Abstract

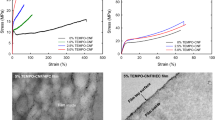

Reinforcing of cellulose nanofibril (CNF) films by partial dissolution with N-methylmorpholine-N-oxide (NMMO) was investigated. The method investigated is composed of impregnation of CNF film with liquid solution of NMMO followed by dry heat activation. The heat activation of the impregnated film was carried out using a heated calendering nip, which enabled simultaneous heating and compression. The partial dissolution of cellulose by NMMO caused a significant increase in the transparency of CNF film due to the decrease of film porosity and increased surface smoothness. The dry strength of the reinforced film was increased from 122 up to 195 MPa. Furthermore, the wet strength of the reinforced film was up to 70% greater than the dry strength of pure CNF film. The changes in the fibrillar structure were investigated with topographical imaging (SEM and AFM) and spectroscopically using NMR and FTIR. No significant changes in the fibril structure or cellulose morphology were observed. Moreover, the treated film resisted significant water pressure, highlighting CNF film’s permanent water resistance. The partial dissolution process with NMMO was also capable of reinforcing a CNF composite film with macro scale structural elements (lyocell short-cut fibres). The strategy investigated is a robust and fast method to improve the mechanical properties of fibrillary cellulose films, allowing them utilization in applications where improved water resistance and fully cellulosic character are required properties.

Similar content being viewed by others

Abbreviations

- CNF:

-

Cellulose nanofibrils

- NMMO:

-

N-methylmorpholine-N-oxidide

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87:963–979. doi:10.1016/j.carbpol.2011.08.078

Ahola S, Salmi J, Johansson L-S et al (2008) Model films from native cellulose nanofibrils. Preparation, swelling, and surface interactions. Biomacromolecules 9:1273–1282

Bledzki AK, Gassan J (1999) Composites reinforced with cellulose based fibres. Prog Polym Sci 24:221–274. doi:10.1016/S0079-6700(98)00018-5

Briassoulis D (2004) An overview on the mechanical behaviour of biodegradable agricultural films. J Polym Environ 12:65–81. doi:10.1023/B:JOOE.0000010052.86786.ef

Chanzy H, Nawrot S, Peguy A et al (1982) Phase behavior of the quasiternary system N-methylmorpholine-N-oxide, water, and cellulose. J Polym Sci Polym Phys Ed 20:1909–1924. doi:10.1002/pol.1982.180201014

Duchesne I, Hult E, Molin U et al (2001) The influence of hemicellulose on fibril aggregation of kraft pulp fibres as revealed by FE-SEM and CP/MAS 13C-NMR. Cellulose 8:103–111

Fink H-P, Weigel P, Purz H, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Progr Polym Sci 26:1473–1524. doi:10.1016/S0079-6700(01)00025-9

Graenacher C (1934) Cellulose solutions. Patent US1943176

Hakalahti M, Mautner A, Johansson L-S et al (2016) Direct interfacial modification of nanocellulose films for thermoresponsive membrane templates. ACS Appl Mater Interfaces 8:2923–2927. doi:10.1021/acsami.5b12300

Henriksson M, Berglund LA (2007) Structure and properties of cellulose nanocomposite films containing melamine formaldehyde. J Appl Polym Sci 106:2817–2824. doi:10.1002/app.26946

Henriksson M, Berglund LA, Isaksson P et al (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Hubbe MA, Rojas OJ (2008) Colloidal stability and aggregation of lignocellulosic materials in aqueous suspension. BioResources 3:1419

Huber T, Müssig J, Curnow O et al (2011) A critical review of all-cellulose composites. J Mater Sci 47:1171–1186. doi:10.1007/s10853-011-5774-3

Iwamoto S, Isogai A, Iwata T (2011) Structure and mechanical properties of wet-spun fibers made from natural cellulose nanofibers. Biomacromolecules 12:831–836. doi:10.1021/bm101510r

Johnson DL (1969) Strengthening swellable fibrous material with an amine oxide. U.S. 3 pp

Kapanen A, Schettini E, Vox G, Itävaara M (2008) Performance and environmental impact of biodegradable films in agriculture: a field study on protected cultivation. J Polym Environ 16:109–122. doi:10.1007/s10924-008-0091-x

Klemm D (1998) Comprehensive cellulose chemistry. Fundamentals and analytical methods, vol 1. Wiley, Weinheim

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed Engl 44:3358–3393. doi:10.1002/anie.200460587

Klemm D, Kramer F, Moritz S et al (2011) Nanocelluloses: a new family of nature-based materials. Angew Chemie Int Ed 50:5438–5466

Ku H, Wang H, Pattarachaiyakoop N, Trada M (2011) A review on the tensile properties of natural fiber reinforced polymer composites. Compos Part B Eng 42:856–873. doi:10.1016/j.compositesb.2011.01.010

Kurihara T, Isogai A (2014) Properties of poly(acrylamide)/TEMPO-oxidized cellulose nanofibril composite films. Cellulose 21:291–299. doi:10.1007/s10570-013-0124-z

