Abstract

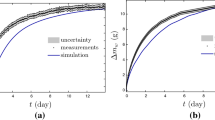

The theory of mass transport in porous media is of fundamental importance for different applications such as food, paper packaging, textiles, and wood for building materials. In this study, a theoretical water vapor transport model has been developed for cellulose-based materials, such as paper and regenerated cellulose film. Pore diffusivities were determined from the dynamic moisture breakthrough experiments comprising a stack of paper sheets and regenerated cellulose films in a configuration similar to a packed adsorption column. Other mass transfer parameters were determined from transient moisture uptake rate measurements. The model incorporates pore and surface diffusion as a lump parameter into a variable effective diffusion coefficient. The mass transport, involving both pore and surface diffusions, is evaluated independently. The theoretical water vapor transmission rates (WVTRs) obtained from the model were compared with experimentally determined WVTRs measured under steady-state conditions. The theoretical model, based on intrinsic diffusion, stipulates higher WVTR values compared to the experimental results. However, the theoretical water vapor transfer rates agree well with the experimental results when external mass transfer resistance is incorporated in the model.

Similar content being viewed by others

References

Ahlen AT (1970) Diffusion of sorbed water vapor through paper and cellulose film. Tappi J 53(7):1320–1326

Anderson RB (1946) Modifications of the brunauer, emmett and teller equation. J Am Soc 68:681–691

Bandyopadhyay A, Ramarao BV, Ramaswamy S (2002) Transient moisture diffusion through paperboard materials. Colloids Surf A Physicochem Eng Asp 206:455–467

Bedane AH, Huang Q, Xiao H, Eić M (2012) Mass transfer of water vapor, carbon dioxide and oxygen on modified cellulose fiber-based materials. J Nord Pulp Paper Res 27(2):409–417

Bedane AH, Xiao H, Eić M (2014) Water vapor adsorption equilibria and mass transport in unmodified and modified cellulose fiber-based materials. J Adsorption 20(7):863–874

Bedane AH, Xiao H, Eić M, Madjid FF (2015) Water vapor transport properties of regenerated cellulose and nanofibrillated cellulose films. J Membr Sci 493:46–57

Belbekhouchea S, Brasb J, Siqueirab G, Chappeya C, Lebruna L, Khelifib B, Maraisa S, Dufresneb A (2011) Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohydr Polym 83(4):1740–1748

Bhatt BJ (2012) Regenerated cellulose for controlled oral drug delivery. PhD thesis, University of Iowa. http://ir.uiowa.edu/etd/4577

Chatterjee SG, Ramarao BV, Tien C (1997) Water-vapor sorption equilibria of a bleached-Kraft paperboard-a study of hysteresis region. J Pulp Paper Sci 23(8):366–373

Chen YD, Yang RT (1993) Surface diffusion of multilayered adsorbed species. AIChE J 39(4):559–606

Crank J, Park GS (1968) Diffusion in Polymers. Academic Press, London

Defrenne Y, Zhdankin V, Takagaki S, Ramaswamy S, Lavrykov S, Ramarao B (2009) Multi-scale moisture transport in paper: Impact of pore and fiber tortuosity and anisotropy. Proc Advances in Pulp and Paper Research pp 455–473

Del Nobile MA, Fava P, Piergiovanni L (2002) Water transport properties of cellophane flexible films intended for food packaging applications. J Food Eng 53:295–300

Epstein N (1989) On tortuosity and the tortuosity factor in flow and diffusion through porous media. Chem Eng Sci 44:777–779

Foss WR, Bronkhorst CA, Bennett KA (2003) Simultaneous heat and mass transport in paper sheets during moisture sorption from humid air. Int J Heat Mass Transfer 46:2875–2886

Gupta H, Chatterjee SG (2003a) Parallel diffusion of moisture in paper. Part 1: steady-state conditions. Ind Eng Chem Res 42:6582–6592

Gupta H, Chatterjee SG (2003b) Parallel diffusion of moisture in papers. Part 2: transient conditions. Ind Eng Chem Res 42:6593–6600

Hashimoto A, Stenstrom S, Kameoka T (2003) Simulation of convective drying of wet porous materials. Drying Tech 21(8):1411–1431

Hedenqvist M, Gedde UW (1996) Diffusion of small molecule penetrants in semicrystalline polymers. Prog Polym Sci 21:299–333

Henriksson M, Berglund LA, Isaksson P, Lindstrom T, Nishino N (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9(6):1579–1585

Hines AL, Maddox RN (1985) Mass transfer fundamentals and applications. Prentice-Hall Inc, Englewood Cliffs

Ichwan M, Son TW (2011) Preparation and characterization of dense cellulose film for membrane application. J Appl Polym Sci 124(2):1409–1418

Karger J, Ruthven DM (1992) Diffusion in zeolites and other microporous solids, Chapter 9. Wiley, New York

Khare VP, Greenberg AR, Kelley SS, Pilath H, Roh J II, Tyber J (2007) Synthesis and characterization of dense and porous cellulose films. J Appl Sci 105:1228–1236

Liang B, Fields RJ, King JC (1990) The mechanisms of transport of water and n-propanol through pulp and paper. Dry Tech 8(4):641–665

Lin SH (1990) Moisture absorption in cellulosic materials. Int J Eng Sci 28(11):1151–1156

Liu H, Ruthven DM (1996) Diffusion in carbon molecular sieves. Fundament Adsorption 356:529–536

