S, Pla F (2013) State of the art manufacturing and engineering of nanocellulose: a review of available data and industrial applications. J Biomater Nanobiotechnol 4:165–188

Roguet E, Tencé-Girault S, Castagnet S, Grandidier J, Hochstetter G (2007) Micromechanisms involved in the atypical tensile behavior observed in polyamide 11 at high temperature. J Polym Sci Part B Polym Phys 45(22):3046–3059

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by tempo-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491 PMID: 17630692

Siro I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494

Stoclet G, Sclavons M, Devaux J (2013) Relations between structure and property of polyamide 11 nanocomposites based on raw clays elaborated by water-assisted extrusion. J Appl Polym Sci 127(6):4809–4824

Ten E, Turtle J, Bahr D, Jiang L, Wolcott M (2010) Thermal and mechanical properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/cellulose nanowhiskers composites. Polymer 51(12):2652–2660

Wagner J R, Mount III E M, Giles H F Jr (2014) Extrusion the definitive processing guide and handbook. William Andrews Publications, New York

Wang B, Ding Z, Hu G (2008) Melting behavior and isothermal crystallization kinetics of nylon 11/EVOH/dicumyl peroxide blends. Polym Eng Sci 48(12):2354–2361

Winter A, Andorfer L, Herzele S, Zimmermann T, Saake B, Edler M, Griesser T, Konnerth J, Gindl-Altmutter W (2017) Reduced polarity and improved dispersion of microfibrillated cellulose in poly(lactic-acid) provided by residual lignin and hemicellulose. J Mater Sci 52(1):60–72

Xiao B, Sun X, Sun R-C (2001) Chemical, structural, and thermal characterizations of alkali-soluble lignins and hemicelluloses, and cellulose from maize stems, rye straw, and rice straw. Polym Degrad Stab 74(2):307–319

Zhang Q, Mo Z, Liu S, Zhang H (2000) Influence of annealing on structure of nylon 11. Macromolecules 33(16):5999–6005

Zhang Q, Mo Z, Zhang H, Liu S, Cheng S (2001) Crystal transitions of nylon 11 under drawing and annealing. Polymer 42(13):5543–5547

Zhang G, Li Y, Yan D (2004) Polymorphism in nylon-11/montmorillonite nanocomposite. J Polym Sci Part B Polym Phys 42(2):253–259

Zierdt P, Weber A (2015) Processing and characterization of wood plastic composites from biobased polyamide 11 and chemically modified beech fibers. Mater Sci Forum 825–826:1039–1046

Zierdt P, Theumer T, Kulkarni G, DÃd’umlich V, Klehm J, Hirsch U, Weber A (2015) Sustainable wood-plastic composites from bio-based polyamide 11 and chemically modified beech fibers. Sustain Mater Technol 6:6–14

Acknowledgments

The authors thank the department of education of the Canton of Aargau, Switzerland for providing a scholarship (to S.R.). They also acknowledge the facilities, and the scientific and technical assistance, of the Australian Microscopy and Microanalysis Research Facility at the Centre for Microscopy and Microanalysis, The University of Queensland, Alireza Hosseinmardi for taking images and providing FTIR data, and John Milne for his help during the extrusion processing.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Rohner, S., Humphry, J., Chaléat, C.M. et al. Mechanical properties of polyamide 11 reinforced with cellulose nanofibres from Triodia pungens. Cellulose 25, 2367–2380 (2018). https://doi.org/10.1007/s10570-018-1702-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1702-x