Abstract

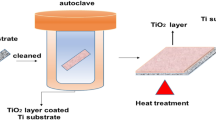

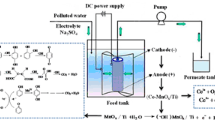

Commercially Ti membrane was chosen as the substrate of electrochemical technique because of its excellent conductivity and oxidation resistivity. However, a sole macroporous structure and low porosity limit reaction efficiency in application of electrochemical reaction. Nowadays, hierarchically porous structure have attracted interest in catalytic or electrochemical reactions owing to their large surface areas and rich pore channels. Herein, we report a hierarchically porous titanium (Ti) membrane (hp-Ti) with pore sizes mesopores (2–10 nm) and macropores (0.2–50 µm), which was fabricated by a combination of sintering and melt-dealloying processes. The macropores guaranteed an adequate flow rate through the membrane with low pressure, while the mesopores provided an ultrahigh surface area. The hierarchically porous Ti membrane with nano-MnOx loaded (MnOx/hp-Ti) by the sol–gel method exhibited better electrochemical properties than the commercially porous Ti membrane with nano-MnOx loaded (MnOx/cp-Ti), mainly due to the massive pathways of rapid diffusion, high surface areas, and abundant active sites. Further, MnOx/hp-Ti as the anode constituted an electrocatalytic membrane reactor (ECMR) for congo red wastewater treatment (50–200 mg·L−1). With the same energy consumption (0.654 kW·h·m−3) of ECMR, the removal rate of the total organic carbon (TOC) obtained by ECMR with MnOx/hp-Ti at an optimized condition was up to 80% which was higher than 73.8% of MnOx/cp-Ti. This work offers significant insights into developing new porous membrane electrodes for dye separation and degradation.

Graphic Abstract

Similar content being viewed by others

References

Dasgupta J, Singh A, Kumar S, Sikder J, Chakraborty S, Curcio S, Arafat HA (2016) Poly (sodium-4-styrenesulfonate) assisted ultrafiltration for methylene blue dye removal from simulated wastewater: optimization using response surface methodology. J Environ Chem Eng 4:2008–2022

Chakraborty S, Loutatidou S, Palmisano G, Kujawa J, Mavukkandy MO, Al-Gharabli S, Curcio E, Arafat HA (2017) Photocatalytic hollow fiber membranes for the degradation of pharmaceutical compounds in wastewater. J Environ Chem Eng 5:5014–5024

Sarkar S, Sondhi K, Das R, Chakraborty S, Choi H, Bhattacharjee C (2015) Development of a mathematical model to predict different parameters during pharmaceutical wastewater treatment using TiO2 coated membrane. Ecotoxicol Environ Saf 121:193–198

Das R, Sarkar S, Chakraborty S, Choi H, Bhattacharjee C (2014) Remediation of antiseptic components in wastewater by photocatalysis using TiO2 nanoparticles. Ind Eng Chem Res 53:3012–3020

Yang Y, Wang H, Li JX, He BQ, Wang TH, Liao SJ (2012) Novel Functionalized nano-TiO2 loading electrocatalytic membrane for oily wastewater treatment. Environ Sci Technol 46:6815–6821

Wei X, Wang H, Yin Z, Qaseem S, Li JX (2017) Tubular electrocatalytic membrane reactor for alcohol oxidation: CFD simulation and experiment. Chin J Chem Eng 25:18–25

Fang X, Yin Z, Wang H, Li JX, Liang XP, Kang JL, He BQ (2015) Controllable oxidation of cyclohexane to cyclohexanol and cyclohexanone by a nano-MnOx/Ti electrocatalytic membrane reactor. J Catal 329:187–194

Bin DS, Wang H, Li JX, Wang H, Yin Z, Kang JL, He BQ, Li ZH (2014) Controllable oxidation of glucose to gluconic acid and glucaric acid using an electrocatalytic reactor. Electrochim Acta 130:170–178

Yang Y, Li J, Wang H, Song X, Wang T, He B, Liang X, Ngo HH (2011) An electrocatalytic membrane reactor with self-cleaning function for industrial wastewater treatment. Angew Chem Int Ed 50:2148–2150

Wang H, Guan QQ, Li JX, Wang TH (2014) Phenolic wastewater treatment by an electrocatalytic membrane reactor. Catal Today 6:121–126

Yang SM, Liang XP, Zhang D, Lin CH, Zhao JQ, Zhu YP, Chen ZS, Wang H, Wang H, Li JX (2018) MnOx/Ti composite membrane anode in the electrocatalytic membrane reactor for phenolic. Wastewater treatment. J Electrochem Soc 165:20–27

Parlett CM, Wilson K, Lee AF (2013) Hierarchical porous materials: catalytic applications. Chem Soc Rev 42:3876–3893

Song T, Yan M, Qian M (2018) The enabling role of dealloying in the creation of specific hierarchical porous metal structures—a review. Corros Sci 134:78–98

Mccue I, Gaskey B, Geslin PA, Karma A, Erlebacher J (2016) Kinetics and morphological evolution of liquid metal dealloying. Acta Mater 115:10–23

Tsuda M, Wada T, Kato H (2013) Kinetics of formation and coarsening of nanoporous α-titanium dealloyed with Mg melt. J Appl Phys 114:113503

Zhao GY, Zhang L, Niu YN, Sun KN (2017) A molten Mg corrosion method for preparing porous Ti foam as self-supported Li–O2, battery cathodes. Electrochim Acta 224:64–70

Kim JW, Tsuda M, Wada T, Yubuta K, Kim SG, Kato H (2015) Optimizing capacitors. Acta Mater 84:497–505