Lonsdale HK (1982) The growth of membrane and technology. J Membr Sci 10:81–181

Massoquete A (2005) Study of Anisotropic moisture diffusion in paper materials. PhD thesis. State University of New York College of Environmental Science and Forestry Syracuse, New York

Matyka M, Khalili A, Koza Z (2008) Tortuosity-porosity relation in porous media flow. Phys Rev E 78:026306

Morillon V, Debeaufort F, Blond B, Capelle M, Voilley A (2002) Factors affecting the moisture permeability of lipid-based edible films: a review. Crit Rev Food Sci Nutr 42(1):67–89

Nagy E (2012) Basic equations of the mass transport through a membrane layer. Waltham, MA 02451, USA, Elsevier Inc. pp 6–29

Nair SS, Zhu JY, Deng Y, Ragauskas AJ (2014) High performance green barriers based on nanocellulose. Sustain Chem Process 2:23. doi:10.1186/s40508-014-0023-0

Nilsson L, Wilhelmsson B, Stenstrom S (1993) The diffusion of water vapor through pulp and paper. Drying Tech. 11(6):1205–1225

Pangarkar VG, Ray SK (2015) Pervaporation: theory, practice, and applications in the chemical and allied industries. Handbook of membrane separations–chemical, pharmaciutical, food, and biotechnological applications. Taylor and Francis Group, Boca Raton, pp 81–202

Pascat B (1986) Study of some factors affecting permeability. In: Mathlouthi M (ed) Food packaging and preservation. Theory and practice. Elsevier Applied Science Publishers, London, pp 7–24

Radhakrishnan H, Chatterjee SG, Ramarao BV (2000) Steady-state moisture transport in a bleached Kraft paperboard stack. J Pulp Paper Sci 26(4):140–144

Ramarao BV, Massoquete A, Lavrykov S, Ramaswamy S (2003) Moisture diffusion inside paper materials in the hygroscopic range and characteristics of diffusivity parameters. Dry Tech 21(10):2007–2056

Rogers CE (1985) Permeation of gases and vapors in polymers. In: Comyn J (ed) Polymer permeability. Elsevier Applied Science Publishers, New York, pp 11–73

Ruthven DM (1984) Principle of adsorption and adsorption processes. Wiley, New York

Spence KL, Venditti RA, Rojas OJ, Pawlak JJ, Hubbe MA (2011) Water vapor barrier properties of coated and filled microfibrillated cellulose composite films. Bioresources 6(4):4370–4388

Sun Z, Tang X, Cheng G (2013) Numerical simulation for tortuosity of porous media. Microporous Mesoporous Mater 173:37–42

Tolle WE (1971) Variables affecting film permeability requirements for modified-atmosphere. Agricultural Research Service. U.S Department of Agriculture, Technical Bulletin No. 1422

Topgaard D, Soderman O (2001) Diffusion of water absorbed in cellulose fibers studied with H-NMR. Langmuir 17:2694–2702

Yang Q, Fukuzumi H, Saito T, Isogai A, Zhang L (2011) Transparent cellulose films with high gas barrier properties fabricated from aqueous alkali/urea solutions. Biomacromolecules 12:2766–2771

Yang Q, Saito T, Isogai A (2012) Facile fabrication of transparent cellulose films with high water repellency and gas barrier properties. Cellulose 19:913–1921

Acknowledgments

The authors gratefully acknowledge financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC) Strategic Green Fiber Network program. We also thank Dr. Xiao’s graduate student, Ms. Zhaoping Song, for preparation of the samples in the UNB Limerick Pulp and Paper Laboratory.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix: Calculated result for the Knudsen diffusion coefficient

Appendix: Calculated result for the Knudsen diffusion coefficient

Knudsen diffusion is a means of molecular transport through pores that are small in comparison to the mean free path of the gas. For straight and round pores, the Knudsen diffusion coefficient can be predicted from the diameter of the pore by the expression (Hines and Maddox 1985):

where r is the pore radius, m, T is temperature, K, D A,K is the Knudsen diffusion coefficient, m2/s, and M A is the molecular weight of component A.

In order to account for the tortuosity path of the molecule (τ) and the porosity of the material (ε), an effective Knudsen diffusivity (D A,K,e) can be expressed as:

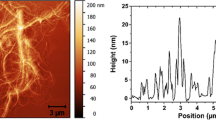

Regenerated cellulose film has a small mean pore size and ranges between 0.5 to 2.0 nm (Tolle 1971; Ichwan and Son 2011). It is possible that the regenerated cellulose film exhibits a dominant Knudsen diffusion mechanism. Molecules collide more often with the pore walls than with other molecules in the Knudsen diffusion mechanism. Assuming straight and round pores in the cellulose film, the effective diffusivity can be calculated using Eq. 26.

The calculated D A,K,e is found to be around 5.3 × 10−9 m2/s using the porosity value, ε = 0.20, tortuosity, τ = 15, molecular weight of the water vapor molecule, M A = 18 g/mol, T = 298 K, and pore radius, r ≈ 1.25 nm.

Rights and permissions

About this article

Cite this article

Bedane, A.H., Eić, M., Farmahini-Farahani, M. et al. Theoretical modeling of water vapor transport in cellulose-based materials. Cellulose 23, 1537–1552 (2016). https://doi.org/10.1007/s10570-016-0917-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0917-y