Abstract

The mechanism of higher alcohol synthesis (HAS) from syngas on a stepped Rhodium surface was explored using first principles calculations based on density functional theory. Results showed that the activation of CO proceeds most energetically feasible via a sequential hydrogenation towards CH2OH, followed by the C–OH bond cleavage yielding CHx species. Because the initial CO hydrogenation step is highly activated, the cascade of elementary steps toward methane formation is highly favored. The formation of C2 oxygenates toward ethanol production is kinetically favored by CO insertion to CH2, or alternatively, by a lower activation barrier CHO insertion to CH3. On the other hand, the C3 species is formed more preferably by CO rather than CHO insertion to a CH3CH2 fragment, indicating the effect of a more extended carbon structure on the reaction mechanism. The overall reaction mechanism for HAS points to a cycle of CO insertion, hydrogenation, and OH elimination steps.

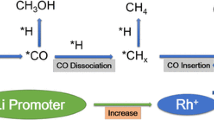

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

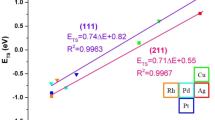

The direct conversion of syngas (CO + H2) into higher alcohols (two or more carbon atoms) is a contemporary challenge in catalysis. Its potential as a sustainable route to manufacturing fuels and valuable chemicals is hindered by low selectivity and product yield of conventional catalysts such as Rh [1,2,3,4]. Thus, in the development of active and selective catalysts for this reaction, it is crucial to clarify the reaction mechanism of higher alcohol synthesis (HAS) from syngas on a Rh catalyst. Previous theoretical studies revealed that elementary steps such as hydrogenation, C–C coupling, and C–O bond breaking reactions are relevant to produce the C2 oxygenates [5,6,7,8]. There is a consensus in the literature that the C–C bond of a C2 species is formed by CHxO insertion to a CHx fragment (where x is an integer) [3, 6, 7, 9, 10]. For example, Kapur et al. showed through first principles calculations that ethanol is formed on both the (111) and (211) surfaces of an fcc Rh by CO insertion to a CH2 fragment [7]. On the other hand, Wang et al. revealed that a more energetically favorable pathway on Rh(211) is via the CHO insertion to CH3 [6]. While the reaction mechanism for the production of C2 alcohol was clarified on these studies, the mechanism of the succeeding CHxO (x = 0, 1) insertion reactions to a C2 species towards the production of C3 oxygenates has remained unexplored in theoretical studies. This is important because the insertion of a CHxO species on a C2 hydrocarbon involves a more complex reorientation of the C2Hx species in the formation of the C–C bond with CHxO. Experimentally, it was shown that a C3 alcohol (n-propanol) can be produced on a Rhodium catalyst [11]. In the current work, the mechanism for the production of C2 oxygenates on Rh(211) is first revisited and further extended to the formation of C3 oxygenates. The explored elementary steps for HAS synthesis include the activation of CO by dissociation and hydrogenation, C–O bond cleavage for the formation of CHx species from CHxO, C–C coupling by insertion of CHxO species to CHx forming C2 oxygenates and coupling of CHx species, and the formation of C3 oxygenates from C2 species. To this end, a general scheme for the mechanism of HAS will provide insights into the design and development of catalysts for this reaction.

2 Results and Discussion

As an overview of the results, the identified reaction paths for HAS are shown in Scheme 1. Here, CO is first activated through hydrogenation to form the CHO species, which further hydrogenates into CH2O and CH2OH species. Note that in Scheme 1, the hydrogenation of CO is depicted as an equivalent reaction of CO insertion to an H adatom. CH2OH dissociates yielding CH2, which easily hydrogenates into CH3 and CH4. Methanol is produced by the hydrogenation of CH2O into CH3O and further into CH3OH. The insertion of CO is more preferred in CH2 than in CH3, albeit the CHO insertion to CH3 has a lower activation barrier than the CO insertion to CH2. Further hydrogenation of C2 species from these insertion steps forms ethanol. Meanwhile, an OH elimination step can form the CH3CH2 species, which can be converted to n-propanol by CO insertion and subsequent hydrogenation steps. The details of this identified reaction mechanism are discussed in the following sections. The activation barriers for different elementary steps are shown in Table 1. While there are many other possible elementary steps involved in the overall HAS, Table 1 only shows the relevant elementary steps based on the calculated activation barriers (i.e., low-barrier steps).

