Abstract

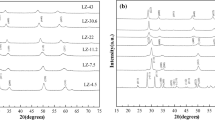

Novel coke-resistant Ni-containing TUD-1 supported catalysts were successfully synthesized for the steam reforming of biomass-derived acetic acid. The catalysts exhibited exceptional catalytic activity, coupled with remarkable stability. Rigorous characterization through XRD, N2 adsorption–desorption, ICP-MS, and Pyridine-DRIFT analyses provided valuable insights into their structural and physical features. The investigation focused on the effects of diverse preparation methods and reaction temperatures on hydrogen selectivity, with a meticulous comparison of the one-pot hydrothermal synthesis and impregnation techniques. Catalytic activity measurements at various temperatures revealed a captivating trend: lower temperatures yielded superior hydrogen selectivity, underscoring the pivotal role of temperature in steering the desired reaction pathway. Notably, the catalysts synthesized via the one-pot hydrothermal method exhibited remarkable hydrogen selectivity and stability. Their outstanding performance promises substantial advancements in the field. Moreover, the catalysts displayed exceptional endurance during the steam reforming of acetic acid, sustaining their activity for a minimum of 12 h, signifying their potential for long-term applications. These findings hold great promise for the development of efficient and durable catalyst systems, contributing to the progression of sustainable hydrogen production from biomass sources.

Graphical Abstract

Synthesize steps of Ni/TUD-1 catalyst using the one-pot method

Similar content being viewed by others

References

Hou T, Yuan L, Ye T et al (2009) Hydrogen production by low-temperature reforming of organic compounds in bio-oil over a CNT-promoting Ni catalyst. Int J Hydrogen Energy 34:9095–9107. https://doi.org/10.1016/j.ijhydene.2009.09.012

Mohanty P, Patel M, Pant KK (2012) Hydrogen production from steam reforming of acetic acid over Cu–Zn supported calcium aluminate. Bioresour Technol 123:558–565. https://doi.org/10.1016/j.biortech.2012.07.019

Resende KA, Ávila-Neto CN, Rabelo-Neto RC et al (2015) Hydrogen production by reforming of acetic acid using La–Ni type perovskites partially substituted with Sm and Pr. Catal Today 242:71–79. https://doi.org/10.1016/j.cattod.2014.07.013

Fu P, An S, Yi W, Bai X (2012) Thermodynamic investigation of acetic acid steam reforming for hydrogen production. Adv Mater Res 550–553:2801–2804. https://doi.org/10.4028/www.scientific.net/AMR.550-553.2801

Pekmezci Karaman B, Cakiryilmaz N, Arbag H et al (2017) Performance comparison of mesoporous alumina supported Cu & Ni based catalysts in acetic acid reforming. Int J Hydrogen Energy 42:26257–26269. https://doi.org/10.1016/j.ijhydene.2017.08.155

Cakiryilmaz N, Arbag H, Oktar N et al (2019) Catalytic performances of Ni and Cu impregnated MCM-41 and Zr-MCM-41 for hydrogen production through steam reforming of acetic acid. Catal Today 323:191–199. https://doi.org/10.1016/j.cattod.2018.06.004

Ibrahim SA, Ekinci EK, Karaman BP, Oktar N (2021) Coke-resistance enhancement of mesoporous γ-Al2O3 and MgO-supported Ni-based catalysts for sustainable hydrogen generation via steam reforming of acetic acid. Int J Hydrogen Energy 46:38281–38298. https://doi.org/10.1016/j.ijhydene.2021.09.084

Bimbela F, Oliva M, Ruiz J et al (2007) Hydrogen production by catalytic steam reforming of acetic acid, a model compound of biomass pyrolysis liquids. J Anal Appl Pyrolysis 79:112–120. https://doi.org/10.1016/j.jaap.2006.11.006

Bimbela F, Oliva M, Ruiz J et al (2012) Pruning of the surface species on Ni/Al 2O 3 catalyst to selective production of hydrogen via acetone and acetic acid steam reforming. Int J Hydrogen Energy 37:12987–12993. https://doi.org/10.1016/j.cattod.2012.06.021

