Abstract

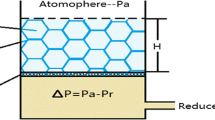

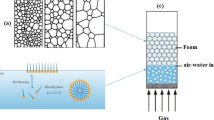

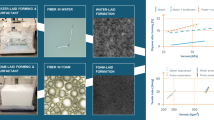

Foam forming is a promising papermaking technology, which can reduce water and energy consumption while saving raw material. It can be used to produce low quantity thick special products such as non-woven fabrics and filter papers with high porosity and smooth surfaces. This study mainly introduced the effect of polyvinyl alcohol (PVA) foaming properties on foam forming, including foam generation rate, liquid drainage rate, properties of the suspension and foam stability. Moreover, the effect of surfactant, air content and stirring speed on the behavior and characteristics of the foams were also investigated. The results indicate that foams prepared at 1200 rpm rotational speed under room temperature (25 °C) with a particular surfactant loading range from 0.75 to 1.25% have a life time of 7.5 min and its bubble size is uniform. It is also found that the degree of hydrolysis of PVA, would affect the bubble size and foam stability. Eventually, fiber-based materials with low density and highly porous structure were fabricated via a foam forming technology.

Similar content being viewed by others

References

Al-Qararah AM, Ketoja JA, Hjelt T, Kinnunen K (2012) Exceptional pore size distribution in foam formed fiber networks. Nord Pulp Pap Res J 27(2):226–230

Al-Qararah AM, Hjelt T, Koponen A, Harlin A, Ketoja JA (2013) Bubble size and air content of wet fiber foams in axial mixing with macro-instabilities. Colloids Surf A Physicochem Eng Asp 436:1130–1139

Al-Qararah AM, Ekman A, Hjelt T et al (2015) A unique microstructure of the fiber networks deposited from foam–fiber suspensions. Colloids Surf A 482:544–553

Beghello L, Eklund D (1997) Some mechanisms that govern fiber flocculation. Nord Pulp Pap Res J 12:119–123

Chang RC, Schoen HM, Grove CS (1956) Bubble size and bubble size determination. Ind Eng Chem 48(11):2035–2039

Cohen-Addad S, Höhler R, Pitois O (2013) Flow in foams and flowing foams. Annu Rev Fluid Mech 45:241–267

Fatehi P, Xiao H (2010) Effect of cationic PVA characteristics on fiber and paper properties at saturation level of polymer adsorption. Carbohydr Polym 79(2):423–428

Gonzenbach UT, Studart AR, Tervoort AE, Gauckler LJ (2007) Tailoring the microstructure of particle-stabilized wet foams. Langmuir 23(3):1025–1032

Grove CS, Wise GE, March WC (1951) Viscosity of fire fighting foam. Ind Eng Chem 43:1120–1122

Hirt DE, Prud’homme RK, Rebenfeld L (1988) A new technique to study foam flow in porous media: radial flow in fibrous mats. AIChE J 34(2):326–328

Jäsberg A, Selenius P, Koponen A (2014) Experimental results on the flow rheology of fiber-laden aqueous foams. Colloids Surf A Physicochem Eng Asp 473:147–155

Kaboorani A, Riedl B, Blanchet P, Fellin M, Hosseinaei O (2012) Nanocrystalline cellulose (NCC): a renewable nano-material for polyvinyl acetate (PVA) adhesive. Eur Polym J 48(11):1829–1837

Koponen A, Torvinen K, Jäsberg A, Kiiskinen H (2016) Foam forming of long fibers. Nord Pulp Pap Res J 16(2):239–247

Lappalainen T, Lehmonen J (2012) Determinations of bubble size distribution of foam-fiber mixture using circular hough transform. Nord Pulp Pap Res J 27:930–939

Lappalainen T, Salminen K, Kinnunen K, Järvinen M, Mira I, Andersson M (2014) Foam forming revisited. Part II. Effect of surfactant on the properties of foam-formed paper products. Nord Pulp Pap Res J 29:689–699