The proposed reaction mechanism for HAS from syngas on Rh(211). The arrows are color-coded according to the type of elementary steps: desorption (green), hydrogenation (black), C–OH bond cleavage by OH elimination (blue), and CO or CHO insertion (red). Each elementary step is labeled (R1, R2, R3, …) based on Table 1

2.1 CO Activation: Dissociation Versus Hydrogenation

In the HAS reaction from syngas, the activation of CO via dissociation or hydrogenation determines the mechanistic route to produce alcohol and other products such as methane, CO2, and other hydrocarbons. The dissociation of CO into C and O adatoms has been proposed to be the initial step to produce CH4 and CH3CH2OH (ethanol) [7]. CO adsorbs at the bridge-edge site of Rh(211) and dissociates, as shown in Fig. 1a. However, CO dissociation on Rh(211) requires a large activation barrier of 3.61 eV, which is consistent with other DFT studies on other surfaces such as Co(0001) [9] and Rh(111) [5.7–8]. Although the calculation of hydrogen-assisted C–O bond dissociation (CO + H → C + OH, R2) revealed a lower energy barrier of 2.70 eV, the kinetics is still expected to be slow. In contrast, the calculated activation barrier for CO hydrogenation (CO + H → CHO, R6) is 1.33 eV, consistent with a previous DFT study [6]. This indicates a strong kinetic preference for CO hydrogenation rather than dissociation, which is supported by studies that reported CO hydrogenation as the dominant pathway for alcohol production, such as methanol and ethanol [5, 6, 8]. Meanwhile, the hydrogenation of CO into COH (O–H bond formation) requires an activation barrier of 1.85 eV, which is higher than its hydrogenation into CHO. This implies that the C–H bond formation is easier compared to O–H bond formation for the first hydrogenation of CO. In this regard, the subsequent elementary steps considered are the pathways via the CHO as an intermediate species (herein referred to as the CHO-pathway).

The initial (left), transition (middle), and final (right) states of some key elementary steps on Rh(211): (a) CO → C + O (R1), (b) CO + H → CHO (R6), (c) CH3O + H → CH3OH (R12), (d) CH2OH → CH2 + OH (R14), (e) CH2 + CO → CH2CO (R32), (f) CH2 + CHO → CH2CHO (R33), (g) CH3 + CO → CH3CO (R34), (h) CH3 + CHO → CH3CHO (R35), (i) CH3CH2 + CO → CH3CH2CO (R37), (j) CH3CH2 + CHO → CH3CH2CHO (R38). The red, brown, pink, and gray colors denote the O, C, H, and Rh atoms, respectively. In these figures, the < 111 > plane is directed upward. The figures for the other elementary steps are shown in the Supplementary Information

Subsequent hydrogenation (C–H bond formation) steps from CHO to CH2O and CH3O require lower activation barriers of 0.79 eV and 0.24 eV, respectively. These results suggest that while the initial hydrogenation of CO is kinetically challenging, the subsequent hydrogenation steps are more facile. This is consistent with a previous study identifying the initial hydrogenation of CO into CHO as the rate-determining step in the hydrogenation pathway of CO into ethanol [5]. As shown in Fig. 1b, the initial hydrogenation of CO into CHO requires a high activation energy because the CO molecule must tilt from its bidentate adsorption configuration into a monodentate structure at the transition state. Nevertheless, the activation barriers for the sequential hydrogenation of CO are still much lower than its direct dissociation into atomic carbon (CO → C + O, R1).

To assess the impact of hydrogenation on C–O bond cleavage, the dissociation barriers were calculated for the CHxO species. Results showed that the C–O bond dissociation barriers decrease and the reaction energies become more exothermic as the number of hydrogen atoms x in the CHxO species increases (Table 1a). This indicates that the C–O bond of a CHxO species is weakened by hydrogenation. This is consistent with other DFT studies, that identified the significant lowering of the C–O dissociation barrier by hydrogenation [5, 6, 8].

