Abstract

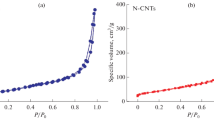

A series of tetraalkylammonium catalysts immobilized on polystyrene or carbon nanotubes were investigated in a reaction between alkyl halides, amines, and CO2. The yield of carbamates was up to 85 % at 100 °C and 1 MPa of CO2 after 3 h (first stage 25 °C, 1 h) in the presence of Cs2CO3 and DMF as a solvent. The best results were achieved in the case of large ammonium substituents (C4 and C6) in the catalyst, benzyl amine, and benzyl chloride as reagents. The catalysts retained their activity after at least five cycles when carefully dried between cycles. Both polymer and carbon nanotube supports were equally effective, but the latter were less prone to deactivation.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years there has been a growing interest in the field of carbon dioxide utilization. It has sparked off from the worldwide effort to reduce the CO2 emission into the atmosphere, as well as from its potential use as a renewable C1 source [1]. Because of the relatively inert nature of CO2, it is used in the industrial scale only for urea, carbonates, and salicylic acid synthesis, but a number of other possible applications of CO2 in the organic synthesis has been proposed [2]. Promising results have been reported in the case of the carbamate synthesis [3]. Carbamates are an interesting group of compounds that are esters and amides simultaneously. Various compounds incorporating carbamate groups have shown importance as agrochemicals, antibacterial, antiviral, and anticancer agents [4]. Some carbamates have also found various applications in the organic synthesis [5]. Usually they are obtained in a reaction between amines, phosgene, and alcohols, but because of a highly toxic nature of phosgene safer routes towards carbamates are in high demand. The most notable examples include the urea alcoholysis [6], the carbonate aminolysis [7, 8] or the urea-carbonate reaction [9]. The starting materials for those syntheses can be derived from CO2, but direct paths from CO2 towards carbamate are available, too [10]. The simplest approaches include alkylation of intermediate carbamic acid by a halide [11–13].

The reaction has a wide scope and various amines or halides can be used. The mechanism includes the formation of a carbamic acid salt in the reaction between an amine and CO2. In the second stage the salt reacts with a halide in the presence of a base and a phase transfer (PT) catalysts [13]. The flaw of this approach is that the halide is not incorporated into the final product and halide containing waste is produced. The reported yields are usually moderate (50–70 %) but can reach 98 % [12]. The process is usually conducted at 25–100 °C, up to 8 MPa of CO2 in the presence of Cs2CO3 and an ammonium catalyst in DMF [12, 13]. Other strong bases, such as 1,8-diazabicycloundec-7-ene (DBU) or guanidine, can also be used. The role of a base is deprotonation of carbamic acid, which improves its reactivity with the halide [14, 15].

Alcohols can also be employed as an alternative to halides as alkylating agents [16, 17], but the reaction conditions are harsher due to the low reactivity of alcohols. It can be partially circumvented by the application of Mistunobu’s reagent [18], or when reactive propargyl alcohols and an appropriate catalytic system is used [19].

One of the trends in the development of catalytic systems for the carbamates synthesis, as well as in other types of catalysis, is the immobilization of existing homogeneous catalysts to obtain reusable, easily separable catalysts of high activity. Among possible supports there are: polymers, metal oxides, carbon nanomaterials, nanoparticles, and many others. In this work we investigated immobilized alkylammonium salts in the synthesis of carbamates from halides.

2 Experimental

2.1 Materials

Carbon dioxide of 99.5 % purity was obtained from SIAD. Tributylmethylammonium chloride (TBMAC), polymer-bound tributylmethylammonium chloride (PS1-C4H9) 200–400 mesh; Cl loading = 1.2 mmol g−1, polystyrene (cross-linked with DVB) were purchased from Fluka. Cesium carbonate (99.5 %), DBU (98 %), benzyl chloroformate (pure), 1-chlorobutane (>99 %), 2-chlorobutane (>99 %), benzyl chloride (99 %), choline chloride (99 %), triethylamine (99 %), tributylamine (99 %) were supplied by Acros Organics. Carbon nanotubes (CNT) (6–9 nm × 5 μm), tetrabutylammonium bromide (TBAB) (>99 %), trihexylamine (96 %) were provided by Sigma Aldrich. Aniline, benzylamine, butylamine, diisobutylamine, and other chemicals were bought from local manufacturers. Merrifield’s resins, chloromethylated polystyrenes PS2: 200–400 mesh, Cl loading: 2.25 mmol g−1, polystyrene 2 % cross-linked with DVB (Sigma Aldrich), and PS3, 200–400 mesh, Cl loading: 2.5–3 mmol g−1, polystyrene 1 % cross-linked with DVB was purchased from Acros Organics.

