Abstract

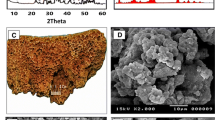

The study aimed to synthesize the hydroxyapatite (HAp), Na/HAp, and CaOCeO2/HAp materials, which were carried out using constant pH coprecipitation and wet impregnation methods and subsequently applied in the production of biodiesel using a by-product as a raw material. First, the HAp material was synthesized, and later there was the conventional impregnation by moisture to form the materials Na/HAp and CaOCeO2/HAp. The catalysts were characterized by X-ray diffraction (XRD), N2 adsorption and desorption, infrared spectral analysis (FT-IR), thermogravimetric analysis (TG), and morphology. The results showed that the residual lipid feedstock (vegetable oil deodorization distillate—VODD) that was used in the transesterification reactions for conversion into methyl esters (biodiesel) to determine the catalytic activity of the HAp, Na/HAp, CaOCeO2/ HAp it was shown that the HAp catalyst was not efficient in the complete transesterification of the starting materials. In this way, this catalyst remained with low activity, since the conversion to methyl esters reached 66% and, therefore, proved to be not a suitable catalyst for the transesterification reaction. On the other hand, the catalyst significantly improved its activity when HAp was impregnated with NaNO3 and CaOCeO2. The use of CaOCeO2/HAp in the transesterification of VODD was the catalyst that presented the best quality of catalytic activity (~ 99%) superior in relation to the Na/HAp catalyst. Thus, the CaOCeO2/HAp catalyst was selected as the most active catalyst in the transesterification reaction using VODD as raw material, and further tests were performed in order to optimize the process conditions. Therefore, an experimental design (design composed of face-centered 22 and center points) was carried out and the analysis of the results revealed that the formation of methyl esters (biodiesel) (> 95%) was strongly influenced by the temperature variable with a confidence level of 95%. Thus, confirming that the chemical catalyst was efficient to form the main esters of fatty acids even using a residual lipid raw material.

Graphical Abstract

Similar content being viewed by others

References

Chen G, Shan R, Shi J, Liu C, Yan B (2015) Biodiesel production from palm oil using active and stable K doped hydroxyapatite catalysts. Energy Convers Manag 98:463–469. https://doi.org/10.1016/j.enconman.2015.04.012

Kwon EE, Kim S, Jeon YJ, Yi H (2012) Biodiesel production from sewage sludge: new paradigm for mining energy from municipal hazardous material. Environ Sci Technol 46:10222–10228. https://doi.org/10.1021/es3019435

Wan L, Liu H, Skala D (2014) Biodiesel production from soybean oil in subcritical methanol using MnCO3/ZnO as catalyst. Appl Catal B 152–153:352–359. https://doi.org/10.1016/j.apcatb.2014.01.033

Rezania S, Oryani B, Park J, Hashemi B, Yadav KK, Kwon EE, Cho J (2019) Review on transesterification of non-edible sources for biodiesel production with a focus on economic aspects, fuel properties and by-product applications. Energy Convers Manag 201:112155. https://doi.org/10.1016/j.enconman.2019.112155

Rehan M, Gardy J, Demirbas A, Rashid U, Budzianowski WM, Pant D (2018) Waste to biodiesel: a preliminary assessment for Saudi Arabia. Bioresour Technol 250:17–25. https://doi.org/10.1016/j.biortech.2017.11.024

Ashraful AM, Masjuki HH, Kalam MA, Fattah IR, Imtenan S, Shahir SA, Mobarak HM (2014) Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oils: a review. Energy Convers Manag 80:202–228. https://doi.org/10.1016/j.enconman.2014.01.037

Almeida LA, Bôas RNV, Mendes MF (2021) Process simulation of biodiesel production from vegetable oil deodorization distillate using hydrotalcite-hydroxyapatite as catalyst. Res Soc Dev 10(6):e15210615452–e15210615452. https://doi.org/10.33448/rsd-v10i6.15452