The formation of an O–H bond in the CHxO species is important for the formation of the hydroxyl group in an alcohol. The increasingly hydrogenated CHxO species (CO → CHO → CH2O) has a decreasing trend of activation barriers and lesser endothermic reaction energies for O–H bond formation (Table 1c). The lowest activation barrier (0.53 eV) is for the hydrogenation of CH2O into CH2OH. However, the hydrogenation of CH2O into CH3O has a lower barrier of 0.24 eV, which implies that a C–H bond formation is more likely than the O–H bond formation for CH2O. It can be noted that the O–H bond formation for CH3O to produce CH3OH (methanol) requires a large activation barrier of 1.22 eV as the CH3O species must break loose the O–Rh bonds as it transitions from the bidentate to monodentate adsorption configuration (Fig. 1c).

2.2 Formation of CHx Species

In the CHO-pathway, CH can form via the hydrogen-assisted dissociation of CO (CO + H → CH + O, R17), dissociation of CHO (CHO → CH + O, R18), or hydrogen-assisted dissociation of CHO (CHO + H → CH + OH, R19). Among these reactions, the hydrogen-assisted dissociation of CO requires the lowest activation barrier equal to 1.45 eV. It can be noted that the CH formation by hydrogenation of C only requires an activation barrier of 0.84 eV, but it is unlikely to have surface adsorbed C reactants because of the earlier mentioned high activation barrier for CO dissociation. For CH2 formation via the CHO-pathway, CH2 can be produced via the hydrogenation of CH with an activation barrier of 1.09 eV, but such reaction is unlikely because of the large barriers for CH formation in the CHO-pathway. Meanwhile, CH2 formation from the dissociation of CH2OH into CH2 and OH requires the lowest activation barrier of 0.96 eV. On the other hand, CH3 can be formed most favorably from the hydrogenation of CH2. Based on these calculations, the pathway towards the formation of CHx species that requires the lowest activation barrier is CO → CHO → CH2O → CH2OH → CH2 → CH3 → CH4.

In this pathway toward the formation of methane (CH4), the elementary step that requires the highest activation barrier is the initial hydrogenation of CO. This indicates that once the initial hydrogenation of CO is achieved, the subsequent steps toward the formation of methane is facile. Experimentally, it was shown that a large amount of methane is produced in the HAS from syngas on Rh, which limits the desired production of higher alcohols [11].

Note that in the formation of a CH2 species, OH is eliminated through the dissociation of CH2OH (Fig. 1d). The adsorbed OH species can react with hydrogen adatoms to produce H2O, or dissociate into H and O. The calculation of energy barriers for these elementary steps showed that OH prefers to dissociate rather than to form H2O (Table 1j). In this regard, the O adatoms that are produced from the dissociation of OH can oxidize the surface CO adsorbates yielding CO2 gas. The calculated activation barrier for the oxidation of CO is 1.72 eV, which is slightly higher than for the hydrogenation of CO. Experimentally, a small amount of CO2 has been detected in the HAS from syngas on Rh [11].

2.3 C2 Formation: CO Insertion vs CHO Insertion

As mentioned in the previous Section, the CH2 and CH3 species are the relevant CHx species before the formation of methane. The subsequent production of C2-species can proceed via the CHx-CHy coupling or the insertion of a CHxO species in a CHx fragment. Calculations revealed large activation barriers for the CHx-CHy coupling reactions on Rh(211) (Table 1h). This is consistent with another DFT study that reported high barriers for producing C2 hydrocarbons via CHx–CHy coupling on Rh [12]. In this regard, the C–C coupling reactions via the insertion of CHxO species to CH2 and CH3 were calculated. Results showed that for the case of CH2, the insertion of CHO promotes lower activation barrier and more exothermic reaction energy than for CO insertion. Figure 1e, f shows the initial, transition, and final states for these reactions. A high activation barrier of 1.11 eV is required for CO insertion to CH2 as similarly noted for CO hydrogenation into CHO because of the change of the CO adsorption configuration from a bidentate C–Rh interaction at the initial state into a monodentate C–Rh binding at the transition state. On the other hand, the CHO insertion requires a lower activation barrier of 0.72 eV and a more exothermic reaction energy. For this reaction, the CHO molecule has a favorable initial adsorption configuration to facilitate a facile binding with CH2. Such trend was also observed for the case of CO and CHO insertion to CH3. As shown in Table 1i, CHO insertion to CH3 requires a lower activation barrier and more exothermic reaction energy than CO insertion. Similar to the case of CO and CHO insertion to CH2, a lower activation barrier for CHO insertion than for CO insertion is due to the favorable initial adsorption configuration of CHO that facilitates a facile reaction with CH3 (Fig. 1g, h). Among the CHxO insertion reactions with CH2 and CH3, the lowest activation barrier is achieved by CHO insertion to CH3. However, in an environment with abundant CO molecules, the CO insertion reaction is more favorable for CH2 than for CH3. This indicates that the reaction mechanism to produce C2 oxygenates depends highly on the presence of oxidants CO or CHO. That is, C2 oxygenates are either produced via CO insertion to CH2 in a CO-abundant environment, or via the CHO insertion to CH3 in the presence of high quantities of CHO. These observations agree with the previous works of Kapur et al. and Wang et al., [6, 7] which identified either CH2 or CH3 as intermediates for ethanol formation. Nevertheless, the hydrogenation of CH2 to produce CH3 is still more kinetically favored than the CO insertion reaction to CH2, which explains the experimentally observed high methane quantities produced in HAS on Rh [11].