The synthetic procedure and characterization of polymer-supported catalysts (polymer-bound triethylmethylammonium chloride: PS3-C2H5, polymer-bound trihexylmethylammonium chloride: PS3-C6H13, polymer-bound tributylmethylammonium chloride: PS2-C4H9) [20] and CNT-supported alkylammonium catalysts (CNT-C4H9) have been reported previously [21].

2.2 Instruments

Chromatography was carried out using Waters Acquity Ultra Performance Liquid Chromatography (UPLC) system. HR-MS spectra were registered with a Waters Xevo G2 QTof instrument and the ESI-MS source after chromatographic separation. Syntheses of carbamates were conducted in a 100 mL stainless steel autoclave placed in a thermostat (EasyMax™ 102, Mettler Toledo).

2.3 Synthesis of Carbamates from CO2

An amine (2.85 mmol) and anhydrous DMF (15 mL) were introduced into an autoclave. The autoclave was purged twice with CO2 and the reaction was conducted at 25 °C under 1 MPa of CO2. After 1 h, an appropriate amount of the catalyst, cesium carbonate (9 mmol), and alkyl or benzyl chloride (9 mmol) was added. The autoclave was purged twice with CO2 and the mixture was stirred at 100 °C under 1 MPa of CO2 for 3 h. After cooling to room temperature, the excess of CO2 was vented, and the catalyst was separated by filtration. The post-reaction mixture was poured into water (30 mL) and extracted with ethyl acetate (3 × 30 mL). The organic layer was washed with brine (30 mL) and water (2 × 30 mL). The organic layer was dried over anhydrous magnesium sulfate, and evaporated to give crude alkyl carbamate in the form of a yellow oil.

2.4 Quantitative Analysis of Products

The structure of all products was confirmed by HR-MS and NMR. A quantitative analysis was performed with the UPLC-PDA system. The mobile phase consisted of acetonitrile (60 %) and water (40 %) delivered at 0.2 mL min−1. A BEH C18 1.7 μm 2.1 × 50 mm column was kept at 40 °C. Injections of 0.2 μL of a solution of the crude product (0.01 g in 10 mL of acetonitrile) were made on the column to quantify all the products. Calculations were based on external calibration lines established by injecting standards of known purity. The retention time of 1 was typically 1.2–1.4 min; of 2 was 4.2–4.7 min, while 3 was eluted at 2.0 min. If pure standards were not available, 1H NMR spectra (in DMSO) of crude products with maleic acid as an internal standard were used for quantification purposes. Yields of products 1 and 2 were calculated based on the initial quantity of the amine (2.85 mmol), while yields of 3 were related to the initial quantity of benzyl chloride (9 mmol).

3 Results and Discussion

The aim of this work was to asses the performance of immobilized tetraalkylammonium salts as catalyst in the carbamate synthesis. Two types of supports were used: crosslinked polystyrene, and CNT. The general scheme of the investigated reaction and the main impurities are shown in Scheme 1. The mechanism of carbamate synthesis catalyzed by quaternary ammonium salts was published earlier [13].

3.1 Reaction Conditions

Based on the literature data regarding the synthesis of carbamates from CO2 and halides with the use of alkylammonium catalysts, we selected the pressure of CO2 = 1 MPa and 100 °C as suitable conditions. The relative impact of the base and the catalyst amount is summarized in Table 1.

The yield of benzyl benzylcarbamate (1a) increased with the basicity of the carbonate (Cs2CO3 > K2CO3). It was also improved with the amount of the catalyst. However, at higher catalyst loading corresponding TONs were lower comparing with 0.9 mmol of the catalyst. The addition of DBU led to the increase of 1a yield and the corresponding TONs, but only in the combination with a low quantity of the catalyst. A detrimental effect of the addition of DBU was also observed in the case of the PS1-C4H9-catalysed reaction (Table 2), when it reduced the yield of 1a two fold and the yields of both by-products, as well.

The effect can be rationalized based on the general PT catalysis mechanism [22]. It is likely that DBU acts primarily as a base and has the strongest effect when combined with K2CO3 (Table 1, entries 1, 2, 5, 6). A higher catalyst content can offset insufficient basicity of the environment (Table 1, entries 2, 3, 5, 8). It is likely that the reactivity of carbamic acid and benzyl chloride determined the yield when strong bases were present. Otherwise, inadequate concentrations of ions or transfer of reagents between phases were the limiting factors.