Assaf PGM, Nogueira FGE, Assaf EM (2013) Ni and Co catalysts supported on alumina applied to steam reforming of acetic acid: Representative compound for the aqueous phase of bio-oil derived from biomass. Catal Today 213:2–8. https://doi.org/10.1016/j.cattod.2013.02.012

Basagiannis AC, Verykios XE (2007) Catalytic steam reforming of acetic acid for hydrogen production. Int J Hydrogen Energy 32:3343–3355. https://doi.org/10.1016/j.ijhydene.2007.04.039

Zheng XX, Yan CF, Hu RR et al (2012) Hydrogen from acetic acid as the model compound of biomass fast-pyralysis oil over Ni catalyst supported on ceria-zirconia. Int J Hydrogen Energy 37:12987–12993. https://doi.org/10.1016/j.ijhydene.2012.05.067

Burghoff B, Sousa Marques J, van Lankvelt BM, de Haan AB (2010) Solvent impregnated resins for MTBE removal from aqueous environments. React Funct Polym 70:41–47. https://doi.org/10.1016/j.reactfunctpolym.2009.10.002

Hu X, Zhang L, Lu G (2012) Pruning of the surface species on Ni/Al 2O 3 catalyst to selective production of hydrogen via acetone and acetic acid steam reforming. Appl Catal A Gen 427–428:49–57. https://doi.org/10.1016/j.apcata.2012.03.029

Cakiryilmaz N, Arbag H, Oktar N et al (2018) Effect of W incorporation on the product distribution in steam reforming of bio-oil derived acetic acid over Ni based Zr-SBA-15 catalyst. Int J Hydrogen Energy 43:3629–3642. https://doi.org/10.1016/j.ijhydene.2018.01.034

Telalović S, Ramanathan A, Mul G, Hanefeld U (2010) TUD-1: Synthesis and application of a versatile catalyst, carrier, material. J Mater Chem 20:642–658. https://doi.org/10.1039/b904193a

Jansen JC, Shan Z, Marchese L et al (2001) A new templating method for three-dimensional mesopore networks. Chem Commun. https://doi.org/10.1039/b101000j

Parkhomenko K, Tyunyaev A, Martinez Tejada LM et al (2012) Mesoporous amorphous silicate catalysts for biogas reforming. Catal Today 189:129–135. https://doi.org/10.1016/j.cattod.2012.03.057

Quek XY, Liu D, Cheo WNE et al (2010) Nickel-grafted TUD-1 mesoporous catalysts for carbon dioxide reforming of methane. Appl Catal B Environ 95:374–382. https://doi.org/10.1016/j.apcatb.2010.01.016

Heikkilä T, Salonen J, Tuura J et al (2007) Mesoporous silica material TUD-1 as a drug delivery system. Int J Pharm 331:133–138. https://doi.org/10.1016/j.ijpharm.2006.09.019

Devi TG, Kannan MP (2007) X-ray diffraction (XRD) studies on the chemical states of some metal species in cellulosic chars and the Ellingham diagrams. Energy Fuels 21:596–601. https://doi.org/10.1021/ef060395t

Supriya BS, Nagaraja P, Byrappa K (2015) Hydrothermal synthesis and characterization of carbon spheres using citric-acid-catalyzed carbonization of starch. E-Polymers 15:179–183. https://doi.org/10.1515/epoly-2015-0025

Ozel Sahin S, Arbag H, Oktar N, Murtezaoglu K (2019) Catalytic Performances of Bi-Metallic Ni-Co Catalysts in Acetic Acid Steam Reforming Reaction: Effect of Mg Incorporation. Int J Chem React Eng 17:1–15. https://doi.org/10.1515/ijcre-2018-0164

Acknowledgements

Financial support from University Research Funds through Gazi University (06/2017-19 and 06/2018-09) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest regarding the publication of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ekinci, E., Oruç, M., Oktar, N. et al. Catalytic Performances of Ni-containing Mesoporous TUD-1 Catalysts in Steam Reforming of Acetic Acid. Catal Lett (2024). https://doi.org/10.1007/s10562-024-04621-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10562-024-04621-1