2.4 C3 Formation

After the formation of a C2 oxygenate, further hydrogenation steps towards the production of ethanol (CH3CH2OH) require the highest activation barrier of 1.36 eV, in agreement with a previous DFT study [6]. Ethanol can desorb from the surface with a desorption energy of 1.02 eV, or dissociate into CH3CH2 + OH with an activation barrier of 0.93 eV. The production of C3 oxygenates is proposed to proceed via CO or CHO insertion to CH3CH2. Calculations showed that CO insertion is more favored than CHO insertion, unlike the cases of CH2 and CH3 that prefer the CHO insertion reaction (Table 1i). This indicates the effect of a more extended C2 hydrocarbon structure in the CO or CHO insertion reaction. For CHO insertion in both monocarbon CH2 or CH3 and dicarbon CH3CH2 (Fig. 1i, j), the hydrocarbon fragment must detach from the surface to form a new C–C bond with CHO. This step costs a larger amount of energy for a more extended C2 structure than a C1 fragment. Thus, CH3CH2CO rather than CH3CH2CHO is predicted to be the first C3 species that can be produced in the investigated sequence of carbon chain growth. This may indicate that, contrary to the production of a C2 alcohol, CO insertion is more favorable than CHO insertion for the production of higher alcohols (>C2). Further hydrogenation of CH3CH2CO into n-propanol (CH3CH2CH2OH) requires the highest activation barrier of 1.26 eV, which is lower than the activation barrier for CO insertion to CH3CH2. This shows that the possible limiting step to produce a C3 species is the CO insertion reaction to a C2 species.

A general scheme for this overall reaction mechanism is shown in Scheme 2. Here, the overall reaction cycle is facilitated by a series of CO insertion to a CnHx species, hydrogenation of a Cn+1HxO oxygenate into a Cn+1Hx+αOH alcohol (where α + 1 denotes the number of added hydrogen atoms), and an OH elimination step to form a new hydrocarbon. The reaction starts with n = 0 for an adsorbed H, then CO insertion to form a CHO species, which further hydrogenates to produce methanol or CH2OH, which can undergo an OH elimination reaction to form a CHx species. The reaction continues with another CO insertion, followed hydrogenation to form an alcohol, and so on.

While the current study provides a fundamental insight into the mechanism of alcohol synthesis on a conventional catalyst, recent advances in catalyst design revealed that the catalyst selectivity toward higher alcohol synthesis can be tuned by modifying the catalyst composition and morphology, [13,14,15] as well the introduction of promoters and support effects [16]. Nevertheless, the current study highlights the importance of promoting a facile CO insertion reaction in catalyst design, as well as the roles of the hydrogenation and OH elimination steps in the carbon chain growth for the synthesis of higher alcohols.