Another experiment that favors a PT-based explanation of the observed results is the entry 7 of Table 2. The presence of water had a negative impact on the yield of carbamate 1a and the overall conversion of the amine toward the CO2 derived products (the yield of 2a was more than doubled comparing with the entry 3, the sum of 1a and 2a was 61 %). It can be a consequence of a less efficient transfer of carbamic acid to the organic phase, because it is more likely trapped in the aqueous Cs2CO3-rich phase.

The order of the reagent addition was also investigated. If the reaction between benzylamine and CO2 was conducted in the presence of a immobilized catalyst, Cs2CO3, and benzyl chloride, the yield of 1a was low comparing with the typical procedure, when the catalyst and the base were added after saturation of the amine with CO2. One of the possible reasons is partial alkylation of the amine to tribenzylamine or tetrabenzylammonium salt when not protected by the formation of carbamic acid.

3.2 Catalyst Structure

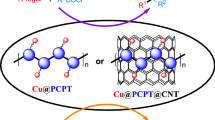

The general structure of immobilized catalysts was shown in Fig. 1. The materials were either commercial or were synthesized according to previous reports [20, 21]. Both types of catalysts were used as alternatives of homogeneous TBAB and the results were collected in Table 2. Under homogeneous conditions the observed TON values were not higher than 1.9 (Table 1), whereas immobilization increased it by 50 % to reach 2.7–3.0, depending on the support. In the case of a homogeneous system the efficiency of tributylmethylammonium chloride (TBMAC) was low comparing with tetrabutylammonium bromide (16 vs. 75 %, Table 1). Similarly, the heterogeneous catalysts (Table 2) containing the triubutylammonium functionality showed the best activity (85 % yield of 1a, TON = 3.0) from amongst their alternatives containing three R = C2H5 (42 %, 0.9) or R = C6H13 groups (78 %, 2.0). The relative order agrees with the observations made by other authors studying various PT reactions. Typically, symmetrical ammonium cations containing alkyl chains of 4 atoms are the most efficient catalysts [23]. The relative efficiency of various quaternary ammonium salts is also affected by the solvent. It is due to the optimal balance between hydrophilicity of small ammonium cations and their ability to bind anions when the nitrogen atom is more accessible [24], which in turn diminishes their ability to enter the organic phase.

A higher reactivity of immobilized PT catalysts was observed in various systems [22]. Such behavior can be explained on the ground of the PT catalysis mechanism. Under PT conditions the rate of the reaction is strongly affected by the partitioning of a quaternary ammonium salt between the organic and aqueous phase or the interphase. From this perspective the most efficient catalyst should have a partitioning coefficient of 1 [25]. Such a situation is not likely in the case of a homogeneous catalyst because of different solvation energies in different solvents. As the immobilized catalyst forms a third phase then it should be well accessible by reagents that reside either in the organic or aqueous phase.

Other authors rationalized the phenomenon on the ground of increased lipophilicity of immobilized catalysts. The explanation is based on the observation that quaternary ammonium salts that are insoluble in organic solvents are poor catalysts unless immobilized on lipophilic support [26], such as polymers, but not on SiO2 [27].

Another important aspect that can contribute to the increased efficiency of an immobilized catalyst is better thermal stability of immobilized ammonium salts. Typically, they undergo Hoffman degradation above 100 °C, which decreases the amount of the catalyst available. After immobilization no apparent degradation occurs [20] at the same conditions.

The increased yield observed for immobilized catalysts can be partially attributed to better accessibility of carbamic acid when coordinated by ammonium cations on the surface of the support comparing with a homogeneous system. Such a phenomenon may also explain the fact that the catalyst of a 2 % cross-linking degree was less effective comparing with a 1 % counterpart (55 vs. 85 % yield of 1a).

3.3 Reaction Scope

The scope of the PS1-C4H9 catalyst was investigated with various combinations of amines and halides. All the data are collected in Table 3. The type of amine had a strong effect on the yield of a carbamate. Only the primary and benzyl amine gave good yields, while the aromatic and secondary amine yielded only 3–6 % of the desired product. The yield of the carbamate was also dependent on the halide type, and among chlorides it increased in the order of benzyl > primary > secondary, which reflects typical reactivity in the nucleophilic substitution.

3.4 Catalyst Recycle

The possibility of reusing of the polymer-based and CNT-based catalysts were investigated in the reaction of benzyl amine and benzyl chloride. As shown in Fig. 2, it was possible to reuse the same portion of the catalyst immobilized on CNT in at least 5 reaction cycles. The catalyst could be easily separated by filtration from the reaction mixture. No special precautions were required besides 8–12 h drying in a desiccator. In each cycle a fresh portion of Cs2CO3 was used. In the case of the polymer-supported catalyst, the first and second reuse with the same portion of Cs2CO3 yielded only 5 and 3 % of the carbamate when a 12-h drying in a desiccator was employed. The yield was improved by the addition of fresh Cs2CO3 (45 % at the fourth cycle). When the catalyst was left in a vacuum desiccator for 2 weeks (over NaOH, 50 mbar) it allowed for full regeneration of its catalytic activity. Comparing with CNT support it indicates that the polymer is more prone to water sorption and more difficult to be dried.