Vilas-Bôas RN, Da Silva LL, Fernandes LD, Augusto BL, Mendes MF (2020) Study of the use of hydrotalcite–hydroxyapatite as heterogeneous catalysts for application in biodiesel using by-product as raw material. Catal Lett 150:3642–3652. https://doi.org/10.1007/s10562-020-03274-0

Aboelazayem O, Gadalla M, Saha B (2018) Design and simulation of an integrated process for biodiesel production from waste cooking oil using supercritical methanolysis. Energy 161:299–307. https://doi.org/10.1016/j.energy.2018.07.139

Zhang Y, Dube M, McLean D, Kates M (2003) Biodiesel production from waste cooking oil: 1. Process design and technological assessment. Bioresour Technol 89(1):1–16. https://doi.org/10.1016/S0960-8524(03)00040-3

Teixeira ARS, Santos JLC, Crespo JG (2011) Production of steryl esters from vegetable oil deodorizer distillates by enzymatic esterification. Ind Eng Chem Res 50(5):2865–2875. https://doi.org/10.1021/ie1020766

Yin X, Duan X, You Q, Dai C, Tan Z, Zhu X (2016) Biodiesel production from soybean oil deodorizer distillate usingcalcined duck eggshell as catalyst. Energy Convers Manag 112:199–207. https://doi.org/10.1016/j.enconman.2016.01.026

Wang L, Du W, Liu D, Li L, Dai N (2006) Lipase-catalyzed biodiesel production from soybean oil deodorizer distillate with absorbent present in tert-butanol system. J Mol Catal B 43(1–4):29–32. https://doi.org/10.1016/j.molcatb.2006.03.005

Qu T, Niu S, Zhang X, Han K, Lu C (2021) Preparation of calcium modified Zn-Ce/Al2O3 heterogeneous catalyst for biodiesel production through transesterification of palm oil with methanol optimized by response surface methodology. Fuel 284:118986. https://doi.org/10.1016/j.fuel.2020.118986

Dai YM, Kao IH, Chen CC (2017) Evaluating the optimum operating parameters of biodiesel production process from soybean oil using the Li2TiO3 catalyst. J Taiwan Inst Chem Eng 70:260–266. https://doi.org/10.1016/j.jtice.2016.11.001

Essamlali Y, Amadine O, Larzek M, Len C, Zahouily M (2017) Sodium modified hydroxyapatite: highly efficient and stable solid-base catalyst for biodiesel production. Energy Convers Manag 149:355–367. https://doi.org/10.1016/j.enconman.2017.07.028

Sebti S, Zahouily M, Lazrek HB, Mayoral JA, Macquarrie DJ (2008) Phosphates: new generation of liquid-phase heterogeneous catalysts in organic chemistry. Curr Org Chem 12:203–232. https://doi.org/10.2174/138527208783497484

Solhy A, Tahir R, Sebti S, Skouta R, Bousmina M, Zahouily M (2010) Efficient synthesis of chalcone derivatives catalyzed by re-usable hydroxyapatite. Appl Catal A 374:189–193. https://doi.org/10.1016/j.apcata.2009.12.008

Yan S, Kim M, Salley SO, Ng KYS (2009) Oil transesterification over calcium oxides modified with lanthanum. Appl Catal A 360:163–170. https://doi.org/10.1016/j.apcata.2009.03.015

Gryglewicz S (1999) Rapeseed oil methyl esters preparation using heterogeneous catalysts. Bioresour Technol 70:249–253. https://doi.org/10.1016/S0960-8524(99)00042-5

Liu L, Wen Z, Cui G (2015) Preparation of Ca/Zr mixed oxide catalysts through a birchtemplating route for the synthesis of biodiesel via transesterification. Fuel 158:176–182. https://doi.org/10.1016/j.fuel.2015.05.025

