Abstract

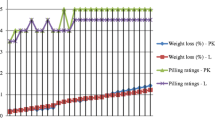

Enzymatic treatments in textile are remarkable because of their environmentally friendly properties, such as less energy, water and chemical need, low waste water pollution. In this paper combined use of amylase, pectinase and cellulase in the same bath was studied in different parts. In the first part of the experiment, raw cotton woven fabrics were treated with amylase, pectinase and cellulase enzymes in the same bath at different process conditions to desize, scour and polish. Results showed that one-bath triple enzymatic mixture process could be done successfully. Therefore, it could be used instead of conventional processes. Moreover, the enzymatic process was completed almost in half of the conventional treatments’ durations and temperatures. In the second part, effects of enzymes’ dosages were analyzed by using enzymes in pairwise combinations. By this way, not only the effects of the amount of enzymes but also the effects of each enzyme on each fabric property were seen more distinctly. The increases of enzymes’ concentrations led to an increase in every tested value except tear strength. Pectinase + cellulase combination resulted in minimum tear strength and whiteness, but maximum absorbency. Usage of enzymes one-by-one constituted the final part of the study. It had been found that amylase affected whiteness and absorbency, cellulase affected tear strength particularly. Although combined enzymatic treatments were conducted at more moderate conditions than conventional processes, comparable results were observed.

Similar content being viewed by others

References

Ali H, Hashem M, Shaker N, Ramadan M, El-Sadek B, Hady MA (2012) Cellulase enzyme in bio-finishing of cotton-based fabrics: effects of process parameters. Res J Text Appar 16(3):57–65. doi:10.1108/RJTA-16-03-2012-B006

Ali S, Khatri Z, Khatri A, Tanwari A (2014) Integrated desizing–bleaching–reactive dyeing process for cotton towel using glucose oxidase enzyme. J Clean Prod 1(66):562–567. doi:10.1016/j.jclepro.2013.11.035

Aly AS, Moustafa AB, Hebeish A (2004) Bio-technological treatment of cellulosic textiles. J Clean Prod 12(7):697–705. doi:10.1016/S0959-6526(03)00074-X

Aly AS, Sayed SM, Zahran MK (2010) One-step process for enzymatic desizing and bioscouring of cotton fabrics. J Nat Fibers 7(2):71–92. doi:10.1080/15440478.2010.481086

Aniş P (1998) Tekstil Ön terbiyesi. Alfa, İstanbul

Bahtiyari MI, Duran K, Körlü AE, Perincek S (2010) Usage of commercial cellulases in biopolishing of viscose fabrics. J Text Appar 20(1):57

Cortez JM, Ellis J, Bishop DP (2001) Cellulase finishing of woven, cotton fabrics in jet and winch machines. J Biotechnol 89(2):239–245. doi:10.1016/S0168-1656(01)00307-8

El-Zawahry MM, Helmy HM, Abou-Okeil A (2009) Enzymatic treatment and its influence on finishing and dyeing properties of jute fabrics. Res J Text Appar 13(4):34–44. doi:10.1108/RJTA-13-04-2009-B005

Eren HA, Anis P, Davulcu A (2009) Enzymatic one-bath desizing–bleaching–dyeing process for cotton fabrics. Text Res J 79(12):1091–1098. doi:10.1177/0040517508099388

Esfandiari A, Firouzi-Pouyaei E, Aghaei-Meibodi P (2014) Effect of enzymatic and mechanical treatment on combined desizing and bio-polishing of cotton fabrics. J Text Inst 105(11):1193–1202. doi:10.1080/00405000.2014.880222

Hajilari M, Esfandiari AH, Dabiryan H, Gharbi SMP (2009) Investigation of effect of fibres modulus on pilling of acrylic fabrics. J Text Inst 100(2):135–140. doi:10.1080/00405000701679681

Hebeish A, Ibrahim NA (2007) The impact of frontier sciences on textile industry. Colourage 54(4):41–55

Hemmpel WH (1991) The surface modification of woven and knitted cellulose fibre fabrics by enzymatic degradation. Int Text Bull Dyeing Print Finish 37(3):5–6

Ibrahim NA, El-Hossamy M, Morsy MS, Eid BM (2004) Optimization and modification of enzymatic desizing of starch-size. Polym Plast Technol 43(2):519–538. doi:10.1081/PPT-120029978

Ibrahim NA, El–Badry K, Eid BM, Hassan TM (2011) A new approach for biofinishing of cellulose-containing fabrics using acid cellulases. Carbohyd Polym 83(1):116–121. doi:10.1016/j.carbpol.2010.07.025

Li Y, Hardin ZR (1997) Enzymatic scouring of cotton: effects on structure and properties. Text Chem Colorist 29(8):71–76

Mojsov K (2012) Biotechnological applications of pectinases in textile processing and bioscouring of cotton fibers. In: II International conference industrial engineering and environmental protection 2012 (IIZS 2012), Proceedings, 31 October 2012, Zrenjanin, Serbia, pp 314–322

O’Neill A, Araújo R, Casal M, Guebitz G, Cavaco-Paulo A (2007) Effect of the agitation on the adsorption and hydrolytic efficiency of cutinases on polyethylene terephthalate fibres. Enzyme Microb Tech 40(7):1801–1805. doi:10.1016/j.enzmictec.2007.02.012

Opwis K, Knittel D, Schollmeyer E (2013) Use of enzymes in the pre-treatment of cotton. Nord-West eV DT

Öner E, Sahinbaskan BY (2011) A new process of combined pretreatment and dyeing: REST. J Clean Prod 19(14):1668–1675. doi:10.1016/j.jclepro.2011.05.008

Saravanan D, Vasanthi NS, Ramachandran T (2009) A review on influential behaviour of biopolishing on dyeability and certain physico-mechanical properties of cotton fabrics. Carbohydr Polym 76(1):1–7. doi:10.1016/j.carbpol.2008.10.019

Slauson SD, Miller B, Rebenfeld L (1984) Physicochemical properties of sized yams Part I: initial studies. Text Res J 54(10):655–664. doi:10.1177/004051758405401004

Stănescu MD, Dochıa M, Fogoraşı M, Pustıanu M, Bucur MS (2010) Enzımes ın cotton bio-scouring. Cellulose 86(93):52

Surribas A, Martínez A, Alamán M, De la Varga M, Paul R, Botet JM (2013) Biotechnological solutions for reducing the environmental impact of cotton processing. AATCC Rev 13(6):44–49

Tavčer PF, Križman P, Preša P (2006) Combined bioscouring and bleaching of cotton fibres. J Nat Fibers 3(2–3):83–97. doi:10.1300/J395v03n02_06

Tzanov T, Calafell M, Guebitz GM, Cavaco-Paulo A (2001) Bio-preparation of cotton fabrics. Enzyme Microb Tech 29(6):357–362. doi:10.1016/S0141-0229(01)00388-X

Ul-Haq N, Nasir H (2012) Cleaner production technologies in desizing of cotton fabric. J Text Inst 103(3):304–310. doi:10.1080/00405000.2011.570045

Acknowledgments

The authors express their sincere thanks to Yürek Tekstil Sanayi ve Ticaret A.Ş. (Turkey), Nuy Tekstil Sanayi ve Dış Ticaret Ltd. Şti. (Turkey), Pentakim Kimya Sanayi (Turkey) and Cargill (Turkey) for providing the enzymes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Toprak, T., Anis, P. Combined one-bath desizing–scouring–depilling enzymatic process and effect of some process parameters. Cellulose 24, 383–394 (2017). https://doi.org/10.1007/s10570-016-1095-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-1095-7