4 Conclusions

A series of immobilized catalysts for the synthesis of carbamates from CO2 was showed to be active and reusable. Comparing with homogeneous counterparts, the TON value was 3–10 times higher and the yield of carbamates using halides as reagents was up to 85 %. Comparing with other similar systems our results are equally good or worse by 10–20 % as many authors were able to reach 99 % yields at least for the best performing reagents [6–13] at a similar time, temperature, and CO2 pressure as used here, but under homogeneous conditions.

Partially responsible for the low yields is the consecutive alkylation of the main product or the alkylation of the amine before the carbamate formation. The former could be limited by shortening of the reaction time and improvement of the catalyst efficiency, while the latter by increasing of the CO2 pressure.

To a certain extend the yields could be improved by an increase of the catalyst amount. In the case of the polymer supported catalyst it was not possible because the swelling prevented efficient stirring of the mixture. The problem was not important in the case of the CNT-based catalyst. Further investigations of immobilized catalysts should aim at increasing the degree of functionalization of polymers or CNT, as well as at other supports of high surface area.

References

Lim X (2015) Nature 526:628

Sakakura T, Choi J-C, Yasuda H (2007) Chem Rev 107:2365

Maeda C, Miyazaki Y, Ema T (2014) Catal Sci Technol 4:1482

Ghosh AK, Brindisi M (2015) J Med Chem 58:2895

Chaturvedi D (2012) Tetrahedron 68:15

Shivarkar AB, Gupte SP, Chaudhari RV (2004) J Mol Catal A 223:85

Mormeneo D, Llebaria A, Delgado A (2004) Tetrahedron Lett 45:6831

Zhou H, Shi F, Tian X, Zhang Q, Deng Y (2007) J Mol Catal A: Chem 271:89

Guo X, Shang J, Li J, Wang L, Ma Y, Shi F, Deng Y (2011) Synth Commun 41:1102

Chaturvedi D, Ray S (2006) Monatsh Chem 137:127

Srivastava R, Manju MD, Srinivas D, Ratnasamy P (2004) Catal Lett 97:41

Salvatore RN, Shin SI, Nagle AS, Jung KW (2001) J Org Chem 66:1035

Yoshida M, Hara N, Okuyama S (2000) Chem Commun 2:151

Zhang W-Z, Ren X, Lu X-B (2015) Chin J Chem 33:610

McGhee W, Riley D, Christ K, Pan Y, Parnas B (1995) J Org Chem 60:2820

Abla M, Choi J-C, Sakakura T (2001) Chem Commun 21:2238

Abla M, Choi J-C, Sakakura T (2004) Green Chem 6:524

Chaturvedi D, Mishra N, Mishra V (2007) Monatsh Chem 138:57

Song Q-W, Yu B, Li X-D, Ma R, Diao Z-F, Li R-G, Li W, He L-N (2014) Green Chem 16:1633

Siewniak A, Jasiak K, Baj S (2014) Appl Catal A 482:266

Baj S, Krawczyk T, Jasiak K, Siewniak A, Pawlyta M (2014) Appl Catal A 488:96

Lasek W, Makosza M (1993) J Phys Org Chem 6:412

Herriott AW, Picker D (1975) J Am Chem Soc 97:2345

Mason D, Magdassi S, Sasson Y (1990) J Org Chem 55:2714

Denmark SE, Gould ND, Wolf LM (2011) J Org Chem 76:4337

Glatzer HJ, Doraiswamy LK (2000) Chem Eng Sci 55:5149

Desikan S, Doraiswamy LK (2000) Chem Eng Sci 55:6119

Acknowledgments

This work was supported by the Polish National Science Centre (NCN); Decision No.: 2011/03/B/ST8/06178. The co-author of this paper, Katarzyna Jasiak, is a scholar under the project “DoktoRIS—Scholarship Program for Innovative Silesia” co-financed by European Union under the European Social Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Krawczyk, T., Jasiak, K., Kokolus, A. et al. Polymer- and Carbon Nanotube-Supported Heterogeneous Catalysts for the Synthesis of Carbamates from Halides, Amines, and CO2 . Catal Lett 146, 1163–1168 (2016). https://doi.org/10.1007/s10562-016-1738-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1738-1