Lee J, Nikolov A, Wasan D (2014) Foam stability: the importance of film size and the micellar structuring phenomenon. Can J Chem Eng 92(12):2039–2045

Lehmonen J, Jetsu P, Kinnunen K et al (2013) Potential of foam-laid forming technology for paper applications. Nord Pulp Pap Res J 28:392–398

Macfarlane AL, Kadla JF, Kerekes RJ (2012) High performance air filters produced from freeze-dried fibrillated wood pulp: fiber network compression due to the freezing process. Ind Eng Chem Res 51(32):10702–10711

Mao J, Grgic B, Finlay WH et al (2008) Wood pulp based filters for removal of sub-micrometer aerosol particles. Nord Pulp Pap Res J 23(4):420–425

Mira I, Mira M, Mira L, Blute I, Carlsson G, Salminen K, Lappalainen T, Kinnunen K (2014) Foam forming revisited. Part I. Foaming behavior of fiber-surfactant systems. Nord Pulp Pap Res J 29:679–688

Niskanen K, Yhdistys PI (2008) Paper physics. Finnish Paper Engineers Association, Helsinki

Poranen J, Kiiskinen H, Salmela J, et al. (2013) Breakthrough in paper making resource efficiency with foam forming. Paper presented at the TAPPI PaperCon 2013, Atlanta, GA

Poskanzer AM, Goodrich FC (1975) Surface viscosity of sodium dodecyl sulfate solutions with and without added dodecanol. J Phys Chem 79(20):2122–2126

Punton VW (1975) Fibre distribution in foam and foam laid-paper. Paper presented at the international paper physics conference, New York, 21–25 Sept

Radvan B, Gatward APJ (1972) The formation of wet-laid webs by a foaming process. Tappi J 55:748–751

Rao AA, Wasan DT, Manev ED (1982) Foam stability—effect of surfactant composition on the drainage of microscope aqueous films. Chem Eng Commun 15(1–4):63–81

Rodman CA, Lessmann RC (1988) Automotive nonwoven filter media: their constructions and filter mechanisms. Tappi J 36:161–168

Rosen MJ, Kunjappu JT (1978) Surfactants and interfacial phenomena, 4th edn. Wiley, New Jersey

Rosen MJ, Song LD (1996) Dynamic surface tension of aqueous surfactant solutions. Effect of spacer on dynamic properties of gemini surfactant solutions. Colloid Interface Sci J 179(1):261–268

Saint JA, Zhang Y, Langevin D (2004) Quantitative description of foam drainage: transitions with surface mobility. Eur Phys J E 15(1):53–60

Shah DO, Djabbarah NF, Wasan DT (1978) A correlation of foam stability with surface shear viscosity and area per molecule in mixed surfactant systems. Colloid Polym Sci 256(10):1002–1008

Smith MK, Punton VW, Rixson AG (1974) Structure and properties of paper formed by a foaming process. Tappi J 57:107–111

Stammen JA, Williams S, Ku DN, Guldberg RE (2001) Mechanical properties of a novel PVA hydrogel in shear and unconfined compression. Biomaterials 22(8):799–806

Stevenson P (2005) Remarks on the shear viscosity of surfaces stabilised with soluble surfactants. J Colloid Interface Sci 290(2):603–606

Sun Z, Ma L, Hu X (2011) Preparation and characterization of Pd/PPy-SDS/foam-Ni and Pd/PPy-CTAB/foam-Ni electrodes with high electroactive surface area. J Solid State Electrochem 15(3):493–501

Acknowledgments

This work was supported by National Natural Science Foundation of China (31470608) and the fundamental Research Funds for the Central Universities (201522117).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou, Q., Wang, X. The effect of PVA foaming characteristics on foam forming. Cellulose 24, 4939–4948 (2017). https://doi.org/10.1007/s10570-017-1452-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1452-1