Yan B, Zhang Y, Chen G, Shan R, Ma R, Liu C (2016) The utilization of hydroxyapatite-supported CaO–CeO2 catalyst for biodiesel production. Energy Convers Manag 130:156–164. https://doi.org/10.1016/j.enconman.2016.10.052

Wong YC, Tan YP, Taufiq-Yap YH, Ramli I, Tee HS (2015) Biodiesel production via transesterification of palm oil by using CaOCeO2 mixed oxide catalysts. Fuel 162:288–293. https://doi.org/10.1016/j.fuel.2015.09.012

Reichle WT (1985) Catalytic reactions by thermally activated, synthetic, anionic clay minerals. J Catal 94:547–557. https://doi.org/10.1016/0021-9517(85)90219-2

Elliot JC (1994) Structure and Chemistry of the Apatites and Other Calcium Orthophosphates. Elsevier Sciense, London, p 404

Elliott JC, Wilson RM, Dowker SEP (2002) Apatite structures. Adv X-Ray Anal 45:172–181

Guerra-López J, Pomés R, Védova CD, Vina R, Punte G (2001) Influence of nickel on hydroxyapatite crystallization. J Raman Spectrosc 32(4):255–261. https://doi.org/10.1002/jrs.689

Opre Z, Grunwaldt JD, Maciejewski M, Ferri D, Mallat T, Baiker A (2005) Promoted Ru–hydroxyapatite: designed structure for the fast and highly selective oxidation of alcohols with oxygen. J Catal 230(2):406–419. https://doi.org/10.1016/j.jcat.2004.12.012

Tsodikov MV, Murzina VY, Chistyakova AV, Yandievaa FA, Gubanova MA, Zharovaa PA, Dumeignilc F (2014) The direct ethanol conversion to hydrocarbons over Pt-containing catalysts. Chem Eng. https://doi.org/10.3303/CET1437098

Yin X, You Q, Ma H, Dai C, Zhang H, Li K, Li Y (2015) Biodiesel production from soybean oil deodorizer distillate enhanced by counter-current pulsed ultrasound. Ultrason Sonochem 23:53–58. https://doi.org/10.1016/j.ultsonch.2014.08.020

Brasil H, Pereira P, Corrêa J, Nascimento L, Rumjanek V, Almeida V, Rodrigues E (2017) Preparation of hydrotalcite–hydroxyapatite material and its catalytic activity for transesterification of soybean oil. Catal Lett 147(2):391–399. https://doi.org/10.1007/s10562-016-1961-9

Coral N, Brasil H, Rodrigues E, da Costa CE, Rumjanek V (2019) Microwave-modified hydrotalcites for the transesterification of soybean oil. Sustain Chem Pharm 11:49–53. https://doi.org/10.1016/j.scp.2019.01.002

Rivera JA, Fetter G, Baños L, Guzmán J, Bosch P (2009) New hydroxyapatite–hydrotalcite composites I. synthesis. J Porous Mater 16(4):401–408. https://doi.org/10.1007/s10934-008-9227-6

Boz N, Degirmenbasi N, Kalyon DM (2013) Transesterification of canola oil to biodiesel using calcium bentonite functionalized with K compounds. Appl Catal B 138–139:236–242. https://doi.org/10.1016/j.apcatb.2013.02.043

Gregg SJ, Sing KSW (1982) Adsorption, surface area and porosity. Academic Press, London

Slósarczyk A, Paszkiewicz Z, Paluszkiewicz C (2005) FTIR and XRD evaluation of carbonated hydroxyapatite powders synthesized by wet methods. J Mol Struct 744–747:657–661. https://doi.org/10.1016/j.molstruc.2004.11.078

Kamalanathan P, Ramesh S, Bang LT, Niakan A, Tan CY, J. Purbolaksono J, (2014) Synthesis and sintering of hydroxyapatite derived from eggshells as a calcium precursor. Ceram Int 40:16349–59. https://doi.org/10.1016/j.ceramint.2014.07.074