Larsson PT, Hult E-L, Wickholm K et al (1999) CP/MAS 13C-NMR spectroscopy applied to structure and interaction studies on cellulose I. Solid State Nucl Magn Reson 15:31–40. doi:10.1016/S0926-2040(99)00044-2

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:735–764. doi:10.1016/j.carbpol.2012.05.026

Lucenius J, Parikka K, Österberg M (2014) Nanocomposite films based on cellulose nanofibrils and water-soluble polysaccharides. React Funct Polym 85:167–174. doi:10.1016/j.reactfunctpolym.2014.08.001

Mantanis GI, Young RA, Rowell RM (1995) Swelling of compressed cellulose fiber webs in organic liquids. Cellulose 2:1–22. doi:10.1007/BF00812768

Moon R, Martini A, Nairn J et al (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Nishino T, Arimoto N (2007) All-cellulose composite prepared by selective dissolving of fiber surface. Biomacromolecules 8:2712–2716. doi:10.1021/bm0703416

Oh SY, Il Yoo D, Shin Y, Seo G (2005) FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohydr Res 340:417–428. doi:10.1016/j.carres.2004.11.027

Österberg M, Vartiainen J, Lucenius J et al (2013) A fast method to produce strong NFC films as a platform for barrier and functional materials. ACS Appl Mater Interfac 5:4640–4647. doi:10.1021/am401046x

Paakko M, Vapaavuori J, Silvennoinen R et al (2008) Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4:2492–2499. doi:10.1039/B810371B

Peresin MS, Vartiainen J, Kunnari V, et al (2012) Large-scale nanofibrillated cellulose film: an overview on its production, properties, and potential applications. In: Book of abstracts international conference of pulping, papermaking and biotechnology

Qing Y, Sabo R, Cai Z, Wu Y (2013) Resin impregnation of cellulose nanofibril films facilitated by water swelling. Cellulose 20:303–313. doi:10.1007/s10570-012-9815-0

Rosenau T, Potthast A, Sixta H, Kosma P (2001) The chemistry of side reactions and byproduct formation in the system NMMO/cellulose (lyocell process). Progr Polym Sci 26:1763–1837

Schasfoort RBM, Tudos AJ, Gedig ET (2008) Handbook of surface plasmon resonance. The Royal Society of Chemistry, Cambridge

Spoljaric S, Salminen A, Luong N, Seppälä J (2013) Crosslinked nanofibrillated cellulose: poly(acrylic acid) nanocomposite films; enhanced mechanical performance in aqueous environments. Cellulose 20:2991–3005. doi:10.1007/s10570-013-0061-x

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

Tammelin T, Hippi U, Salminen A (2013) Method for the preparation of nanofibrillated cellulose (NFC) films on supports. PCT Int Appl 13 pp, Chemical Indexing Equivalent to 160:342652

Toivonen MS, Kurki-Suonio S, Schacher FH et al (2015) Water-resistant, transparent hybrid nanopaper by physical cross-linking with chitosan. Biomacromolecules 16:1062–1071. doi:10.1021/acs.biomac.5b00145

Vanderhart DL, Atalla RH (1984) Studies of microstructure in native celluloses using solid-state carbon-13 NMR. Macromolecules 17(8):1465–1472

Virtanen T, Maunu SL (2014) NMR spectroscopic studies on dissolution of softwood pulp with enhanced reactivity. Cellulose 21:153–165. doi:10.1007/s10570-013-0144-8

Visanko M, Liimatainen H, Sirviö JA et al (2014) Porous thin film barrier layers from 2,3-dicarboxylic acid cellulose nanofibrils for membrane structures. Carbohydr Polym 102:584–589. doi:10.1016/j.carbpol.2013.12.006

Walther A, Timonen JVI, Díez I et al (2011) Multifunctional high-performance biofibers based on wet-extrusion of renewable native cellulose nanofibrils. Adv Mater 23:2924–2928. doi:10.1002/adma.201100580

Wachsmann U, Diamantoglou M (1997) Potential des NMMO-Verfahrens für Fasern und Membranen. Das Pap 51:660–665

Acknowledgments

The work was carried out in the Design Driven Value Chains in the World of Cellulose project (DWOC) funded by Tekes the Finnish Funding Agency for Innovation. The authors also thank the Academy of Finland. The authors appreciate the help given by Unto Tapper (SEM imaging), Tommi Virtanen (NMR analysis), Vuokko Liukkonen (helping with calendering), Hanna Kyllönen (filtration testing), and Salonen Ulla (helping with the tensile testing).

Author contributions

The manuscript was written through contributions of all the authors. All authors have given approval to the final version of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Orelma, H., Korpela, A., Kunnari, V. et al. Improving the mechanical properties of CNF films by NMMO partial dissolution with hot calender activation. Cellulose 24, 1691–1704 (2017). https://doi.org/10.1007/s10570-017-1229-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1229-6