Wada T, Yubuta K, Kato H (2016) Evolution of a bicontinuous nanostructure via a solid-state interfacial dealloying reaction. Scripta Mater 118:33–36

Wada T, Kato H (2013) Three-dimensional open-cell macroporous iron, chromium and ferritic stainless steel. Scripta Mater 68:723–726

Wang H, Wang H, Li JX, Bin DS, Yin Z, Kang JL (2014) An electrocatalytic reactor for the high selectivity production of sodium 2,2,3,3-tetrafluoropropionate from 2,2,3,3-tetrafluoro-1-propanol. Electrochim Acta 123:33–41

Wada T, Setyawan D, Yubuta K, Kato H (2011) Nano- to submicro-porous β-Ti alloy prepared from dealloying in a metallic melt. Scripta Mater 65:532–535

Kornilov II (1973) Effect of oxygen on titanium and its alloys. Met Sci Heat Treat 15:826–829

Wang XS, Lu ZL, Jia L, Chen JX (2017) Preparation of porous titanium materials by powder sintering process and use of space holder technique. J Iron Steel Res Int 24:97–102

Ma YN, Bao CG, Han LH, Chen J (2017) Study on microstructures and properties of porous TiC ceramics fabricated by powder metallurgy. J Mater Eng Perform 26:1–8

Wang FZ, Yang L, Sun GX, Guan LY, Hu SG (2014) The hierarchical porous structure of substrate enhanced photocatalytic activity of TiO2 /cementitious materials. Constr Build Mater 64:488–495

Bard AJ, Faulkner LR (1982) Electrochemical methods: Fundamentals and applications. Wiley, New York

Loiola AR, da Silva LRD, Cubillas P, Anderson MW (2008) Synthesis and characterization of hierarchical porous materials incorporating a cubic mesoporous phase. J Mater Chem 18:4985–4993

Liu H, Vecitis CD (2016) Reactive Transport mechanism for organic oxidation during electrochemical filtration: mass-transfer, physical adsorption, and electron-transfer. J Phys Chem C 116:374–383

Parlett CMA, Wilson K, Lee AF (2013) Hierarchical porous materials: catalytic applications. Chem Soc Rev 42:3876–3893

Duan YL, Hui HS, Wang H, Kang JL, Li JX (2019) Fabrication and characterization of hierarchically porous titanium membrane for dye wastewater treatment. Mater Res Express 6:115534

Solano AMS, Garcia-Segura S, Martınez-Huitle CA, Brillas E (2015) Degradation of acidic aqueous solutions of the diazo dye Congo red by photo-assisted electrochemical processes based on Fenton’s reaction chemistry. Appl Catal B 168–169:559–571

Guan XF, Yu YL, Li XY, Chen DG, Luo PH, Zhang Y, Guo SX (2018) Hierarchically porous MgCo2O4 nanochain networks: template-free synthesis and catalytic application. Mater Res Express 5:015002

Sun S, Diao P, Feng CY, Eleonora MU, Tang Y, Hu B, Hu Q (2018) Nickel-foam-supported β-Ni(OH)2 as a green anodic catalyst for energy efficient electrooxidative degradation of azo-dye wastewater. RSC Adv 8:19776–19785

Rodrigues de Oliveira G, Suely Fernandes N, Vieira de Melo J, Ribeiro da Silva D, Urgeghe C, Martínez-Huitle CA (2011) Electrocatalytic properties of Ti-supported Pt for decolorizing and removing dye from synthetic textile wastewaters. Chem Eng J 168:208–214

Bonyadinejad G, Sarafraz M, Khosravi M, Ebrahimi A, Taghavi-Shahri SM, Nateghi R, Rastaghi S (2015) Electrochemical degradation of the Acid Orange 10 dye on a Ti/PbO2 anode assessed by response surface methodology. Korean J Chem Eng 32:1–8

de Oliveira Morais CC, da Silva AJC, Ferreira MB, de Araújo DM, Zanta CLPS, Castro SSL (2013) Electrochemical degradation of methyl red using Ti/Ru0.3Ti0.7O2: fragmentation of Azo Group. Electrocatalysis. 4:312–319

Thiam A, Sirés I, Garrido JA, Rodríguez RM, Brillas E (2015) Effect of anions on electrochemical degradation of azo dye Carmoisine (Acid red 14) using a BDD anode and air-diffusion cathode. Sep Purif Technol 140:43–52

Ramírez G, Recio FJ, Herrasti P, Ponce-de-León C, Sirés I (2016) Effect of RVC porosity on the performance of PbO2 composite coatings with titanate nanotubes for the electrochemical oxidation of azo dyes. Electrochim Acta 204:9–17

Ramírez C, Saldaña A, Hernández B, Acero R, Guerra R, Garcia-Segura S, Brillas E, Peralta-Hernández JM (2013) Electrochemical oxidation of methyl orange azo dye at pilot flow plant using BDD technology. J Ind Eng Chem 19:571–579

Tavares MG, da Silva LVA, Sales Solano AM, Tonholo J, Martínez-Huitle CA, Zanta CLPS (2012) Electrochemical oxidation of Methyl red using Ti/Ru0.3Ti0.7O2 and Ti/Pt anodes. Chem. Eng. J. 204–206:141–150

Acknowledgments

We gratefully acknowledge the financial supports for this work from National Natural Science Foundation of China (Grant No. 21676200), and Tianjin Science and Technology Planning Project (Grant No. 17JCYBJC19800).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, H., Duan, Y., Kang, J. et al. Fabrication of Hierarchically Porous Titanium Membrane Electrode for Highly-Efficient Separation and Degradation of Congo Red Wastewater. Catal Lett 151, 1167–1179 (2021). https://doi.org/10.1007/s10562-020-03337-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-020-03337-2