Wang F, Liao Q, Chen K, Pan S, Lu M (2015) Glass formation and FTIR spectra of CeO2-doped 36Fe2O3–10B2O3–54P2O5 glasses. J Non-Cryst Solids 409:76–82. https://doi.org/10.1016/j.jnoncrysol.2014.11.020

Magdalane CM, Kaviyarasu K, Vijaya JJ, Siddhardha B, Jeyaraj B (2016) Photocatalytic activity of binary metal oxide nanocomposites of CeO2/CdO nanospheres: Investigation of optical and antimicrobial activity. J Photochem Photobiol B 163:77–86. https://doi.org/10.1016/j.jphotobiol.2016.08.013

Terra J, Dourado ER, Eon JG, Ellis DE, Gonzalez G, Rossi AM (2009) The structure of strontium-doped hydroxyapatite: an experimental and theoretical study. Phys Chem Chem Phys 11(3):568–577. https://doi.org/10.1039/B802841A

Liu C, Huang Y, Shen W, Cui J (2001) Kinetics of hydroxyapatite precipitation at pH 10 to 11. Biomaterials 22(4):301–306. https://doi.org/10.1016/S0142-9612(00)00166-6

Liu J, Huang J, Fan KW, Jiang Y, Zhong Y, Sun Z, Chen F (2010) Production potential of Chlorella zofingienesis as a feedstock for biodiesel. Bioresour Technol 101(22):8658–8663. https://doi.org/10.1016/j.biortech.2010.05.082

Haigh KF, Abidin SZ, Vladisavljevic GT, Saha B (2013) Comparison of Novozyme 435 and Purolite D5081 as heterogeneous catalysts for the pretreatment of used cooking oil for biodiesel production. Fuel 111:186–193. https://doi.org/10.1016/j.fuel.2013.04.056

Babaki M, Yousefi M, Habibi Z, Mohammadi M (2017) Process optimization for biodiesel production from waste cooking oil using multi-enzyme systems through response surface methodology. Renew Energy 105:465–472. https://doi.org/10.1016/j.renene.2016.12.086

Knothe G (2005) Dependence of biodiesel fuel properties on the structures of fatty acid alkyl esters. Fuel Process Technol 86:1059–1070. https://doi.org/10.1016/j.fuproc.2004.11.002

Oktar FN, Göller G (2002) Sintering effects on mechanical properties of glass-reinforced hydroxyapatite composites. Ceram Int 28(6):617–621. https://doi.org/10.1016/S0272-8842(02)00017-2

Silva AL, Farias AFF, Costa ACFM (2019) Evaluation of thermal treatment on magnetic catalyst Ni0,5Zn0,5Fe2O4 and its catalytic activity in biodiesel production by simultaneous transesterification and esterification of frying oil. Ceramica 65(373):13–27. https://doi.org/10.1590/0366-69132019653732408

Chakraborty R, RoyChowdhury D (2014) Optimization of biological-hydroxyapatite supported iron catalyzed methyl oleate synthesis using response surface methodology. J Taiwan Inst Chem Eng 45(1):92–100. https://doi.org/10.1016/j.jtice.2013.05.006

Khan IW, Naeem A, Farooq M, Ghazi ZA, Saeed T (2021) Reusable Na-SiO2@CeO2 catalyst for efficient biodiesel production from non-edible wild olive oil as a new and potential feedstock. Energy Convers Manag 231:113854. https://doi.org/10.1016/j.enconman.2021.113854

Acknowledgements

This work was supported by the Research Support Foundation of the State of Rio de Janeiro (FAPERJ) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES—Finance Code 001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vilas-Bôas, R.N., Lucchetti, L., Fernandes, L.D. et al. Preparation and Utilization of Hydroxyapatite-Supported Na and CaO–CeO2 Catalysts for Biodiesel Production Using Vegetable Oil Deodorization Distillate as Raw Material. Catal Lett 153, 2456–2470 (2023). https://doi.org/10.1007/s10562-022-04173-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-022-04173-2