3 Conclusion

Density functional theory-based calculations revealed the reaction mechanism for higher alcohol synthesis from syngas on Rh(211). Upon the initial adsorption of the CO molecule on the surface, the energetically preferred CO activation is via the hydrogenation reaction yielding a CHO species rather than through the direct dissociation of the C–O bond. The C–O bond is weakened by hydrogenation, resulting in the production of CHx species. Subsequent to the initial hydrogenation of CO to CHO, the elementary steps toward the production of CH4 proceed kinetically facile, which explains the experimentally determined large methane production that limits the synthesis of higher alcohols on Rhodium-based catalysts. The C2 species can be formed by CO insertion to CH2, or by CHO insertion to CH3, with the latter having a lower activation barrier. Meanwhile, the C3 species can be formed by CO insertion to a CH3CH2 fragment, which is more energetically favored than CHO insertion. These results provide the reaction mechanism for higher alcohol synthesis, which points to the importance of promoting a more facile CO insertion to enhance the selectivity of Rh-based catalysts for this reaction, as well as the roles of the hydrogenation and OH elimination steps in the carbon chain growth for the formation of higher alcohols.

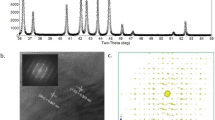

Computational Model An fcc bulk Rh was modelled using a cubic supercell with four Rh atoms at the following fractional coordinates: (0,0,0), (0, 0.5, 0.5), (0.5, 0, 0.5), and (0.5, 0.5, 0). The lattice constant was calculated by relaxing the ions and volume of the supercell using the conjugate gradient algorithm [17] to within a force tolerance of 0.001 eV/ Å. The surface Brillouin zone integrations were performed on a grid of 8 × 8 × 8 Monkhorst–Pack k-points [18] using Methfessel − Paxton smearing [19] of σ = 0.2 eV, and energy cut-off of 500 eV. The interaction between ions and electrons was described using the projector augmented wave (PAW) method [20, 21]. Spin-polarized density functional theory (DFT) calculations were carried out using the Vienna ab initio simulation package (VASP) [22,23,24,25].

Table S1 shows the calculated lattice constants for different DFT functionals. For comparison, the experimentally determined [26] lattice constant is also shown. It can be noted from the table that the obtained lattice constant using the DFT method within the generalized gradient approximation (GGA) based on the Perdew–Burke–Ernzerhof (PBE) functional [27,28,29,30] with van der Waals correction (D3) by Grimme [31] is closest to the experimental value. Such functional was used for all the subsequent calculations.

The stepped surface of an fcc Rh was modeled using a (211) surface in a 4 × 1 supercell (Fig. S2) with thickness equivalent to four atomic layers of the (111) facet and vacuum space of ca. 12.0 Å. The calculation of adsorption energies for the biggest molecule explored in the study (n-propanol) using a 4 × 1 and a 4 × 2 supercell showed an energy difference of only 0.014 eV (Fig. S3). Furthermore, the total energy of the n-propanol-slab system changed by only 0.04 eV as the vacuum space is increased from 12.0 Å to a much larger 20.0 Å. The total energies for the vacuum-slab model were calculated using a 500-eV energy cut-off and 6 × 5 × 1 Monkhorst Pack k-points. An electric dipole correction in the z-direction was used to cut the spurious interaction between the repeated images of the slab model. The gas-phase molecules were modelled using one free molecule inside a 20 × 20 × 20 Å.3 supercell with electric dipole correction implemented in all directions. The optimal adsorption configuration of molecules on the (211) surface was identified by exploring several possible orientations of the molecules at the different sites on the surface. The transition states for elementary steps were identified using the Climbing Image Nudged Elastic Band method [32] and Dimer Method [33]. The activation barriers Ea for the elementary steps are calculated by getting the difference in the total energies of the transition state and initial state. Similarly, the reaction energies ΔE are calculated by subtracting the total energy of the initial state from the final state. A negative value for ΔE implies an exothermic reaction. For comparison, the effect of temperature on the elementary steps are considered by adding the vibrational contributions using the Helmholtz free energy \({F}_{vib}({v}_{i},T)\), to the DFT-calculated total energy, as discussed in our previous works [34,35,36]:

Here, the terms \({E}_{ZPVE}\), \(\Delta {E}_{vib, 0\to T}\), and \({S}_{vib}T\) are the zero-point vibrational energy, vibrational energy change for temperature increase from 0 to T K, and the vibrational entropy, evaluated at temperature T = 300 K. The symbols h, kB, vi, and T, are the Planck’s constant, the Boltzmann constant, harmonic vibrational frequency, and temperature, respectively. The corresponding Gibbs free energies for the barriers ΔGa and reaction energies ΔG are shown in Table 1. It can be noted that while the inclusion of the energy correction changes the barriers to a maximum of 0.20 eV, the proposed reaction mechanism for higher alcohol synthesis remains the same.

References

Suvarna M, Preikschas P, Perez-Ramirez J (2022) ACS Catal 12:15373

Ao M, Pham GH, Sunarso J, Tade MO, Liu S (2018) ACS Catal 8:7025

Mei D, Rousseau R, Kathmann SM, Glezakou VA, Engelhard MH, Jiang W, Wang C, Gerber MA, White JF, Stevens DJ (2010) J Catal 271:325

Gao J, Mo XH, Goodwin JG (2009) J Catal 268:142

Choi Y, Liu P (2009) J Am Chem Soc 131:13054

Wang J, Liu Z, Zhang R, Wang B (2014) J Phys Chem C 118:22691

Kapur N, Hyun J, Shan B, Nicholas JB, Cho K (2010) J Phys Chem C 114:10171

Yang N, Medford AJ, Liu X, Studt F, Bligaard T, Bent SF, Norskov JK (2016) J Am Chem Soc 138:3705

Zhuo M, Tan KF, Borgna A, Saeys M (2009) J Phys Chem C 113:8357

Schweicher J, Bundhoo A, Kruse N (2012) J Am Chem Soc 134:16135

Xu D, Zhang H, Ma H, Qian W, Ying W (2017) Catal Comm 98:90

Filot IAW, Broos RJP, van Rijn JPM, van Heugten GJHA, van Santen RA, Hensen EJM (2015) ACS Catal 9:5453

Birdja Y, Perez-Gallent E, Figueiredo M, Gottle A, Calle-Vallejo F, Koper M (2019) Nat Energy 4:732

Wang D, Qin R, Qui Y, Liu C (2023) Mol Catal 547:113340

Gao Y, Shi L, Li S, Ren Q (2020) Phys Chem Chem Phys 22:5070

Luk H, Mondelli C, Ferre D, Stewart J (2017) Perez-Ramirez J 46:1358

Stich I, Car R, Parrinello M, Baroni S (1989) Phys Rev B 39:4997

Monkhorst H, Pack J (1976) Phys Rev B 13:5188

Methfessel M, Paxton A (1989) Phys Rev B 470:3616

Blochl P (1994) Phys Rev B 50:17953

Kresse G, Joubert J (1999) Phys Rev B 59:1758

Kresse G, Furthmuller J (1996) Phys Rev B 54:11169

Kresse G, Furthmuller J (1996) Comput Mater 6:15

Kresse G, Hafner J (1993) Phys Rev B 47:558

Kresse G, Hafner J (1994) Phys Rev B 49:14251

Arblaster JW (1997) Platin Met Rev 41:184

Perdew J, Burke K, Ernzerhof M (1996) Phys Rev Lett 77:3865

Perdew J, Burke K, Wang Y (1996) Phys Rev B 54:16533

Becke A (1998) Phys Rev A 38:3098

Lee C, Yang W, Parr R (1988) Phys Rev B 37:785

Grimme S (2004) J Comp Chem 25:1463

Henkelman G, Uberuaga BP, Jonsson H (2000) J Chem Phys 113:9901

Henkelman G, Jonsson H (1999) J Chem Phys 11:7010

Arevalo RL, Escano MCS, Kasai H (2013) ACS Catal 3:3031

Arevalo RL, Aspera SM, Escano MCS, Nakanishi H, Kasai H (2017) ACS Omega 2:1295

Arevalo RL, Aspera SM, Nakanishi H (2019) Catal Sci Technol 9:232

Acknowledgements

This work is supported by the Ministry of the Environment, Government of Japan, through the “Demonstration Project of Innovative Catalyst Technology for Decarbonization through Regional Resource Recycling”.

Funding

The Ministry of the Environment, Government of Japan

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Arevalo, R.L., Nakanishi, H. A First Principles Mechanistic Study of Higher Alcohol Synthesis from Syngas on a Stepped Rhodium Surface. Catal Lett (2024). https://doi.org/10.1007/s10562-023-04565-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10562-023-04565-y